Design method for vertical type foundation pit supporting structure

A foundation pit support and design method technology, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems of support removal, difficult control of construction quality, and weak displacement control ability, so as to achieve favorable soil uplift resistance and overall Stability is beneficial, the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

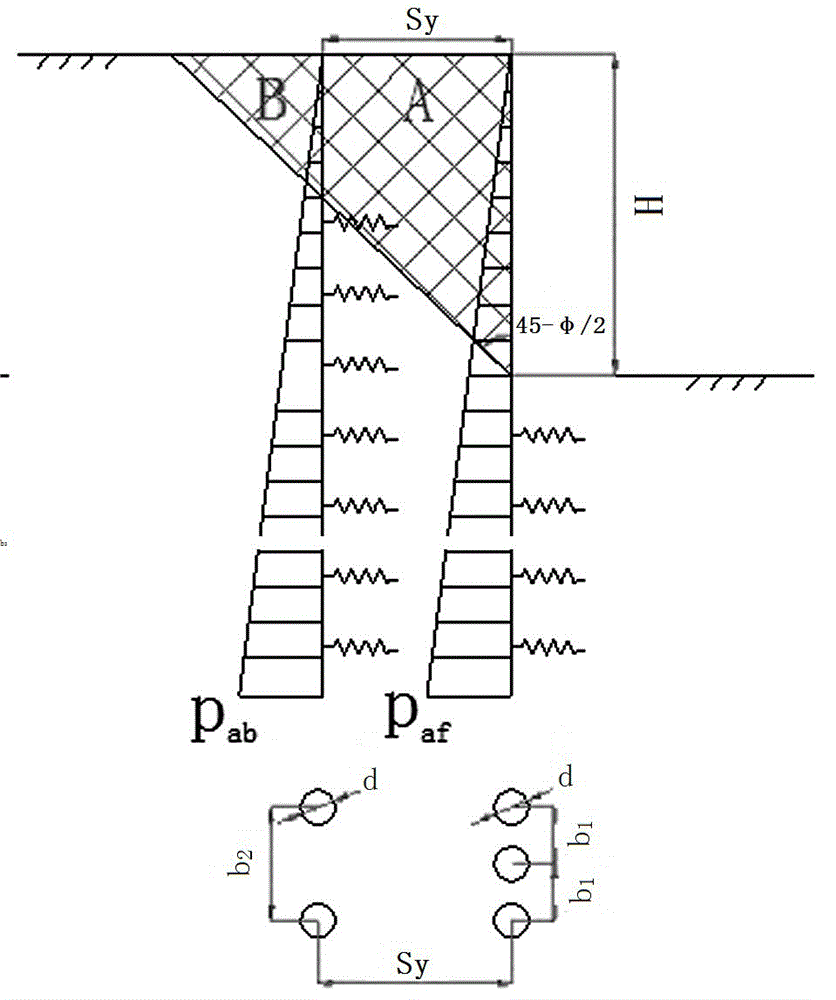

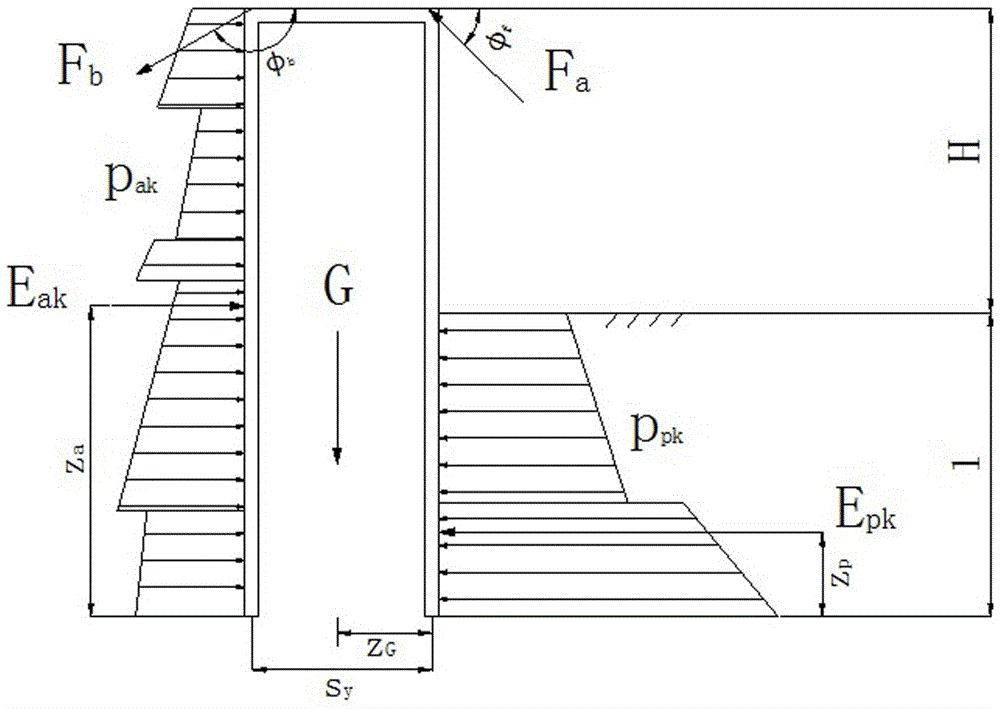

[0044] Embodiment one: if Figure 9 As shown, the inner support type vertical support structure in this embodiment includes support piles 2 and support body 4, wherein the support pile 2 adopts a single-row structure, which is arranged on the periphery of the foundation pit 6 and is vertical, and the support body 4 is used to support the support pile 2 so as to improve the support effect and stability of the support pile 2. A top pressure 1 is arranged on the top of the support pile 2 . The inner end of the top pressing 1 protrudes from the wall of the foundation pit 6 and faces into the foundation pit. One end of the support body 4 is connected and fixed with the pressure top 1 positioned at the pile top of the support pile 2, the support body 4 is inclined, and the other end is inserted into the bottom soil 7 of the foundation pit 6; at this time, due to the support The body 4 is inserted into the bottom soil body 7 to reinforce the bottom soil body 7 and resist the uplift...

Embodiment 2

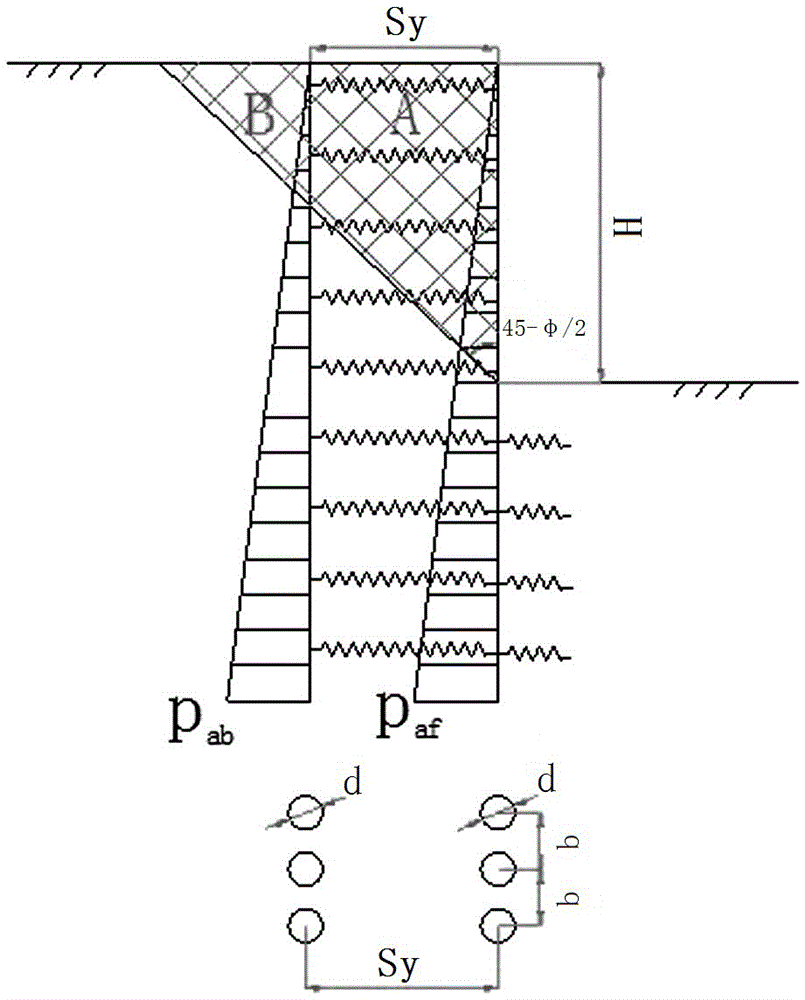

[0077] Embodiment 2: Compared with Embodiment 1, this embodiment differs in that: Figure 11 , Figure 12 and Figure 13 As shown, what this embodiment adopts is the supporting body 4 of pull-out type.

[0078] Such as Figure 11 As shown, the pull-out vertical support structure includes a support pile 2 and a support body 4, wherein the support pile 2 adopts a single-row structure, which is arranged on the periphery of the foundation pit 6 and is vertical, and the support body 4 is used for pulling out The supporting pile 2 can improve the supporting effect and stability of the supporting pile 2 . A top pressure 1 is arranged on the top of the support pile 2 . The inner end of the top pressing 1 protrudes from the wall of the foundation pit 6 and faces into the foundation pit. One end of the supporting body 4 is connected and fixed with the topping 1 located at the pile top of the supporting pile 2, and the supporting body 4 is arranged obliquely, and it passes through t...

Embodiment 3

[0103] Embodiment three: the difference of this embodiment compared with embodiment one and two is: as Figure 16 and Figure 17 As shown, the support body 4 in this embodiment adopts a structural form of a combination of an inner support type and an outer pull type.

[0104] Such as Figure 16 As shown, the inner support and outer pull type vertical support structure includes support piles 2 and two support bodies 4 arranged obliquely, wherein the support piles 2 adopt a single-row structure, which are arranged on the periphery of the foundation pit 6 and are vertical, The support body 4 is used to support and pull the support pile 2 internally, so as to improve the support effect and stability of the support pile 2 . A top pressure 1 is arranged on the top of the support pile 2 . Among them, one end of a supporting body 4 that acts as an internal support for the supporting structure is connected and fixed to the topping 1 located outside the pile body of the supporting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com