Damping and anti-compression and sliding slip sleeper for subsequent trolley transporting battery car of shielding tunnel machine and construction method for damping and anti-compression and sliding slip sleeper

A technology of battery car and shield machine, which is applied to tracks, buildings, movable tracks, etc., can solve problems such as sleeper deformation, derailment of battery car steel wheels, and inapplicability, so as to improve stability and safety, and increase anti-slip friction. The effect of uniform resistance and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

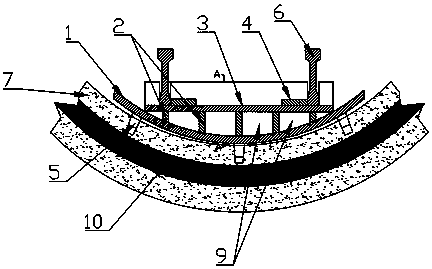

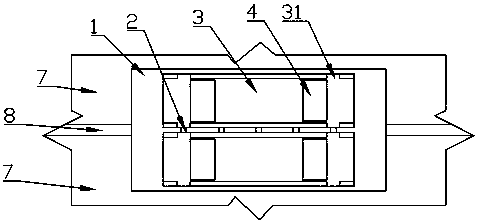

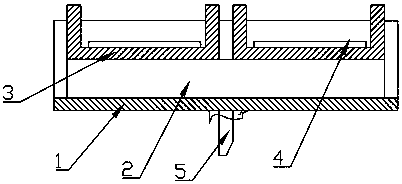

[0037] As shown in the figure, a shock-absorbing, compression-resistant, anti-slip sleeper for subsequent transportation of a shield machine for a battery car relates to a shield tunnel pipe ring for installing a sleeper. The shield tunnel pipe ring is composed of several shield tunnel segments 7 and shield Tunnel ring segment annular seam waterproof tape 10 is assembled, and a shield tunnel ring annular gap 8 is formed between adjacent shield tunnel segments 7; the sleeper includes an arc-shaped steel plate belt 1, and the arc Shaped steel plate strip 1 fits the inner surface of the shield tunnel pipe ring, and it is arranged symmetrically with the longitudinal centerline of the lower part of the shield tunnel pipe ring in the arc length direction; There are more than 3 vertical load-bearing ribs 2 distributed evenly at intervals, and the top surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com