Automatic rotatable installing machine for movable optical fiber connector

A technology for movable connectors and optical fibers, which is used in hand-held tools, manufacturing tools, etc., can solve the problems of low manual assembly efficiency and insufficient screwing, so as to improve the qualification rate of one-time assembly, improve assembly efficiency, and overcome the tightening force. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

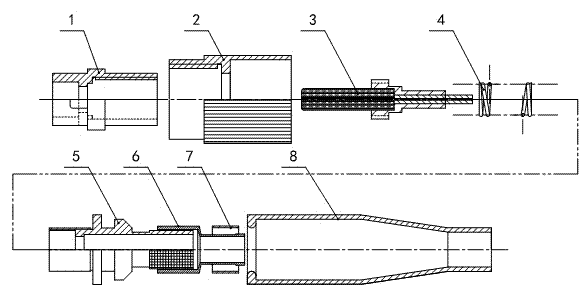

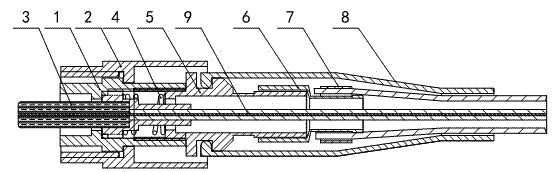

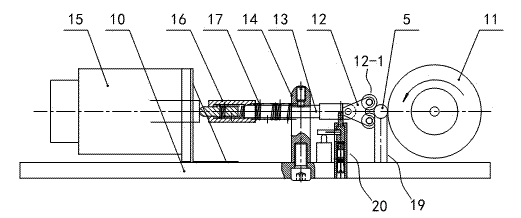

[0019] The specific embodiment of the optical fiber movable connector automatic spinning machine of the present invention is as follows: Figure 3 to Figure 7 As shown, the spinning machine has a base 10, a set of motor drive mechanism 21 is fixedly installed on the installation platform at the top of the base 10, the power output shaft of the motor drive mechanism 21 is horizontally arranged, and radially fixed on the power output shaft A driving wheel 11 utilizing frictional force to drive the parts to be installed, the driving wheel 11 is made of rubber wheels, and a pressure head 12 is provided near the outer rim of the driving wheel 11 left side, on the pressure head 12 towards the The front end of the driving wheel 11 is rotated up and down side by side with two pressure rollers 12-1. The axis of these two pressure rollers 12-1 is parallel to the axis of the driving wheel 11, so that the pressure head 12 is aligned with the outer rim of the driving wheel 11. A three-poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com