Assembling and testing method for two-way sealing bolt type injector

A test method and injector technology, which is applied to jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as reduced reliability, failure of surface shutdown function, irregular test process, etc., to achieve high reliability, The effect of high pass rate and complete test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

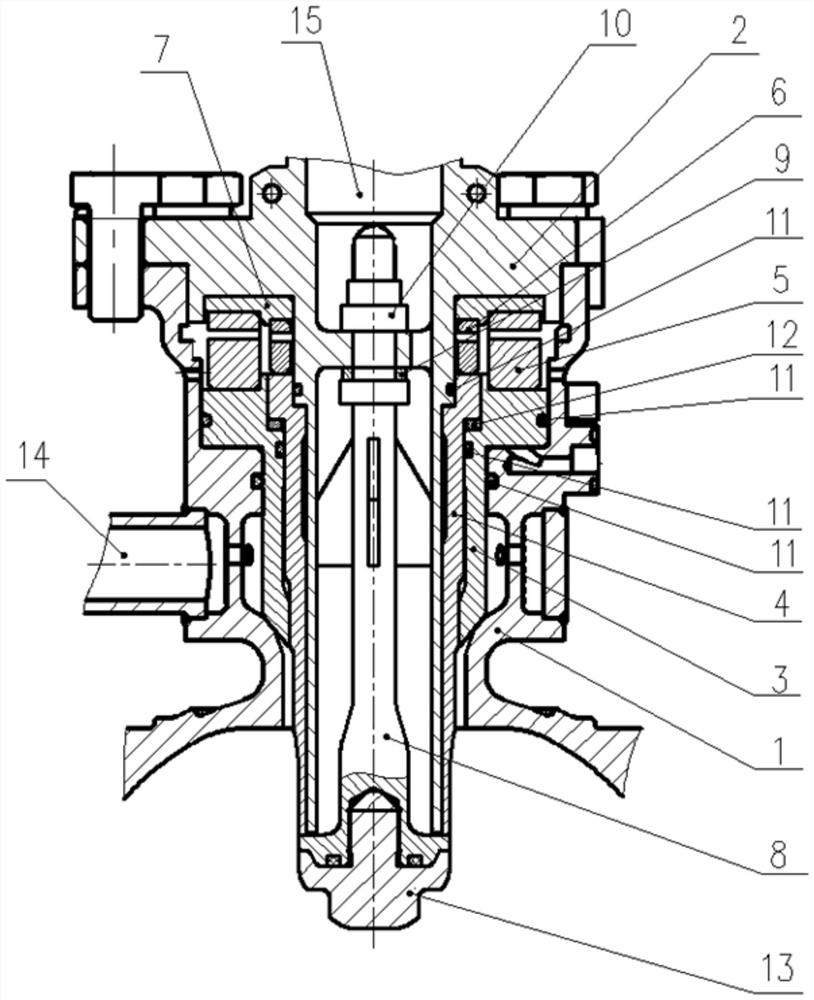

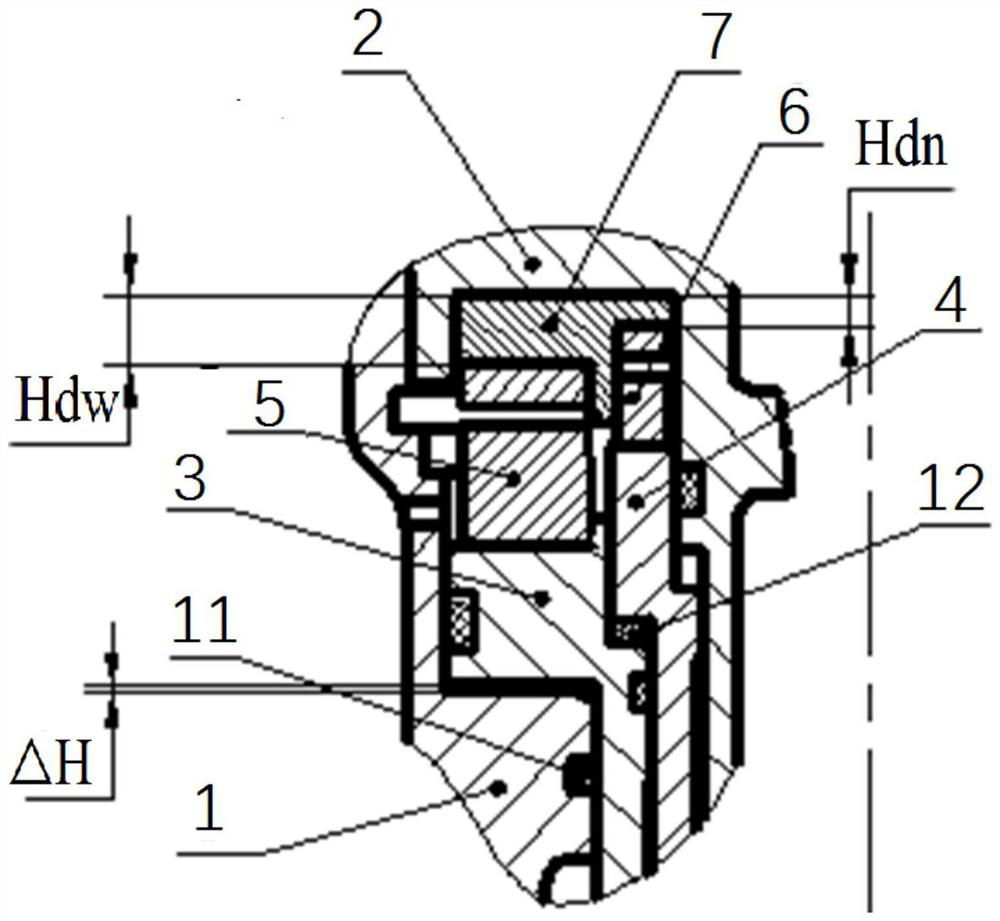

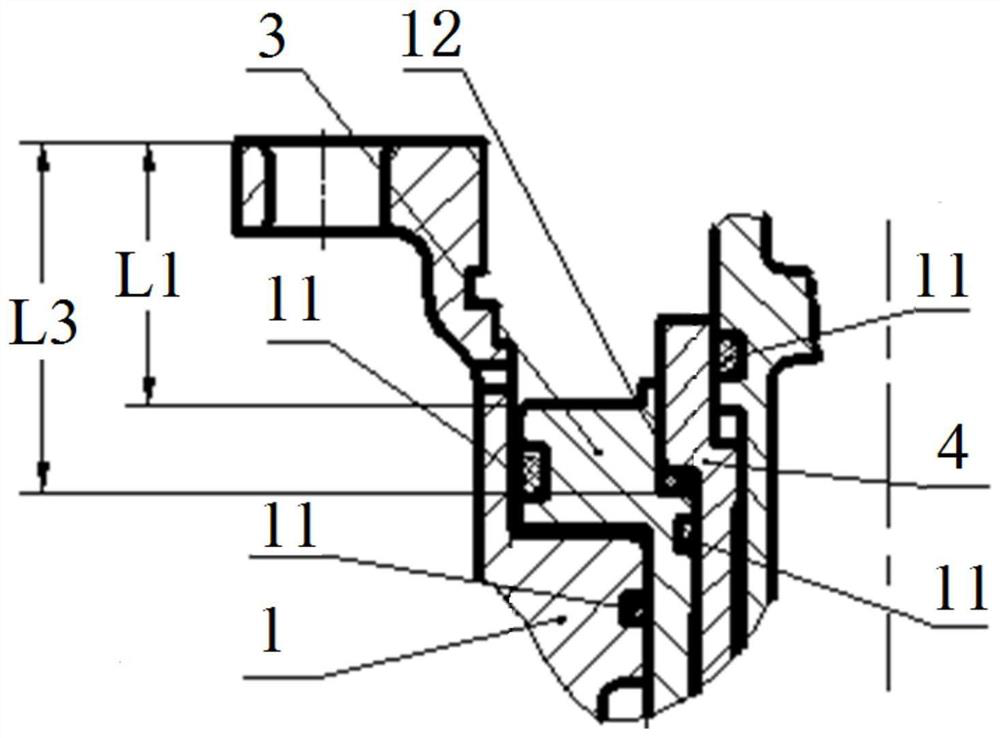

[0046] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood by those skilled in the art that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0047] In the development of the bolted injector, the movement flexibility of the movable needle valve, one of the key components, and the reliability of the two-way sealing structure are extremely important for the operation of the engine. The assembly steps, methods and processes of the spigot injector, especially the dual-road shut-off structure injector, are critical. In order to standardize and improve the assembly reliability of the injector, the present invention provides a two-way sealing plug injector assembly test method, which ensures the movement characteristics (flexibility and response), sealing characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com