Device for rapidly detecting size parameters of cylinder type excircle shape

A technology of circular shape and cylinder is applied in the field of devices for rapidly detecting the size parameters of cylindrical outer circle shape, which can solve the problems of heavy workload of measuring personnel, low qualification rate of one-time assembly, low measurement efficiency, etc., so as to reduce labor intensity and improve Measurement accuracy and measurement efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

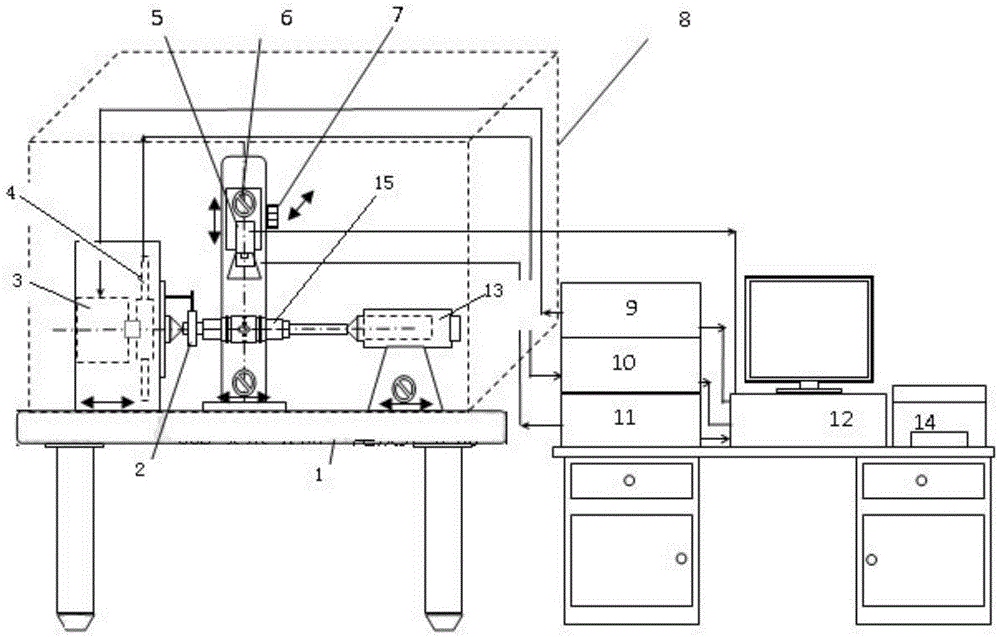

[0010] refer to figure 1 . In the embodiment described below, the device for quickly detecting the shape and size parameters of the cylindrical excircle includes: a servo motor bracket fixed on the working platform, a counter-symmetrical servo motor tip, and a coaxial clamping workpiece with a shift fork 2 top support. The measured workpiece 2 and the circular grating 4 are rigidly connected. Install the valve core or valve sleeve on the dial sleeve, and at the same time, the other end of the workpiece 2 with the shift fork is placed on the top of the high-precision front shaft system 13, put the shift rod on the dial sleeve into the shift fork, and the shift fork On the top of the high-precision circular grating 4, the servo motor is arranged in the motor drive box 9, and the anti-interference cover 8 is covered. Turn the hand wheel to make the tip of the tail reach the proper position, use the manual gear to operate the initial aiming, and then use the automatic gear to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com