Patents

Literature

141results about How to "High dimensional consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

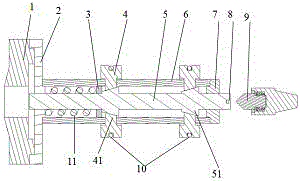

Electrolytic processing method for ribbed deep small holes and special tool cathode

InactiveCN1943951AImprove ECM EfficiencyEasy to prepareMachining electrodesElectrical-based machining electrodesMachining processSmall hole

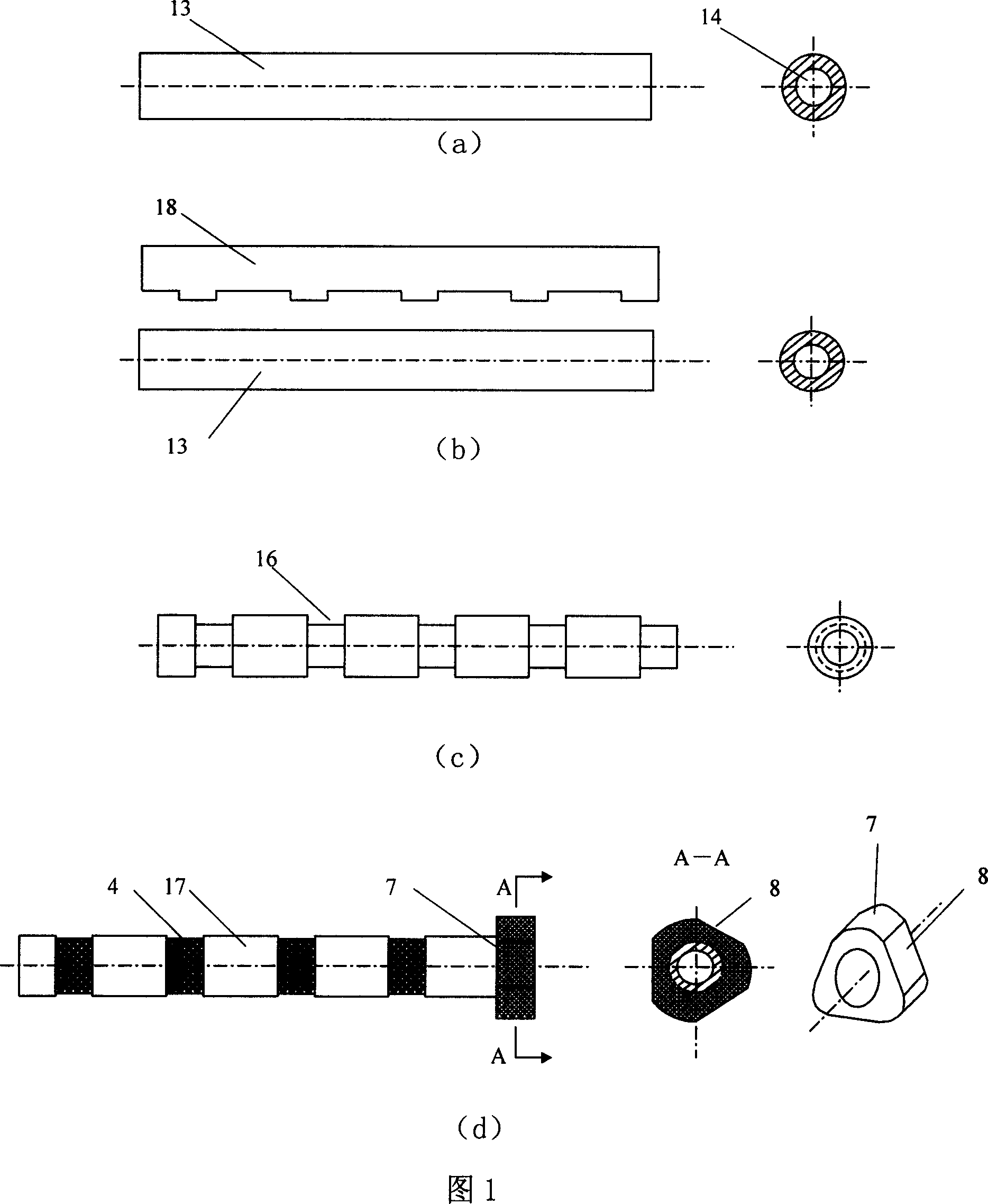

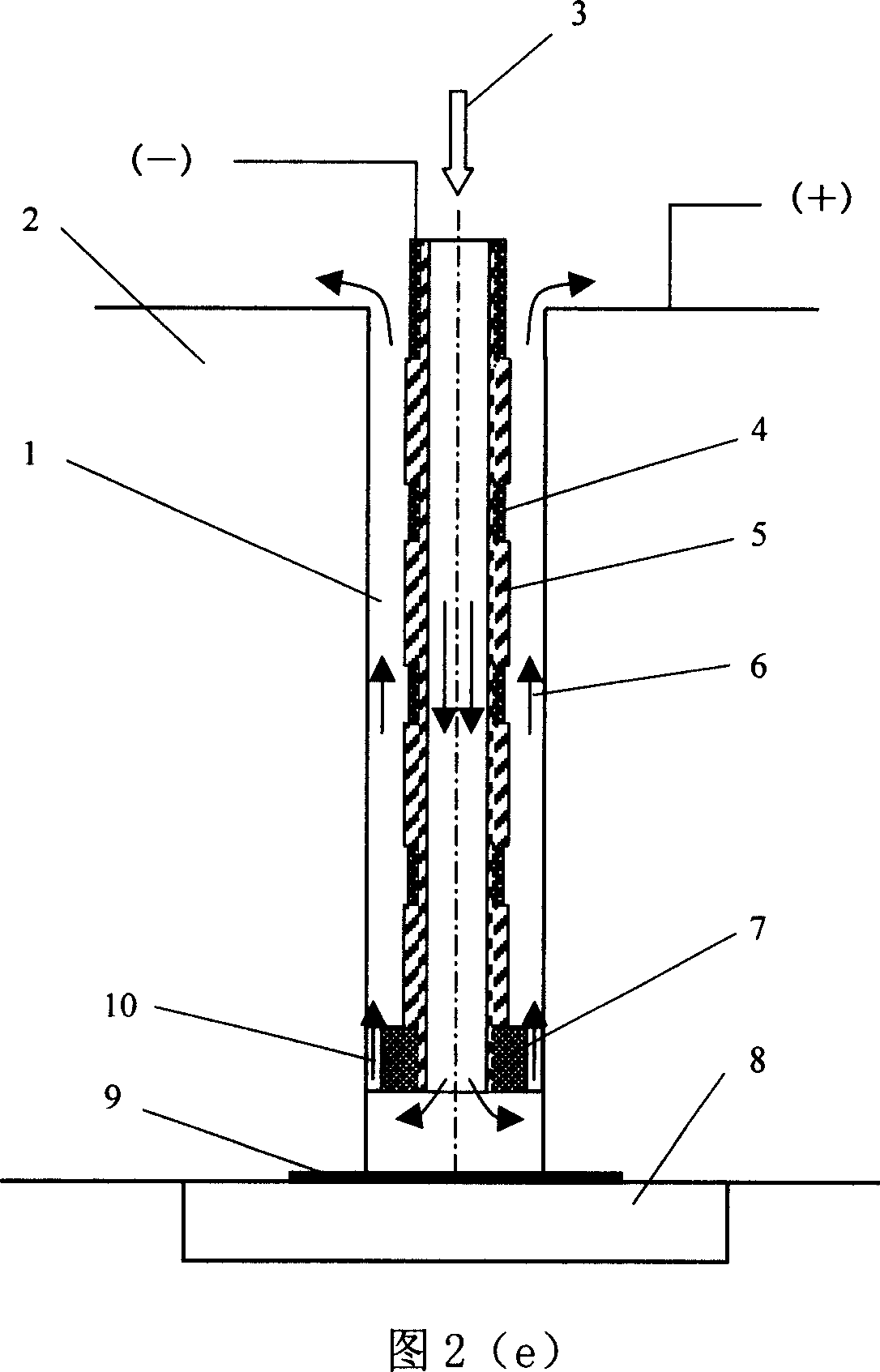

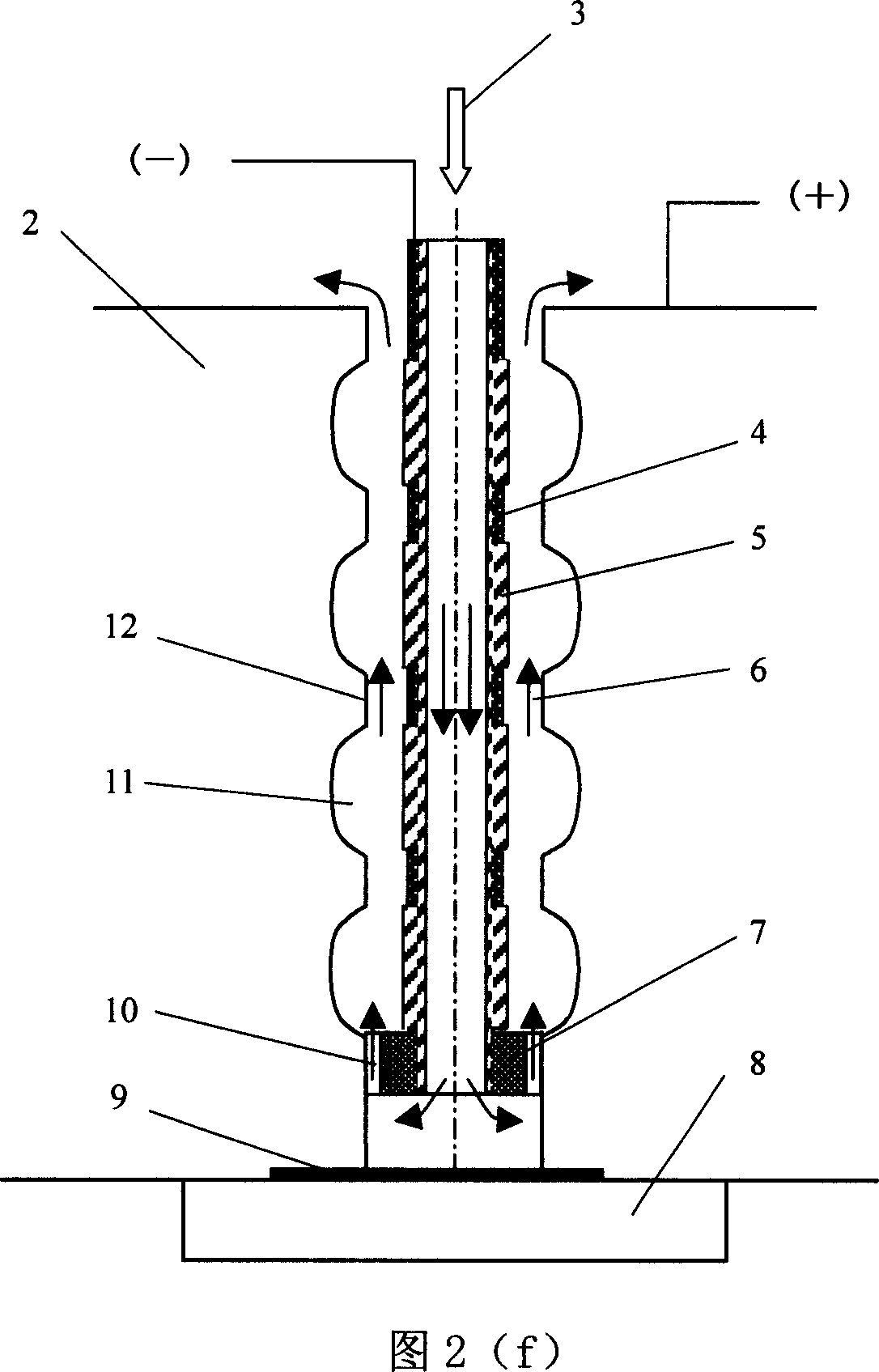

The present invention is electrolytic processing method for ribbed deep small hole and its special tool cathode, and belongs to the field of electrolytic machining technology. The method includes the following steps: electrolytic machining one metal pipe with one reversely copied cathode to form notches in the surface of the metal pipe; coating epoxy resin glue into the notches; installing positioning rack to the end of the tool electrode to make the forming tool electrode; machining smooth hole in the workpiece; stretching the forming tool electrode into the deep smooth hole to machine the ribbed deep small hole. The present invention has simple machining of the forming tool electrode, high ribbed hole machining precision, high machining stability and other advantages.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

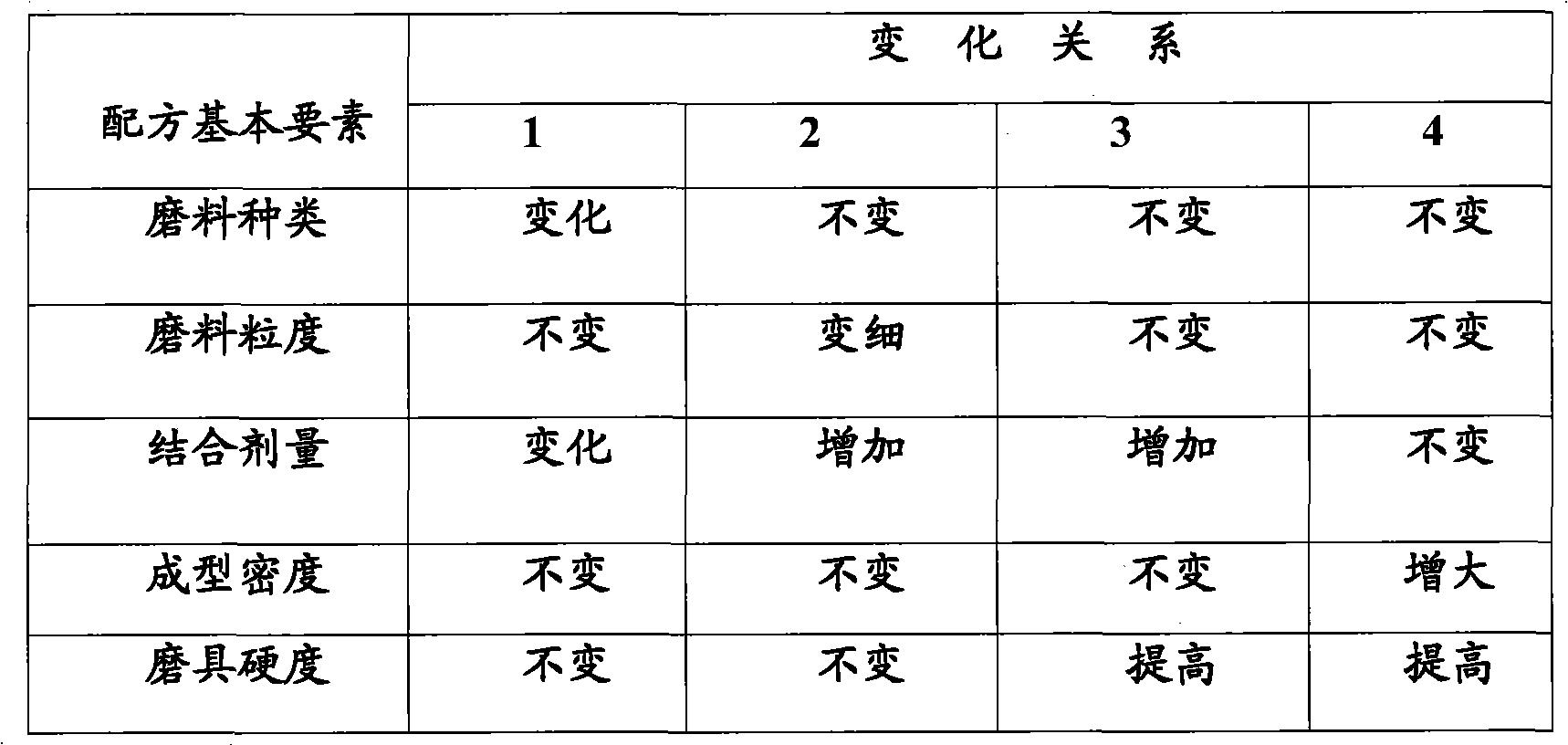

Precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials

InactiveCN101797724AGood toughnessSmall grinding deformationAbrasion apparatusAlumina ceramicAluminium oxide

The invention relates to a precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials, comprising a grinding wheel basal body, grinding material particles distributed on the grinding wheel basal body and a bonding agent bonded and fixed on the grinding material particles, wherein the bonding agent comprises the following components in percentage by weight: 10-15 clay powder, 30-50 feldspar powder, 20-40 talcum powder and 10-20 high-boron glass powder. The grinding wheel has the functions of large cutting depth, high feeding strength, large load and high-efficiency grinding. According to tests, over 0.3 mm can be reached for one-way feeding and the metal removing rate is over 2 times higher than that of a common corundum grinding wheel. The grinding wheel ahs the advantages of high durability, long service life which is 5-10 times that of the common corundum grinding wheel, favorable self sharpening, no blockage and high capability of maintaining stable grinding performance.

Owner:SUZHOU FAR EAST ABRASIVES

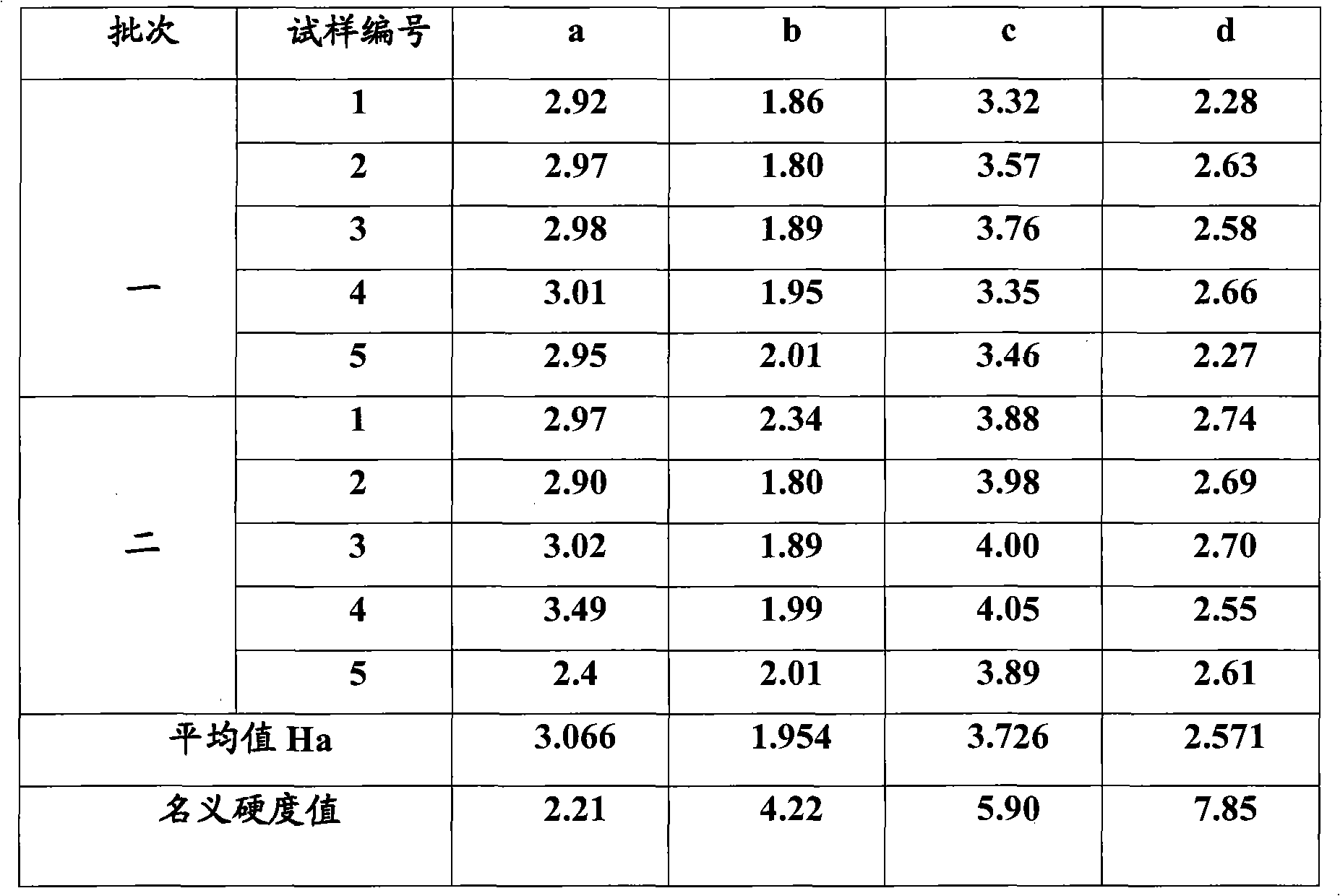

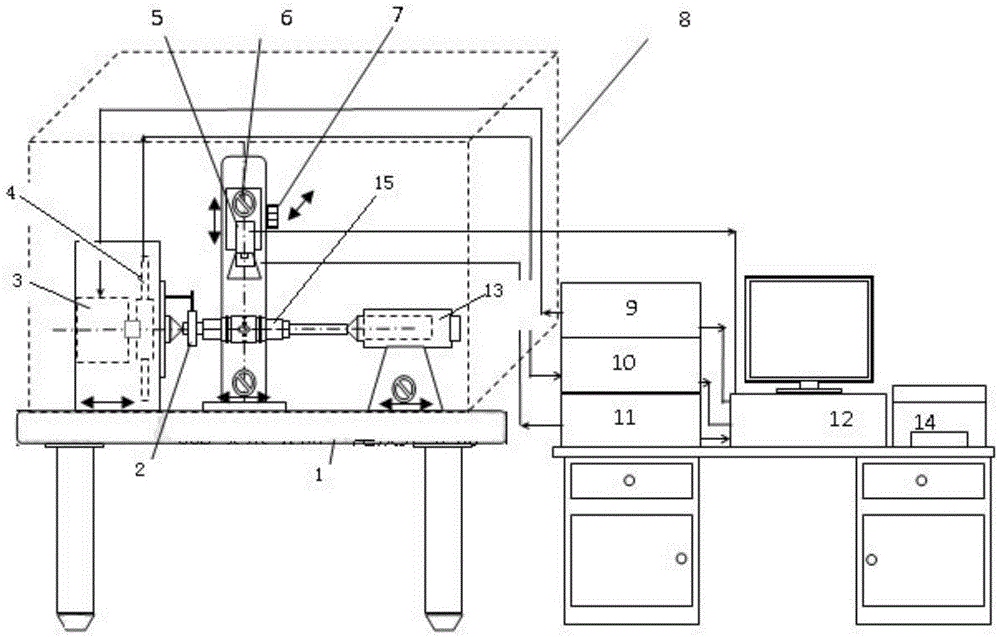

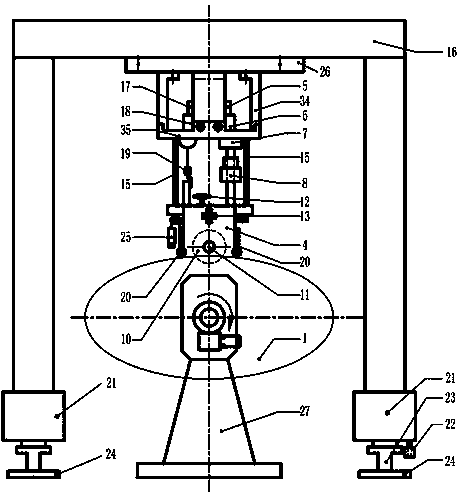

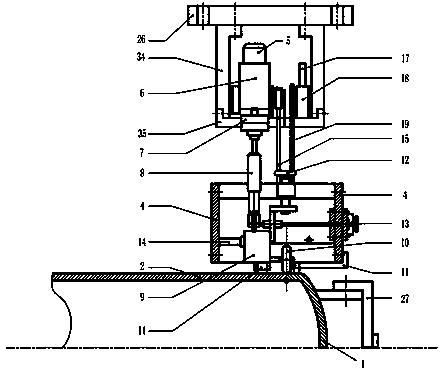

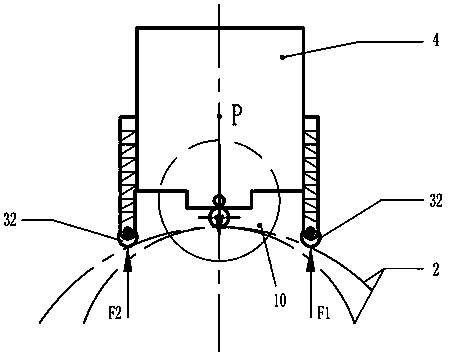

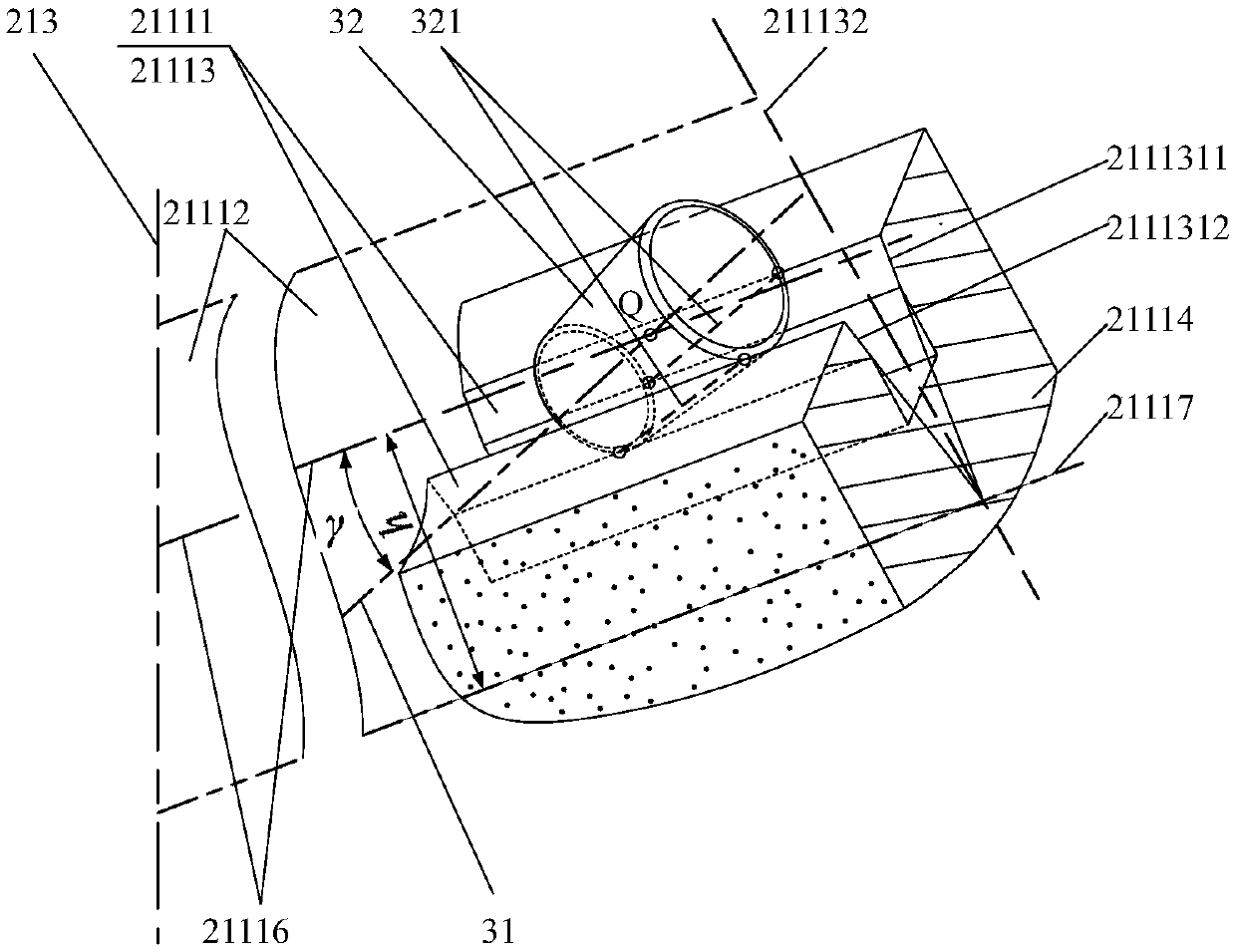

Device for rapidly detecting size parameters of cylinder type excircle shape

InactiveCN105387817AHigh dimensional consistencyImprove one-time assembly pass rateUsing optical meansObservational errorGrating

The invention discloses a device for rapidly detecting size parameters of a cylinder type excircle shape, and aims at providing the rapid detection device simple in structure, high in measuring efficiency and capable of improving the measuring precision. A CCD camera (5) whose lens just faces a clamped detected workpiece (2) is arranged over the clamped detected workpiece, the CCD camera (5) collects images of the clamped detected workpiece which is driven by a servo motor to rotate, the collected calibration position size of each groove is converted into a digital signal, the digital signal is transmitted to a circular grating (4) fixed on a main shaft of the servo motor, the angular displacement of the detected workpiece, namely a moving object, is obtained, a linear array photosensitive tube calculates the position size of each groove via a computer image processing software system input by a reading head device, parameters including the width, the position accuracy and the verticality of the calibration groove of the detected workpiece are displayed and printed. The device can be used to overcome the disadvantages that errors of manual measurement influence test results a lot and cause low measuring efficiency.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

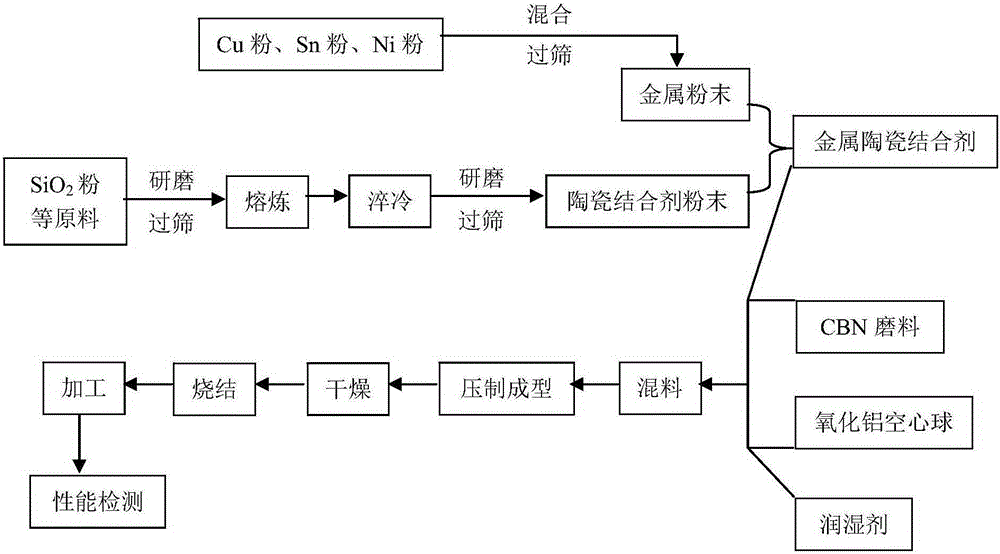

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

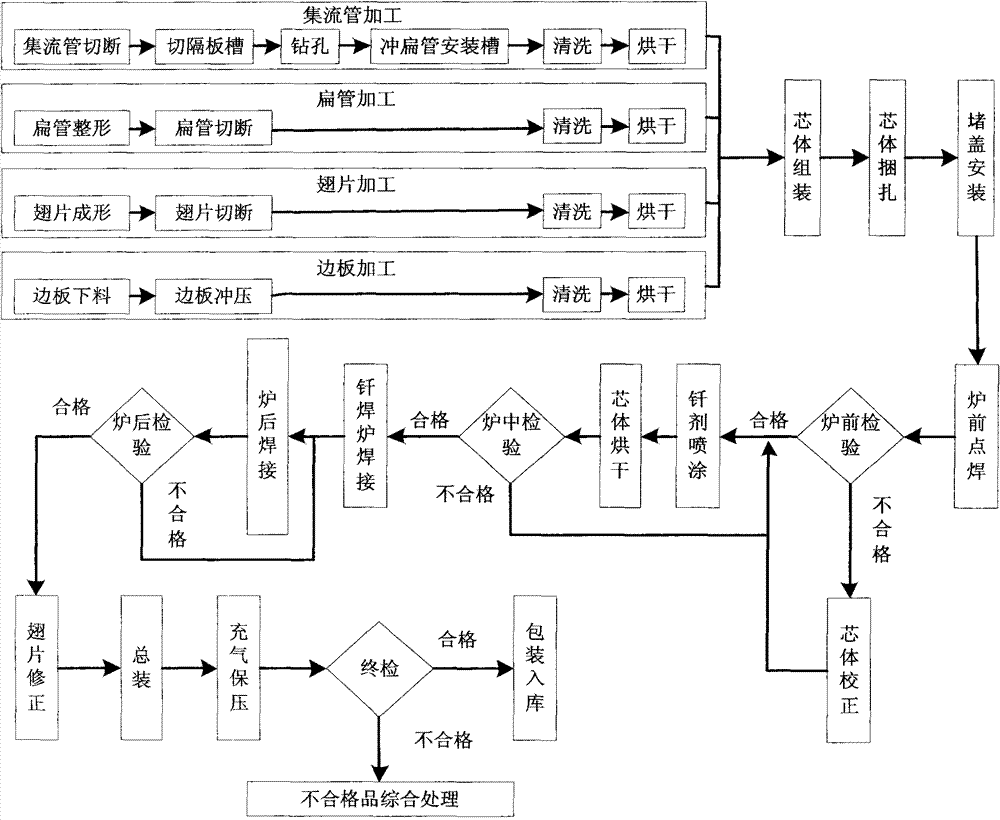

Production method of parallel flow heat exchanger for automobile air conditioner

The invention discloses a production method of a parallel flow heat exchanger for an automobile air conditioner. The method comprises the steps of collecting main processing, flat tube processing, fin processing, side board processing, core body assembly, core body strapping, blanking cover installation, spot welding before furnace, inspection before furnace, core body correction, flux spraying, core body drying, inspection in the middle of furnace, brazing furnace welding, welding after furnace, fin correction, general assembly, inflation and pressure preservation, in-process inspection, comprehensive treatment of non-conforming products, packaging and stock-in procedures. The production method of the parallel flow heat exchanger for the automobile air conditioner has the advantages that due to the adoption of the spot welding before furnace procedure, the utilization efficiency of a brazing furnace is improved; the product conformity rate is improved through the inspection before furnace, inspection in the middle of the furnace, inspection after furnace and final inspection procedures; the product size consistency is improved through the core body correction procedure. Meanwhile, the method has the characteristics of simple process, low equipment cost, easiness in transformation and the like.

Owner:浙江松信汽车空调有限公司

Integrated milling equipment for welding groove of large irregular medium plate structure

InactiveCN104028817AImprove machining productivityEnsure Consistency and ReliabilityMilling equipment detailsWeld seamStructural engineering

The invention discloses integrated milling equipment for a welding groove of a large irregular medium plate structure. The integrated milling equipment comprises a milling cutter system component, a fixed-depth profile modeling component, a milling cutter adjusting component, a normal-direction support component, a horizontal tracking component, a milling cutter box floating component, a 90-degree reversing component, a height raising component, a groove length displacement component and a milling cutter box body. Firstly, separated weldments are assembled into an integrated weldment; afterwards, the welding groove is integrally machined; finally, welding is performed; in this way, the machining productivity of the welding groove is increased to at least double. With regard to integrated machining of the welding groove, the welding groove is machined through one milling cutter at a time, and therefore the consistency and reliability of the size of welding seams of the welding groove integrally machined are higher; the integrated milling equipment is quite beneficial to assembly quality guarantee of the weldments and the dimensional accuracy of the welded product; the machining cost of the welding groove is lower; the dimensional consistency of the welding groove is quite high, and single-sided weld with double-sided formation can usually be achieved; in this way, the welding productivity is further increased, and the production cycle is further shortened.

Owner:武汉纳瑞格智能设备有限公司

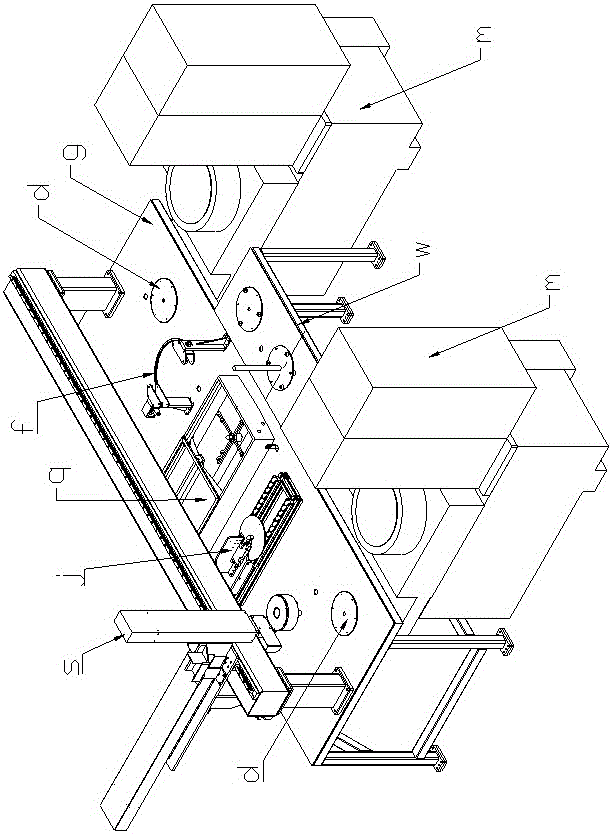

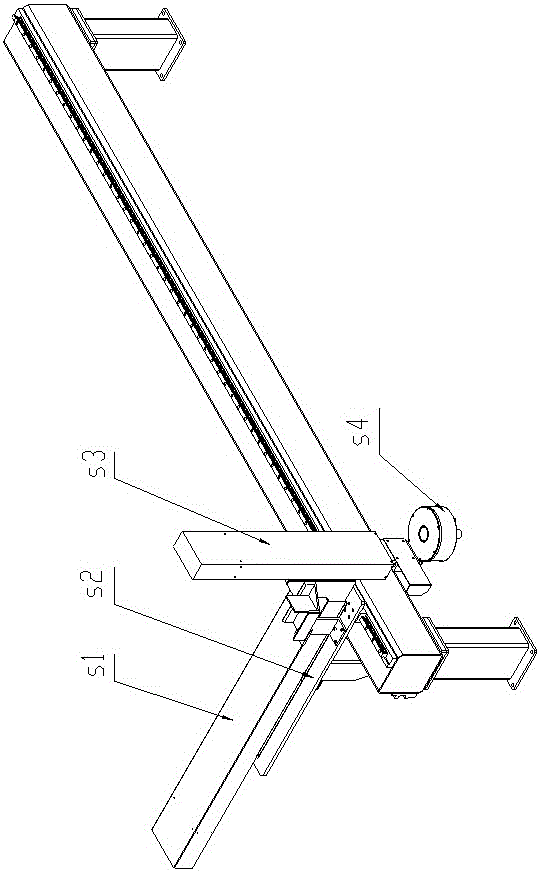

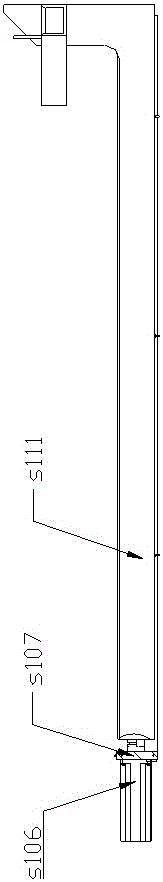

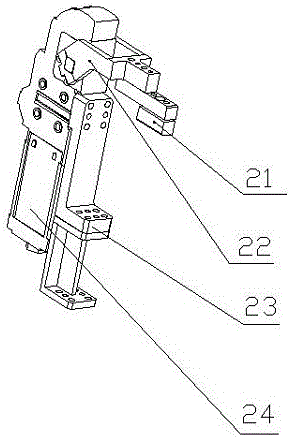

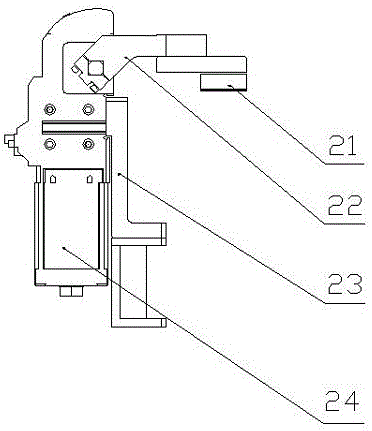

High-precision efficient automatic grinding and detecting production line and high-precision efficient automatic grinding and detecting production method

ActiveCN105728851ARealize automatic detection functionRealize fully automatic processingMetal sawing tool makingMeasurement/indication equipmentsProduction lineThree degrees of freedom

The invention discloses a high-precision efficient automatic grinding and detecting production line which comprises a manipulator mechanism (s) with three degrees of freedom, a cleaning mechanism (q), a turnover mechanism (f), a detecting mechanism (j), a working table (g), a material table (w) and two grinding machines (m). The two grinding machines (w) are respectively arranged at two ends of the working table (g); the manipulator mechanism (s) with the three degrees of freedom is used for loading and unloading materials; the working table (g) is used for mounting the manipulator mechanism (s) with the three degrees of freedom, the cleaning mechanism (q), the turnover mechanism (f), the detecting mechanism (j) and the material table (w); the material table (w) is used for arranging workpieces. The invention further provides a high-precision efficient automatic grinding and detecting production method. The high-precision efficient automatic grinding and detecting production line and the high-precision efficient automatic grinding and detecting production method have the advantages that the high-precision efficient automatic grinding and detecting production line is compact in structure, material grabbing, workpiece cleaning, workpiece turnover and workpiece detecting and mounting can be carried out on the same working table, the two grinding machines can be in simultaneous working states under various actions of manipulators, and accordingly the work efficiency can be greatly improved.

Owner:LINQING XINGHE HONGXIN MACHINE

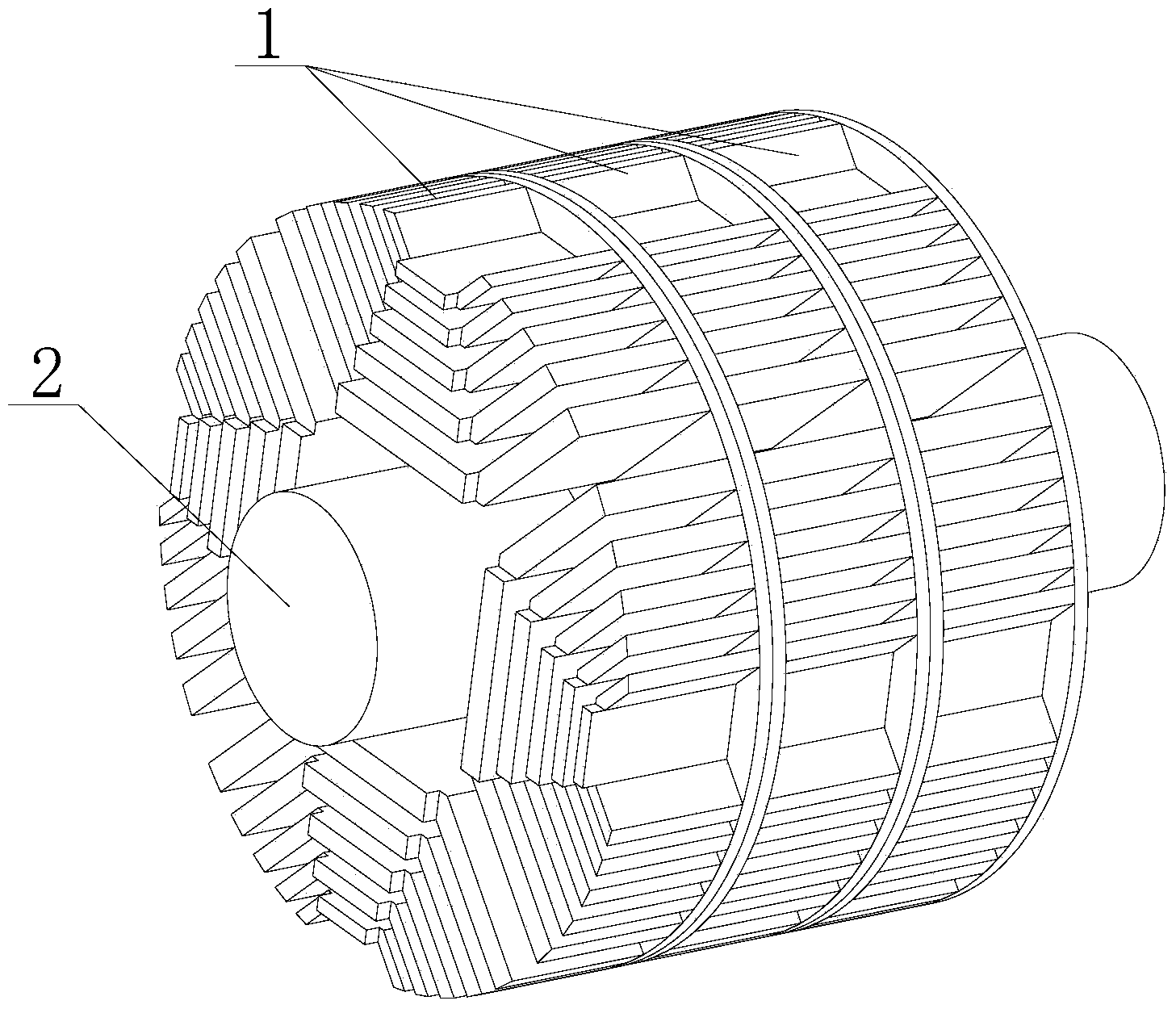

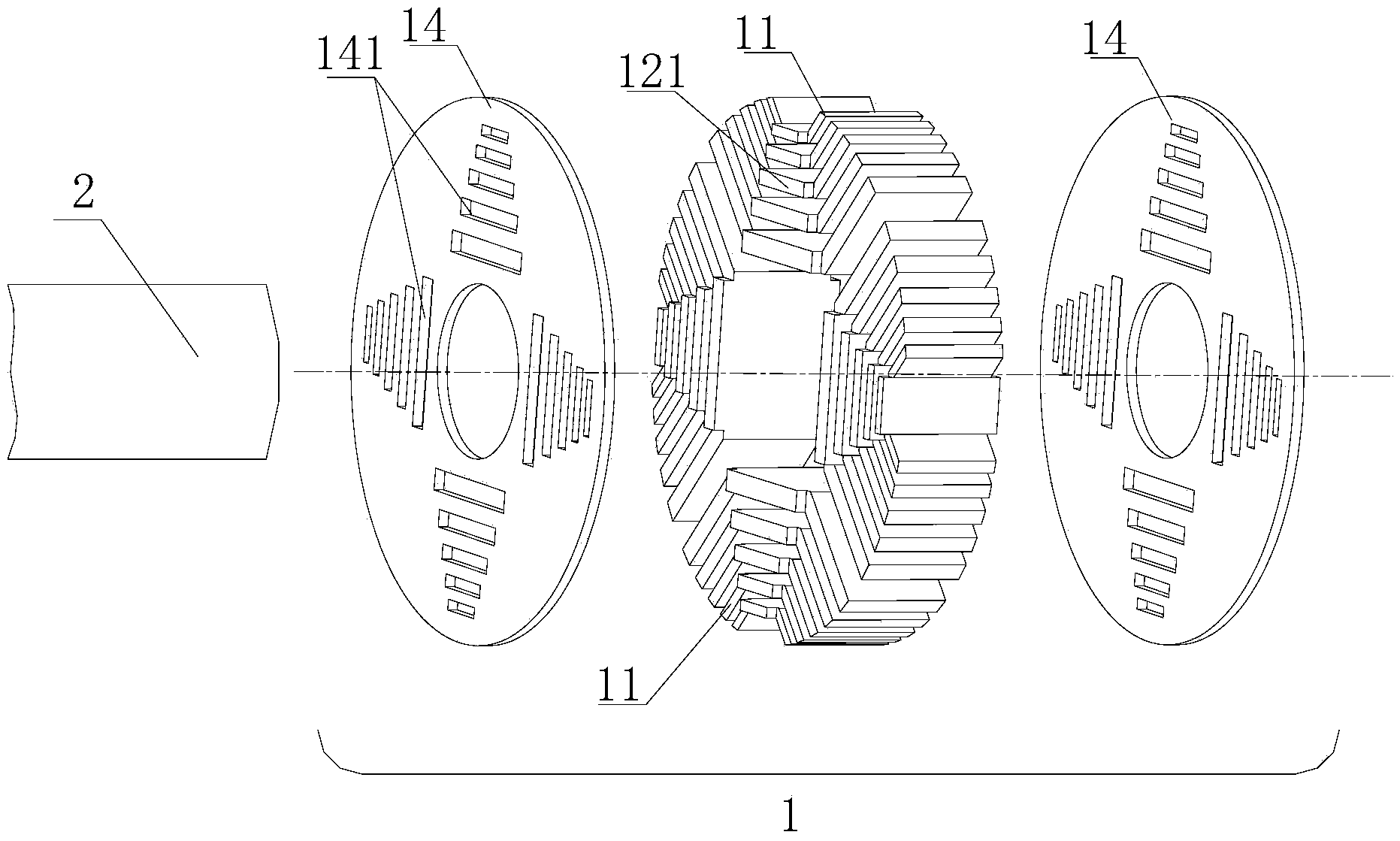

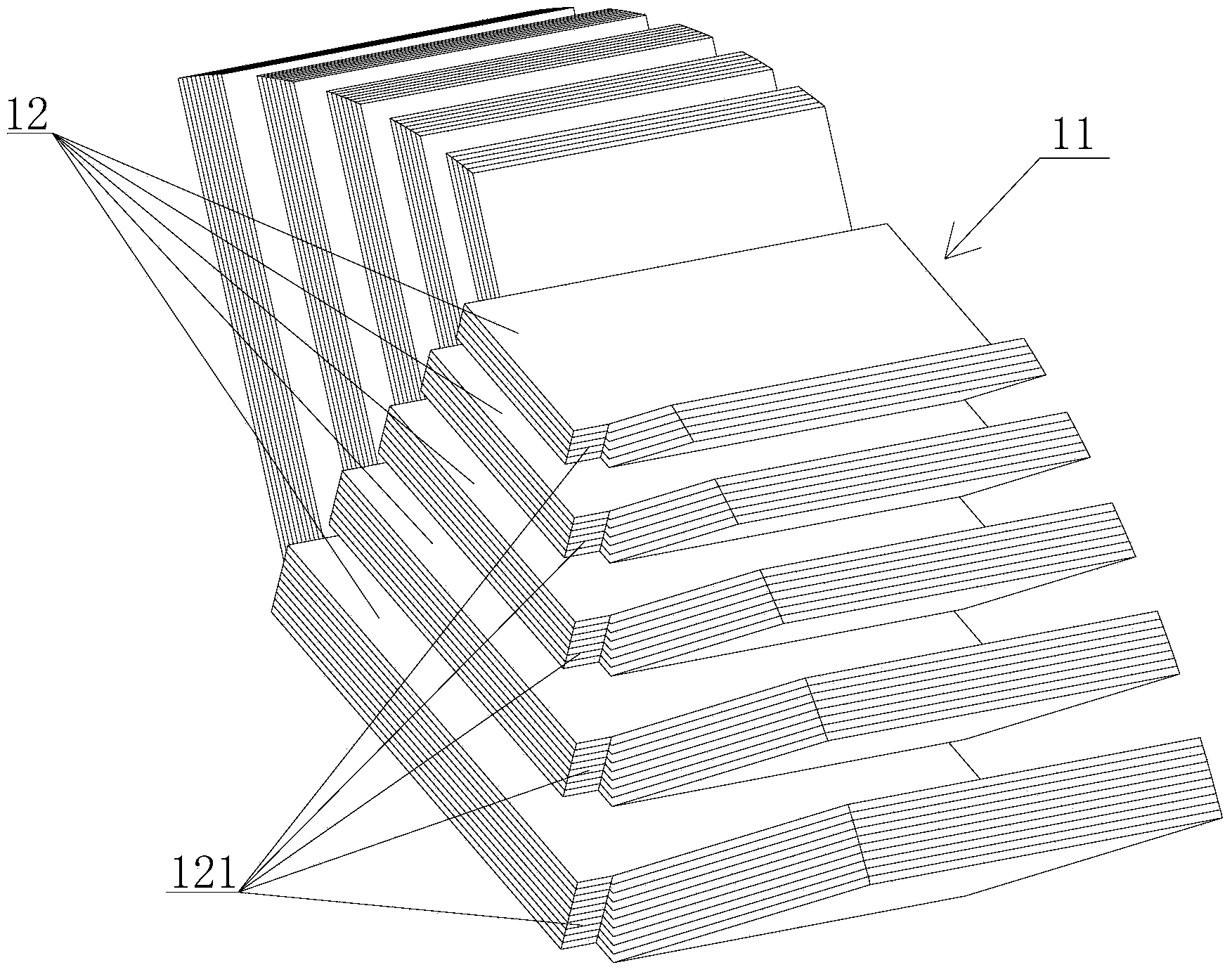

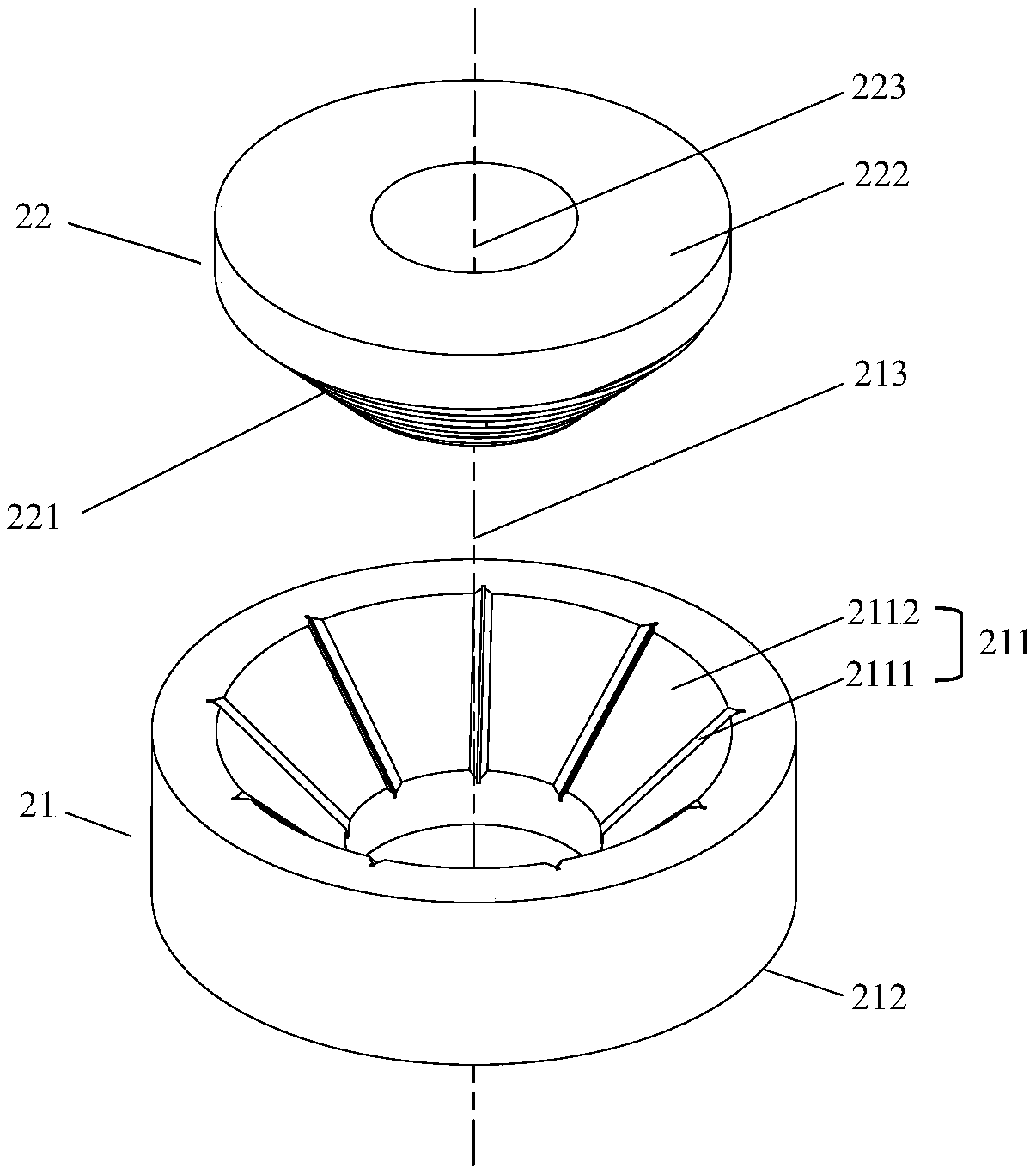

Rotor of synchronous reluctance motor

InactiveCN104242504AReduce in quantityStable structureMagnetic circuit rotating partsSynchronous reluctance motorPower factor

The invention provides a rotor of a synchronous reluctance motor. The rotor of the synchronous reluctance motor comprises multiple rotor modules which are arranged coaxially and staggered sequentially in the axial direction. Each rotor module comprises multiple magnetic poles, and the magnetic poles are arranged in adjacent sections around a common axis. Each magnetic pole comprises multiple magnetic ribs which are distributed in the radial direction at intervals. Each magnetic rib is composed of multiple punched sheets. Locating plates are connected to the two axial side faces of the magnetic poles. The locating plates are mounted on a rotating shaft in a sleeved mode. Bosses are arranged at the two axial ends of each magnetic rib respectively. Grooves are formed in the positions, corresponding to the bosses, of the locating plates. The axial end face of each magnetic pole is tightly attached to the axial end face of the corresponding locating plate in the mode that the bosses are inserted into the grooves. The magnetic poles and the locating plates of the rotor modules of the rotor are assembled through the matching between the bosses and the grooves, assembly is convenient to carry out, the magnetic poles are easy to locate, and position accuracy is high; the rotational inertia of the rotor is lower, manufacturing is easy and convenient to carry out, and the efficiency and the power factors of the motor are improved.

Owner:HANGZHOU EASITECH

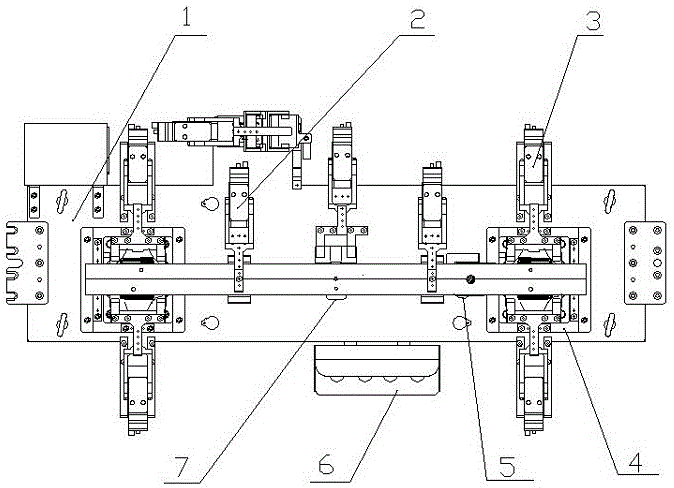

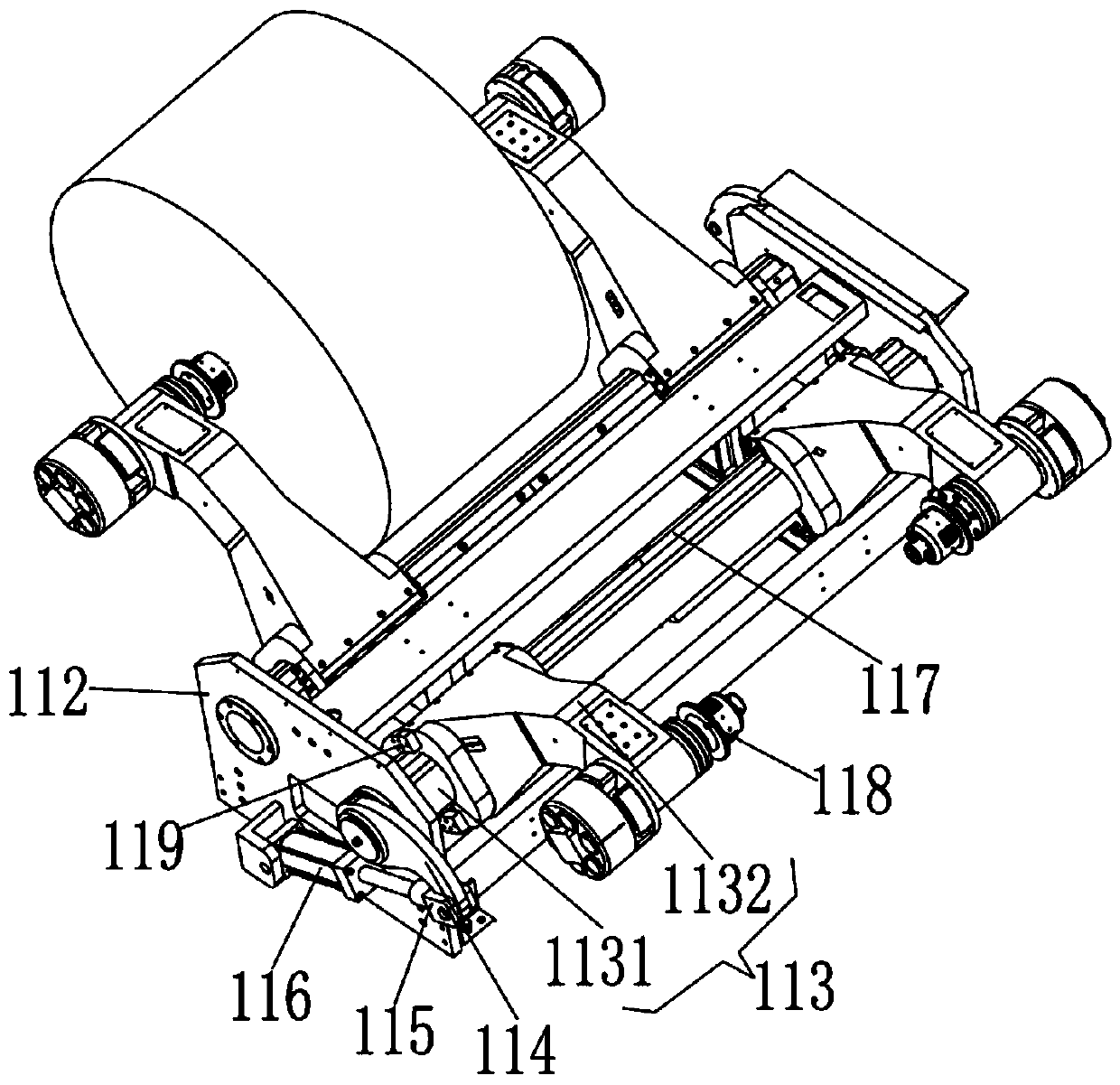

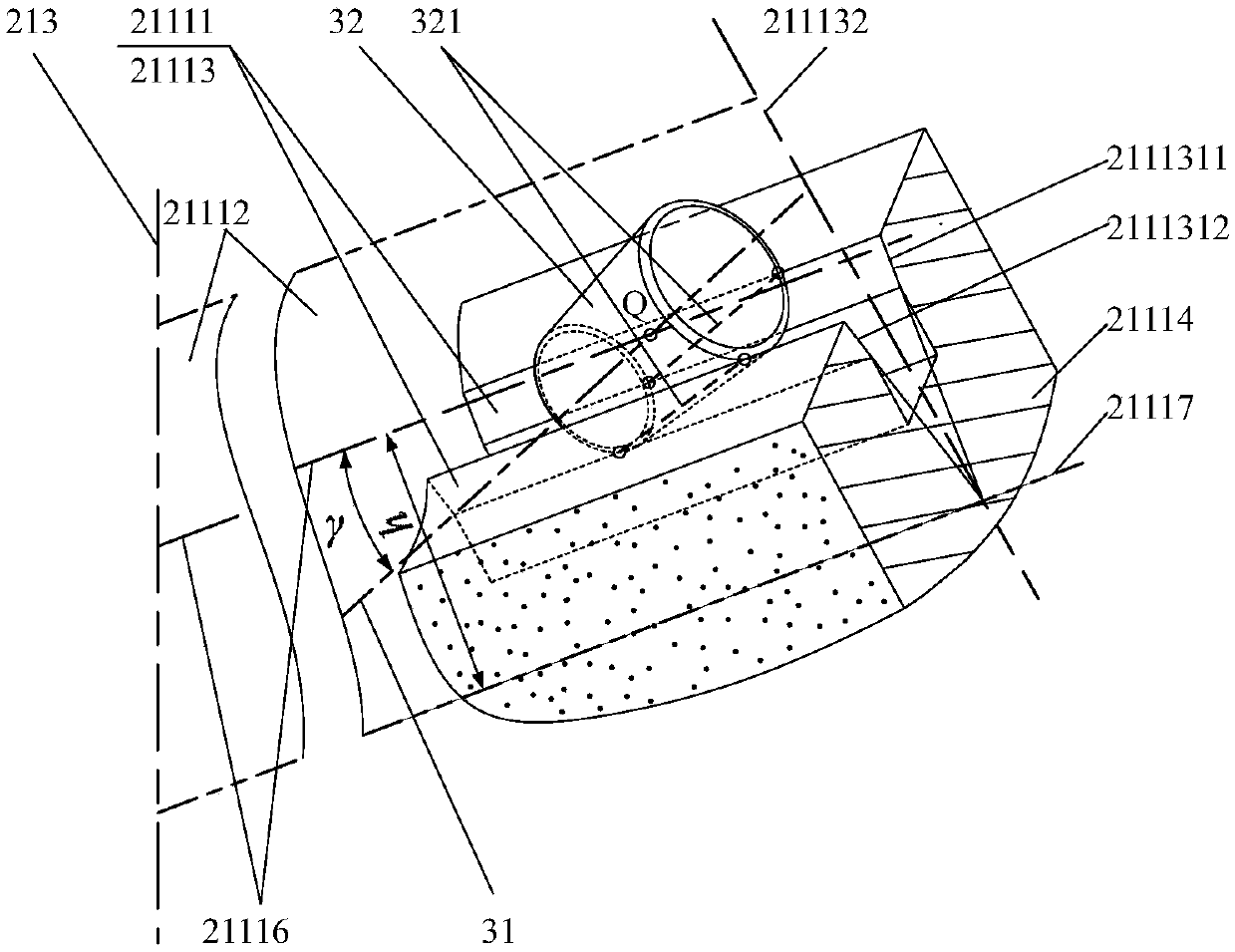

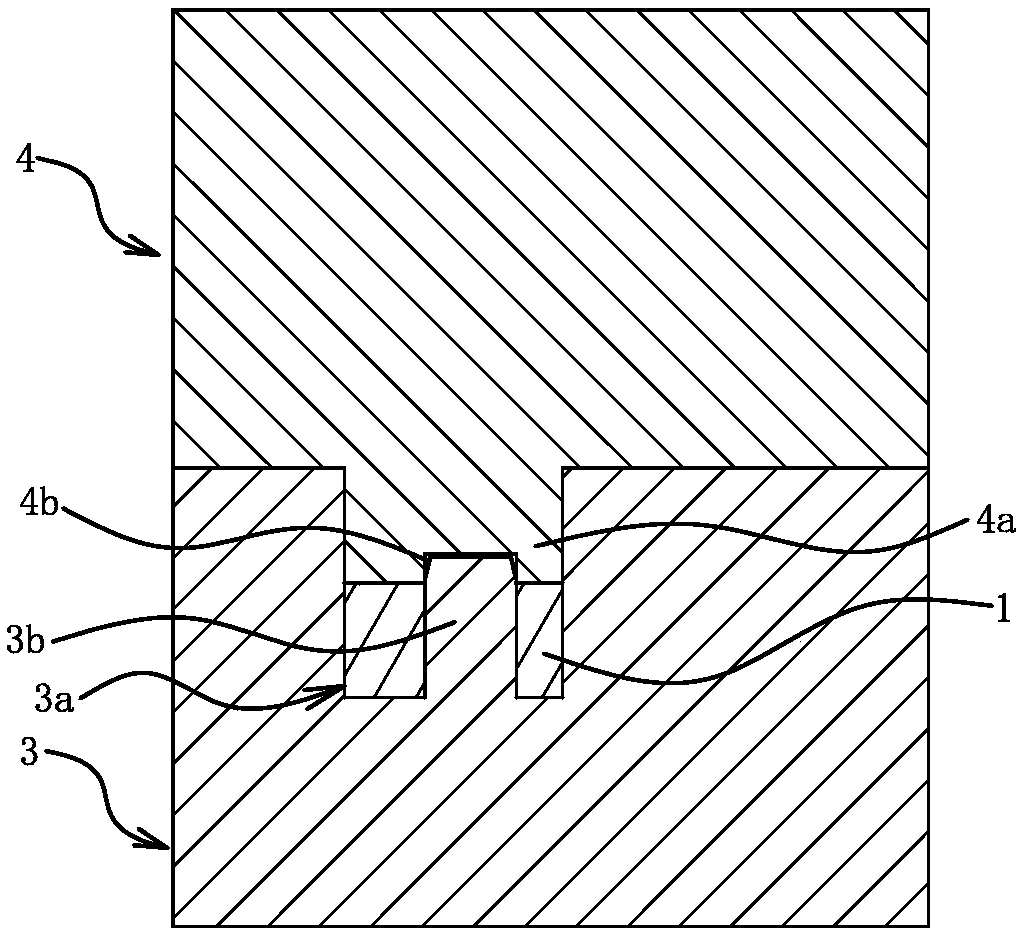

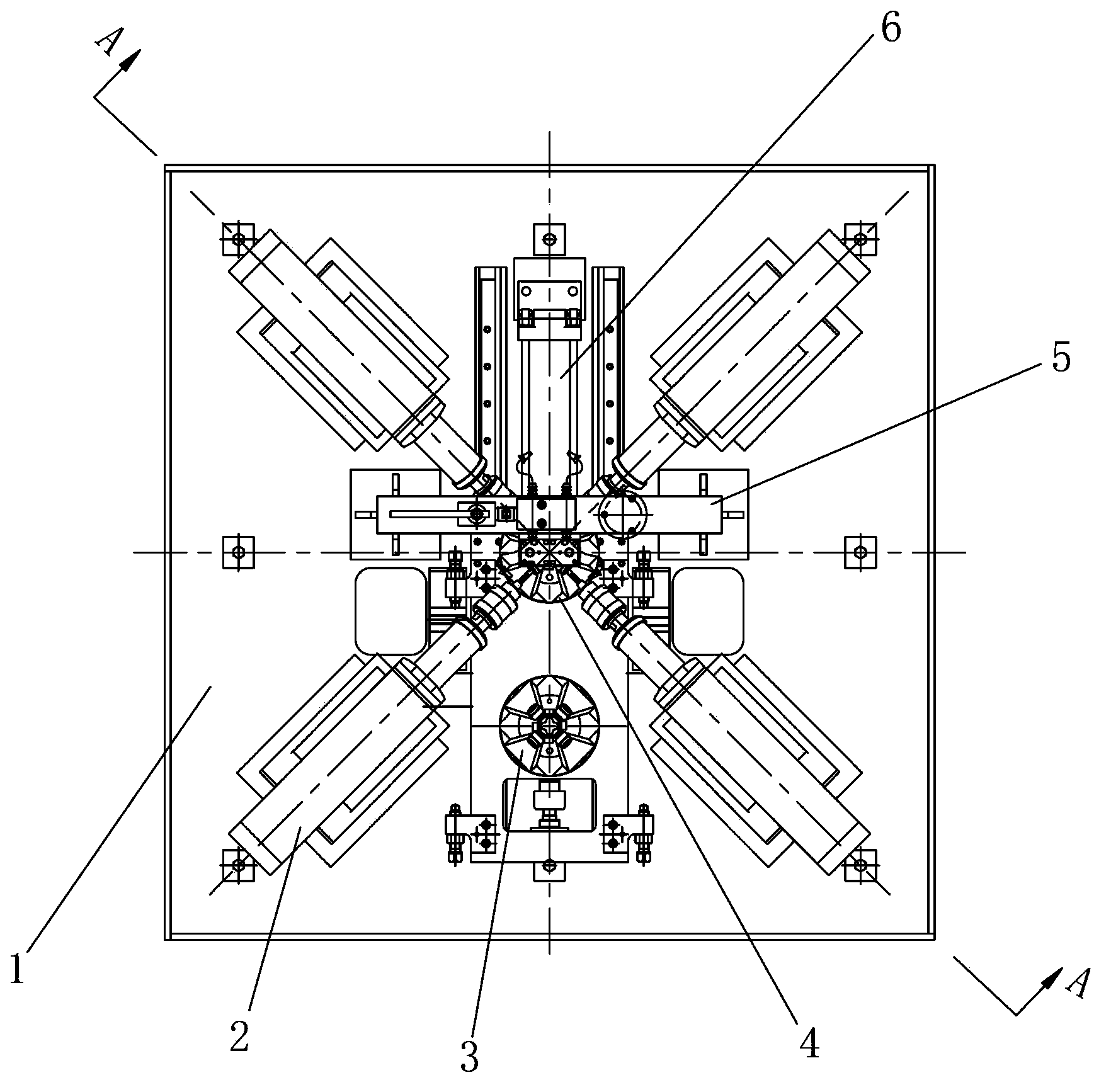

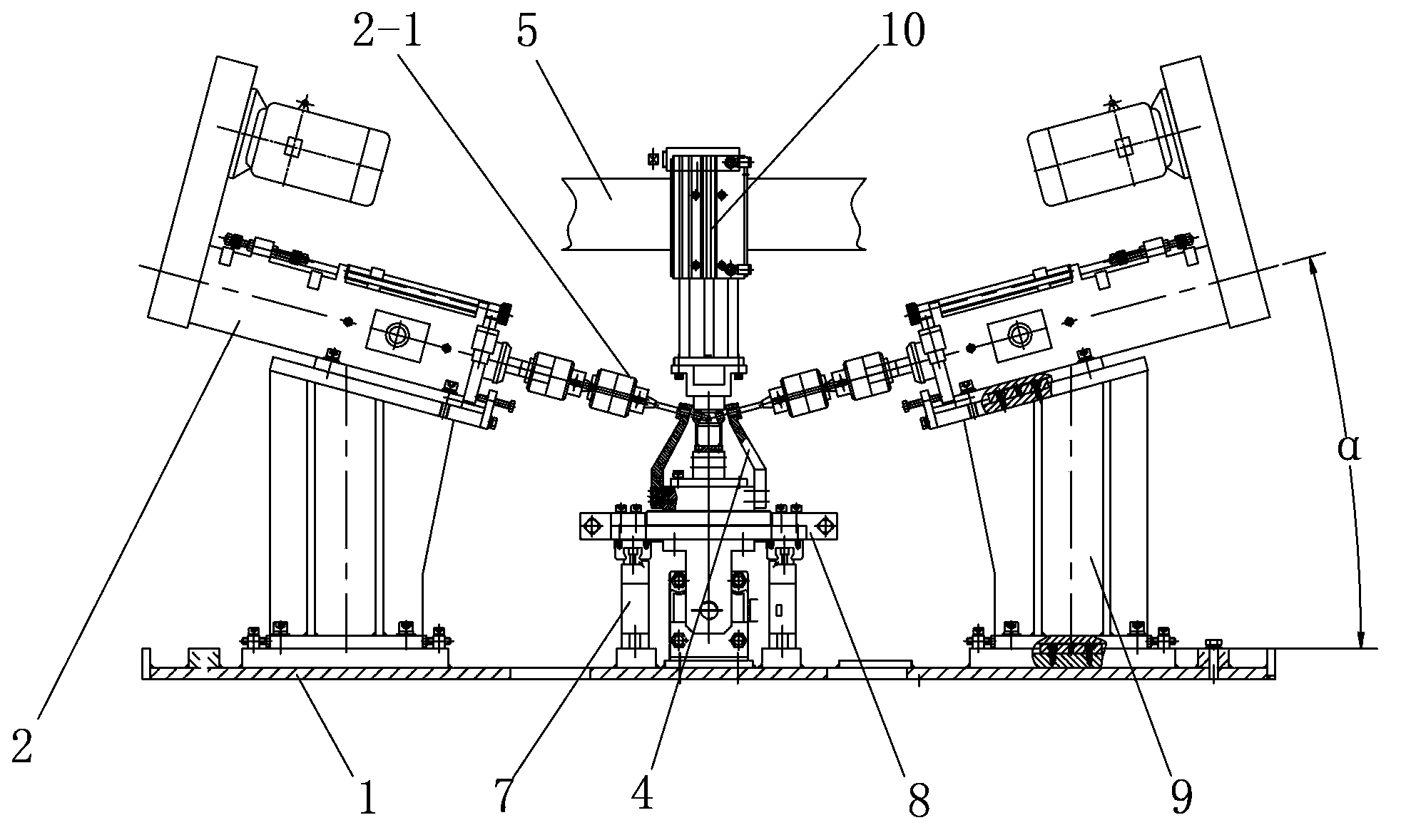

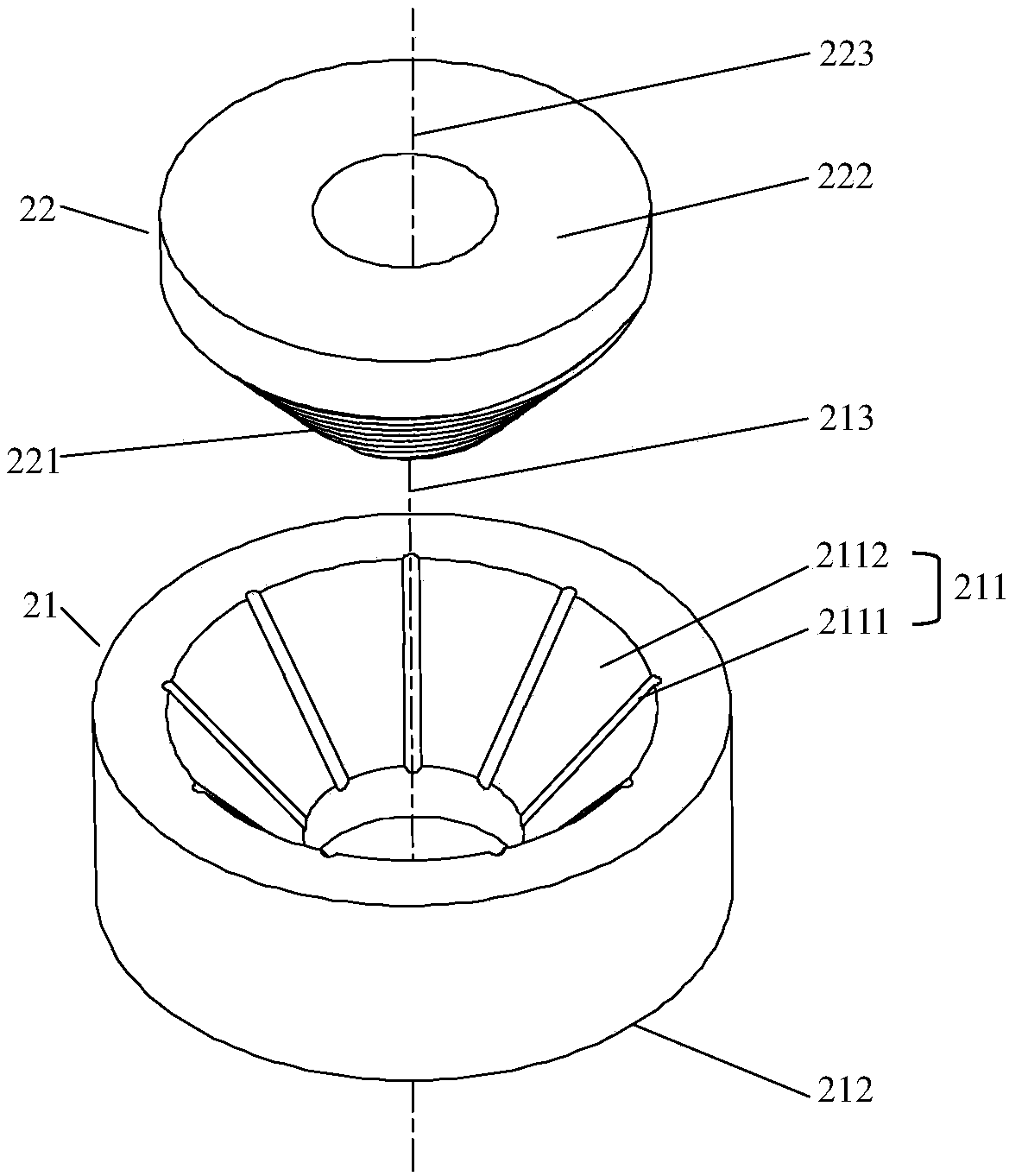

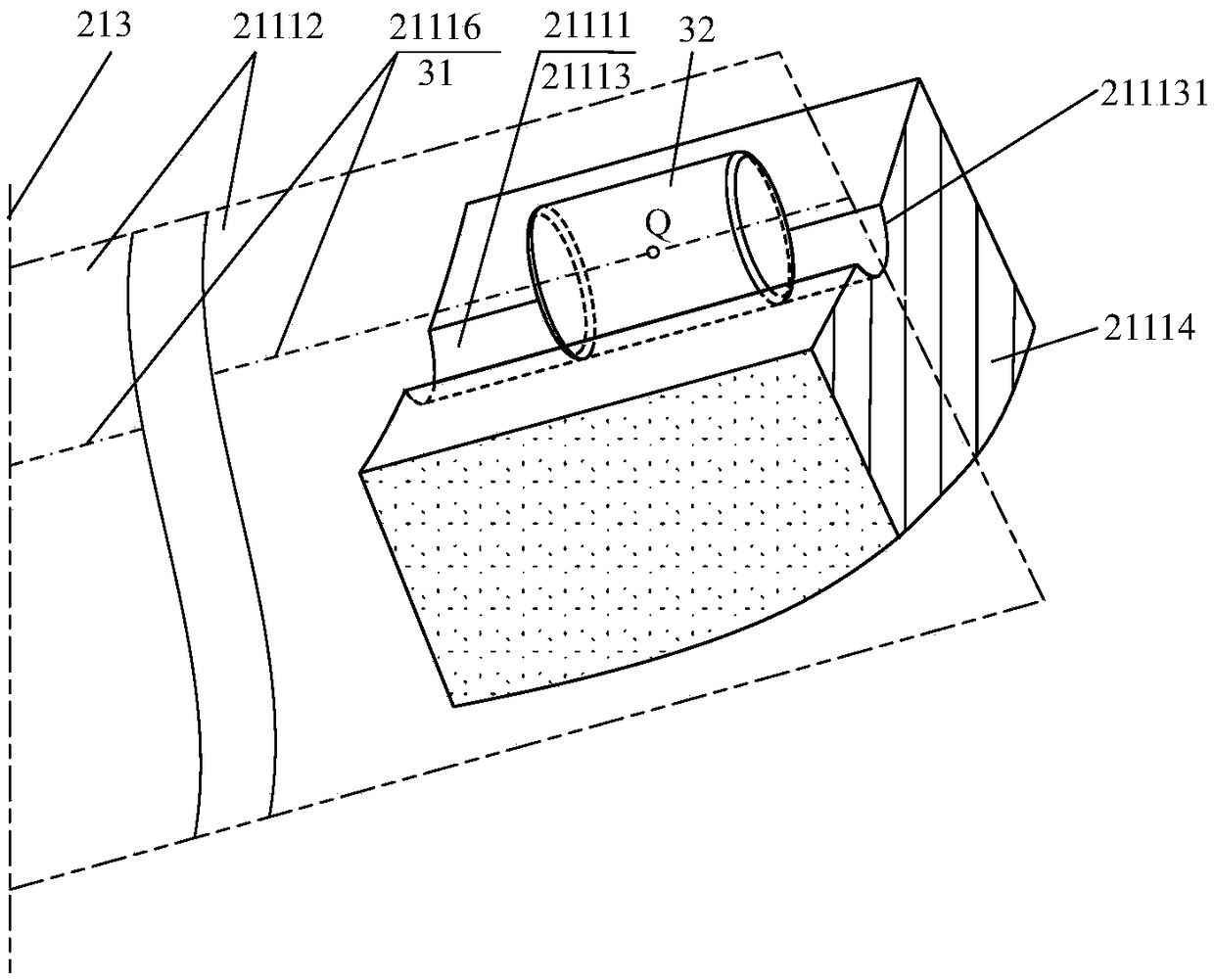

Automobile front anti-collision beam assembly welding tool

ActiveCN106736156AHigh dimensional consistencyImprove clamping stabilityWelding/cutting auxillary devicesAuxillary welding devicesEnergy absorptionEngineering

The invention discloses an automobile front anti-collision beam assembly welding tool. The automobile front anti-collision beam assembly welding tool comprises a bottom plate, anti-collision beam clamping mechanisms, anti-collision beam locating mechanisms, energy absorption box clamping mechanisms, energy absorption box location and ejection mechanisms and an operating platform, wherein the anti-collision beam clamping mechanisms, the anti-collision beam locating mechanisms, the energy absorption box clamping mechanisms and the energy absorption box location and ejection mechanisms are arranged on the bottom plate; the operating platform is arranged on the side edge of the bottom plate; the energy absorption box clamping mechanisms and the energy absorption box location and ejection mechanisms are all arranged at two ends of the bottom plate; the anti-collision beam clamping mechanisms and the anti-collision beam locating mechanisms are arranged on the bottom plate which is located between the energy absorption box clamping mechanisms and the energy absorption box location and ejection mechanisms; the anti-collision beam clamping mechanisms, the energy absorption box clamping mechanisms and the energy absorption box location and ejection mechanisms are all connected with the operating platform. The automobile front anti-collision beam assembly welding tool disclosed by the invention has the advantages that a workpiece can be quickly fixed, the stability is good, the workpiece can be conveniently and quickly taken, the welding efficiency of a robot is adapted, the welding quality is increased, and a rejection rate of products is reduced.

Owner:柳州凌云汽车零部件有限公司

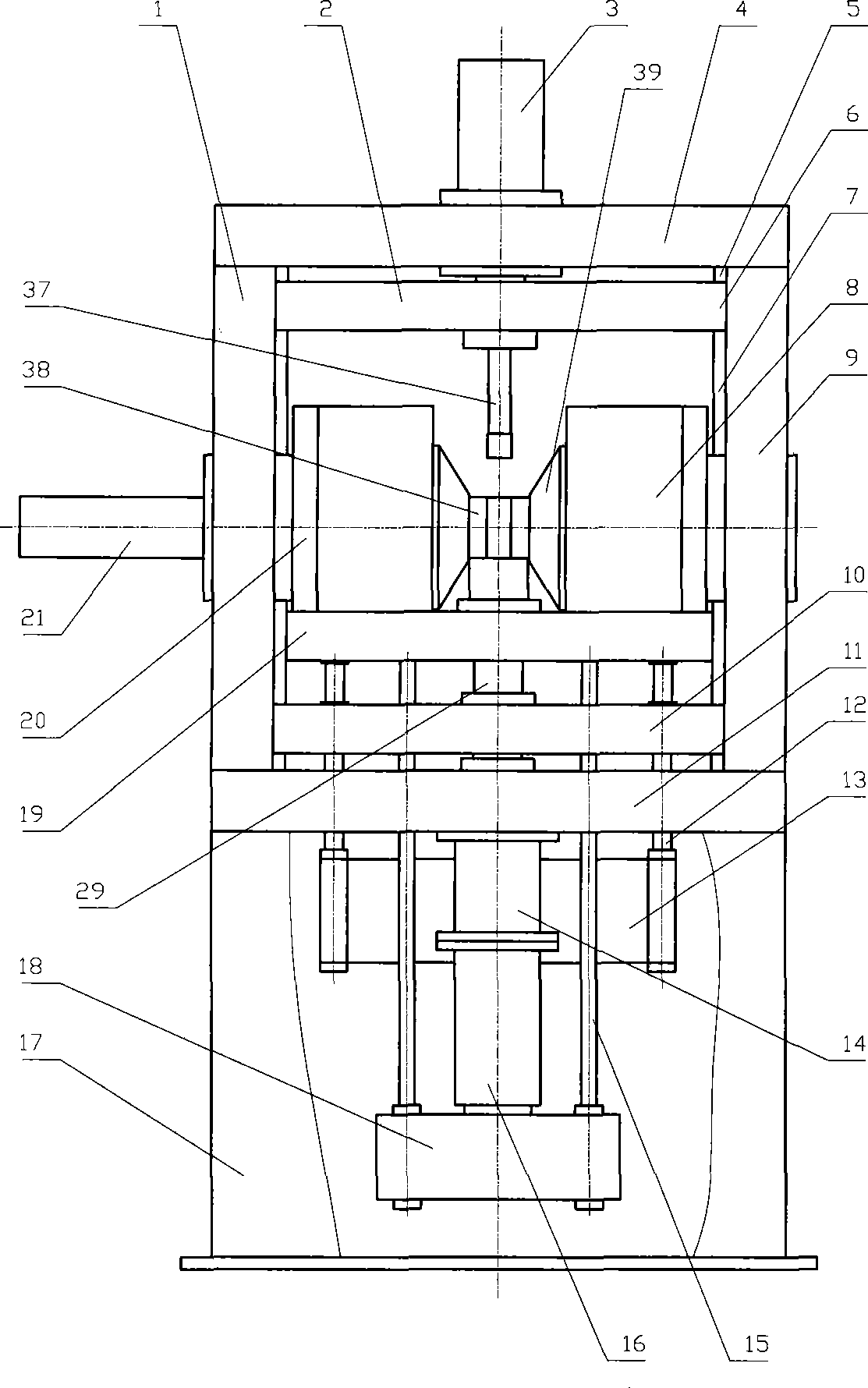

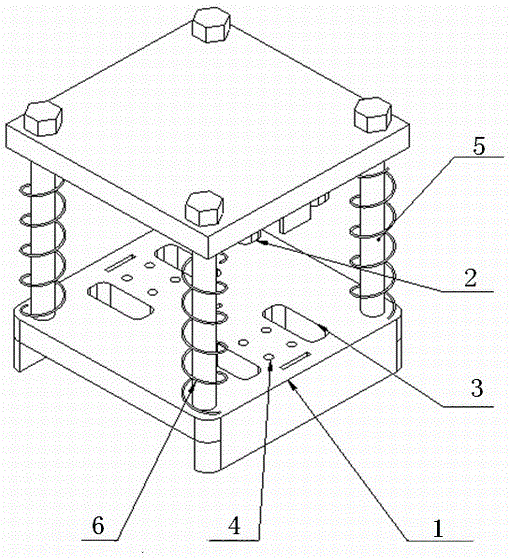

Positional control bidirectional pressed moulding press

The invention discloses a position control two-direction pressing moulding press, comprising a stander formed by the connection of a stander side plate, an upper beam and a lower beam; an upper cylinder fixed on the upper beam; a lower cylinder fixed on the lower beam; an upper die mounting plate installed on an upper die; a lower die mounting plate installed on a lower die; an upper cylinder displacement sensor fixed on the stander; and a lower cylinder displacement sensor fixed on the stander, wherein, the upper cylinder displacement sensor and / or the lower cylinder displacement sensor detect / detects the displacement of the upper cylinder and / or the lower cylinder, generating a displacement signal related to the displacement, and the displacement is processed by a displacement controller and then controls the oil supply state of an oil line of the upper cylinder / or the lower cylinder through a servo proportional valve. The moulding press can precisely press the production height according to production requirements, is characterized by convenient adjustment of the pressed product height and simple arrangement and can markedly improve the quality and dimensional uniformity of pressed products.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

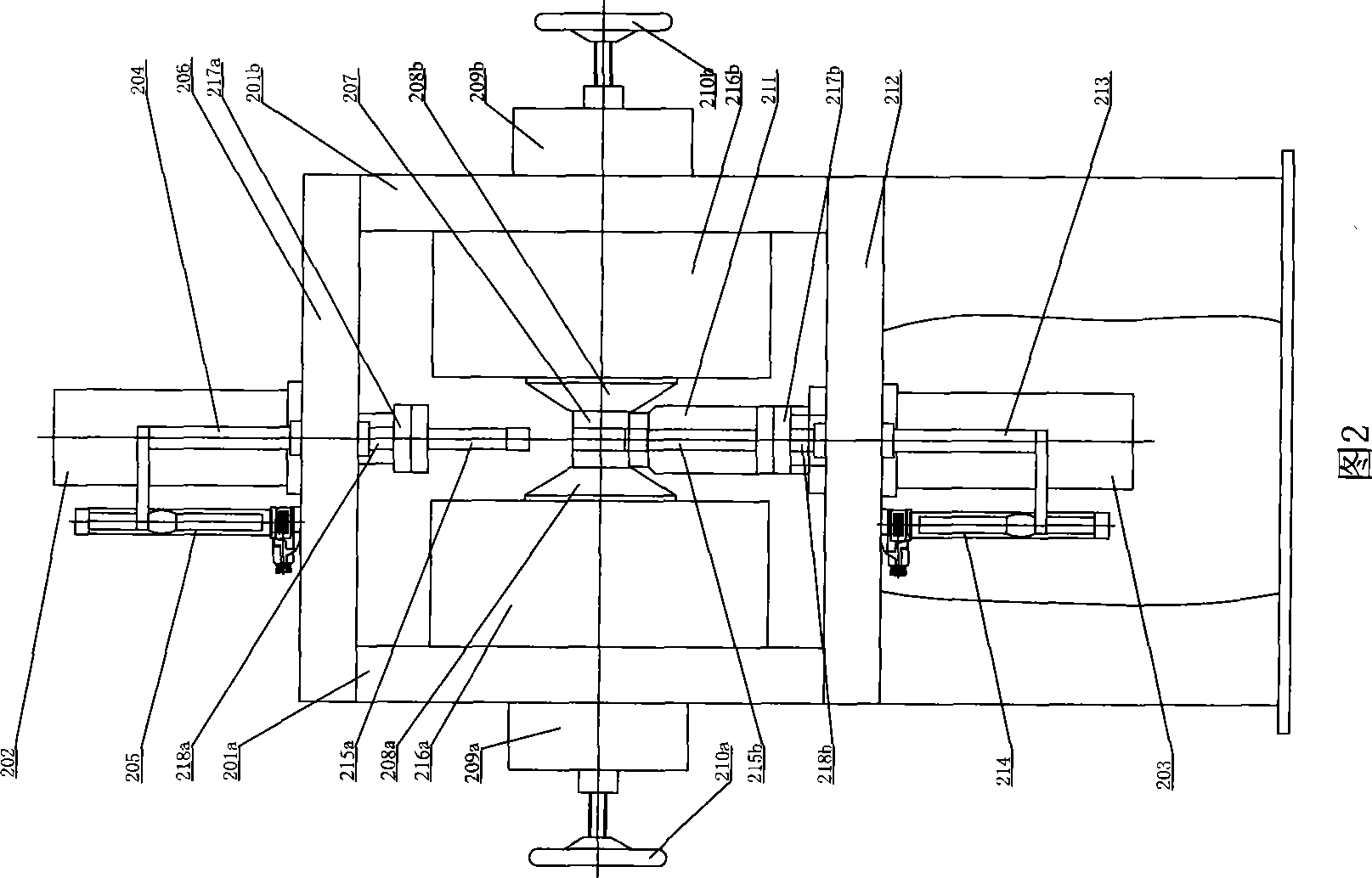

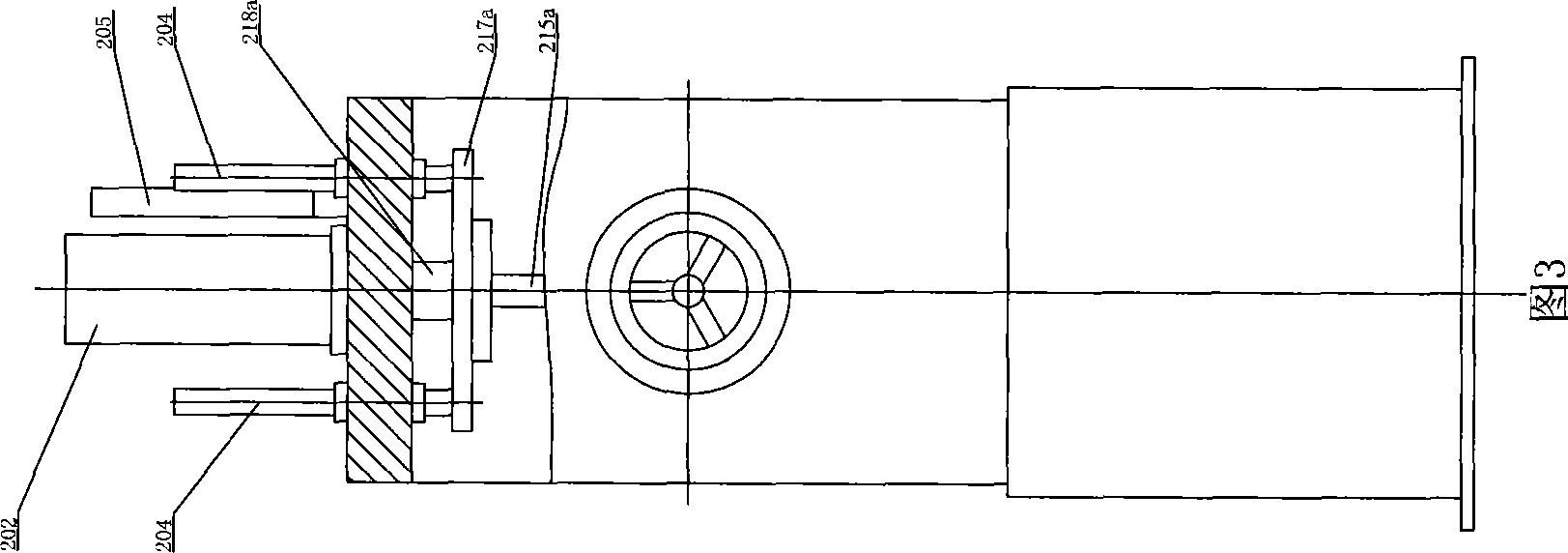

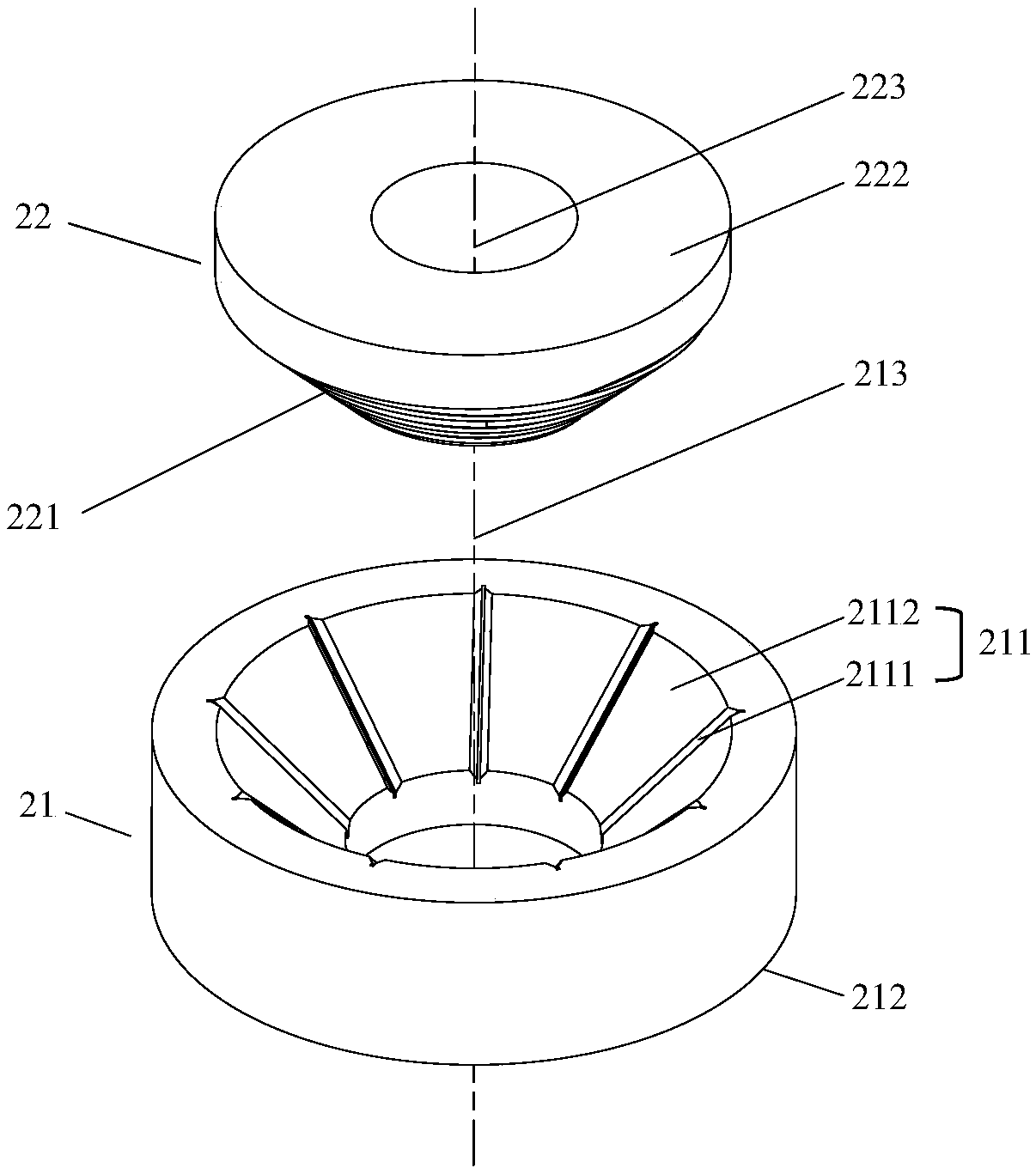

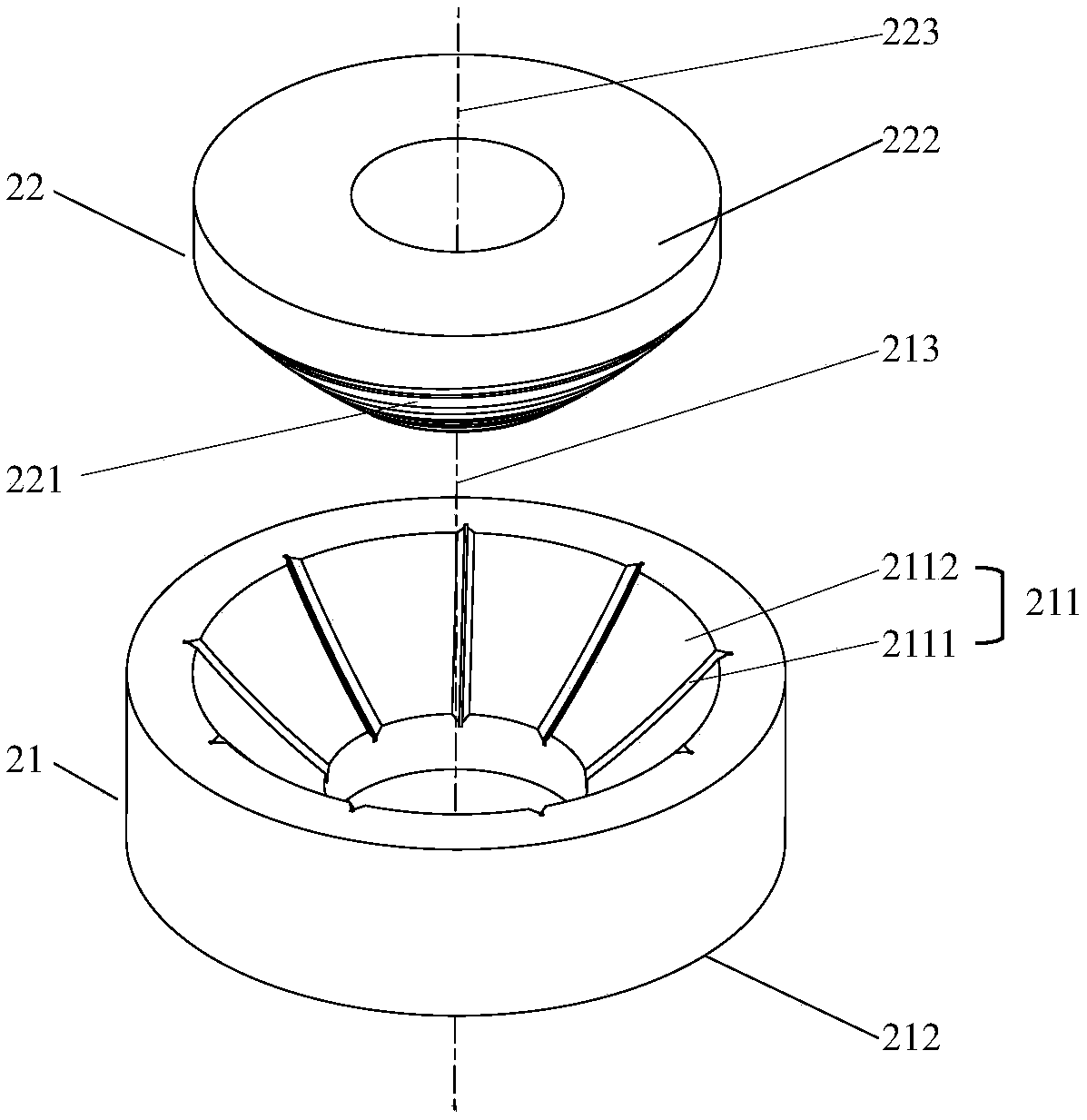

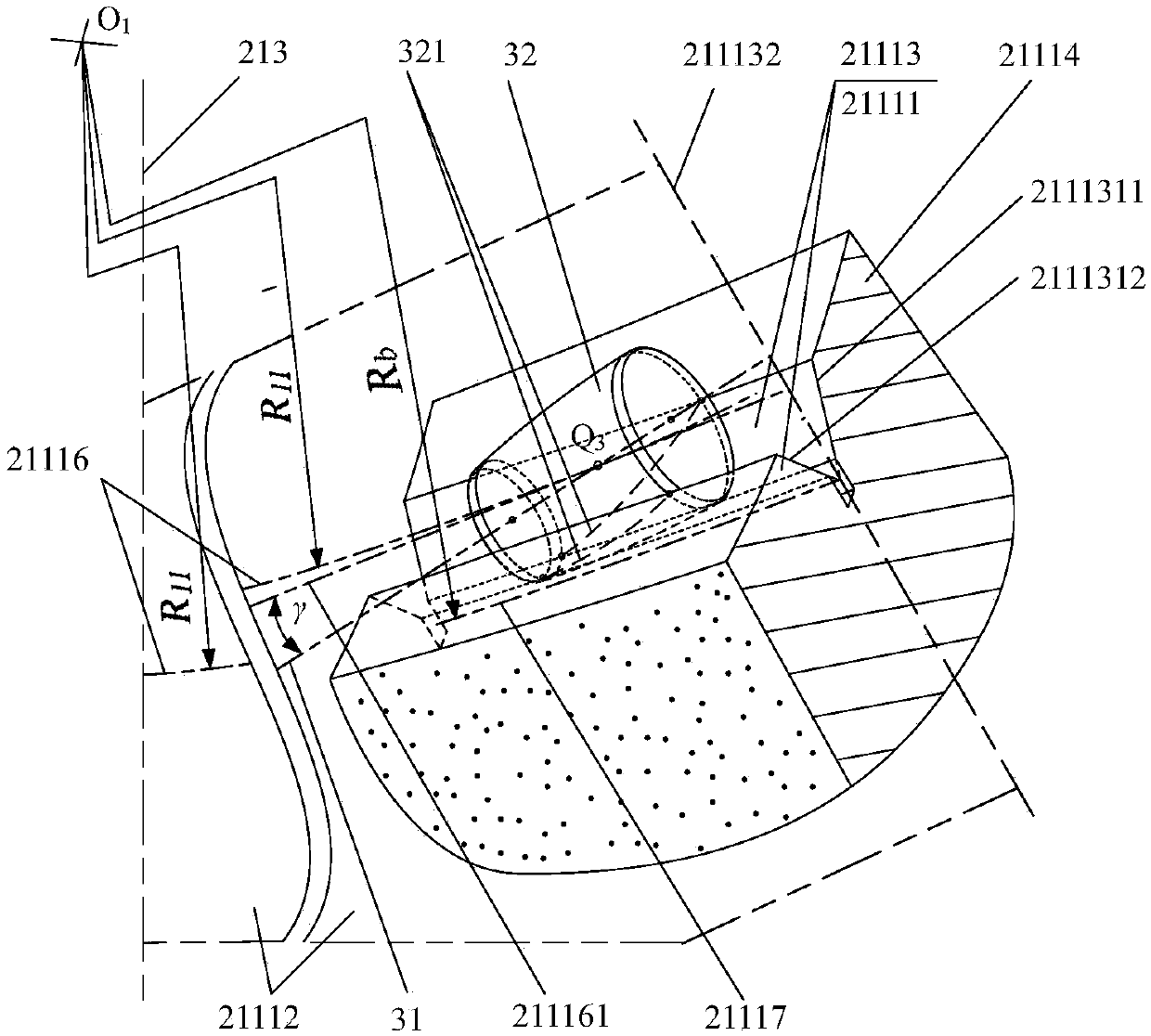

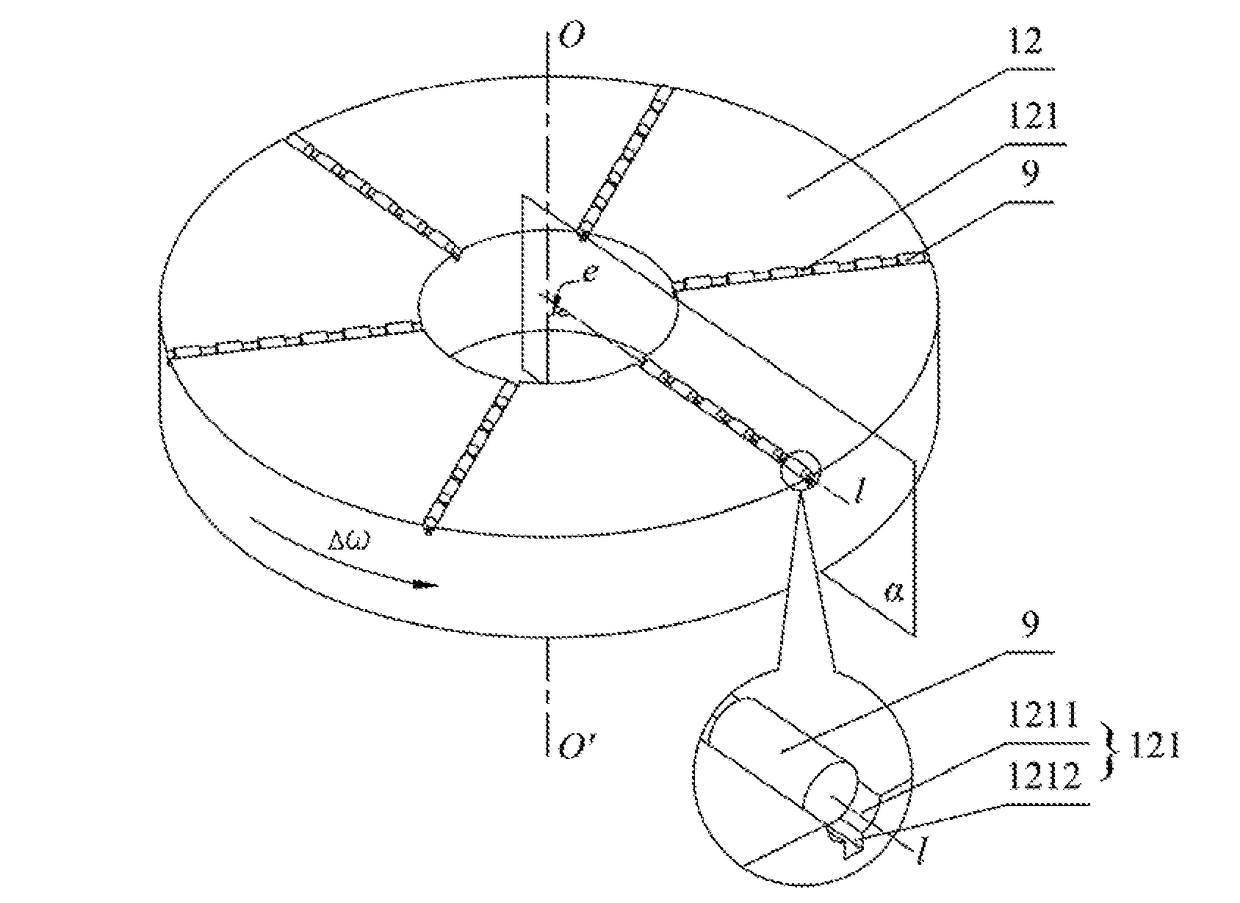

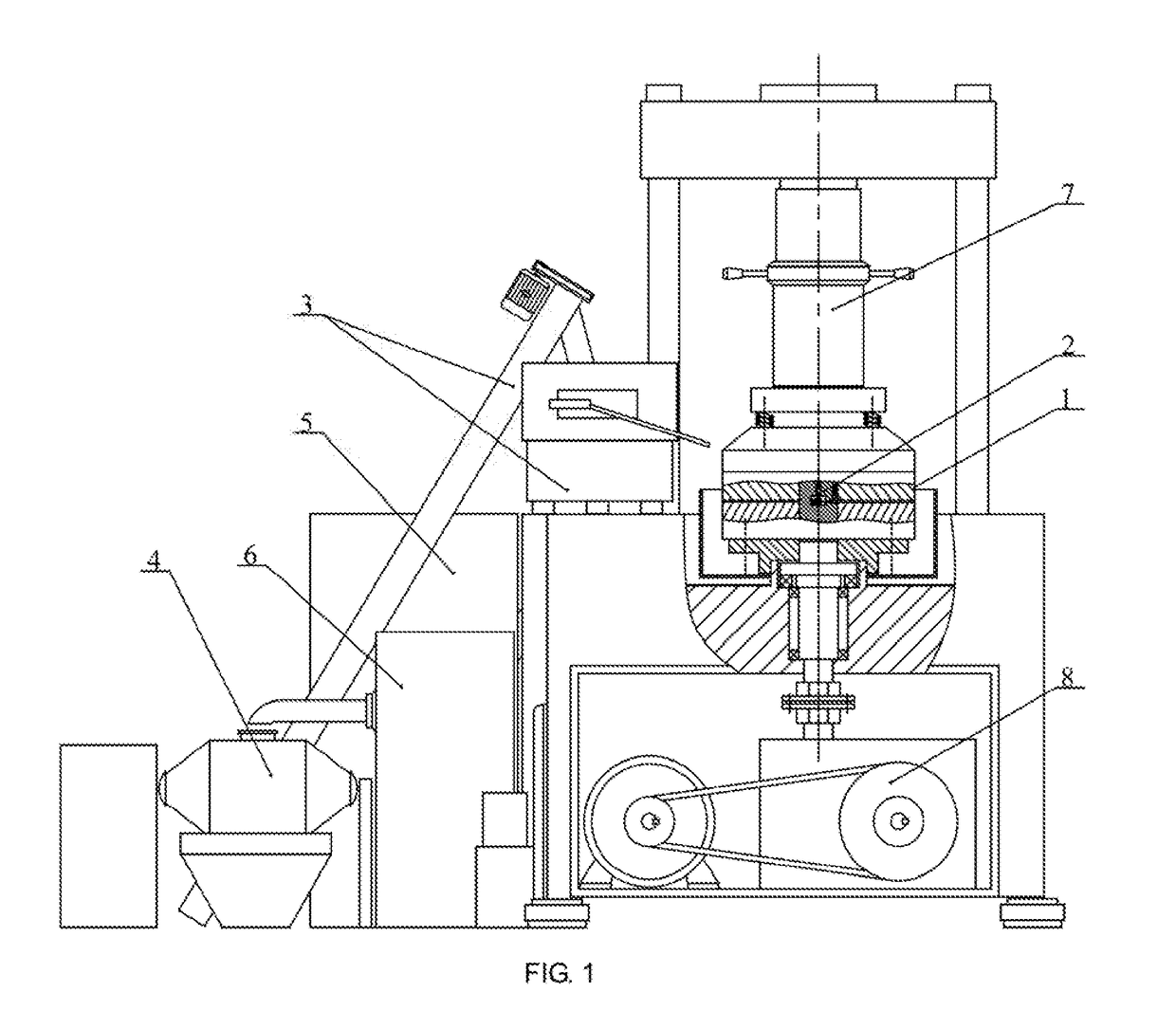

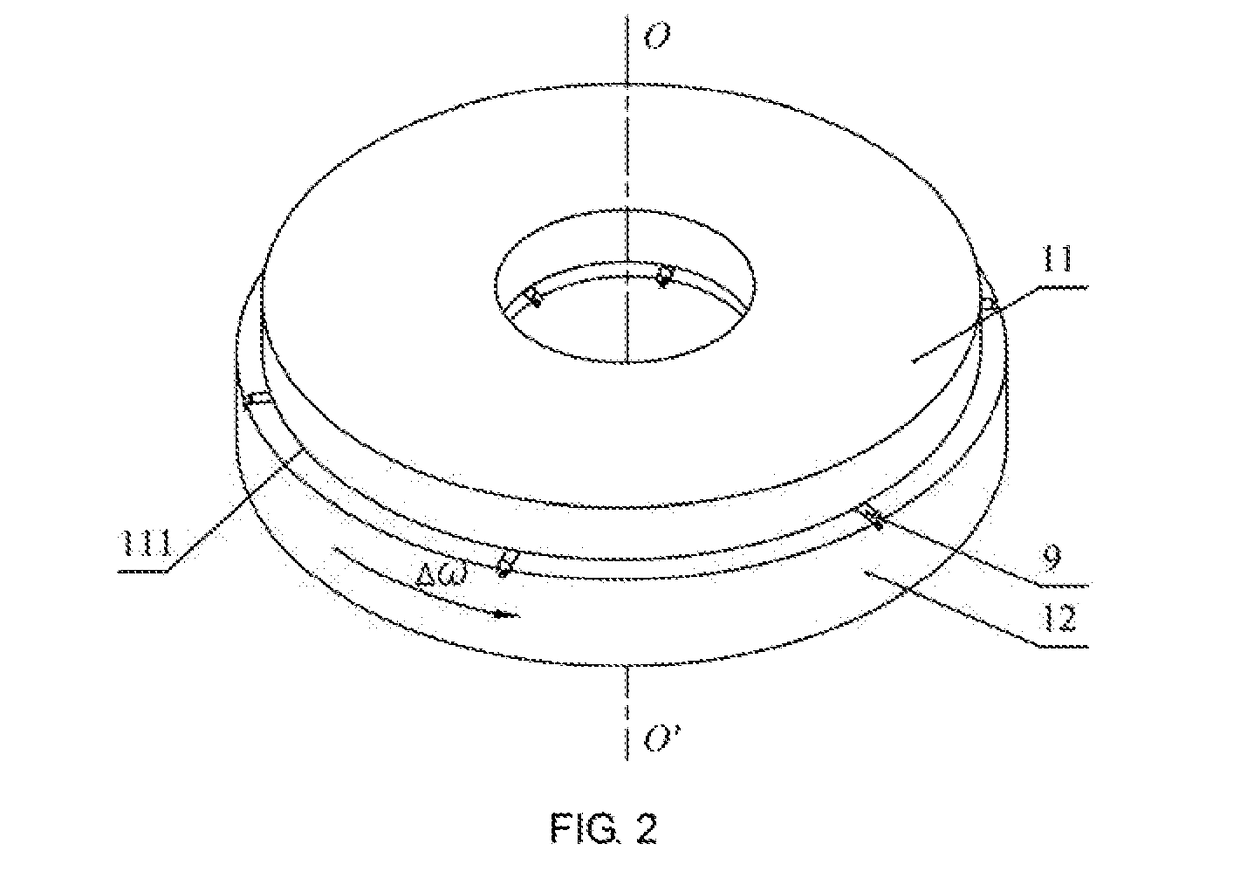

Grinding disc used for precise processing of rolling surface of tapered roller and equipment method

PendingCN108723979AReduce removalRemove comprehensivelyLapping machinesLapping toolsCircular discEngineering

The invention discloses grinding equipment used for precise processing of the rolling surface of a tapered roller and a grinding disc sleeving piece. The grinding equipment comprises main equipment, the grinding disc sleeving piece and a roller circular disc external system, the main equipment comprises a base, an upright column, a beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device, and the roller circular disc external system comprises a roller collecting device, a roller transporting system, a roller arrangement system and a roller feed-in mechanism; the grinding disc sleeving piece comprises a pair of coaxially arranged first and second grinding discs of which the front surfaces are opposite to each other, the front surface of the first grinding disc comprises a set of linear grooves distributed on the base surface (right circular conical surface) of the first grinding disc in a radial form, the front surface of the second grinding disc comprises one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding disc, and the sum of the cone apex angles of the base surfaces of the first and second grinding discs is 360 degrees. The grinding equipment has the precise processing capacity to process the rolling surfaces of mass tapered rollers.

Owner:TIANJIN UNIV

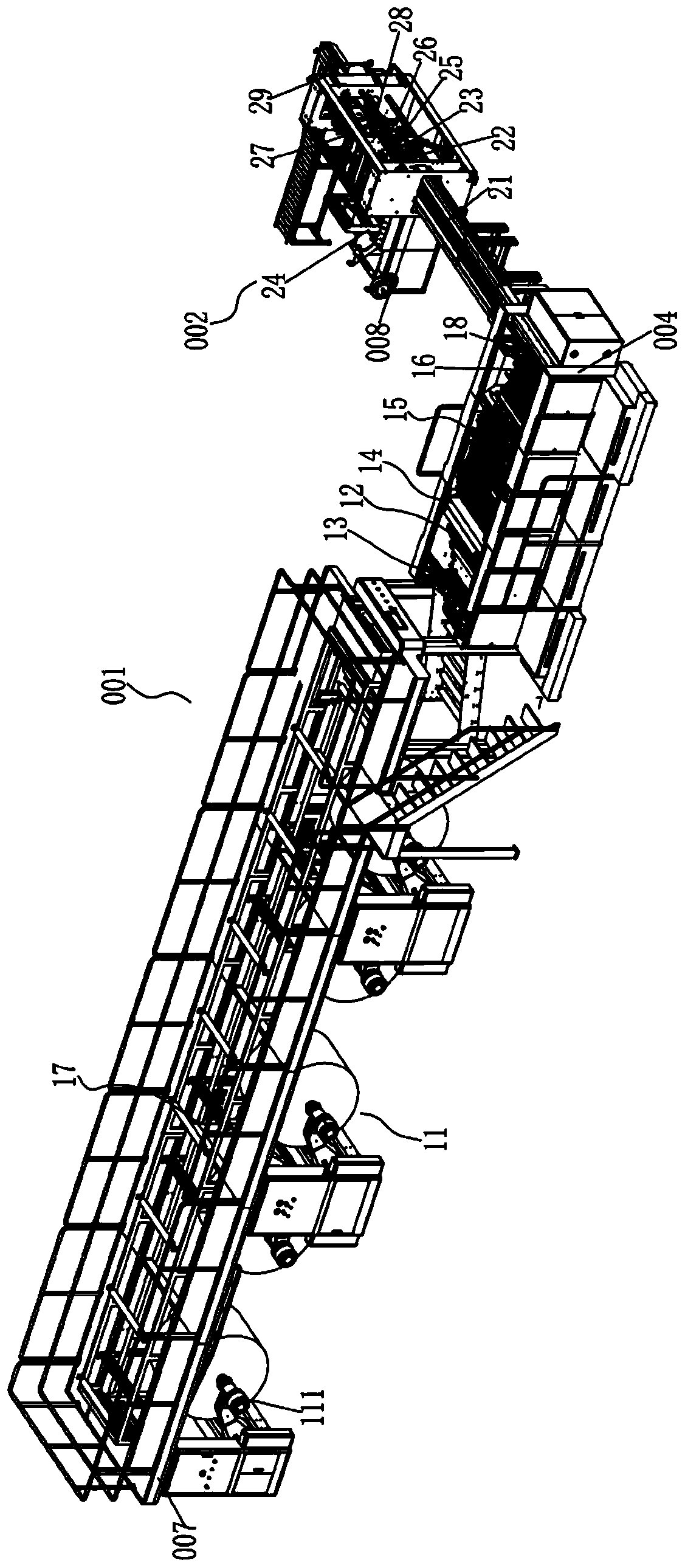

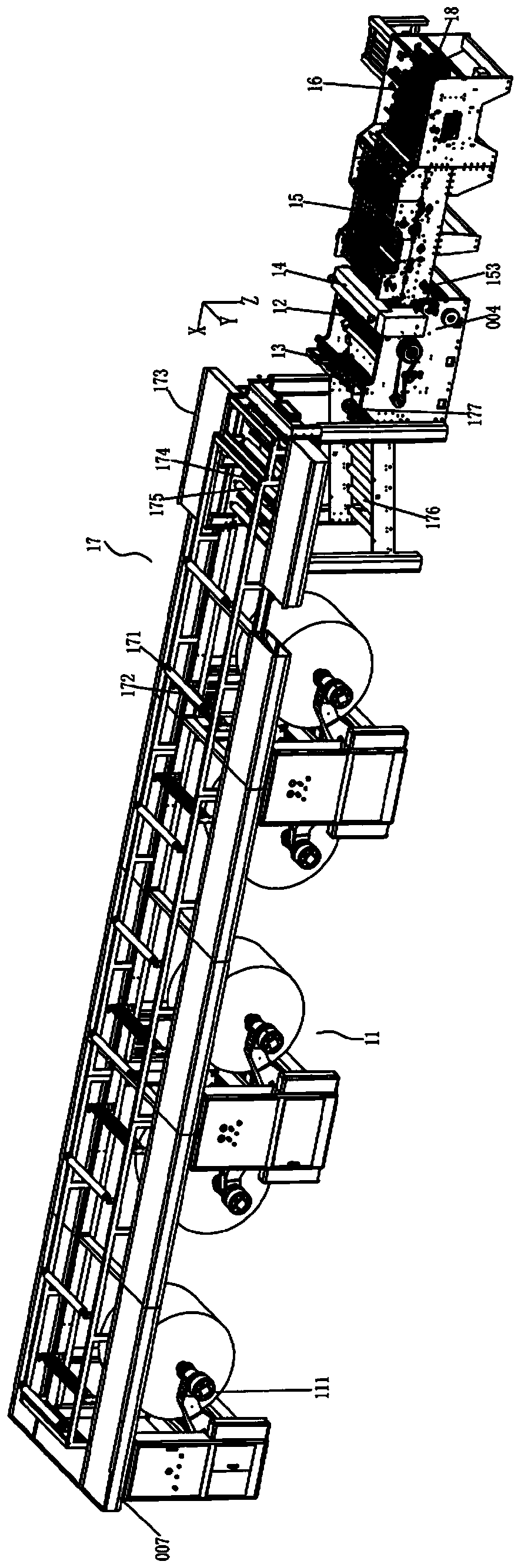

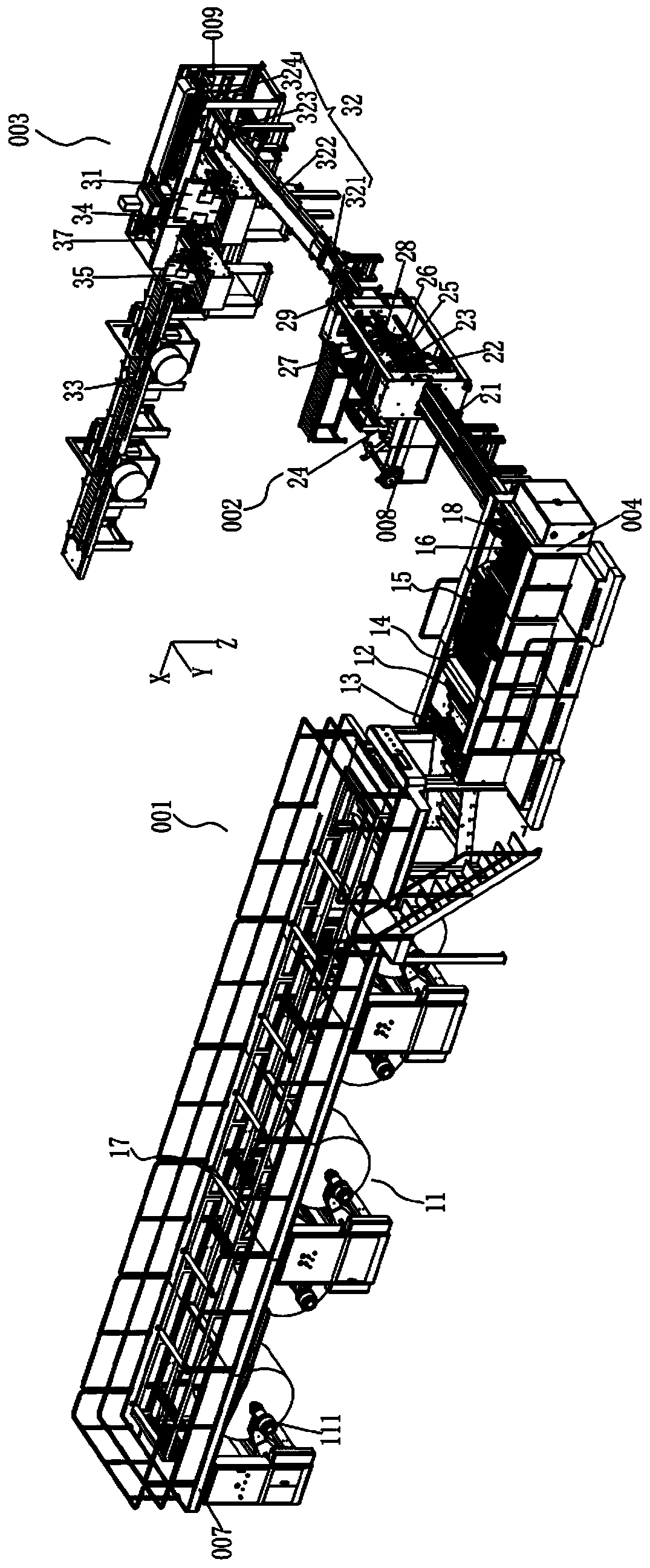

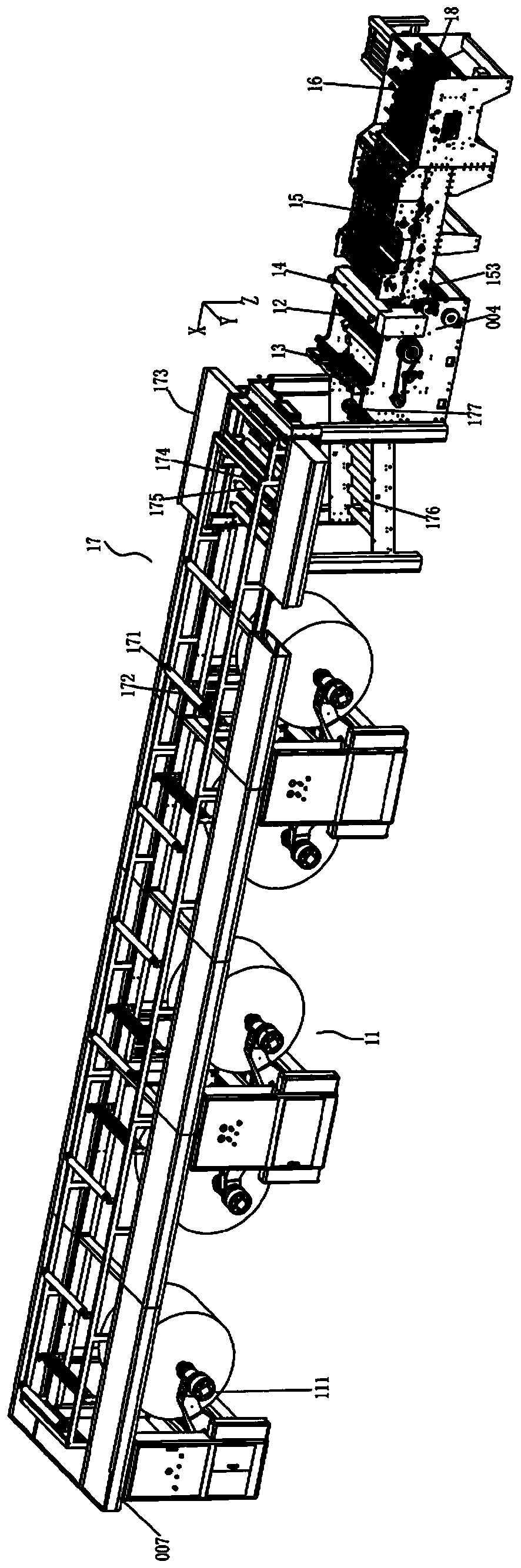

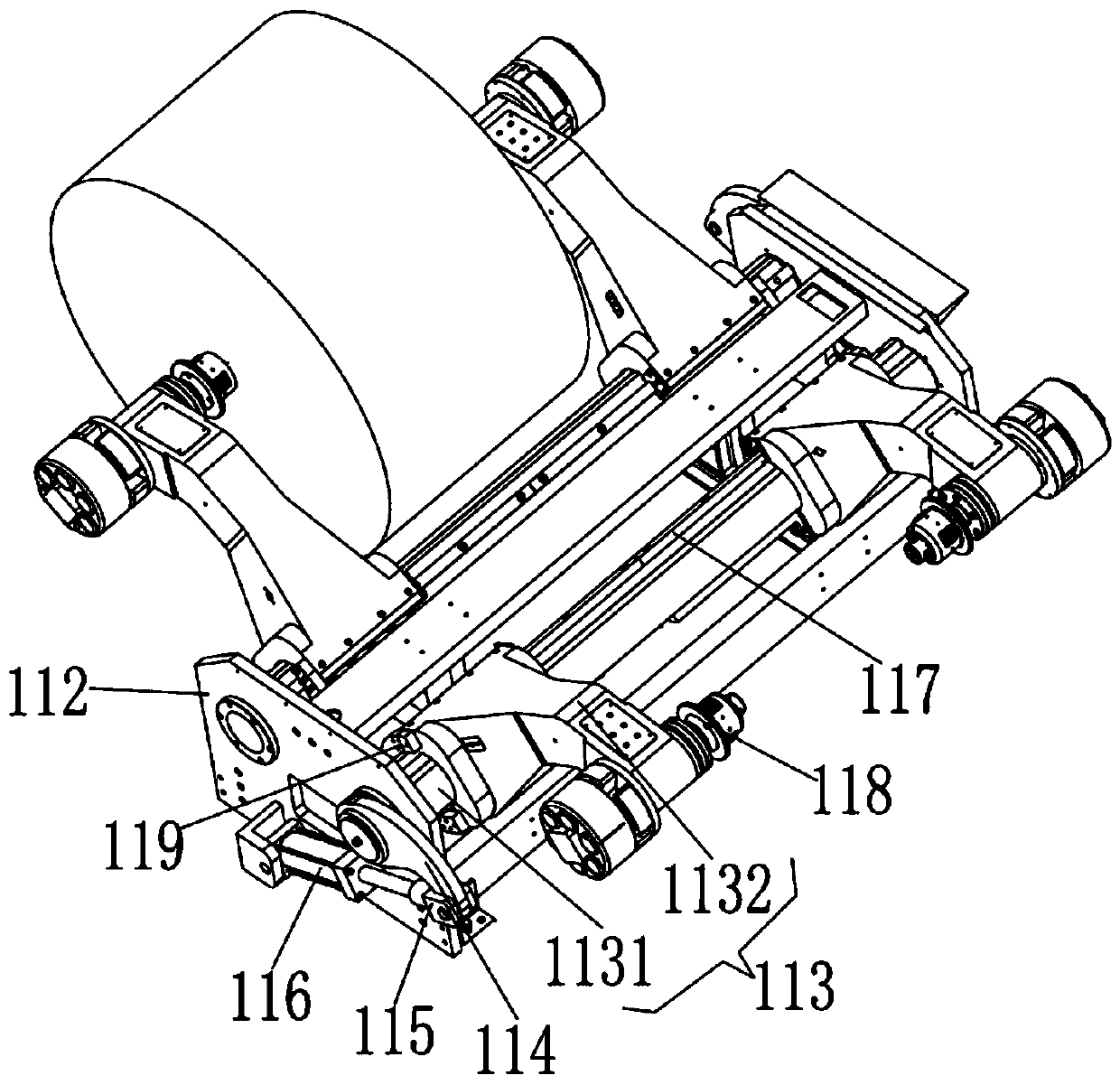

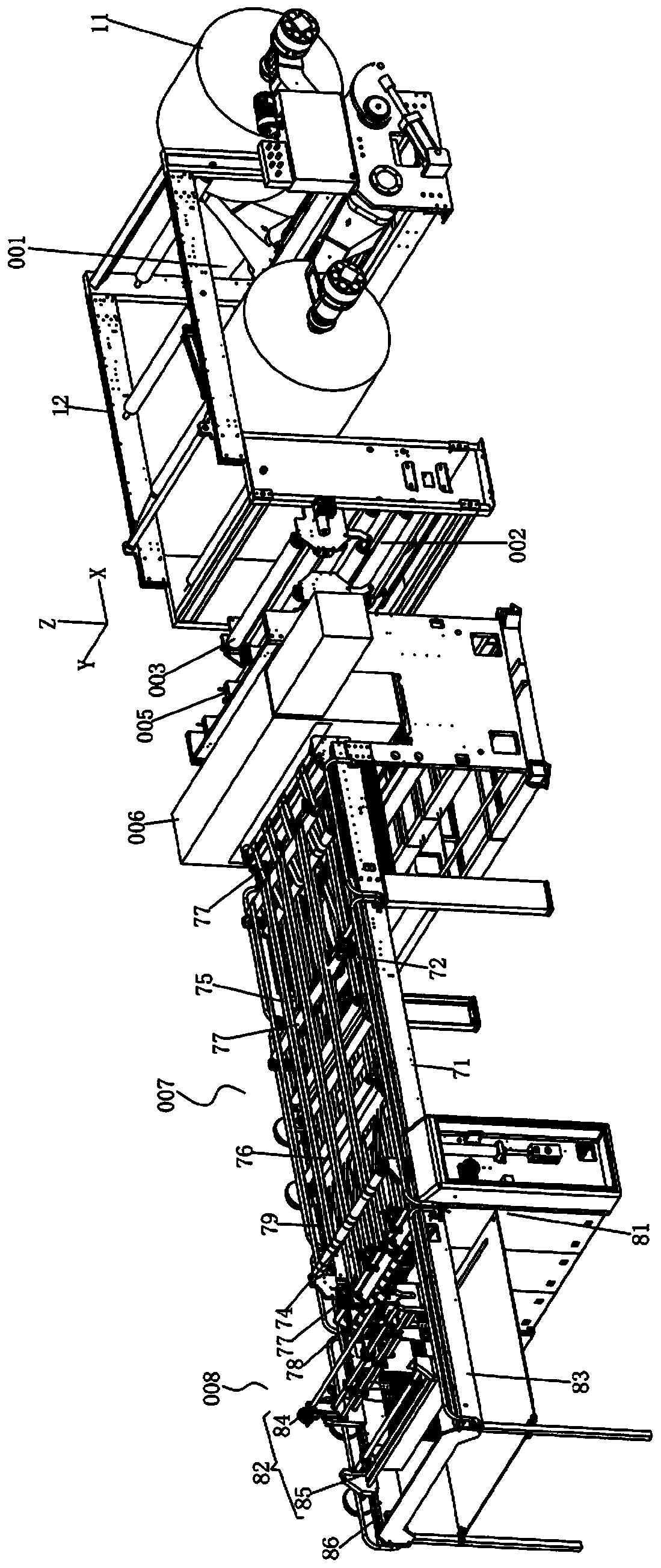

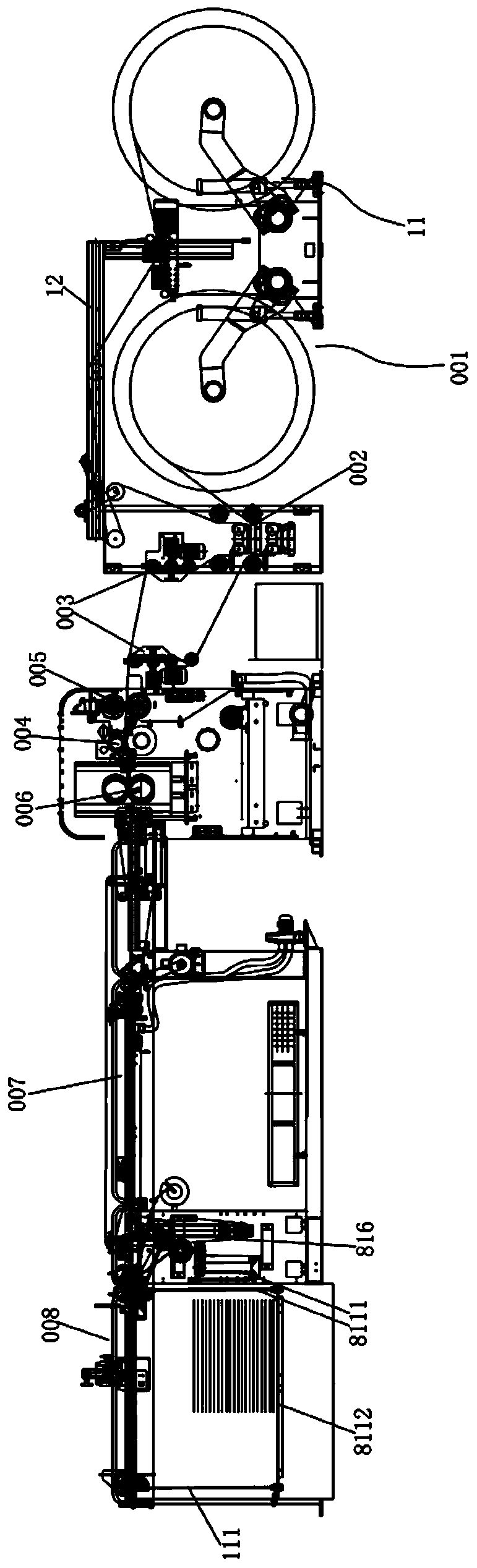

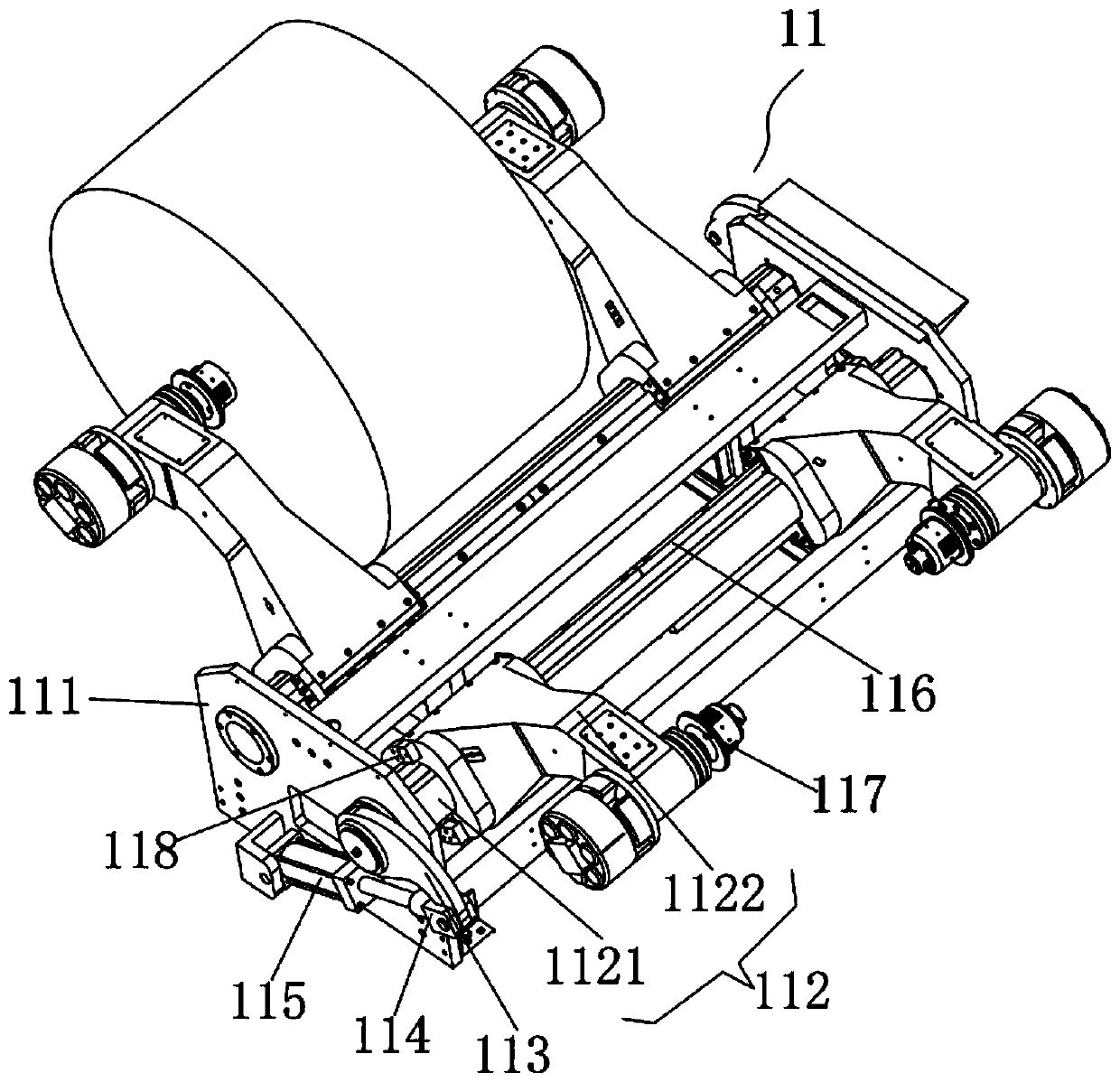

A4 paper double-convolution-knife paper cutting bulk paper production line

PendingCN110271894AReasonable structure layoutSmall footprintWrapper folding/bending apparatusWrapper twisting/gatheringProduction lineRolling paper

The invention discloses an A4 paper double-convolution-knife paper cutting bulk paper production line. The production line comprises a double-convolution-knife paper cutting mechanism for cutting roll paper into A4 paper, and a bulk paper packaging machine, wherein the bulk paper packaging machine is in butt joint with the double-convolution-knife paper cutting mechanism, and is used for packaging stacked A4 paper into bulk. The double-convolution-knife paper cutting mechanism comprises a paper supply assembly, a traction assembly, a cutting assembly, a transverse cutting assembly, a paper feeding assembly and a paper collection assembly. The bulk paper packaging machine comprises a bulk paper conveyer belt, a bulk paper conveying mechanism, a packaging paper feeding mechanism, a material ejection assembly, a transverse packaging assembly, a longitudinal angle folding assembly, a longitudinal edge sealing assembly and a bulk paper shifting assembly. The A4 paper double-convolution-knife paper cutting bulk paper production line integrates paper cutting and bulk paper packaging into a whole, and is high in processing efficiency.

Owner:DONGGUAN JUNXING MACHINERY TECH

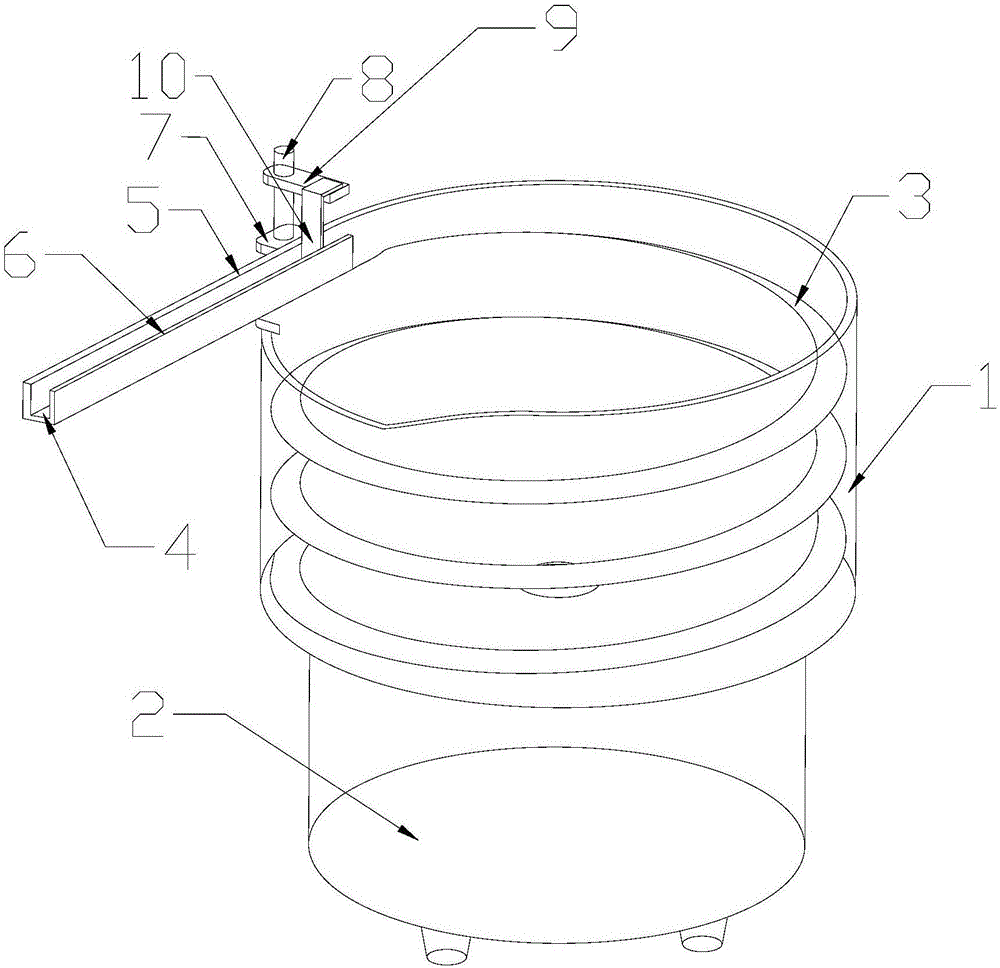

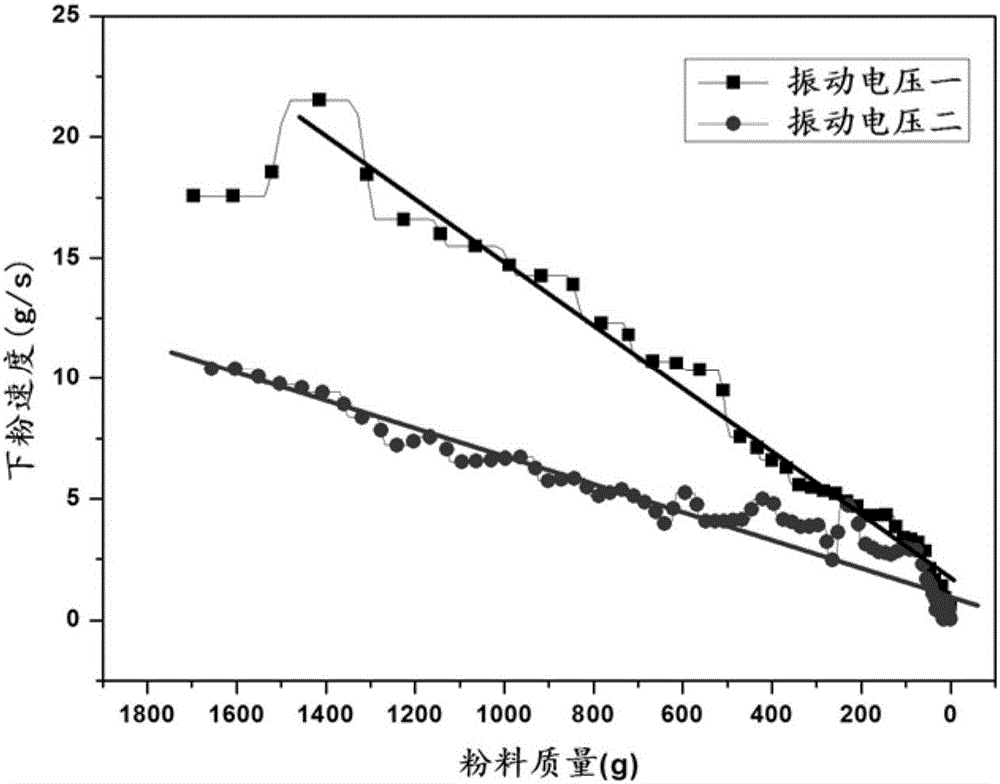

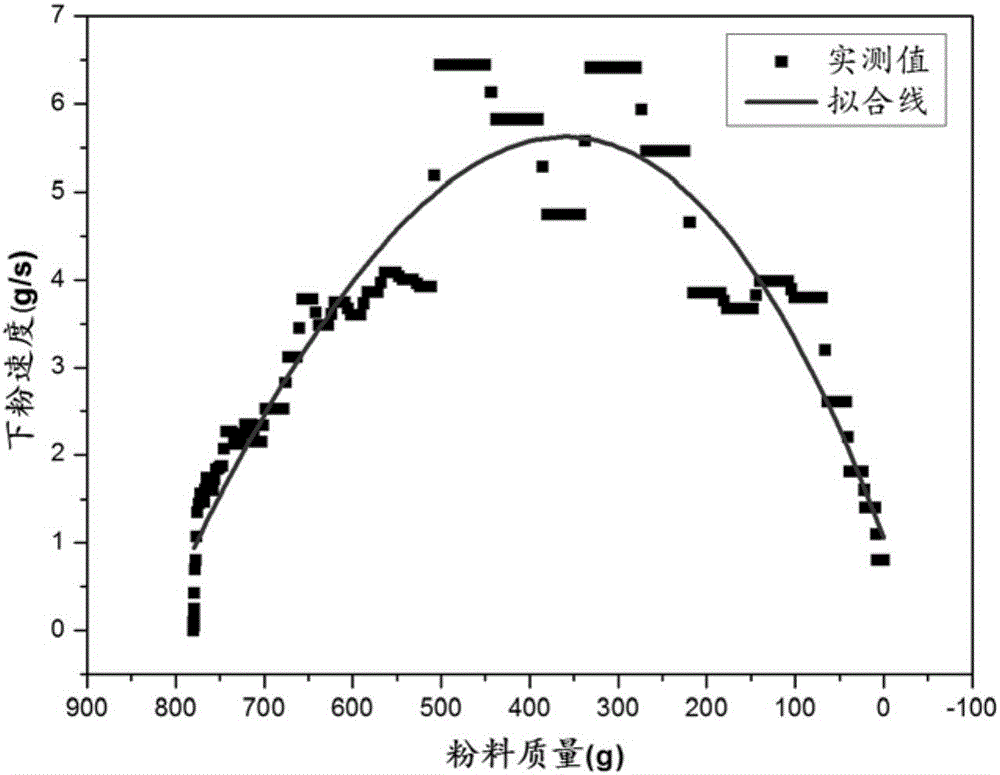

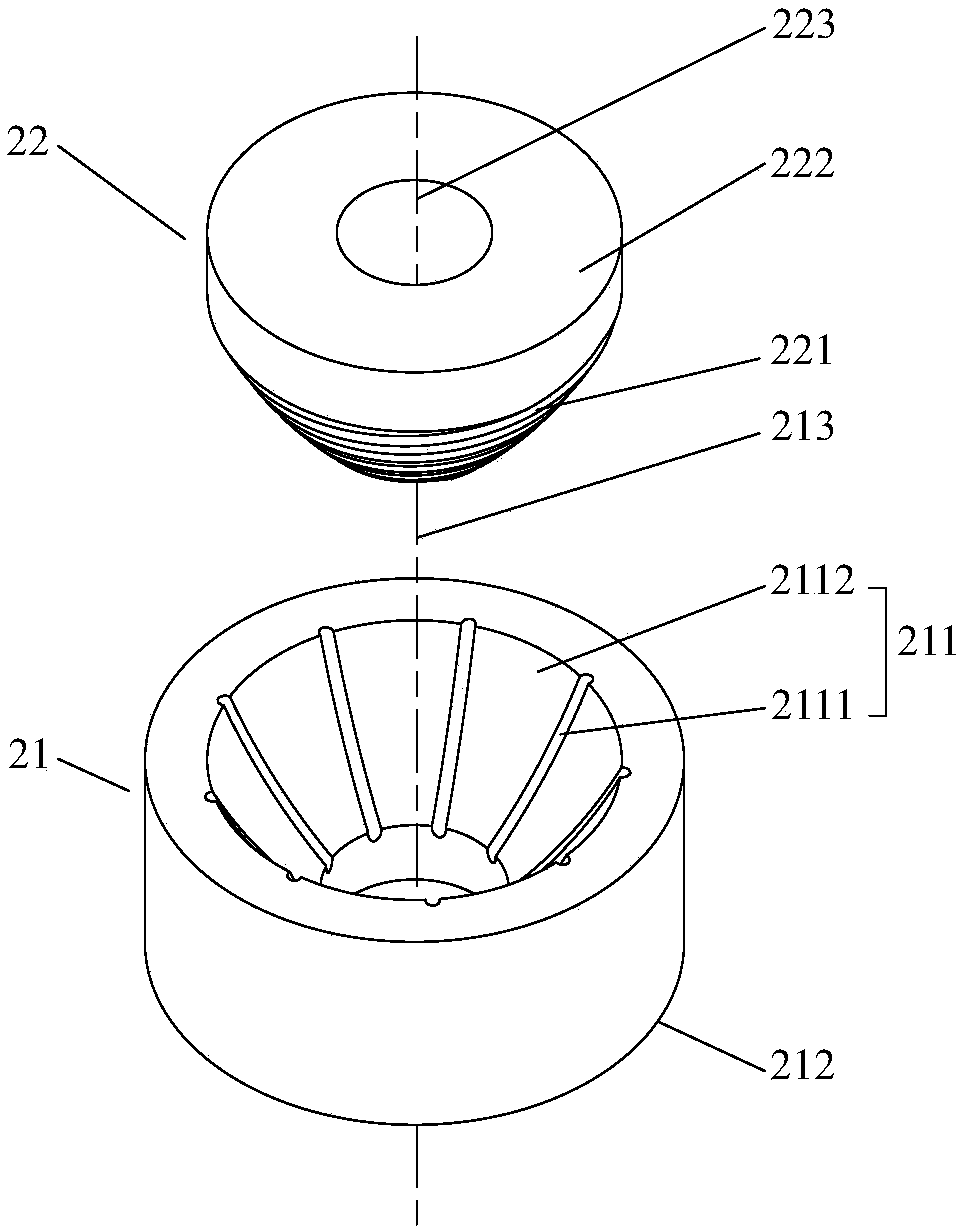

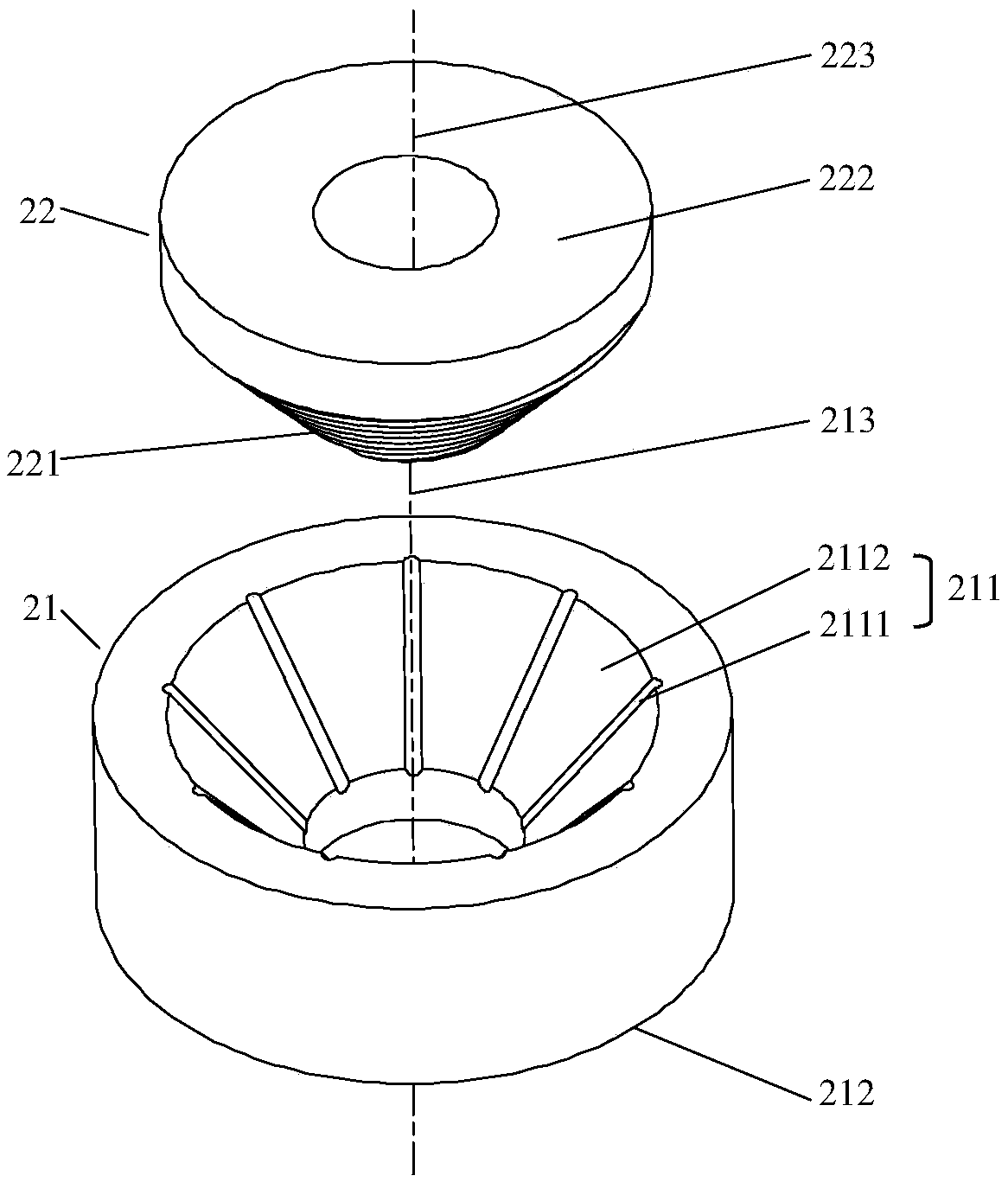

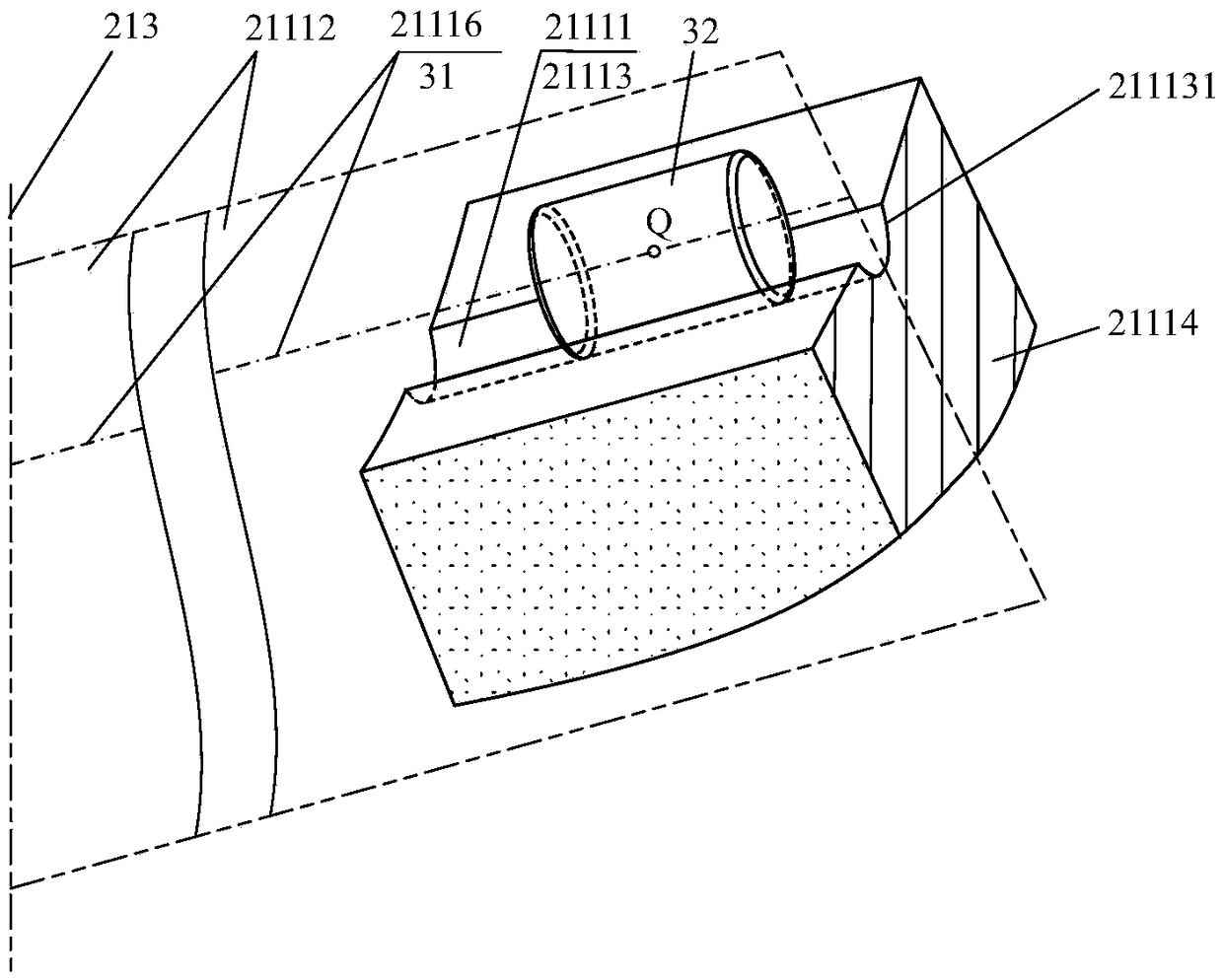

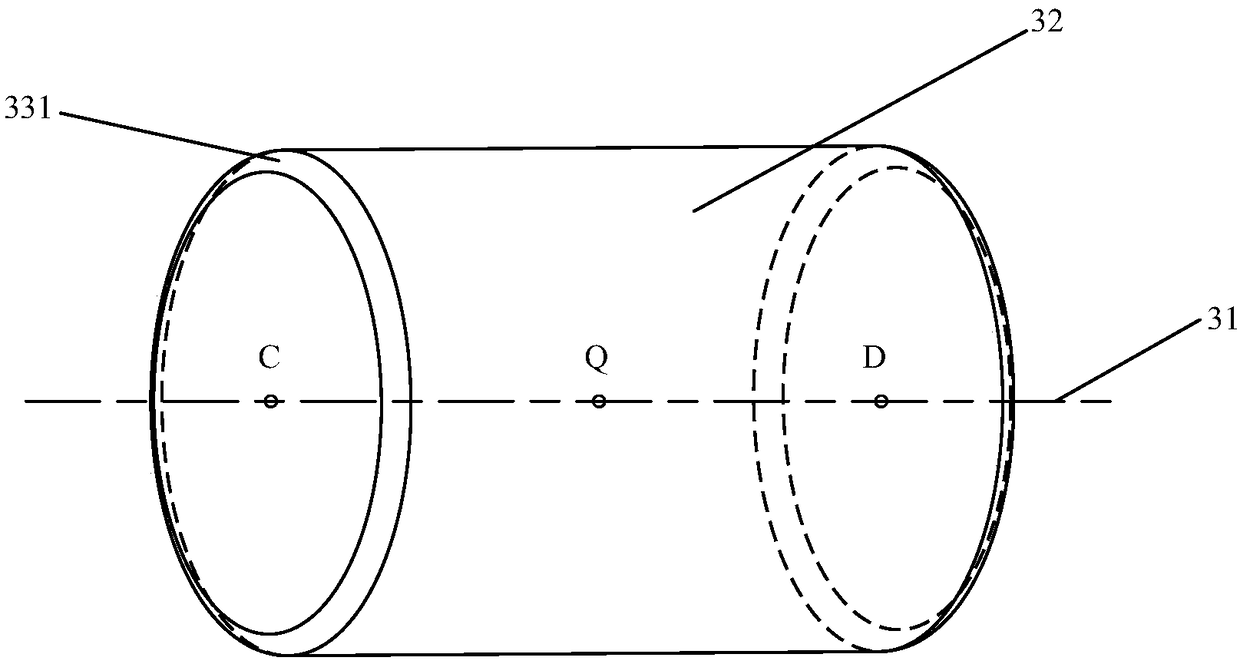

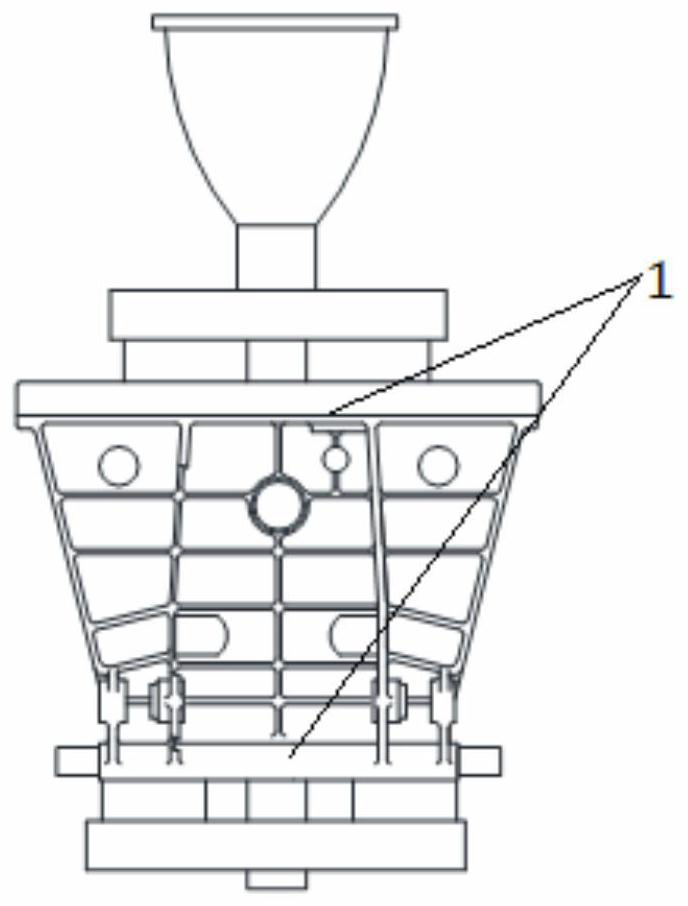

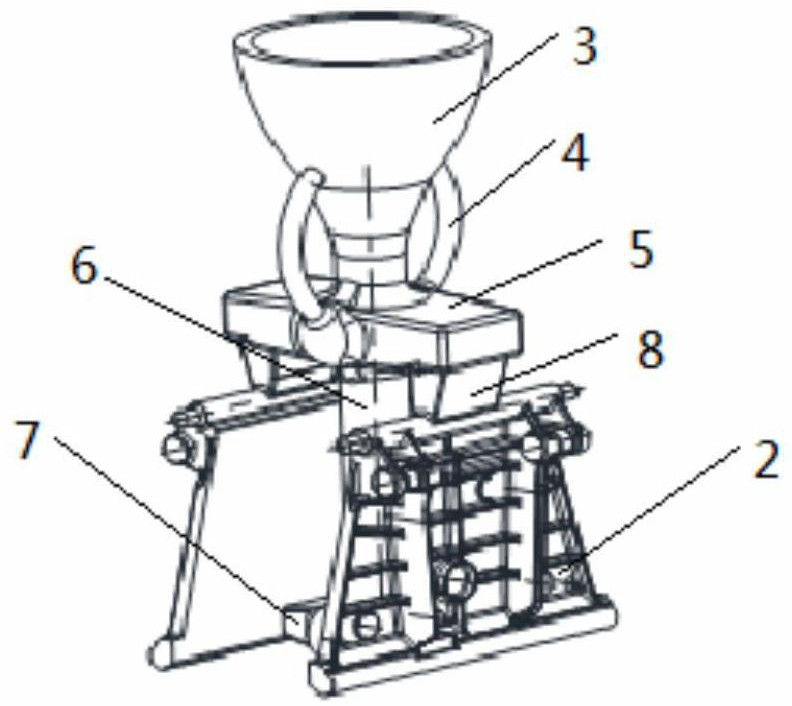

Neodymium iron boron powder vibrating feeding device and automatic feeding system

ActiveCN106743183AReduce the single weight deviation of green bodyGuaranteed uniformityJigging conveyorsConveyor partsVibration amplitudeVoltage regulation

The invention discloses a neodymium iron boron powder vibrating feeding device and an automatic feeding system. The neodymium iron boron powder vibrating feeding device comprises a vibrating disc, a vibrating base, an electric controller, a discharge rail and a height limiting mechanism, wherein the vibrating disc is fixedly arranged on the vibrating base; the electric controller is connected with the vibrating base; the electric controller outputs voltage to control and regulate vibration amplitude of the vibrating base; a feeding rail which spirally ascends is arranged on the inner wall of the vibrating disc; an outlet of the feeding rail is connected with an inlet of the discharge rail; and the height limiting mechanism is arranged above the inlet of the discharge rail. The neodymium iron boron powder vibrating feeding device has the advantages of reducing powder agglomeration and caking, being more sensitive in voltage regulation, and guaranteeing uniformity of neodymium iron boron powder conveying; and the automatic feeding system is constructed based on the neodymium iron boron powder vibrating feeding device, and voltage is regulated to precisely control vibration amplitude and powder unloading speed of the vibrating disc according to real-time judgment of powder unloading weight and weighing time of a weighing system, so that overhead retention volume is improved, automatic, quick and precise feeding is realized, and piece weight and dimension consistency of a neodymium iron boron green body are improved.

Owner:NINGBO YUNSHENG +2

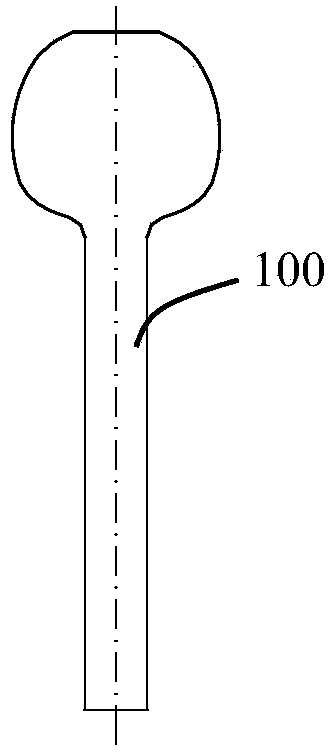

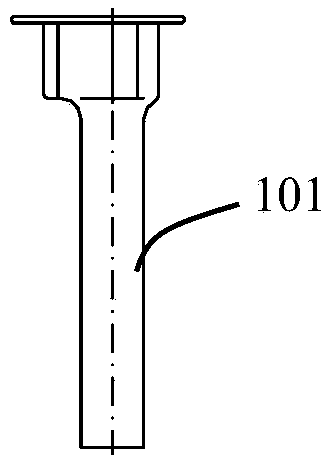

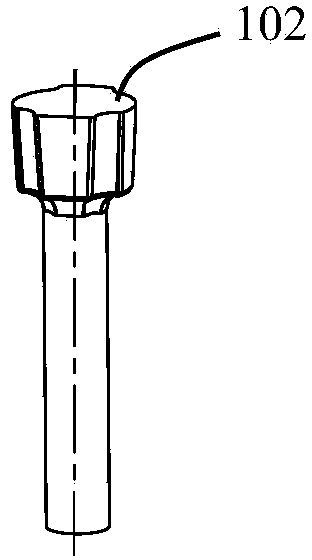

Forming technology for nose body of rifle

The invention discloses a forming technology for a nose body of a rifle. The technology comprises the following processing steps: (a) blanking, wherein round bar materials are selected; (b) heating, wherein the round bar materials are heated to 1150-1250 DEG C; (c) heading, wherein head gathering material heading of the heated round bar materials is performed on an electrothermal upsetting machine to form blanks; (d) extrusion forming, wherein the blanks are put into a forming mold for extrusion forming so as to form forgings; (e) edge cutting, wherein the forgings are put into an edge cutting mold to perform the edge cutting so as to obtain the forgings of the nose body. Through the adoption of the forming technology for the nose body of the rifle, disclosed by the invention, the surface quality and the size consistency of the forgings are improved, the surplus quantity of the forgings is small, the unilateral surplus quantity is decreased within 1mm from 2mm, the utilization rate of materials is increased to 96% from 82% and is substantially increased, and the processing noise of the nose body is effectively reduced.

Owner:CHONGQING JIANSHE IND GRP

Magnetic grinding disc, equipment and method for tapered roller rolling surface finishing

PendingCN108723982AReduce removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceSurface finish

The invention discloses grinding equipment and a magnetic grinding disc kit for tapered roller rolling surface finishing of ferromagnetic materials. The grinding equipment comprises a main body, the magnetic grinding disc kit and a roller circulation disc outer system. The main body includes a base, a column, a beam, a slide table, an upper tray, a lower tray, an axial loading device and a spindledevice. The roller circulation disc outer system includes a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The magnetic grinding disc kit includes a pair of coaxial first and second grinding discs of which the front surfaces are disposed opposite to each other. The front surface of the first grindingdisc includes a set of linear grooves radially distributed on a base surface (positive conical surface) of the first grinding disc, the front surface of the second grinding disc includes one or morespiral grooves distributed in the base surface (positive conical surface) of the second grinding disc, and a ring-shaped magnetic structure is embedded inside a base body. The grinding equipment has the finishing ability of multitudinous ferromagnetic material tapered roller rolling surfaces.

Owner:TIANJIN UNIV

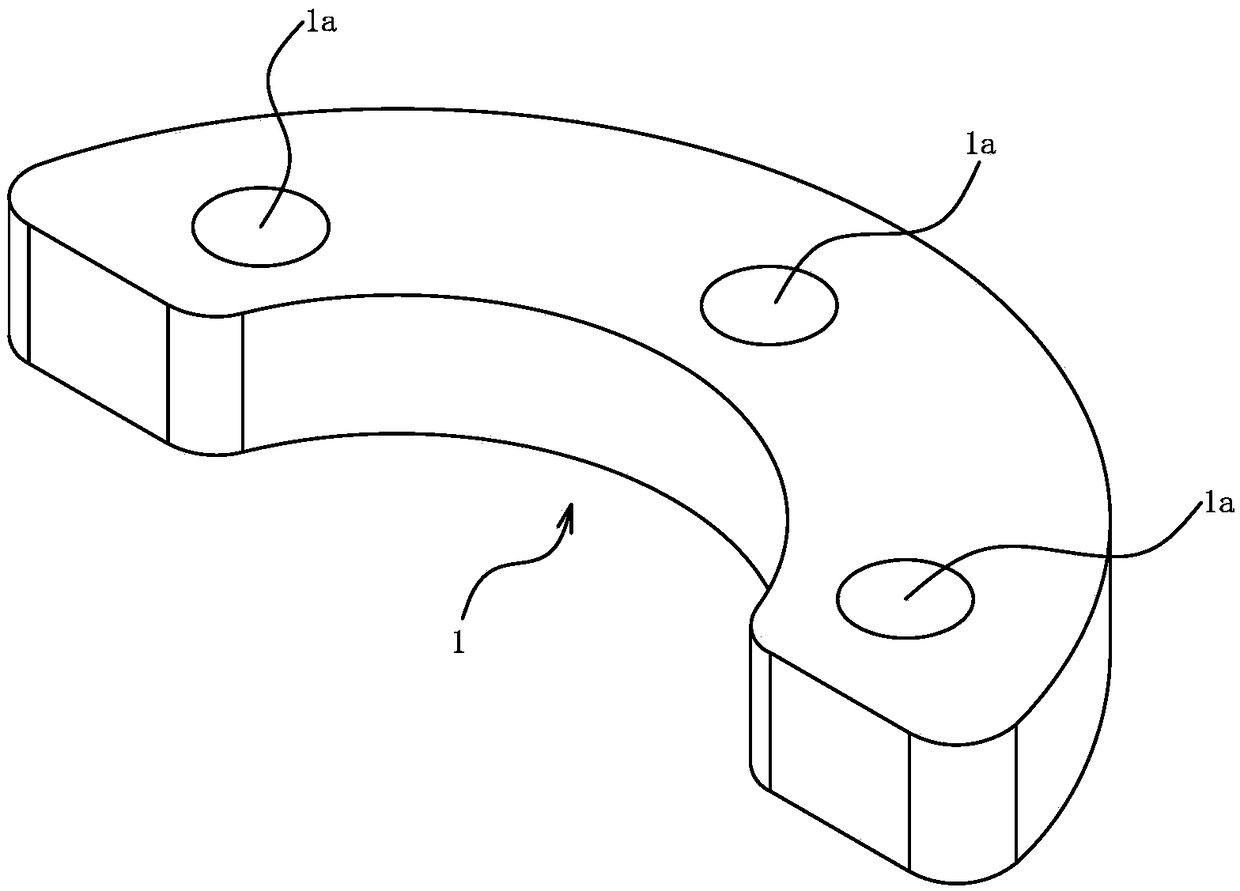

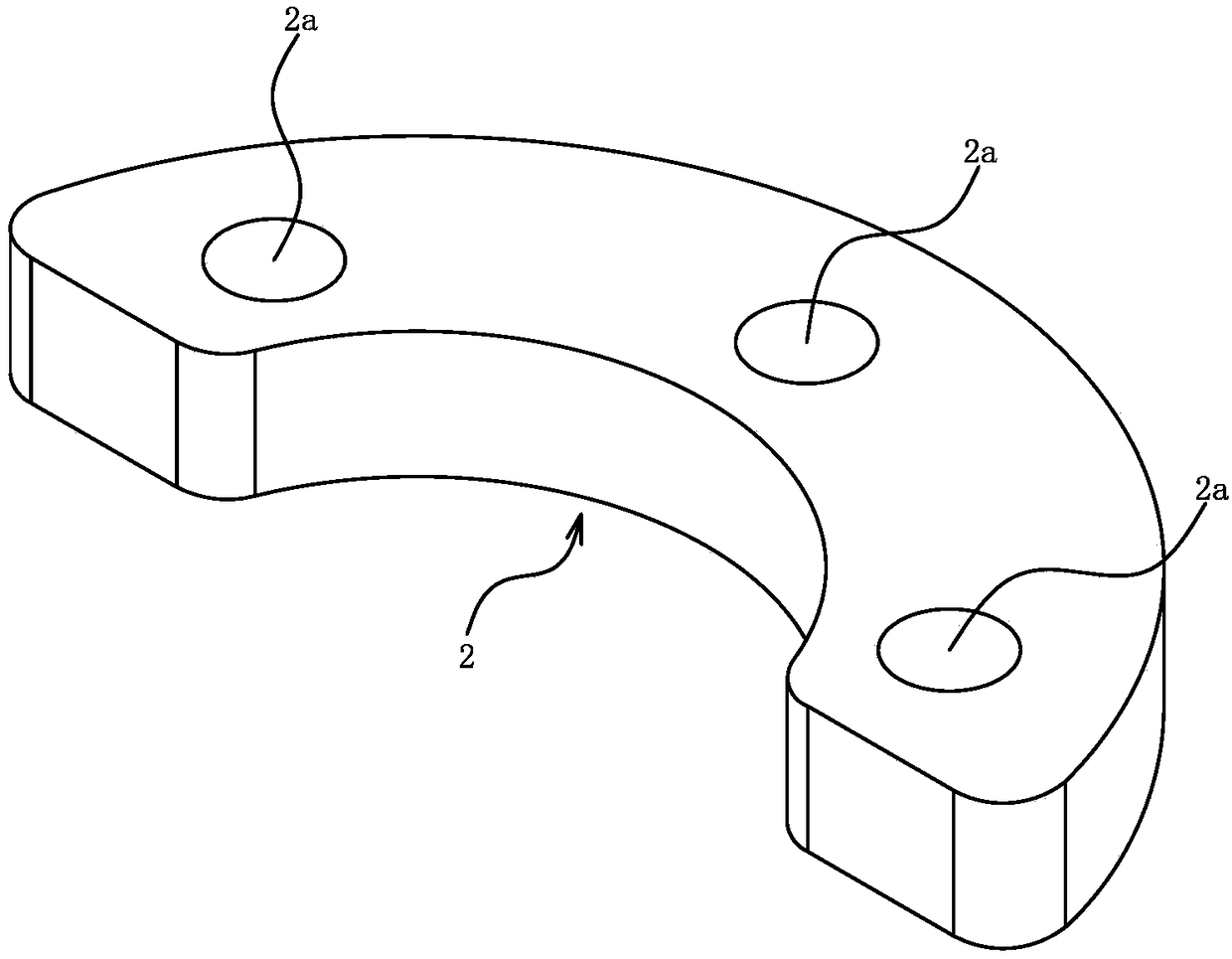

Compressor high manganese steel balancing weight and manufacturing method thereof

InactiveCN109128137AUniform mass distributionQuality controllableTransportation and packagingMetal-working apparatusChemical compositionAlloy

The invention provides a compressor high manganese steel balancing weight and a manufacturing method thereof, and belongs to the technical field of compressors. The problem of high manufacturing costof an existing powder metallurgy high manganese steel balancing weight is solved. Alloy powder pressing molding and high temperature sintering molding are adopted in the compressor high manganese steel balancing weight, alloy powder is formed by mixing high manganese steel powder and a lubricant, and the high manganese steel powder is composed of the following chemical components of C with the weight percentage being less than or equal to 1.0%, Si with the weight percentage being less than or equal to 0.9%, Mn with the weight percentage being 15% to 21%, S with the weight percentage being lessthan or equal to 0.03%, P with the weight percentage being less than or equal to 0.06% and the balance Fe. The compressor high manganese steel balancing weight and compressor high manganese steel balancing weights produced by using the manufacturing method of the compressor high manganese steel balancing weight have the advantages of lower manufacturing cost and higher product quality, and meanwhile have the advantages of high precision of the compressor high manganese steel balancing weights and the density approaching that of a casting forming balancing weight.

Owner:浙江百达精工股份有限公司

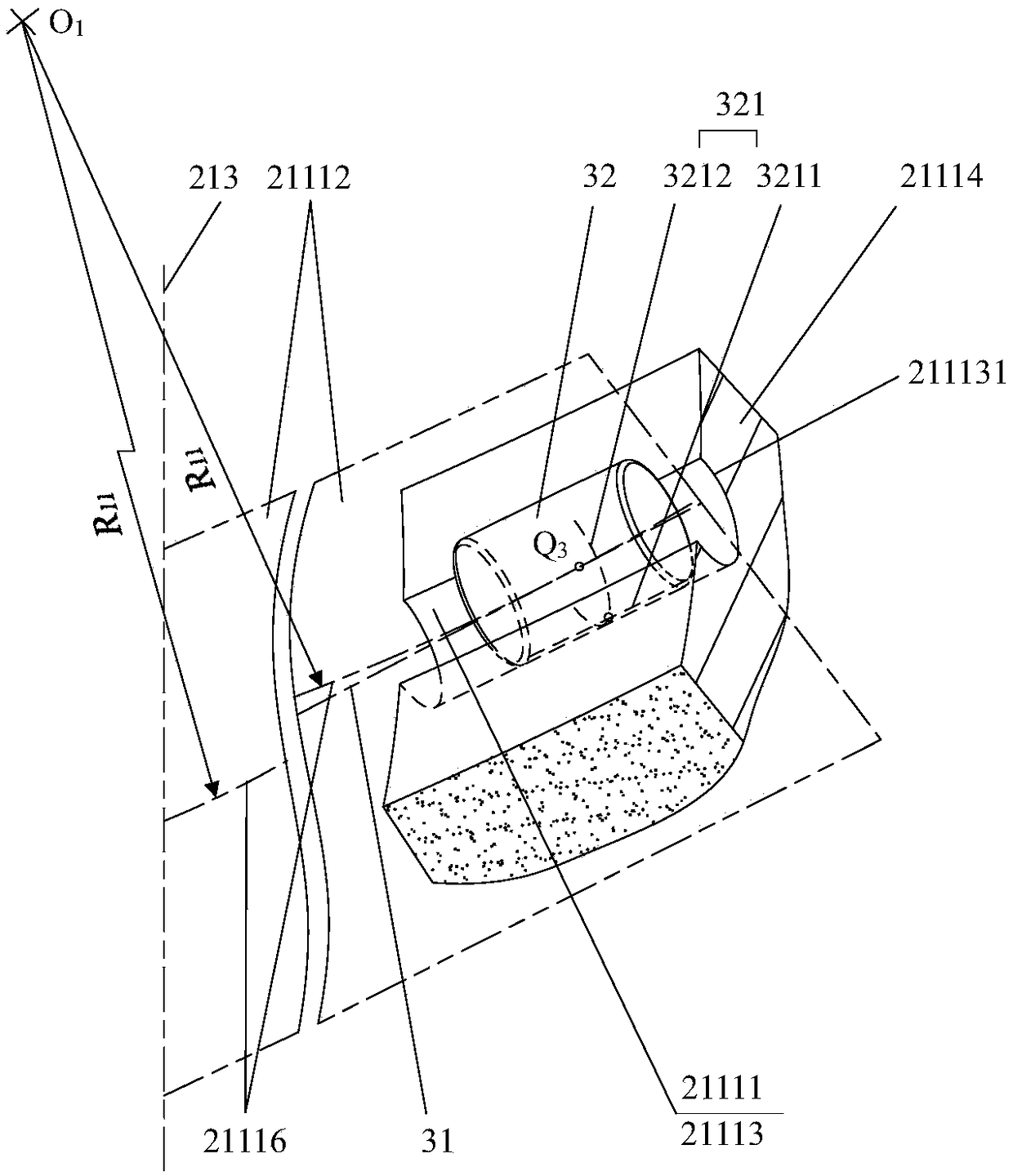

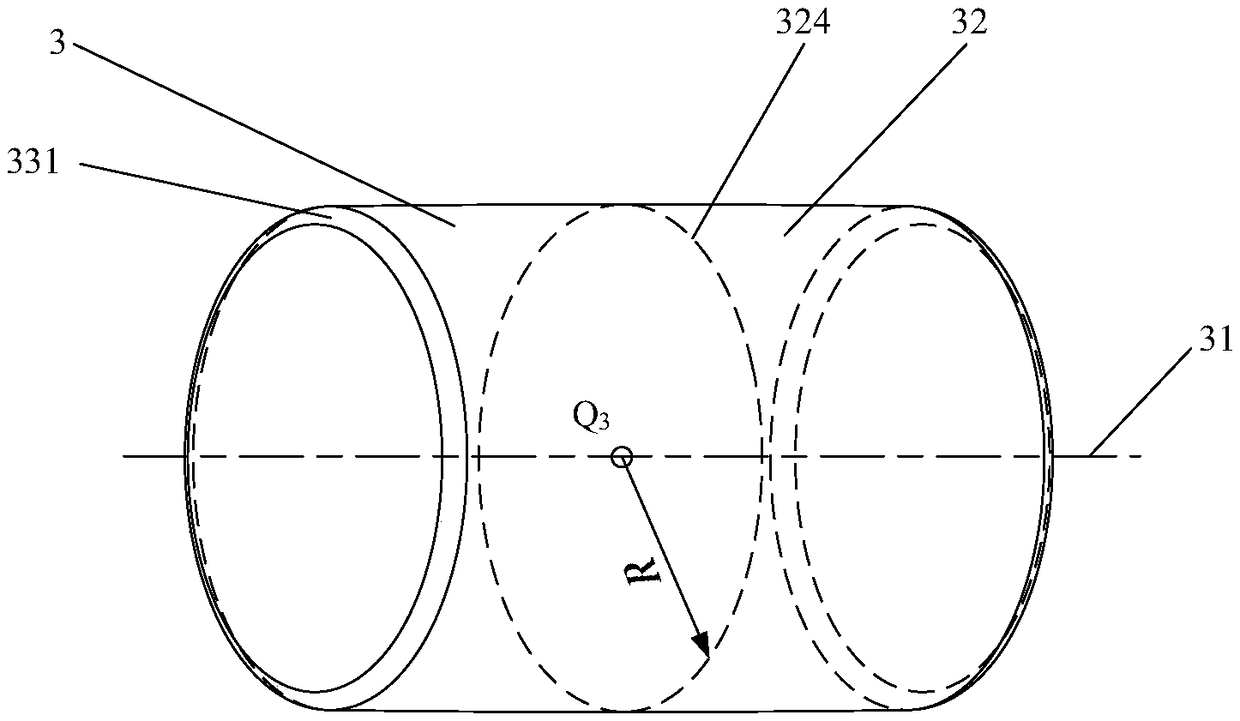

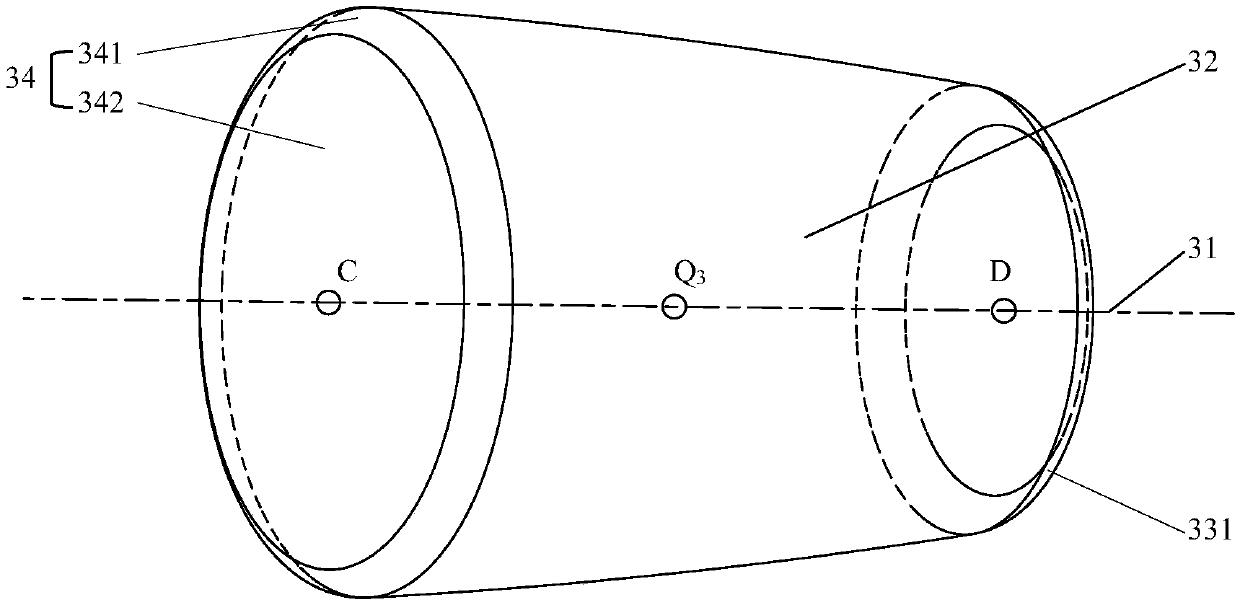

Grinding disk, apparatus and method for finishing rolling surface of convex cylindrical roller

ActiveCN108890516AAchieve removalRemove comprehensivelyLapping machinesLapping toolsMechanical engineeringEngineering

A lapping apparatus and a lapping disk kit for finis a rolling surface of a convex cylindrical roller are disclose. That lapping apparatus includes a main body, a lapping disk kit and a roller circulation disk out system. The main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device, wherein the main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device. The outer system of the roller circulating disk comprises a roller collecting device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The abrasive disk kit includes a pair of first and second abrasive disks coaxially and oppositely disposed facing each other. A front surface of the first abrasive disk includes a set of concave arc grooves radially distributed on a base surface of the first abrasive disk (concave circular arc rotating surface), The front surface of the second abrasive disk includes one or more spiral grooves distributed on the base surface of the second abrasive disk (convex circular arc rotating surface),and the radii of curvature of the base circle and the radii of curvature of the cross-section of the base surface of the first and second abrasive disks are equal to each other. A lapping apparatus ofthat present invention has the finis machining capability of a rolling surface of a large numb of convexity cylindrical rollers.

Owner:TIANJIN UNIV

High flux ferrite powder capable of reducing cracking

ActiveCN109665829AImprove one-dimensional compressibilityHigh dimensional consistencyInorganic material magnetismSesquioxideSlurry

The invention discloses high flux ferrite powder capable of reducing cracking. The raw materials of the high flux ferrite powder capable of reducing the cracking comprise the following components in parts by mole: 51.0 to 55.0 parts of iron sesquioxide, 21.0 to 25.0 parts of zinc oxide, and 20.0 to 28.0 parts of manganese oxide; glue with 0.7 to 1.5 weight parts of solid is added and a certain weight of an inert nano-composite material. Polyvinyl acetate with the glass transition temperature of less than 40 DEG C is added so that the one-dimensional compressibility of the powder is greatly improved; the inert nano-composite particles which are prepared by the main components of nano-amorphous iron oxide (or hydroxyl ferric oxide) and manganous-manganic oxide are adopted, so that the a gluedischarging channel can be provided in an early stage, and the inert nano-composite particles can be molten in original crystal particles without affecting the main component of the ferrite in a lateperiod; and the wear of slurry and a spraying piece of a spraying gun of a spraying tower can be reduced by performing spray-granulating by adopting the ferrite slurry which is coated by the inert nano-material which is coated by adopting a resistance reducing agent, namely a hydroxyethyl cellulose solution, so that the cost is reduced, and meanwhile, the size consistency of the particles is improved.

Owner:山东春光磁电科技有限公司

Drilling machine capable of simultaneously processing multiple holes

InactiveCN103785877ASimple structureNovel and reasonable designFeeding apparatusLarge fixed membersEngineeringSlide plate

The invention discloses a drilling machine capable of simultaneously processing multiple holes. The drilling machine comprises a working table and a plurality of pneumatic power heads arranged around the central position of the working table. The pneumatic power heads are connected with drill bits, a plurality of supports for supporting the pneumatic power heads are installed on the working table, a first supporting frame is arranged at the central position of the working table, a displacement cylinder is arranged on the working table and located in the first supporting frame, and a sliding plate capable of sliding in the length direction of the first supporting frame is installed on a piston rod of the displacement cylinder. The sliding plate is provided with a first clamp and a second clamp, a second supporting frame is installed on the working table and located above the first supporting frame, and a vertically arranged pressing cylinder is installed on the second supporting frame and located above the central position of the working table. The drilling machine shortens the processing cycle of single workpieces, improves working efficiency, guarantees interchangeability of the workpieces and reduces labor intensity of workers.

Owner:THE NORTHWEST MACHINE

Magnetic grinding plates, equipment and method for finish machining of rolling surface of cylindrical roller

The invention discloses grinding equipment and a magnetic grinding plate suite for finish machining of the rolling surface of a cylindrical roller made of a ferromagnetic material. The grinding equipment comprises a main unit, the magnetic grinding plate suite and a roller circulating plate external system, wherein the main unit comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device; the roller circulating plate external system comprises a roller collecting device, a roller demagnetizer, a roller conveyor, a roller finishing mechanism and a roller feed-in mechanism. The magnetic grinding plate suite comprises a first grinding plate and a second grinding plate which are coaxial, and the front sides of the pair of grinding plates are opposite; a group of linear grooves radially distributed on the base surface (right circular conical surface) of the first grinding plate are arranged on the front side of the first grinding plate, one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding plate are formed on the front side of the second grinding plate, and an annular magnetic structure is inlaid in a substrate of the second grinding plate. The grinding equipment has the finish machining capacity for the rolling surfaces of a large scale of cylindrical rollers made of the ferromagnetic material.

Owner:TIANJIN UNIV

A4 paper double-revolving knife paper cutting, ream paper production and box packaging integrated production line

PendingCN110303545AImprove work efficiencyReasonable structure layoutWrapper folding/bending apparatusWrapper twisting/gatheringProduction lineButt joint

The invention discloses an A4 paper double-revolving knife paper cutting, ream paper production and box packaging integrated production line. The A4 paper double-revolving knife paper cutting, ream paper production and box packaging integrated production line comprises a double-revolving knife paper cutting mechanism for cutting roller paper into A4 paper, a ream paper packaging machine which is in butt joint with the double-revolving knife paper cutting mechanism and is used for packaging the stacked A4 paper into a ream and a box packaging mechanism which is in butt joint with the ream paperpackaging machine and is used for conducting box packaging on the ream paper; and the double-revolving knife paper cutting mechanism comprises a paper feeding assembly, a traction assembly, a slitting assembly, a transverse cutting assembly, a paper feeding unit and a paper receiving unit. The A4 paper double-revolving knife paper cutting, ream paper production and box packaging integrated production line integrates paper cutting, ream paper packaging and box packaging and has high processing efficiency.

Owner:DONGGUAN JUNXING MACHINERY TECH

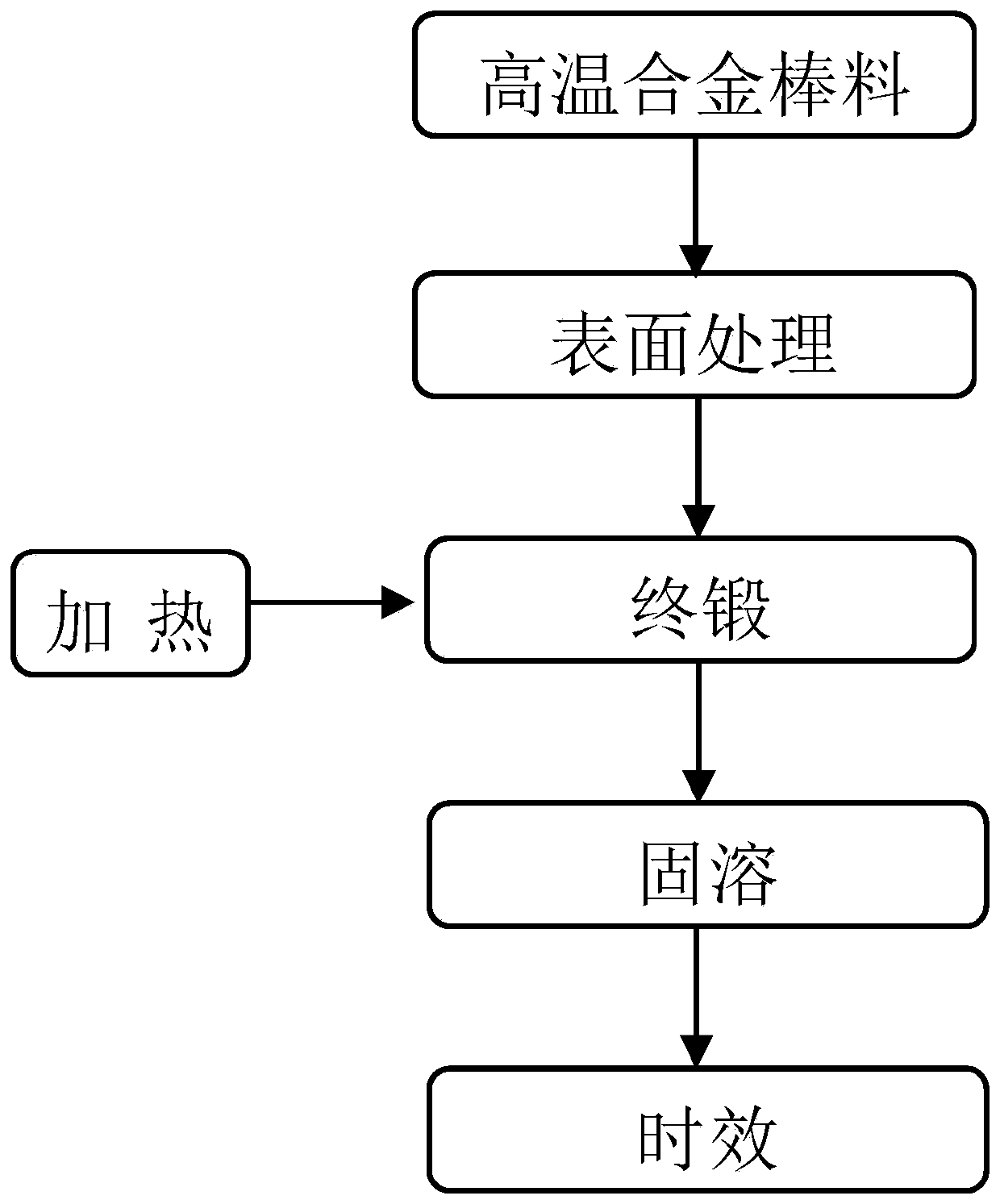

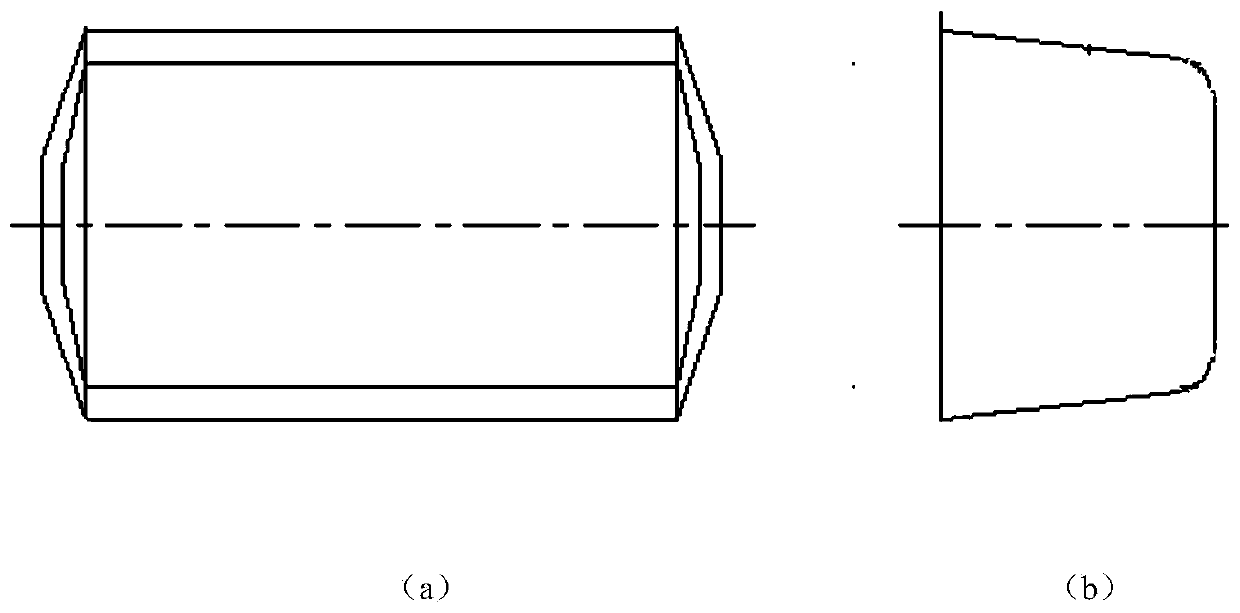

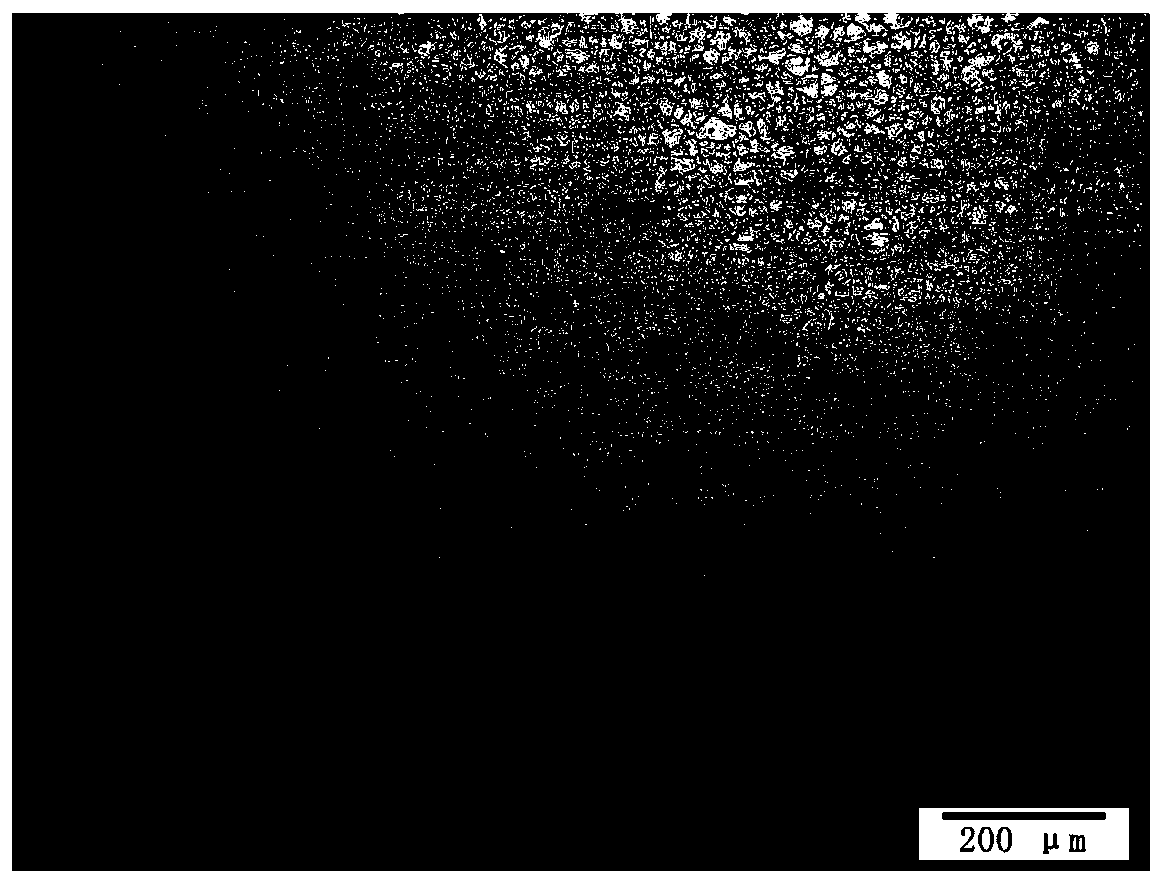

Forging method of GH4586 high-temperature alloy

ActiveCN110434275AGuaranteed Dimensional ConsistencyPrecisely control the amount of deformationEngine componentsAlloyScrew press

The invention discloses a forging method of a GH4586 high-temperature alloy. For a GH4586 high-temperature alloy forge piece, the surface of the forge piece is firstly coated with a high temperature resisting glass coating, and the surface of the forge piece is prevented from being oxidized or cracking in the forging process; in the forging process, an electric spiral press machine is adopted forforging for the first time, the blow energy and deformation of the forge piece can be precisely controlled, the forge piece achieves precise deformation, size consistency is high, meanwhile, a more uniform structure is obtained, and then good mechanical performance is obtained; and the spiral press machine is more stable than a forging hammer, the blow energy can be strictly controlled, forge piece flow lines can be uniformly distributed along the appearance, and the mechanical performance is greatly improved. In the forging method, an electric furnace is adopted for heating both during advanced heating and subsequent heat treatment of the forge piece, and the heating temperature can be precisely controlled within the range of + / -10 DEG C.

Owner:AECC AVIATION POWER CO LTD

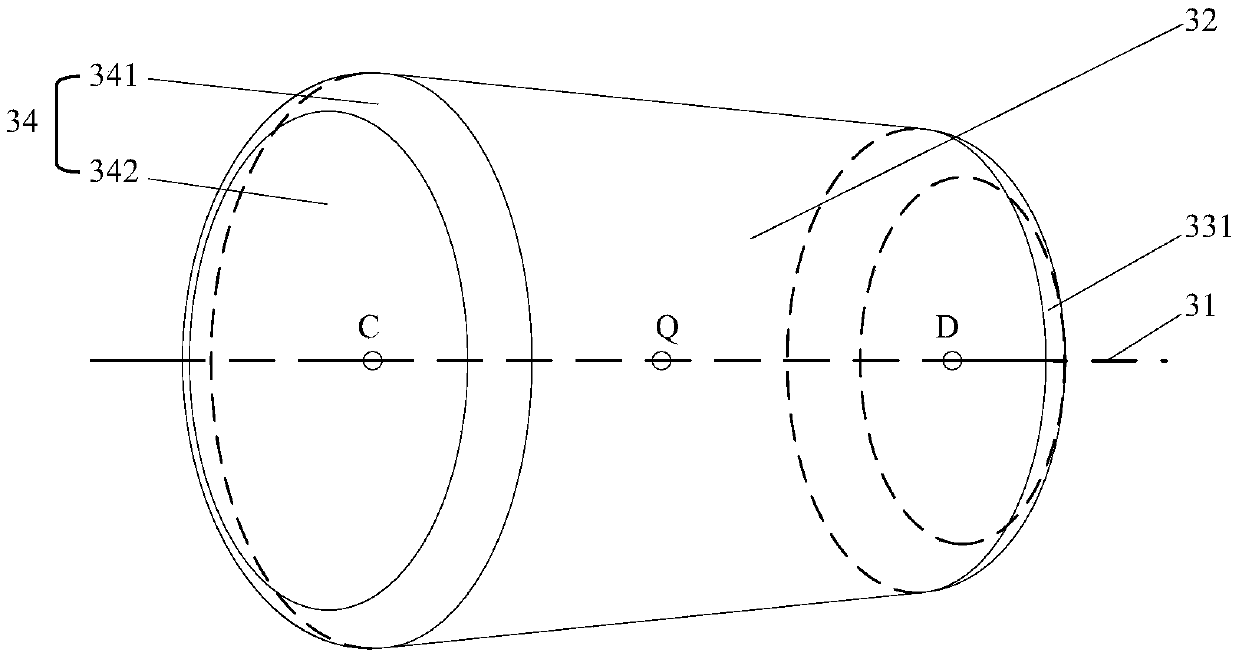

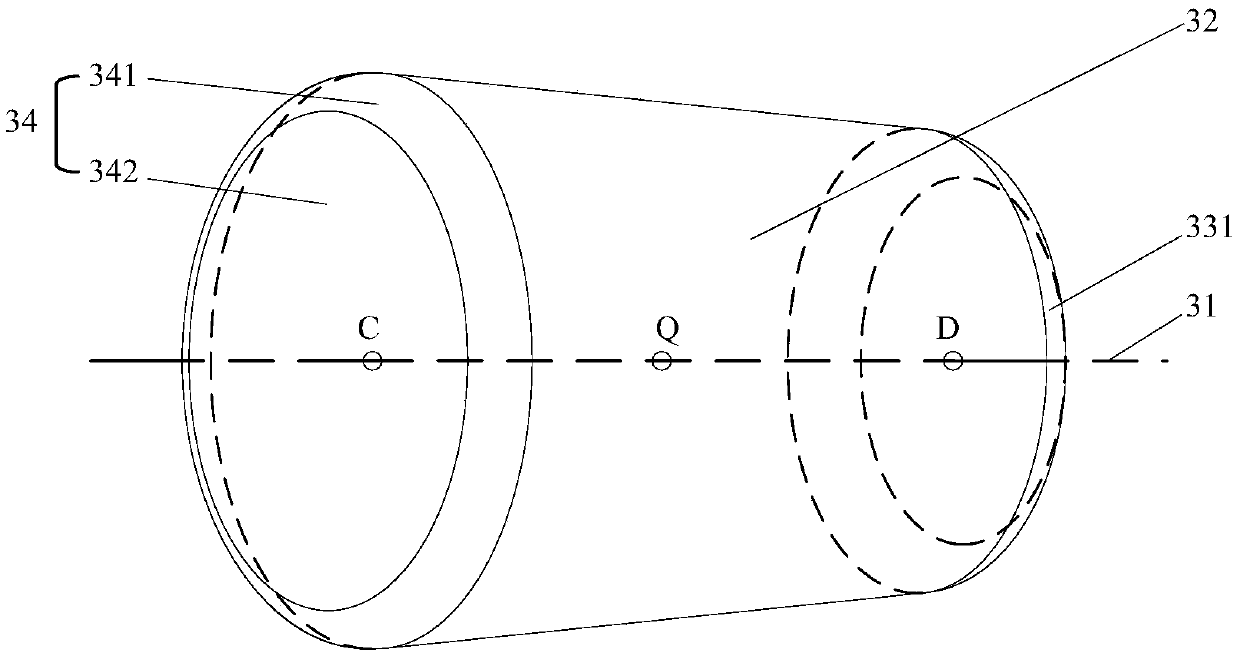

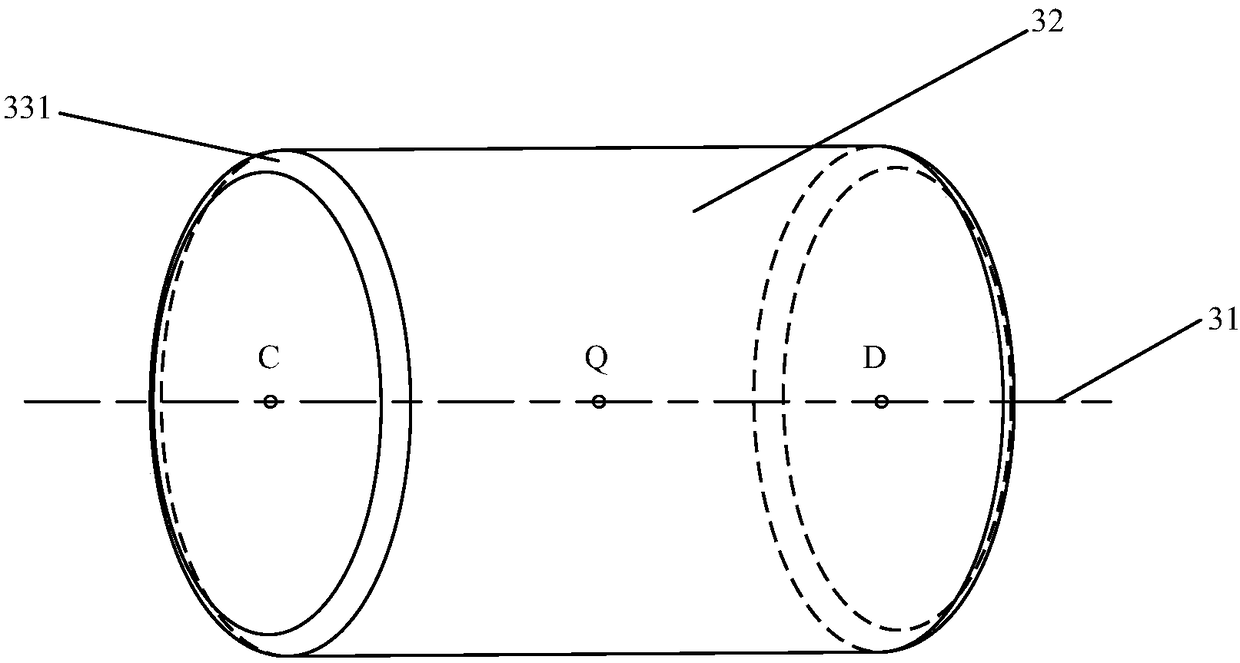

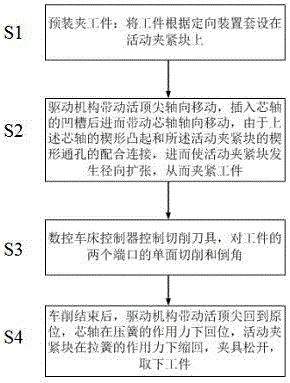

Compressor shell two-port finish turning device and finish turning process

InactiveCN106424762AHigh dimensional accuracyHigh dimensional consistencyExpansion mandrelsTurning machinesNumerical controlEngineering

The invention relates to a compressor shell two-port finish turning device and finish turning process. Two ports of a barrel can be turned after one-time clamping, and the production efficiency is improved; due to the fact that cutters are controlled by a controller for a numerically-controlled machine tool, dimensional precision and chamfer dimension consistency of the barrel are greatly improved, and the labor intensity of workers is reduced.

Owner:苏州市瑞晟制冷设备有限公司

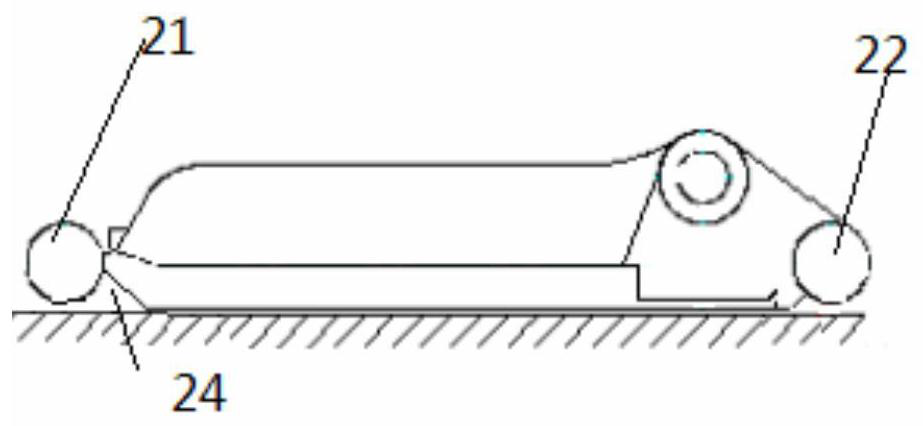

Double rotary knife roll paper splitting machine

PendingCN110271895AHigh dimensional consistencyLarge size errorPile receiversMetal working apparatusRolling paperTraction system

The invention discloses a double rotary knife roll paper splitting machine which comprises a paper supply system, a traction system, a conveying system and a paper collecting system. The paper supply system is used for being matched with a correcting system and a retroflection system to transfer a plurality of roller paper layers along a transverse direction; the traction system is used for sending laminated roll paper to a traction system of double rotary roller trimmer knife after pulling the roll paper to a stripping system; the conveying system comprises a high speed lower conveying assembly and a laminated paper conveying assembly in butt joint connection through a paper pass assembly and also comprises a high speed upper conveying assembly, a reducing assembly and a paper pressing assembly; the high speed lower conveying assembly and the laminated paper conveying assembly are matched with the high speed upper conveying assembly, and a pile of paper can be overlapped to the previous pile of paper successively and is transferred to the paper collecting system by matching with a conveying speed difference generated by the high speed upper conveying assembly and the laminated paper conveying assembly with reduction of the reducing assembly; and the paper collecting system is used for carrying each pile of paper and stacking the paper.

Owner:DONGGUAN JUNXING MACHINERY TECH

Cutting-off chamfering die for lithium-ion battery pole lug

InactiveCN105013923AReduces the chance of scratches and abrasionsIncrease productivityFinal product manufactureSecondary cells manufactureEngineeringLithium-ion battery

The invention relates to a cutting-off chamfering die for a lithium-ion battery pole lug. The cutting-off chamfering die comprises a base, a concave and convex type vertical cutter die set, a pole lug rubber cutting-off cutter set, positioning pins and guide rods. The base is divided into an upper layer and a lower layer which are connected through the guide rods; the concave and convex type vertical cutter die set comprises an upper cutter die and a lower cutter die, wherein the upper cutter die is a rectangular male die with four round corners, and is arranged on the lower surface of the upper layer of the base, and the lower cutter die is a female die in a corresponding shape and is arranged at the corresponding position of the lower layer of the base; the pole lug rubber cutting-off cutter set is divided into an upper cutting-off portion and a lower cutting-off portion, the upper cutting-off portion is a piece-shaped male die and is arranged on the lower surface of the upper layer of the base, and the lower cutting-off portion is a strip-shaped female die and is arranged at the corresponding position of the lower layer of the base; and the positioning pins are arranged between the concave and convex type vertical cutter die set and the pole lug rubber cutting-off cutter set and are used for positioning the position of the pole lug. The cutting-off chamfering die is easy to operate; and a plurality of working procedures are integrated, one plate pole lug can be machined at a time, and therefore the production efficiency is greatly improved.

Owner:WUXI BAISHIJIE METAL PROD TECH

Grinding disc, equipment and method for finish machining of rolling surface of convex circular cone roller

PendingCN108673331AReduce removalIncrease contact stressLapping machinesLapping toolsEngineeringCircular cone

The invention discloses grinding equipment and grinding disc external member for finish machining of the rolling surface of a convexity circular cone roller. The grinding equipment comprises a main machine, the grinding disc external member and a roller circulating disc external system. The main machine comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device. The roller circulating disc external system comprises a roller collecting device, a roller conveying system, a roller cleaning mechanism and a roller feeding mechanism. The grinding disc external member comprises a pair of first and second grinding discs, wherein the front surfaces of the first and second grinding discs are coaxially arranged are arranged in an opposite mode. The front surface of the first grinding disc comprises a group of concave arc grooves radially distributed on the first grinding disc base surface (concave arc rotating surface), the front surface of the second grinding disc comprises one or more spiral grooves distributed on the second grinding disc base surface ( convex arc rotating surface ), and the radius of curvature of the base circle and the radius of curvature of the base surface cutting line of the first and second grinding discs are equal. The grinding equipment and grinding disc external member for finishmachining of the rolling surface of the convexity circular cone roller has the finish machining capability of rolling surfaces of large-scale convexity circular cone rollers.

Owner:TIANJIN UNIV

Grinding disc and equipment and method for accurate machining of rolling surface of cylindrical roller

PendingCN108908094ARemove comprehensivelyRemove lessLapping machinesLapping toolsEngineeringBase plane

The invention discloses grinding equipment for accurate machining of the rolling surface of a cylindrical roller and a grinding disc kit. The grinding equipment comprises a main machine, the grindingdisc kit and a roller circulation disc external system, wherein the main machine comprises a substrate, a vertical column, a transverse beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device; the roller circulation disc external system comprises a roller collecting device, a roller conveying system, a roller arrangement mechanism and a roller feeding mechanism; the grinding disc kit comprises a first grinding disc and a second grinding disc which are coaxial, and the fronts of the first grinding disc and the second grinding disc are arranged oppositely; the front of the first grinding disc comprises a group of linear grooves which are radially distributed on the base plane (right circular conical surface) of the first grinding disc; the front ofthe first grinding disc comprises one or multiple spiral grooves which are distributed on the base plane (right circular conical surface) of the second grinding disc; and the sum of the flaring angles of the base planes of the first grinding disc and the second grinding disc are 360 degrees. The grinding equipment has the capability of accurately machining the rolling surfaces of large quantitiesof cylindrical rollers.

Owner:TIANJIN UNIV

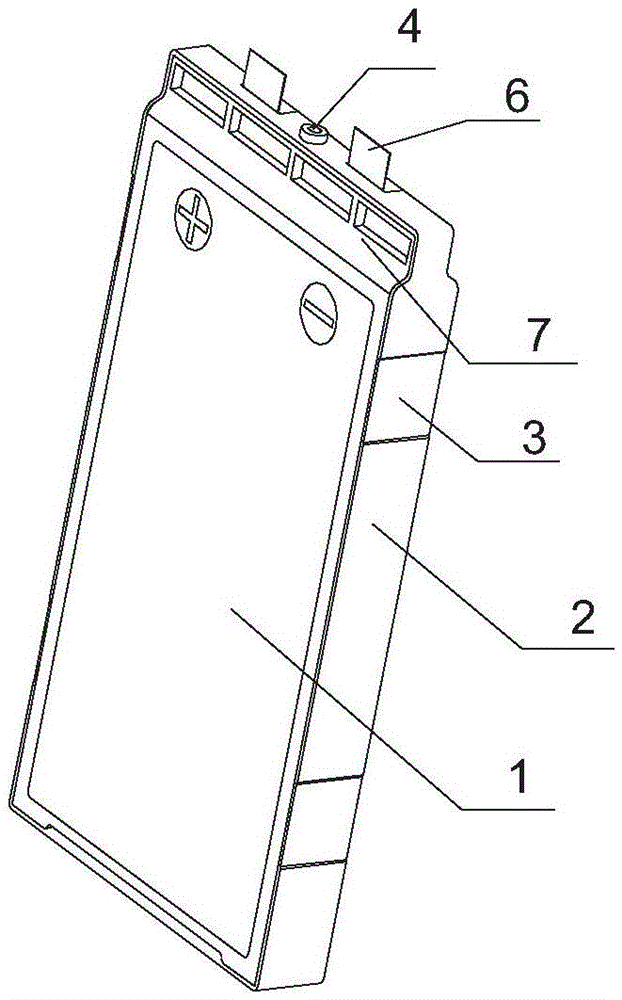

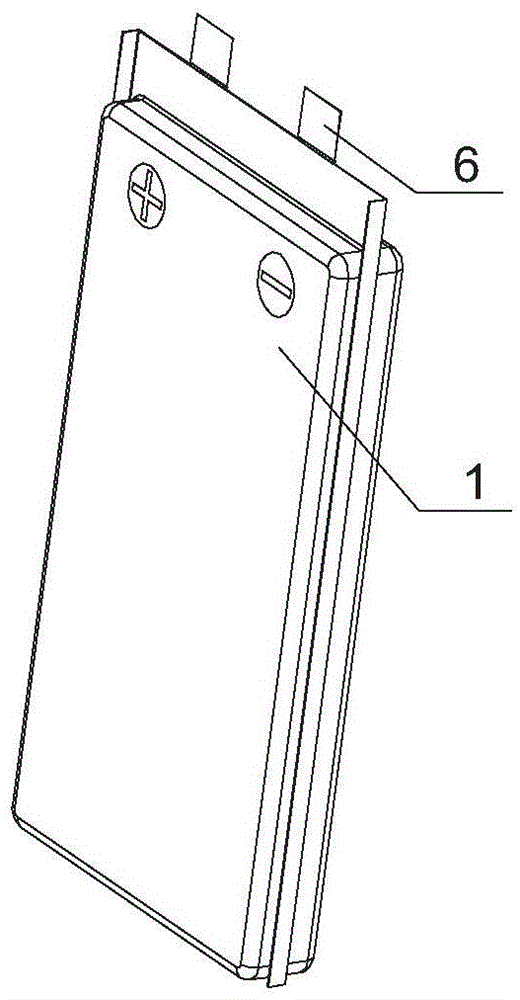

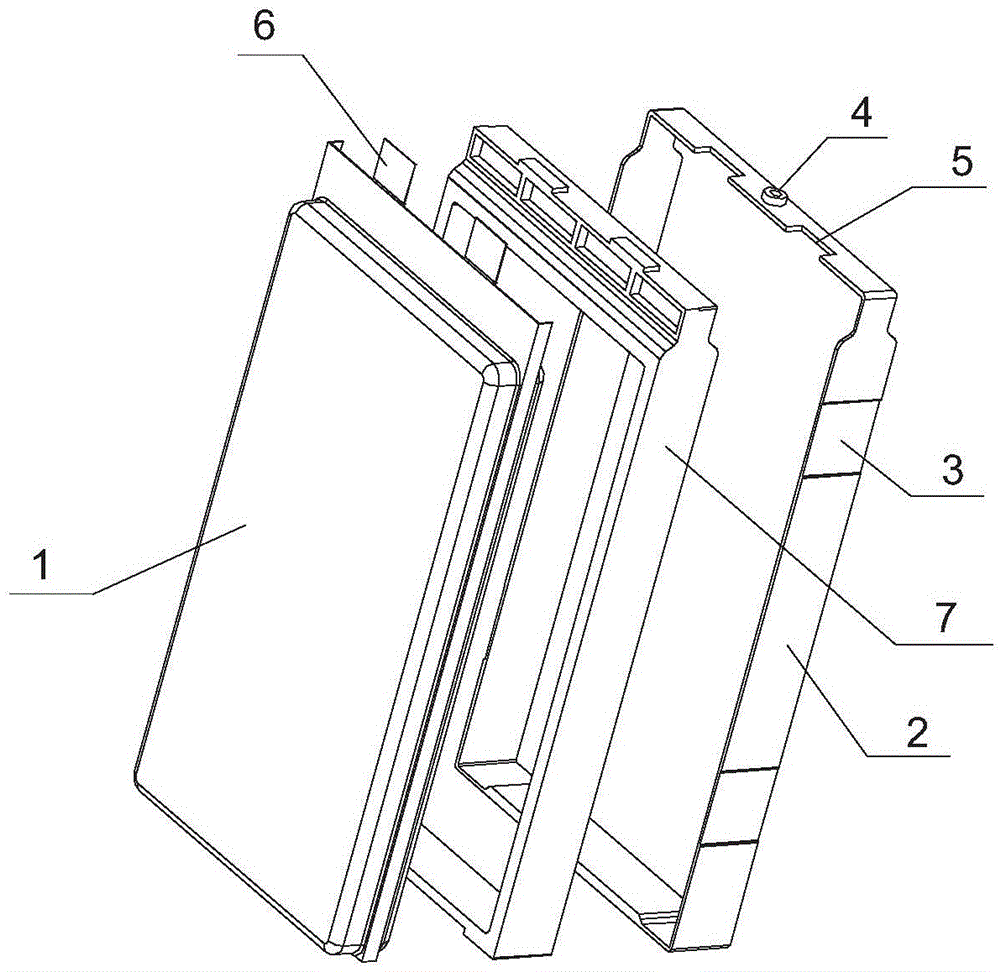

Soft package battery cell module and fabrication method thereof

ActiveCN105489790AImprove structural strengthImprove pass rateFinal product manufactureSmall-sized cells cases/jacketsPower batteryAdhesive

The invention discloses a soft package battery cell module. The soft package battery cell module comprises a soft package battery cell and also comprises a battery cell frame, wherein the battery cell frame sleeves the periphery of the soft package battery cell, and a cured fixing adhesive fills between the inner wall of the battery cell frame and the soft package battery cell. The invention also simultaneously discloses a fabrication method of the soft package battery cell module. In the soft package battery cell module, the soft package battery core and the battery core frame having a regular shape are combined to form the soft package battery cell module, the soft package battery cell module has unified size endowed by the battery cell frame, the soft package battery cell can be protected and strengthened by the battery cell frame and the fixing adhesive, so that a usage unit which is easy to assemble, combine, store and transport, has relatively high strength and is practical is obtained, the battery cell damage caused by the production and transportation process of the soft package battery cell is effectively solved, and the qualified rate and the finished rate of the battery cell are greatly improved; and moreover, full-automatic production of a power battery with the soft package battery cell is conveniently achieved, and the production efficiency can be substantially improved.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

High-temperature alloy thin-walled workpiece tenon-and-mortise combined type pouring system and manufacturing method

ActiveCN112548039ASolve metallurgical defects such as porosityHigh dimensional consistencyFoundry mouldsFoundry coresSuperalloyAero engine

The invention relates to the field of aero-engine high-temperature alloy thin-wall precision casting, in particular to a high-temperature alloy thin-wall part tenon-and-mortise combined type pouring system and a manufacturing method. According to the specific scheme, measures that a special tenon-and-mortise combined type pouring system forming pouring gate is designed according to the actual condition of a casting, and a supporting effect is achieved in a manner that a wax mold is provided with a flow gate are taken, so that metallurgical defects such as looseness are reduced, and the yield of the casting is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Cylindrical-component grinding device, and workpiece advancing apparatus and grinding method thereof

ActiveUS20170274494A1High shape accuracyHigh dimensional consistencyLapping machinesLapping toolsHigh volume manufacturingSurface grinding

A double-disc straight groove cylindrical-component surface grinding disc, includes a first grinding disc and a second grinding disc, rotating relative to each other; the the first grinding disc's working face is planar; the second grinding disc's surface, opposite the first grinding disc, includes a set of radial straight grooves, with groove faces of the straight grooves are the working face of the second grinding disc; the cross-sectional outline of the working face of the second grinding disc is arcuate or V-shaped or is a V-shape having an arc; during grinding, a workpiece spins inside the straight grooves, while under the effect of an advancing apparatus, the workpiece slides in translational motion along the straight grooves. The described grinding disc device has high-volume production capabilities, and the shape accuracy and size consistency of the cylindrical roller's cylindrical surface and the efficiency in machining are improved, and machining cost is reduced.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com