Electrolytic processing method for ribbed deep small holes and special tool cathode

A technology of tool cathode and processing method, applied in the direction of processing electrodes, electric processing equipment, electrode manufacturing, etc., can solve the problems of low processing efficiency and forming accuracy, easy detachment of photoresist, unstable processing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

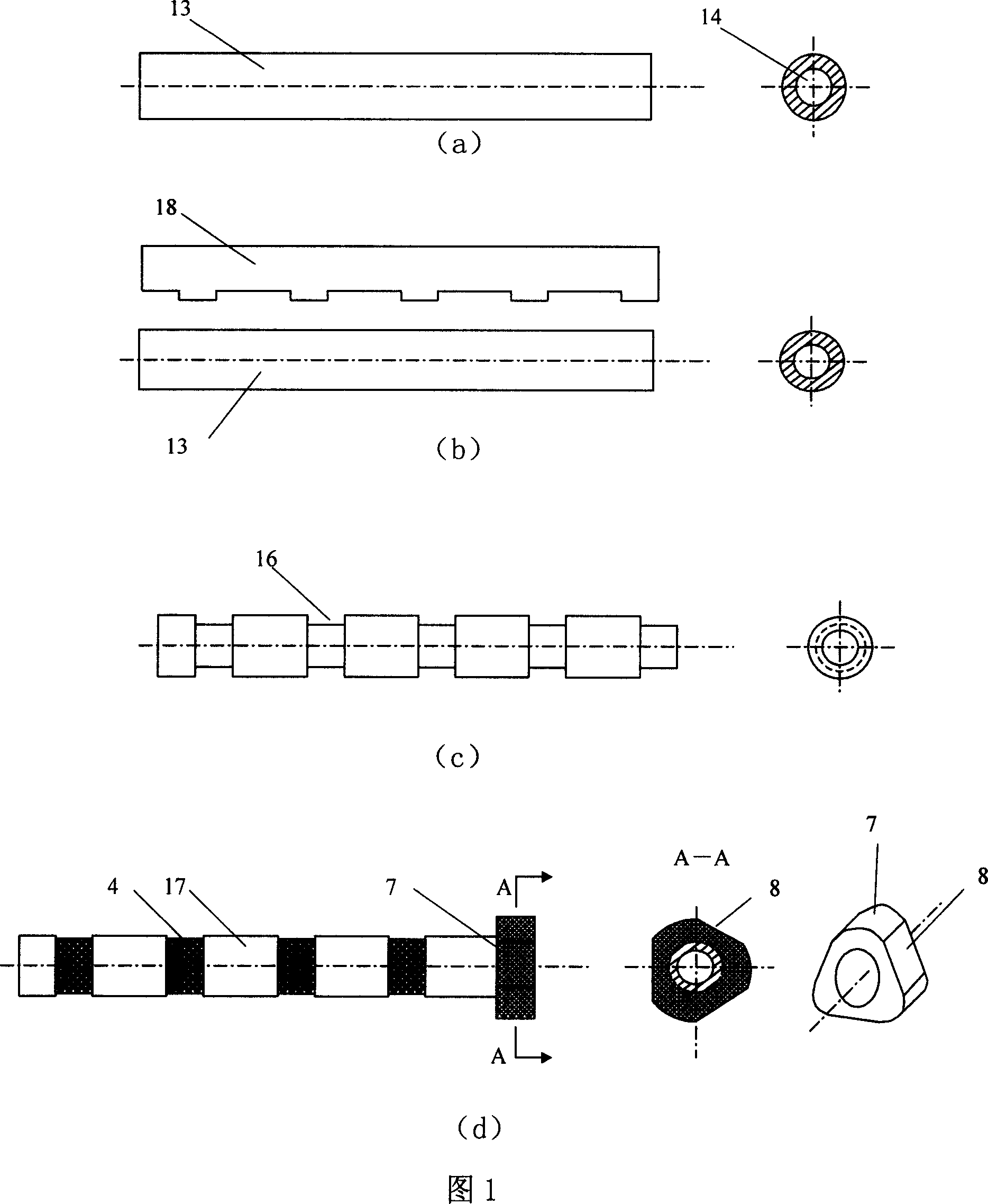

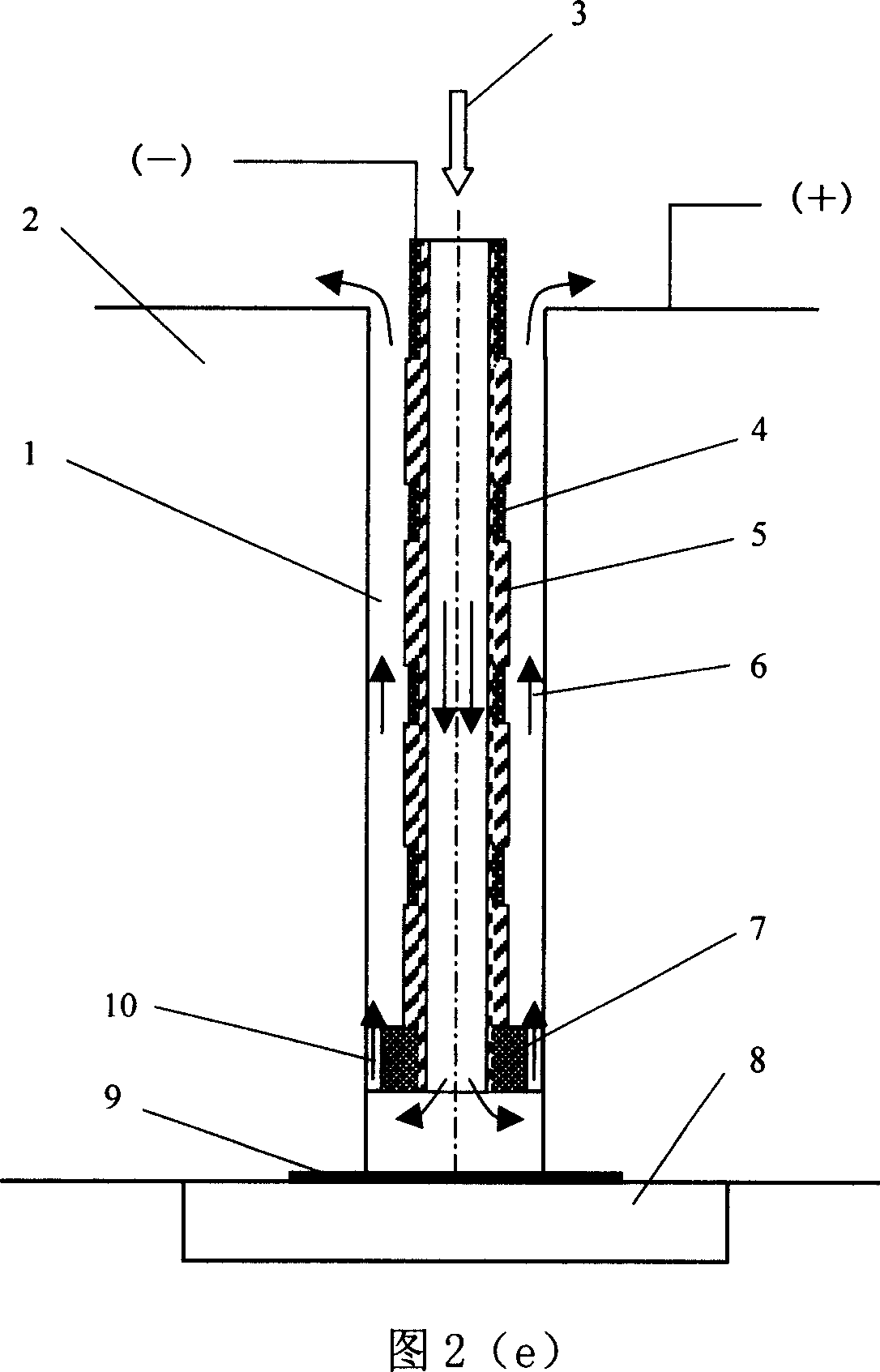

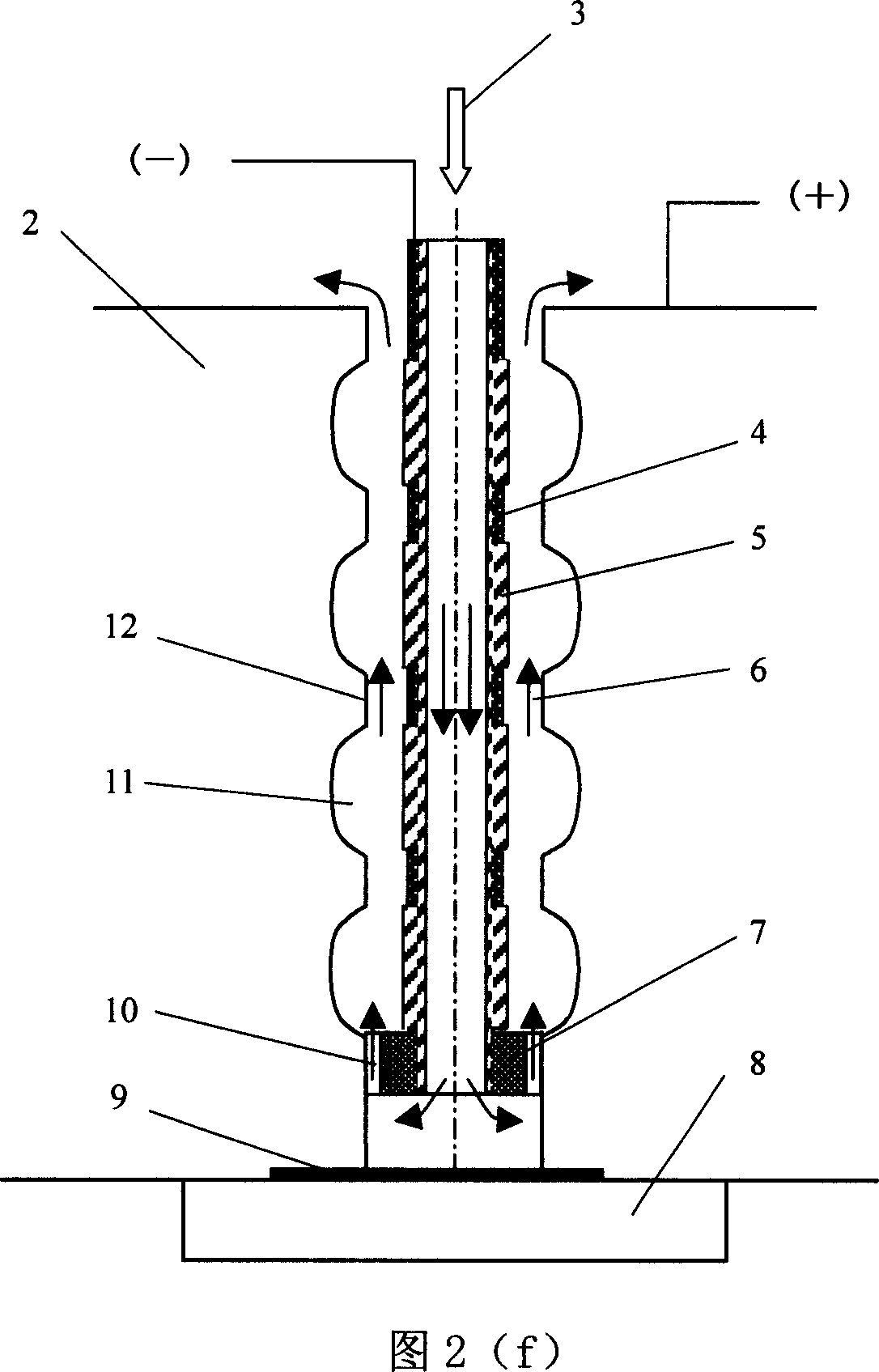

[0016] The following describes in detail how to process the ribbed cooling holes in the engine blade and the preparation of the tool cathode with reference to FIGS. 1 to 3 .

[0017] Step 1: Firstly, the light hole 1 is machined on the workpiece by electrolytic machining.

[0018] The second step: prepare the cathode 28 of the tool for processing bamboo joint holes as shown in FIG. 1 . Choose a metal tube 13 with good electrical conductivity as the basic material of the tool electrode, as shown in Figure 1(a), its cross-sectional shape is circular, and the metal material is corrosion-resistant. Adopt a reverse copy cathode 18, utilize the electrolytic machining reverse copy method to process the outer wall surface of the metal tube into a groove-shaped 16 structure as shown in Figure 2 (c), the depth of the groove 16 should be smaller than the difference between the outer diameter of the metal tube and the inner warp size, The width of the groove 16 can be processed according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com