A kind of micro-hole electrolytic machining machine vision positioning and navigation method

A technology of positioning, navigation and machine vision, applied in electric processing equipment, electrochemical processing equipment, metal processing equipment, etc., can solve the problem of no discovery, and achieve the effect of reducing human error and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] A micropore electrolytic machining machine vision positioning and navigation method, comprising the following steps:

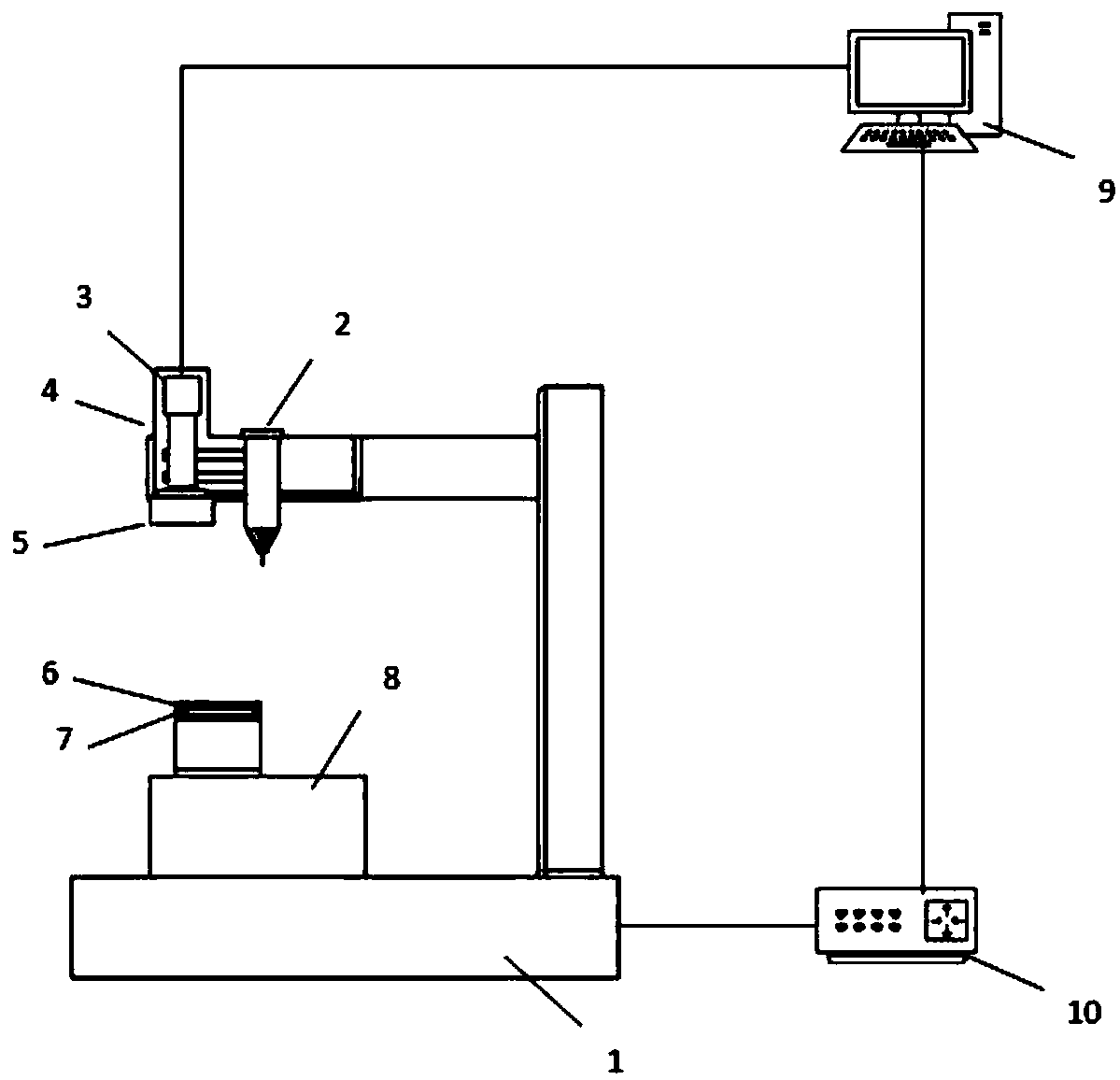

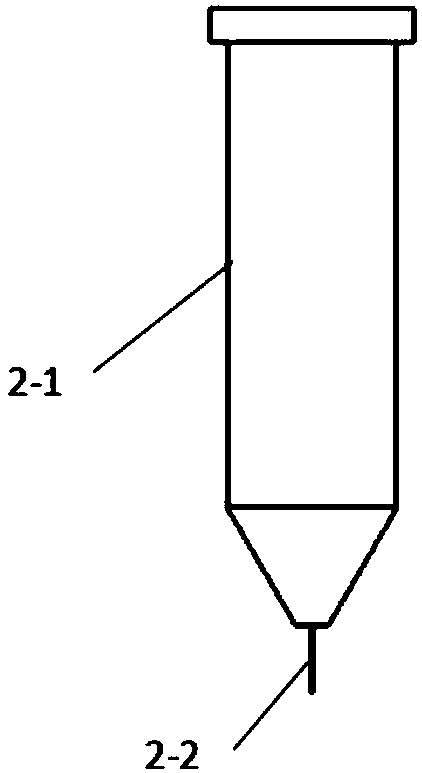

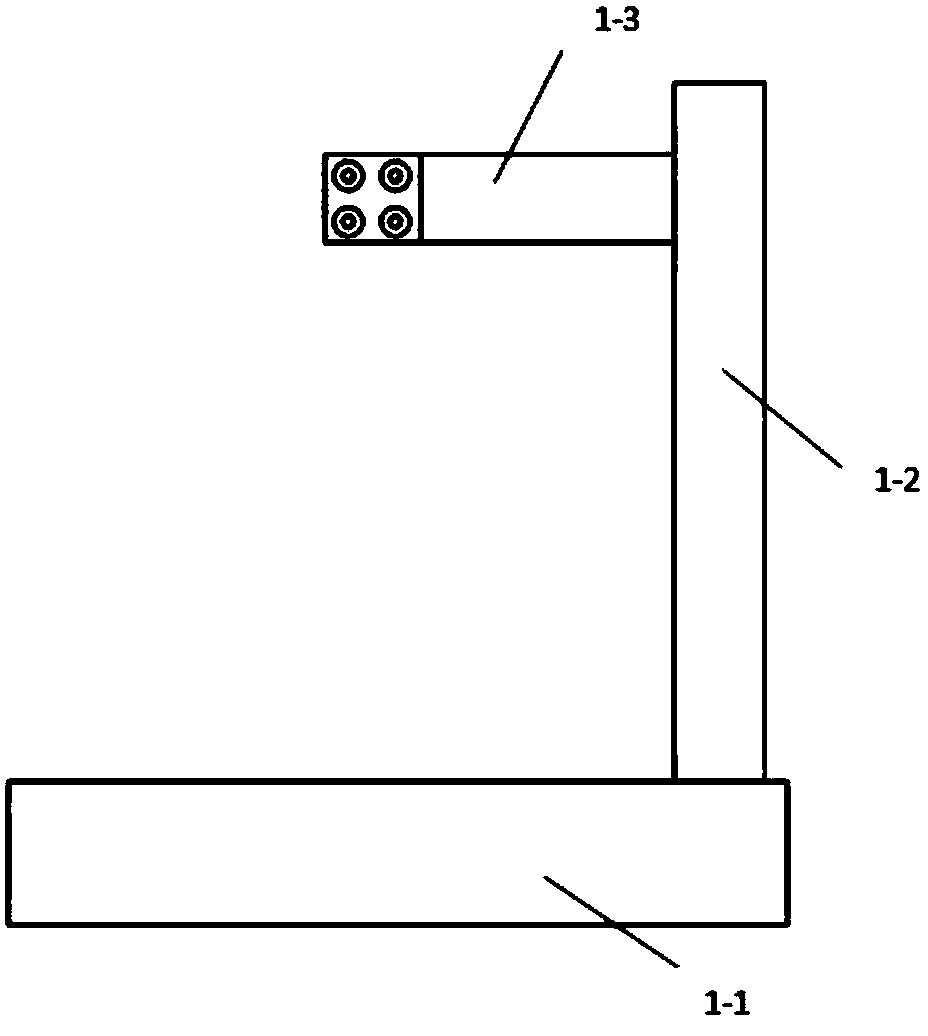

[0029] Step 1: Refer to figure 1 , figure 2 , image 3 and Figure 4 , using a visual device to install the target 7 on the pad 8 through the second clamp 6;

[0030] Step 2: Turn on the camera 3, adjust the camera 3 to a corresponding position, focus, and determine the optimal imaging distance between the camera 3 and the surface of the target 7;

[0031] Step 3: Calibrate the pixel equivalent of the visual device, and use the target 7 to calibrate the pixel equivalent r: First, the visual device collects the image of the target 7 for image processing, and obtains the pixel coordinate values of all calibration points on the target 7, such as Figure 5 As shown, in the four areas of the target image plane in the camera field of view, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com