Patents

Literature

79results about How to "Improve machining productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

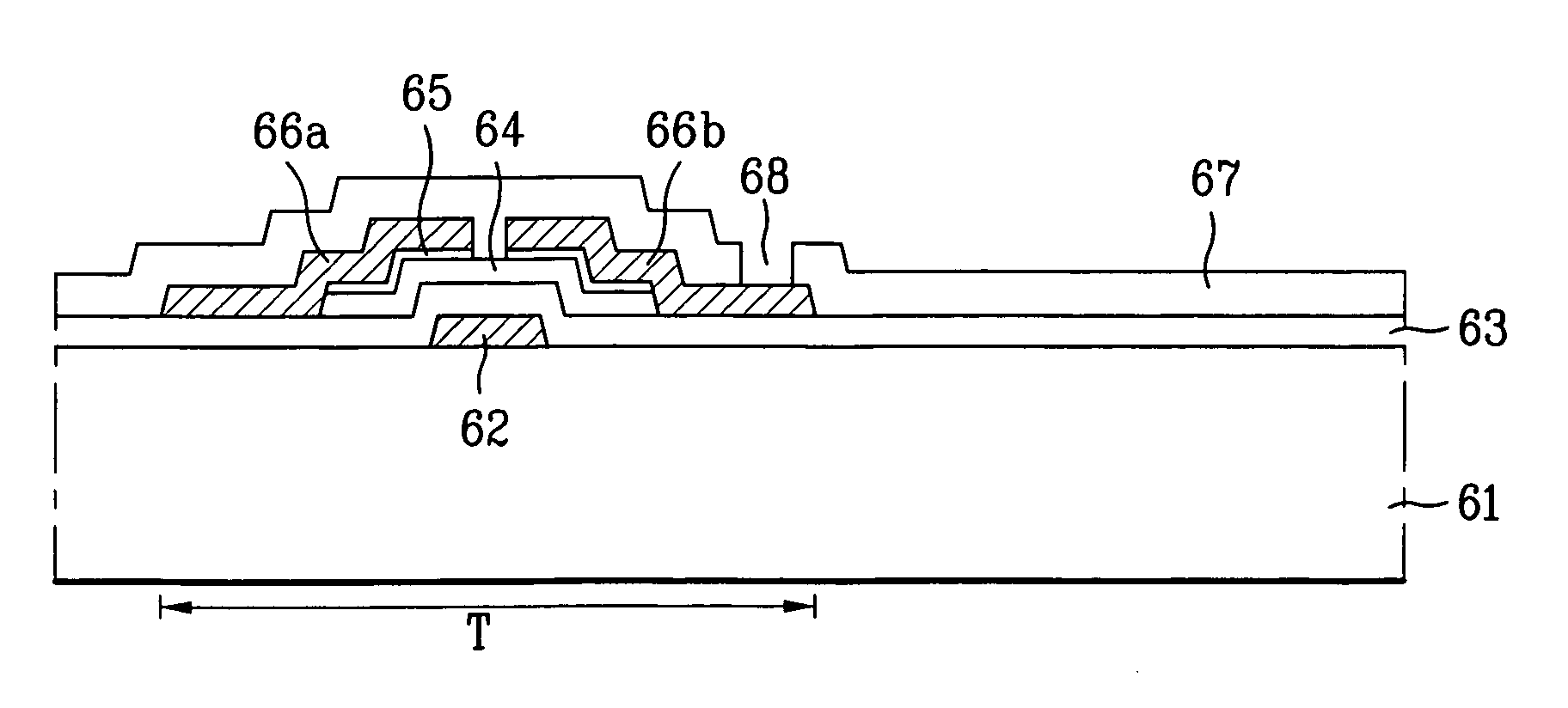

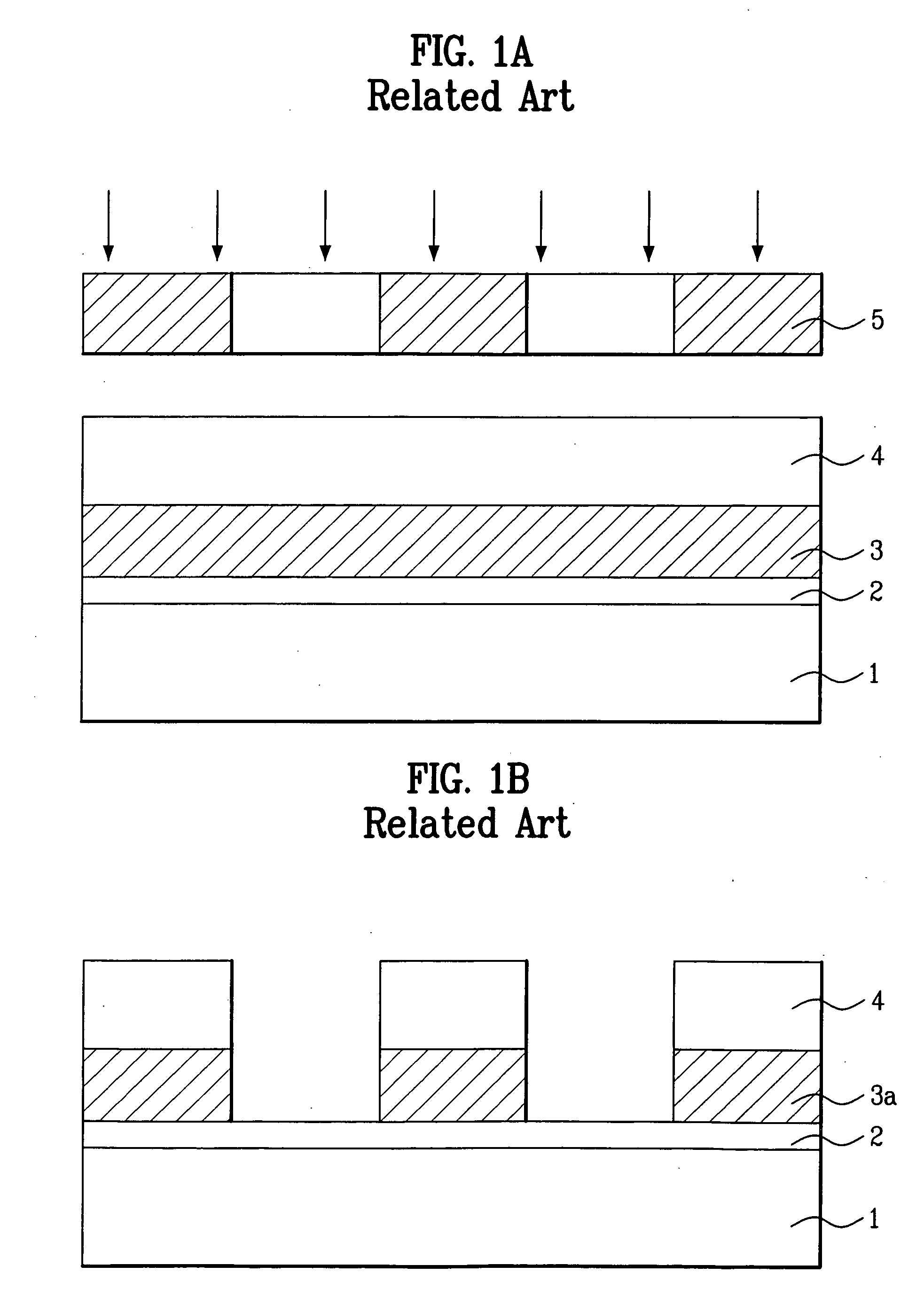

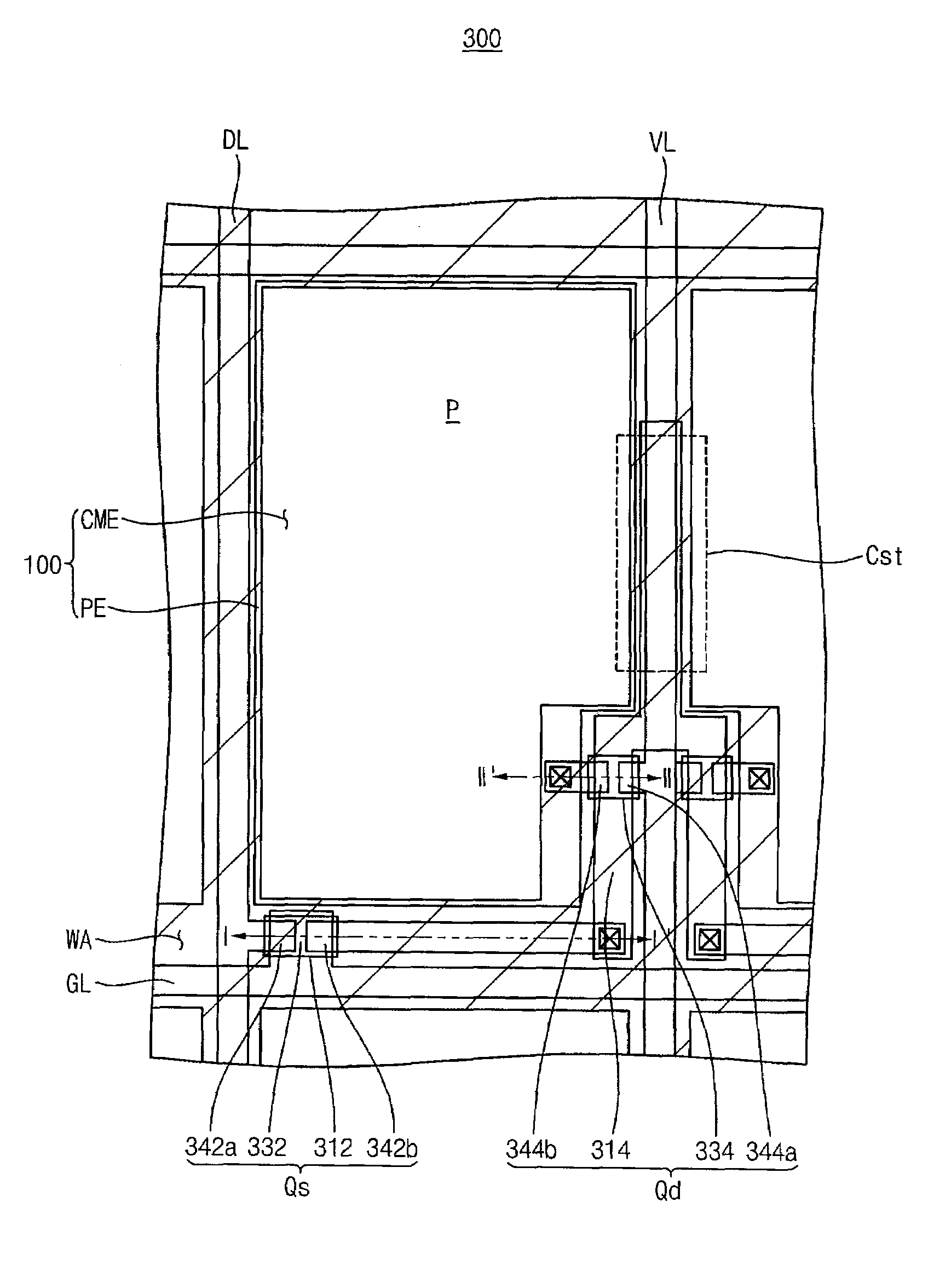

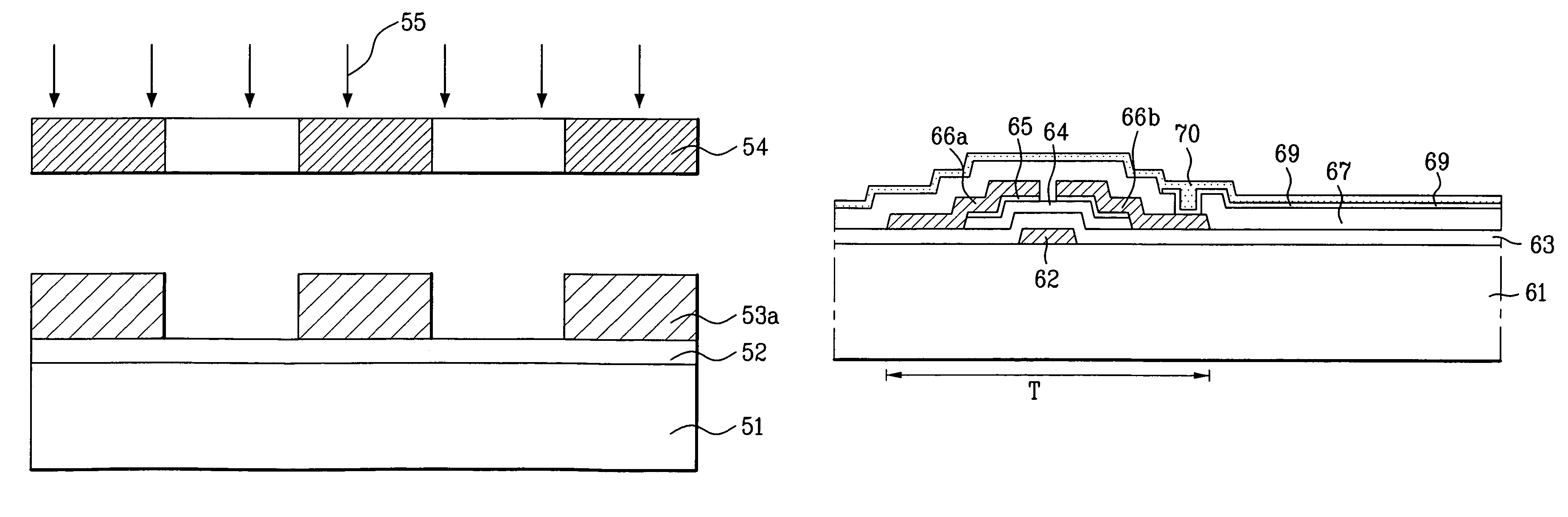

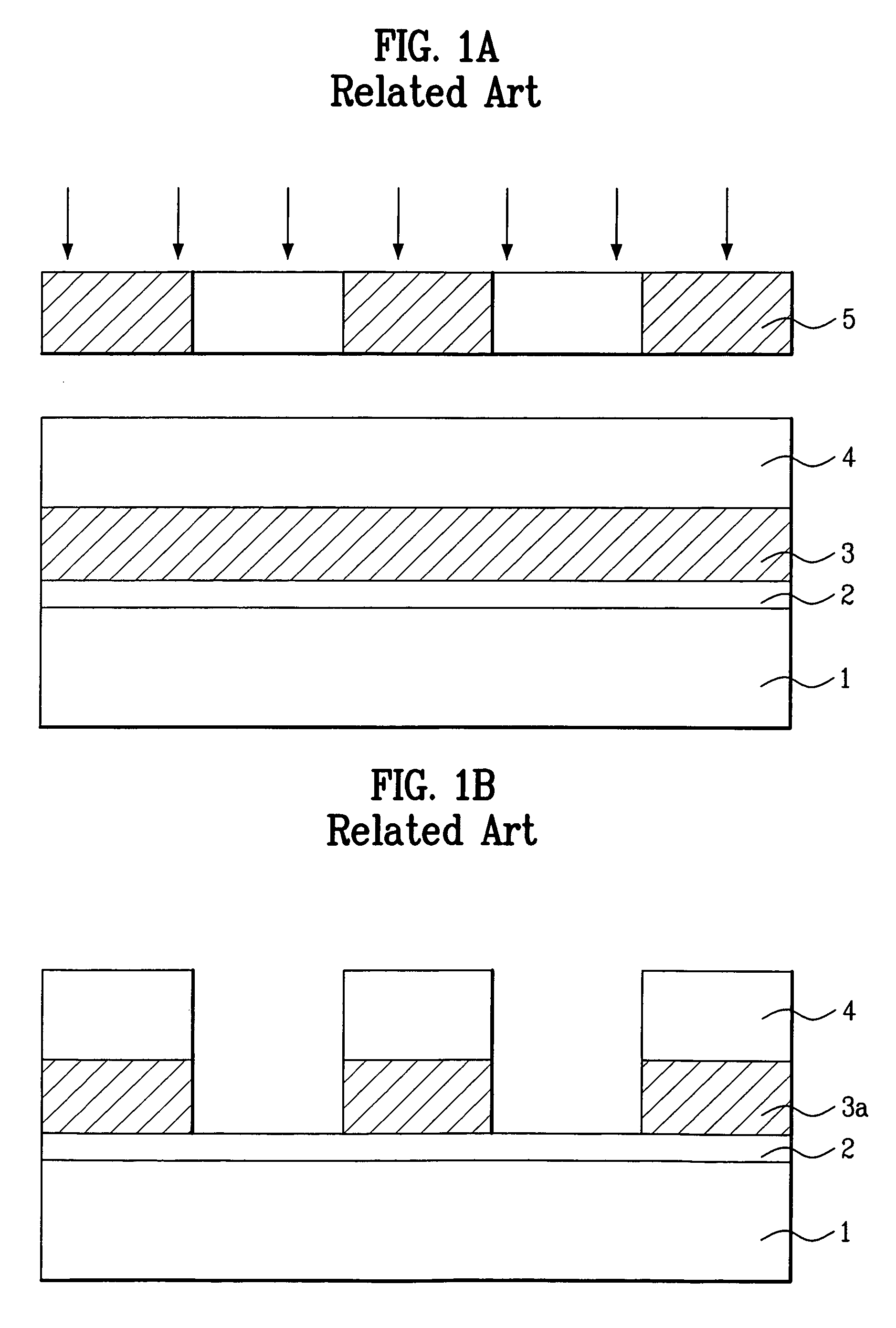

Thin film etching method and method of fabricating liquid crystal display device using the same

ActiveUS20060099747A1Simple processImprove machining productivitySolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

A thin film etching method includes forming a layer on a substrate, aligning a mask having a pattern defined thereon above the layer, and removing a portion of the layer by irradiating the substrate with a femtosecond laser through the mask.

Owner:LG DISPLAY CO LTD

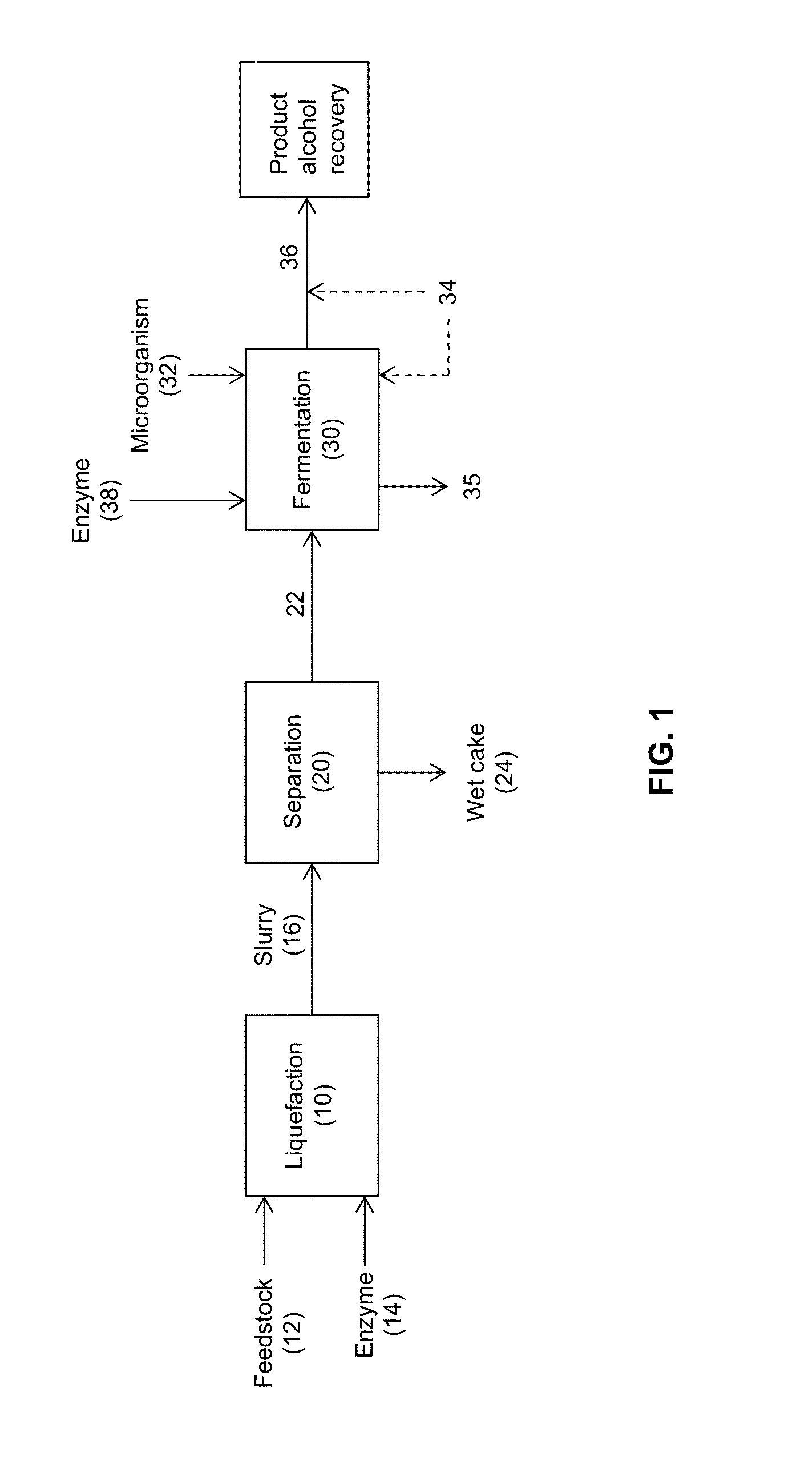

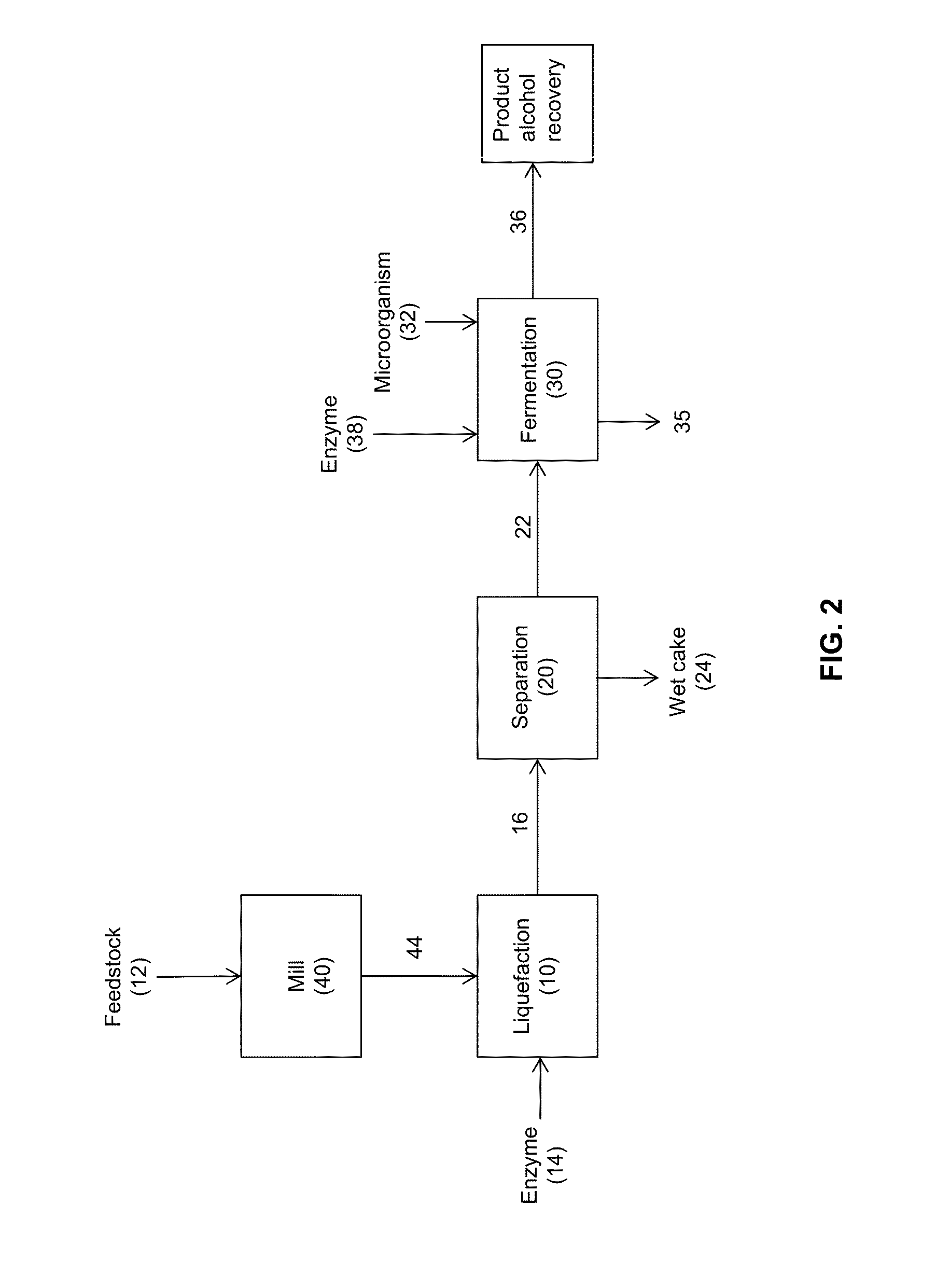

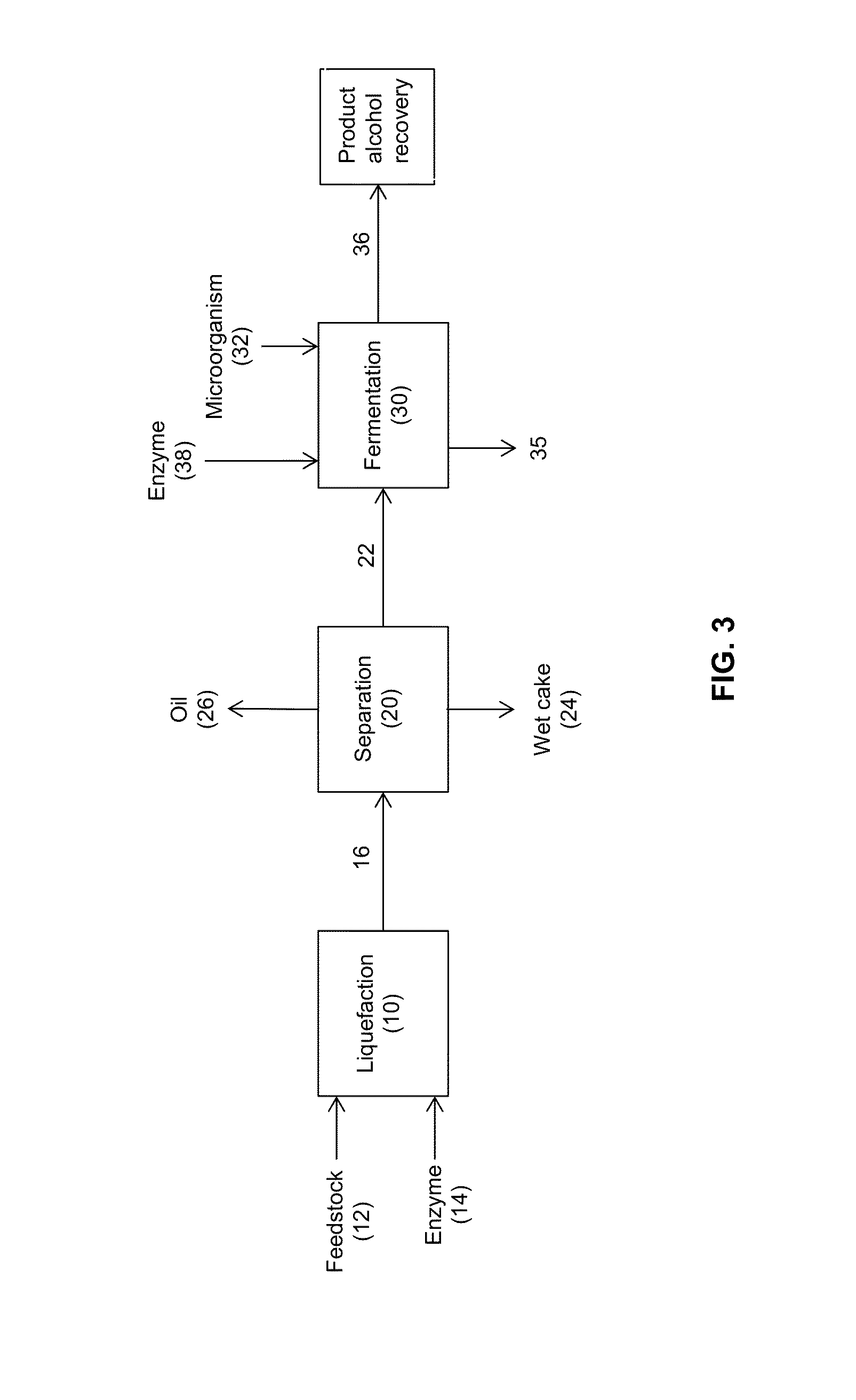

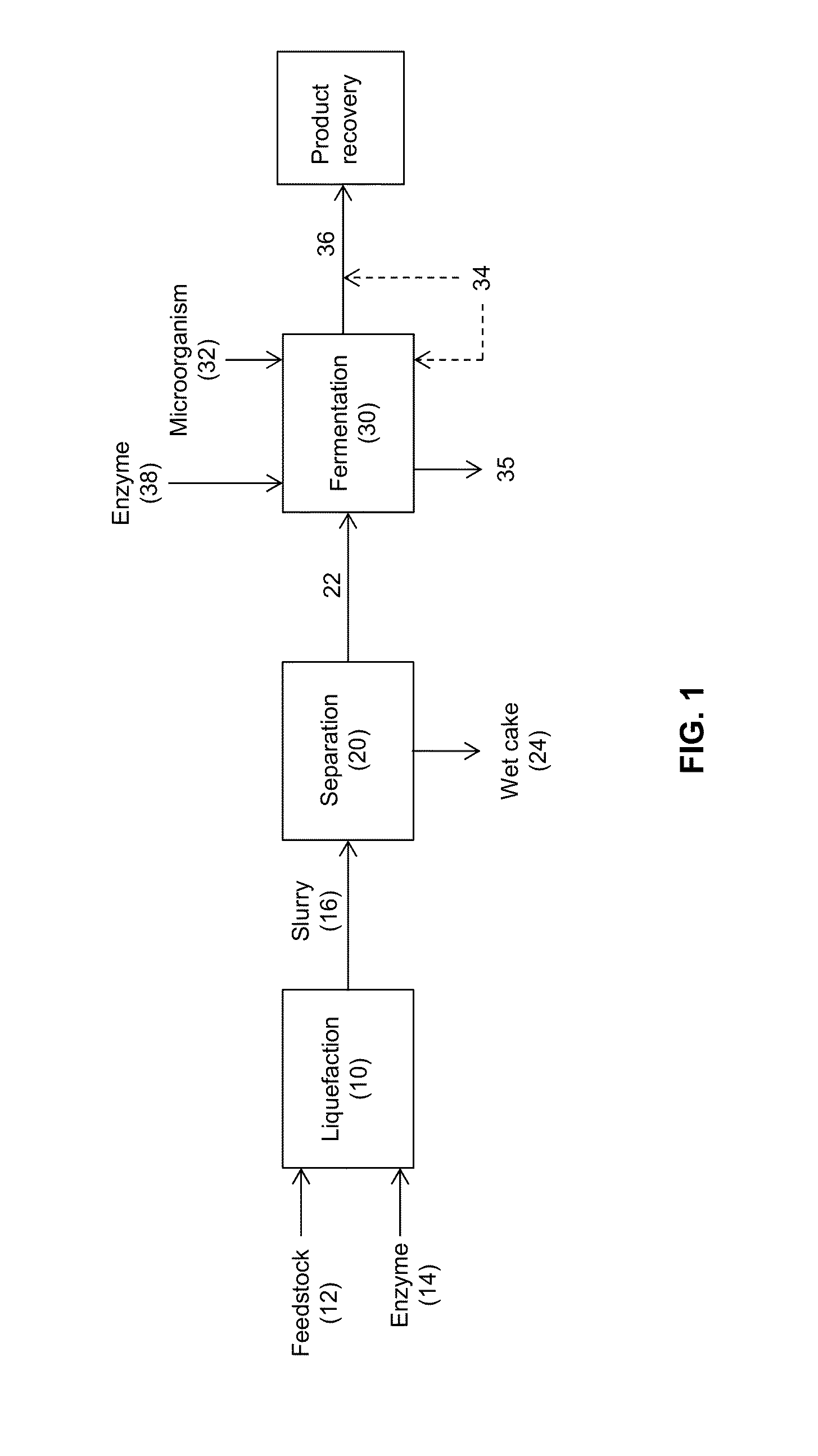

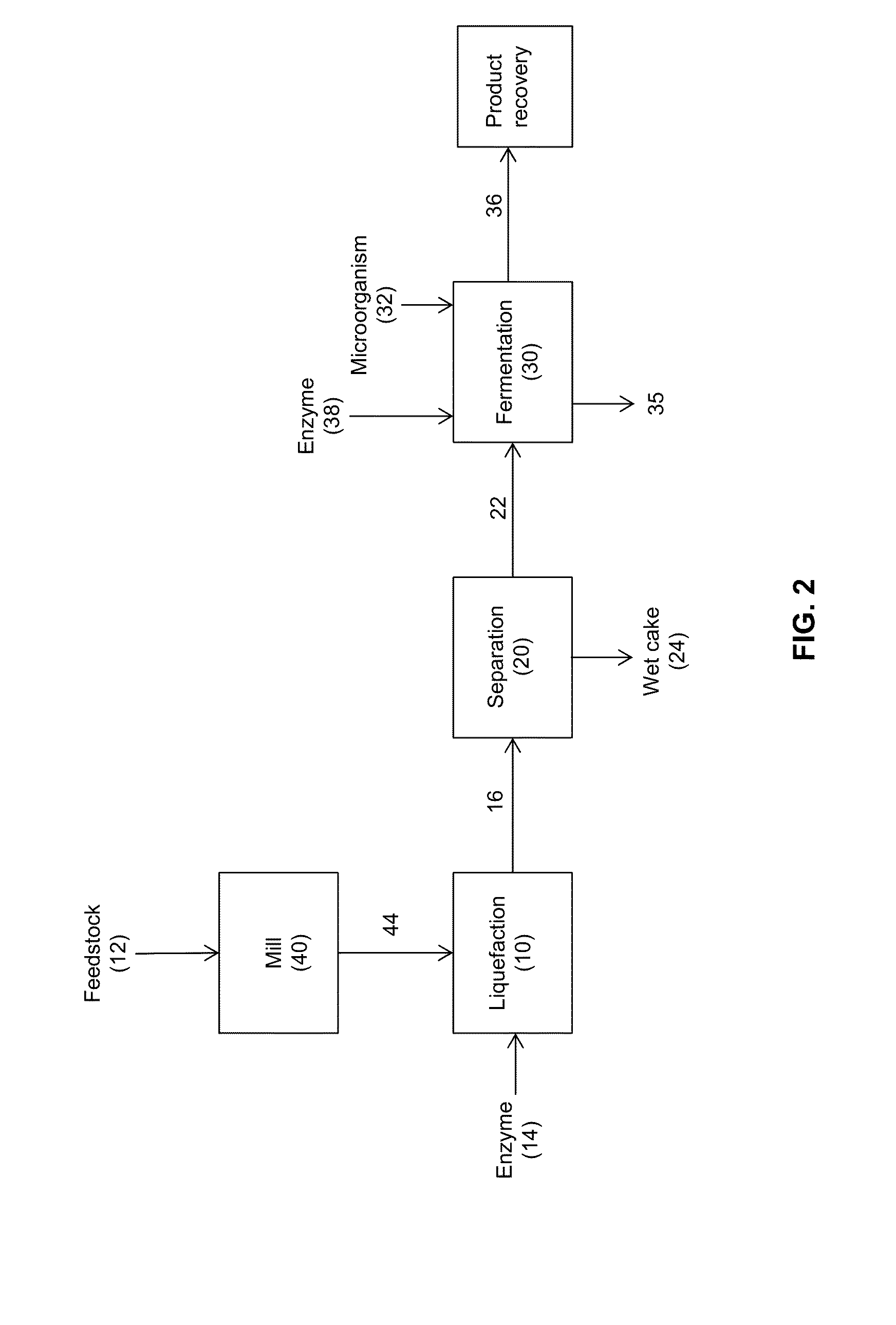

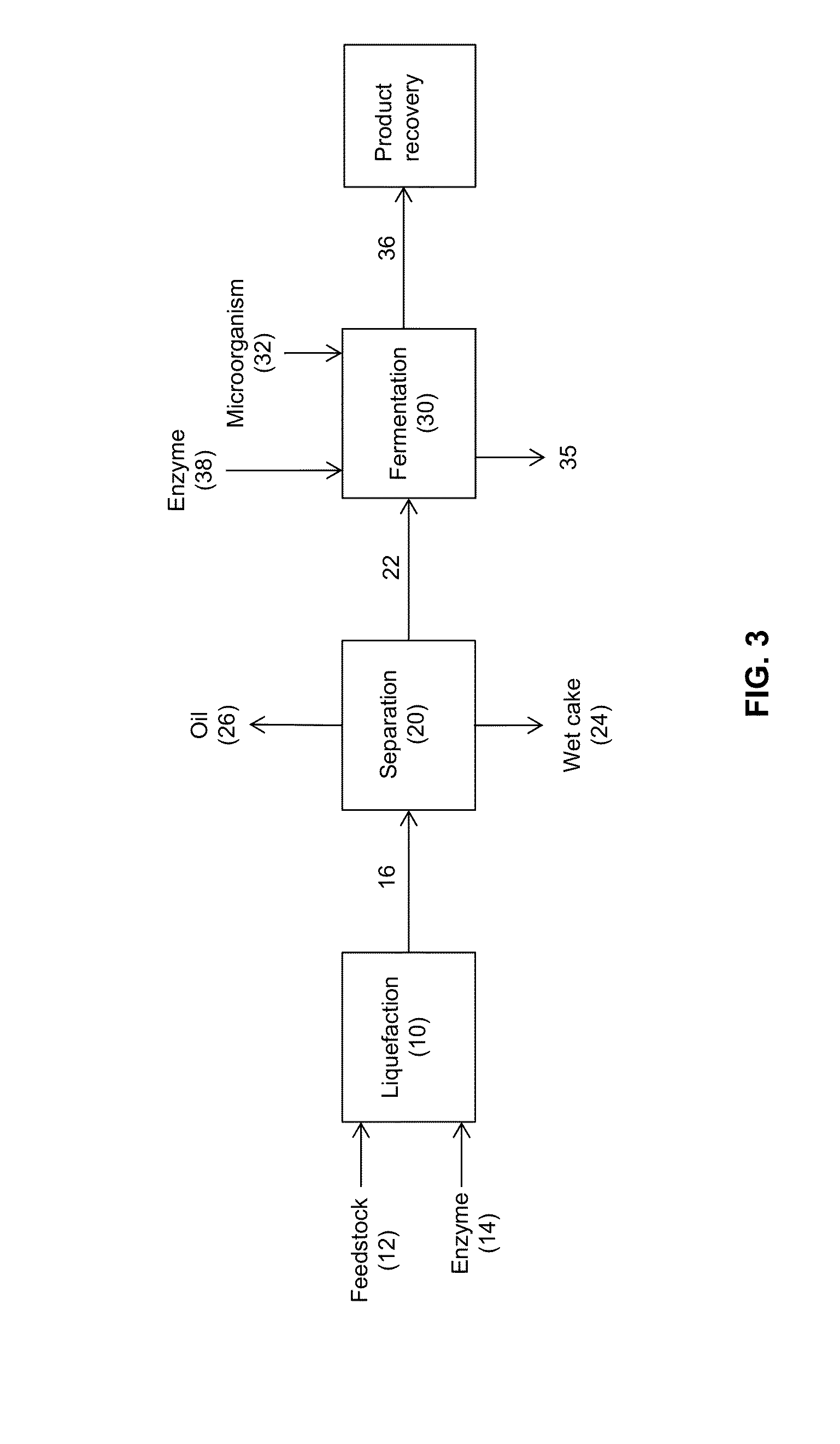

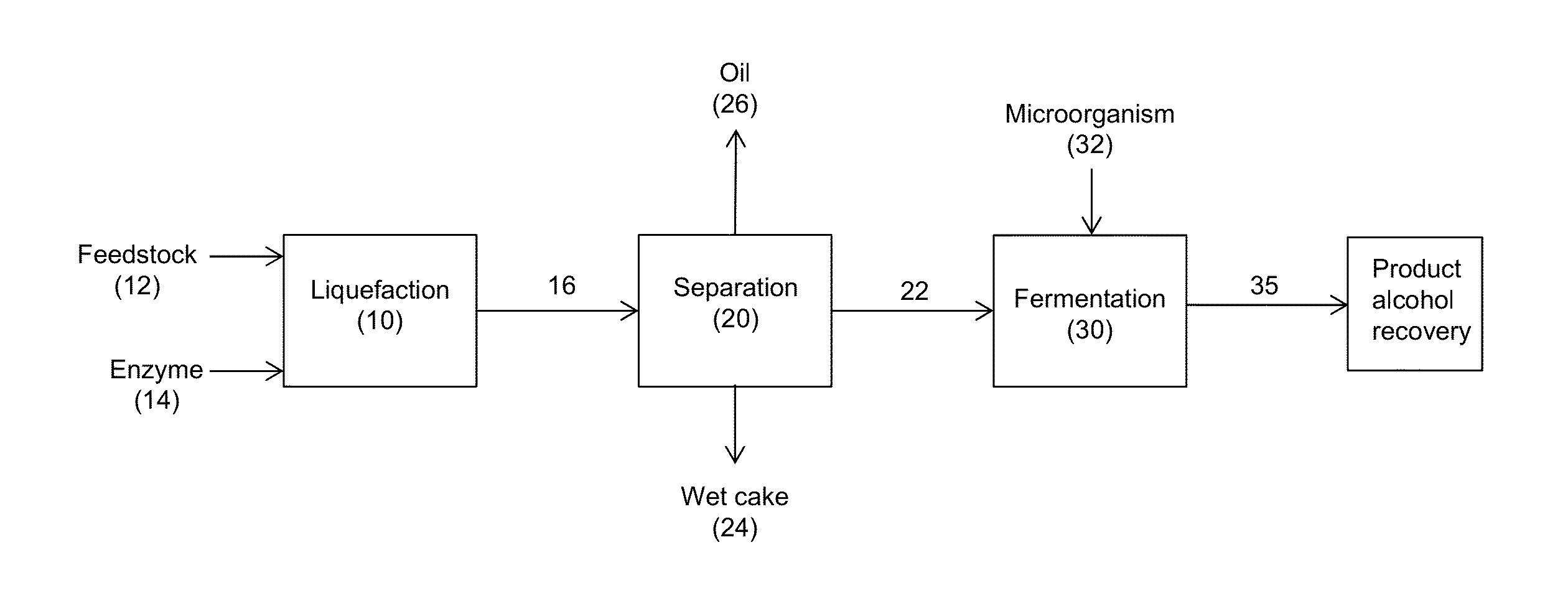

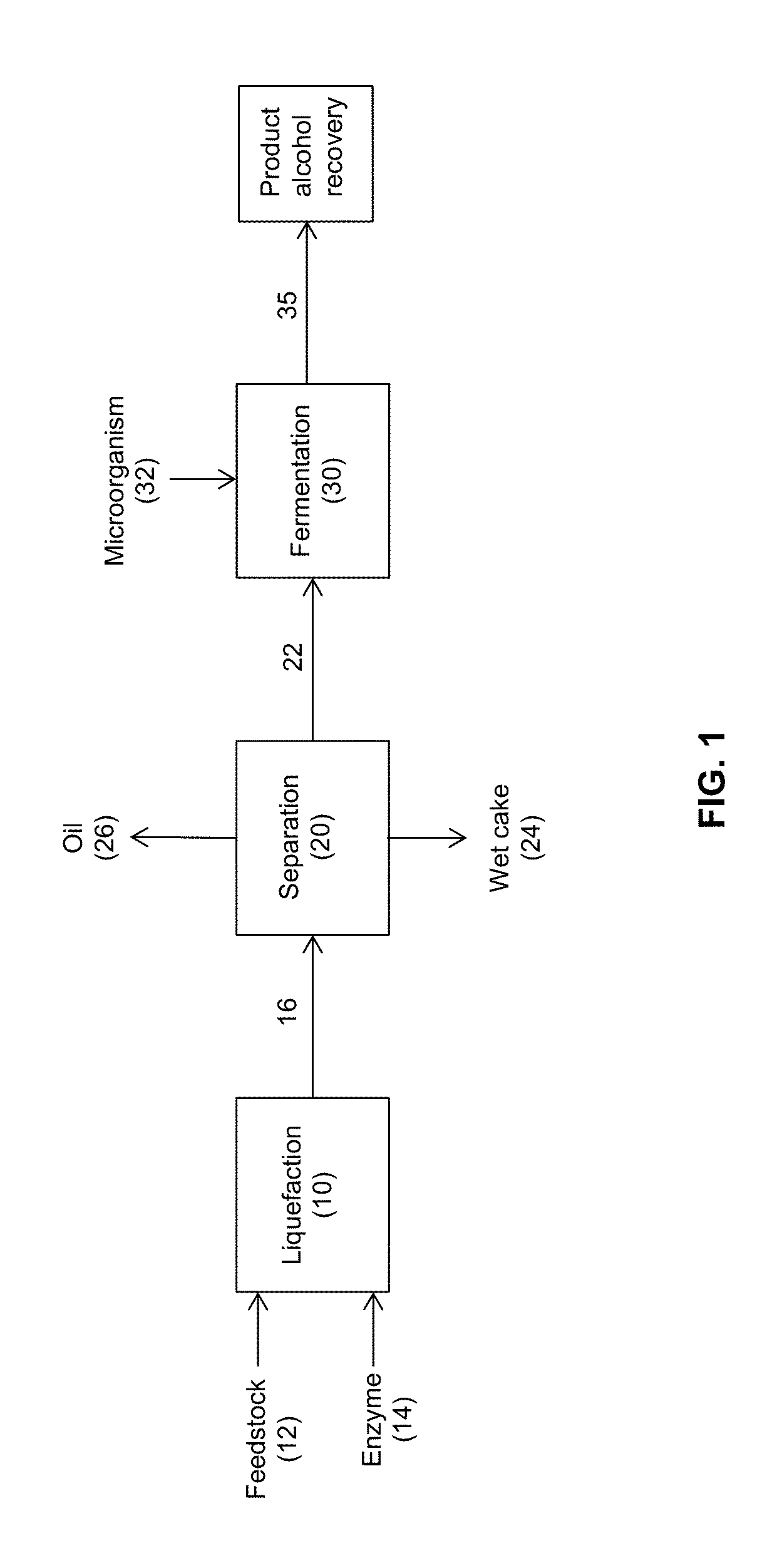

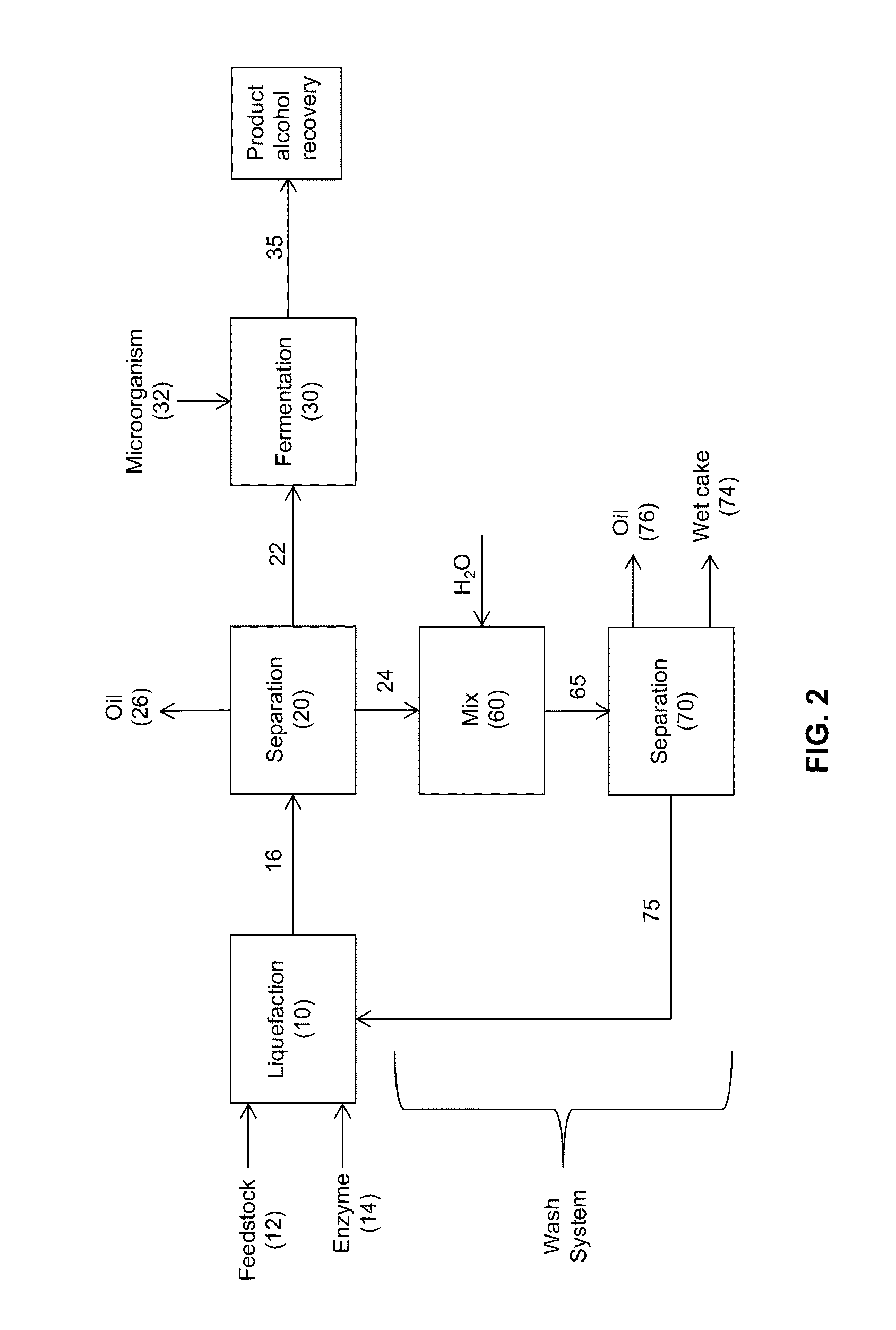

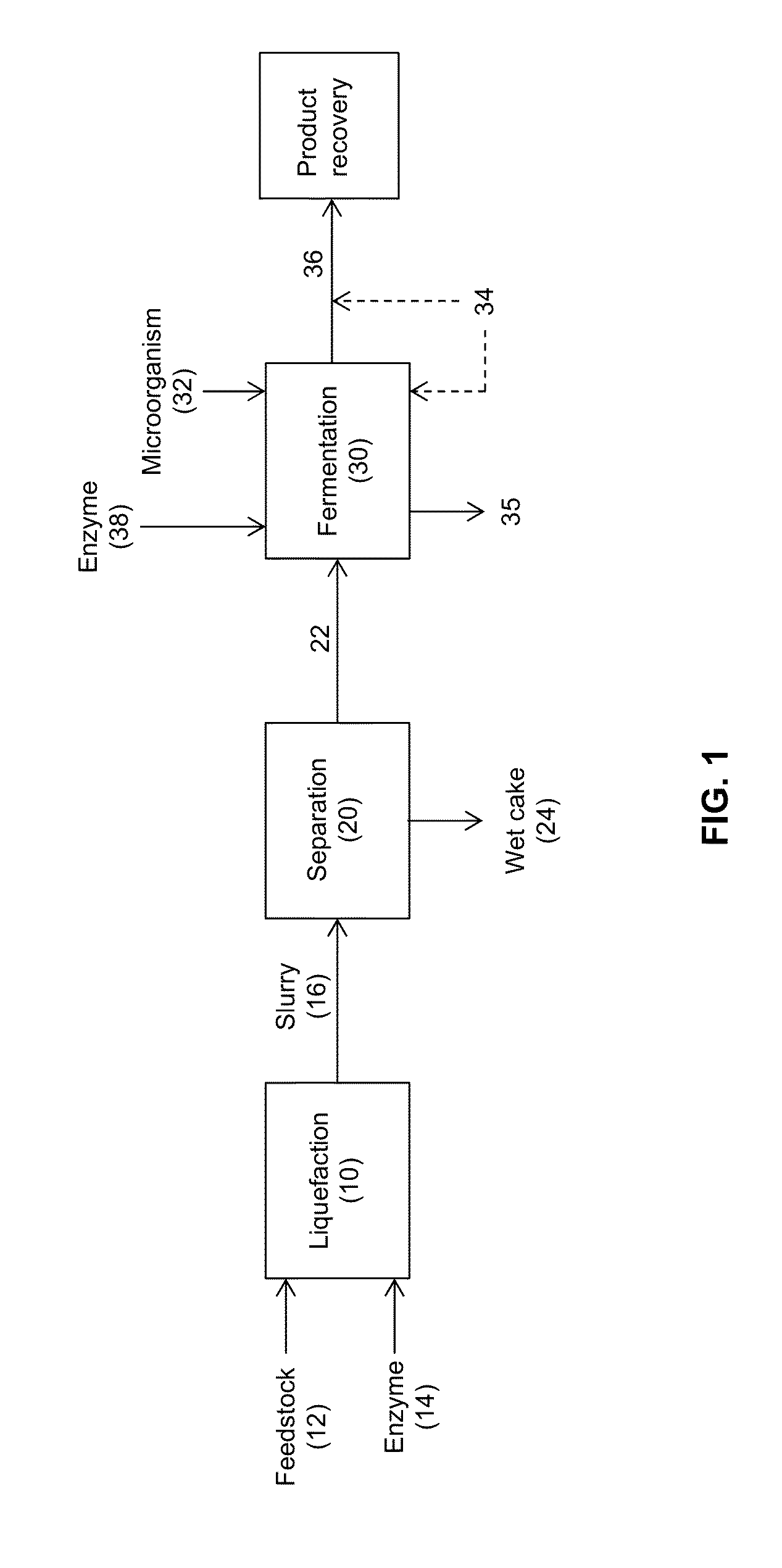

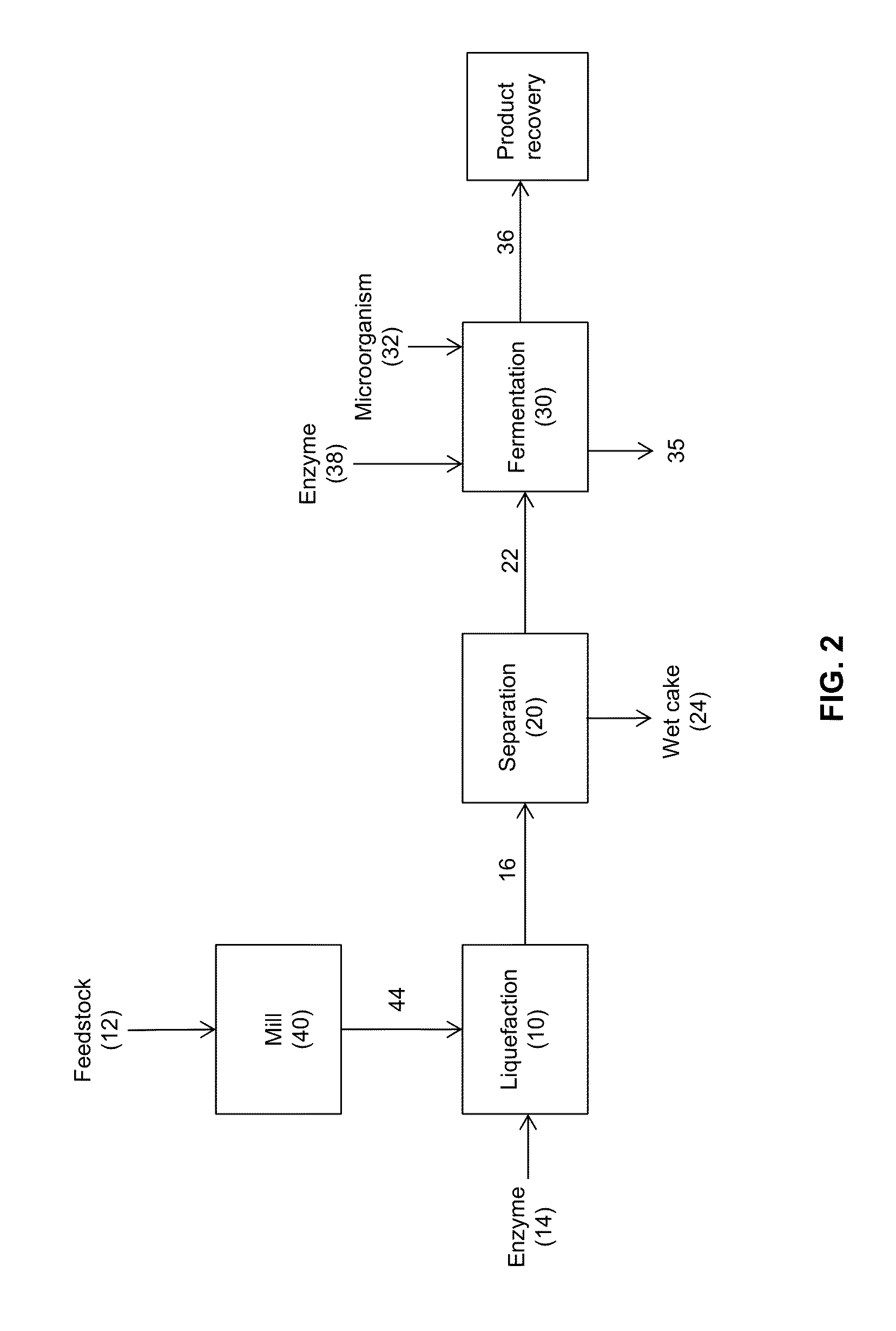

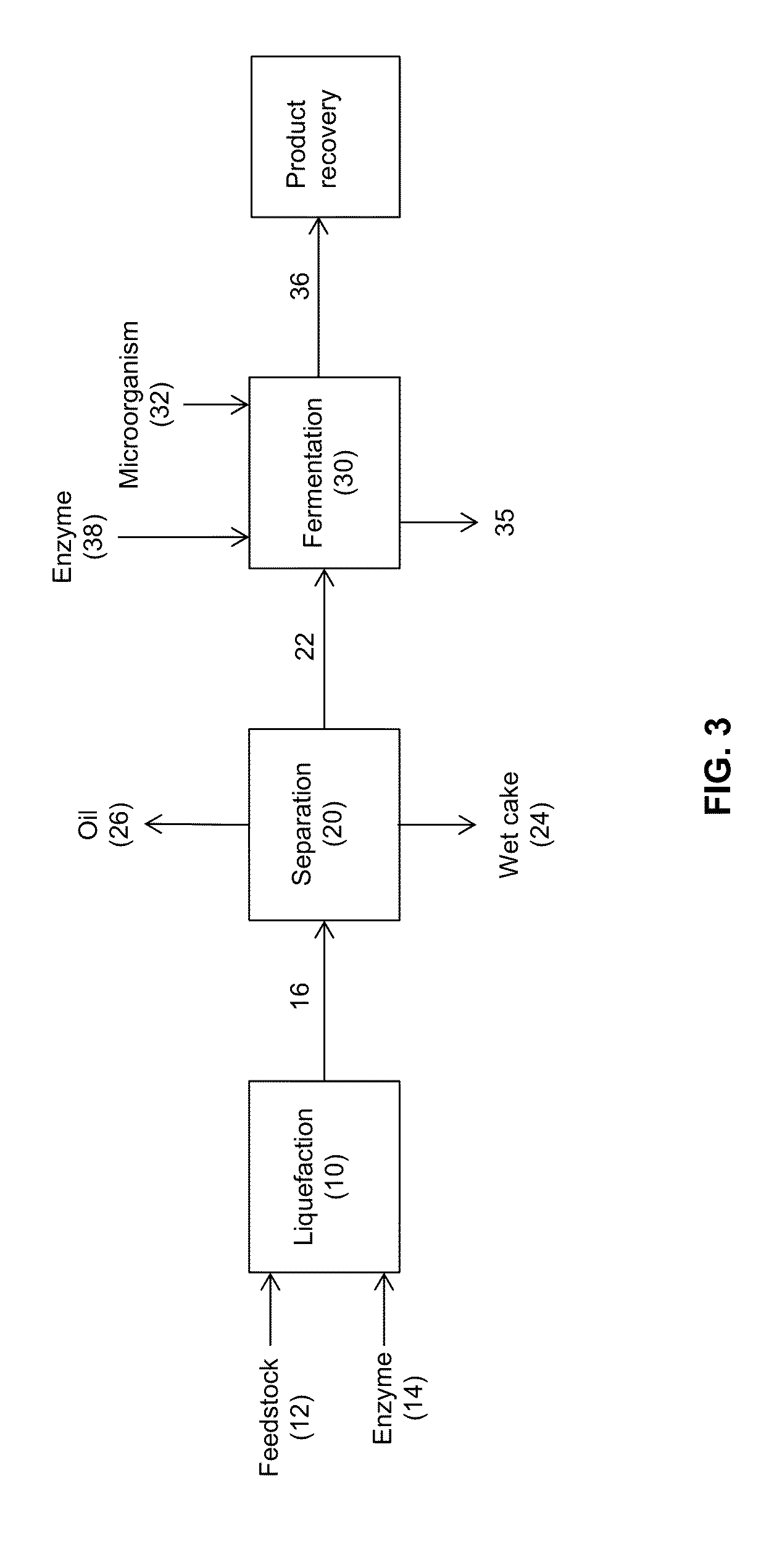

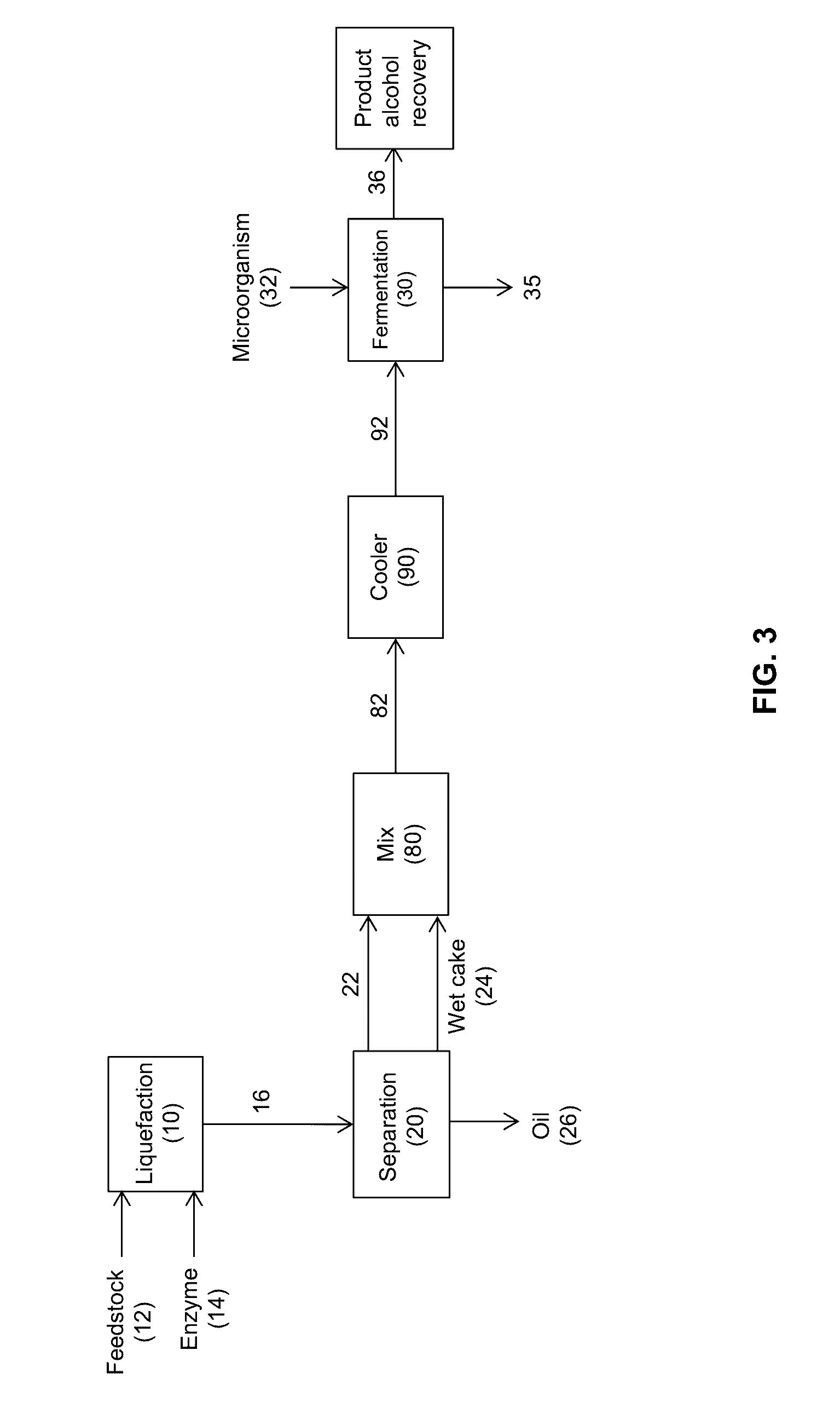

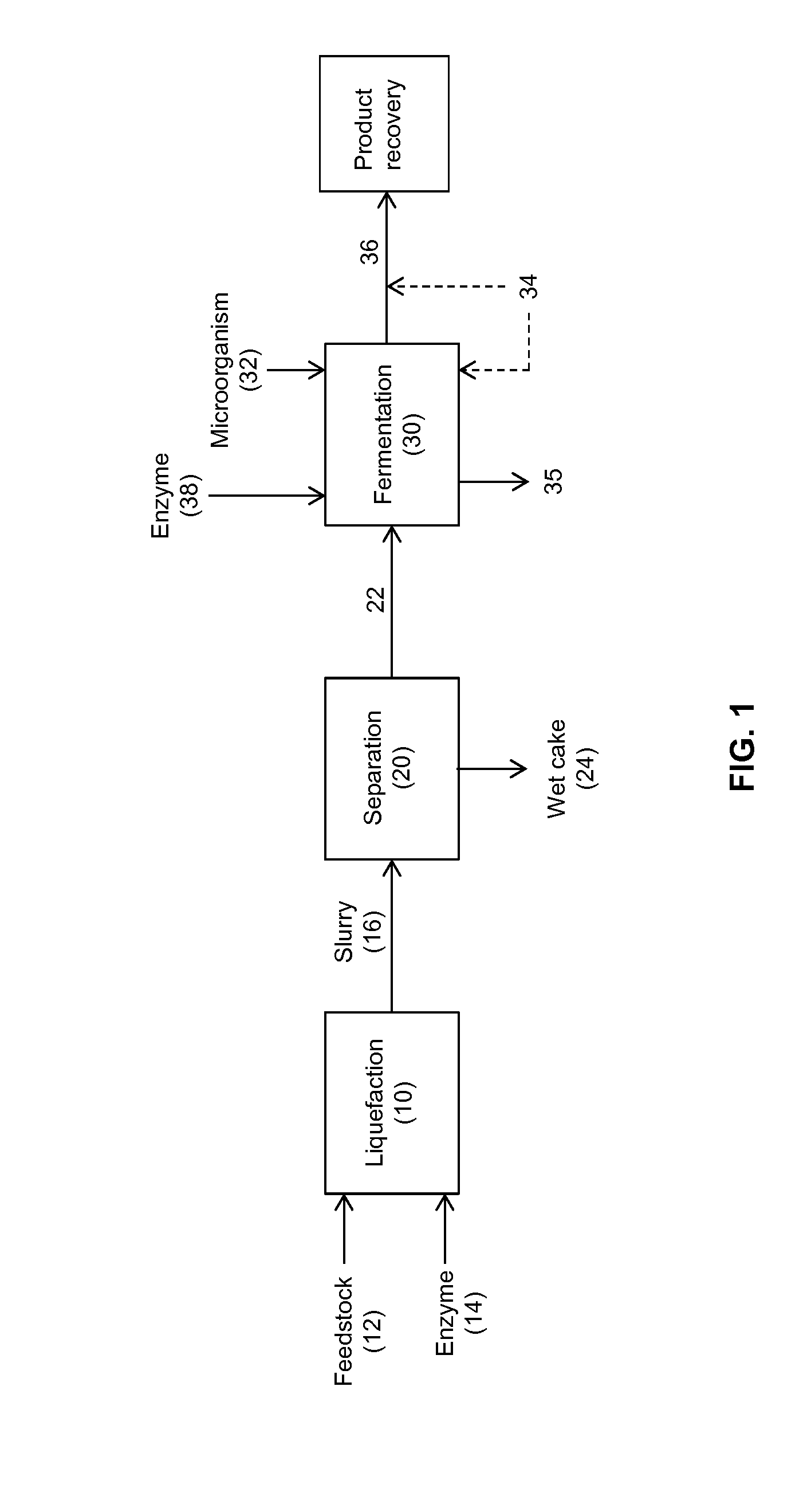

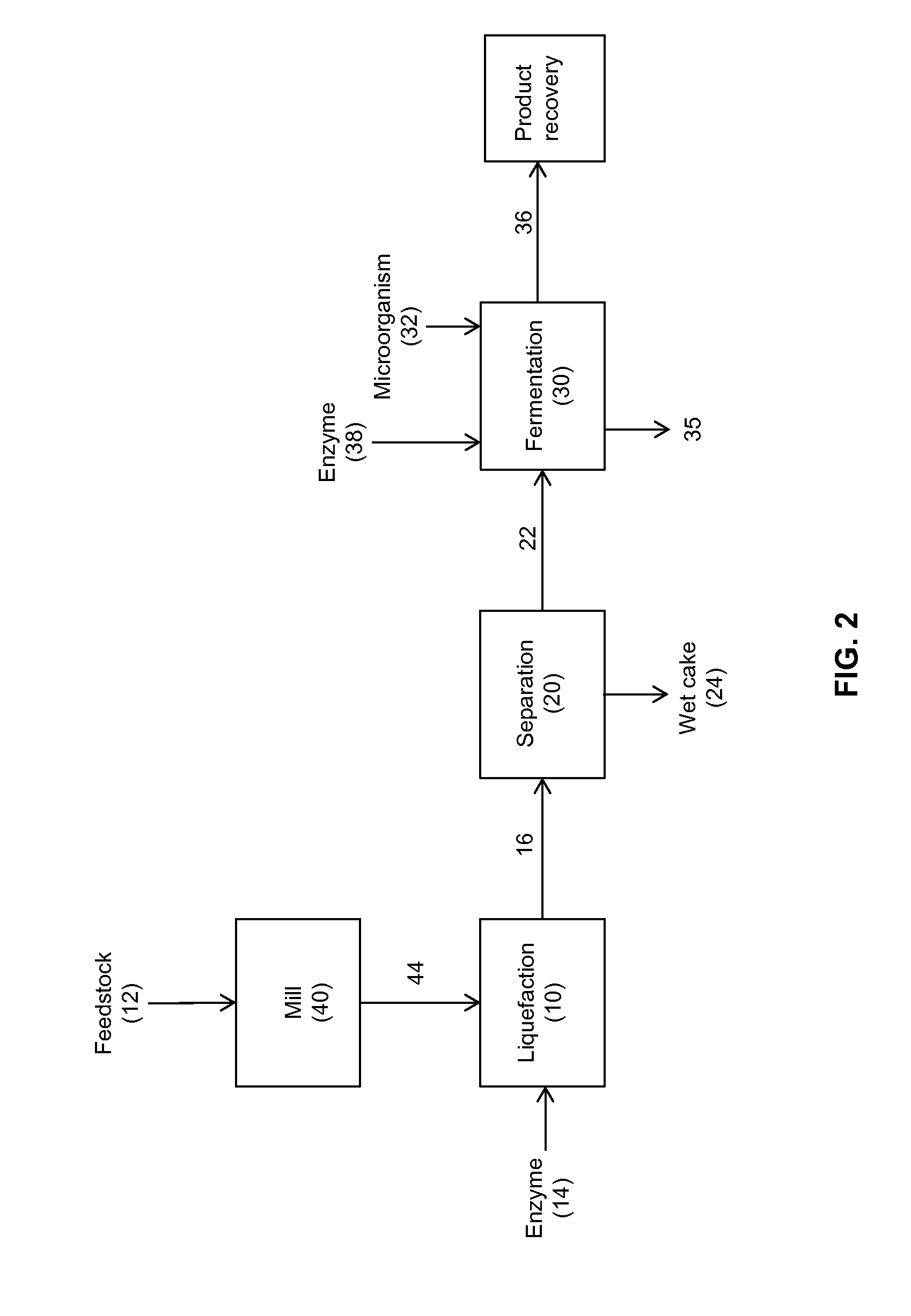

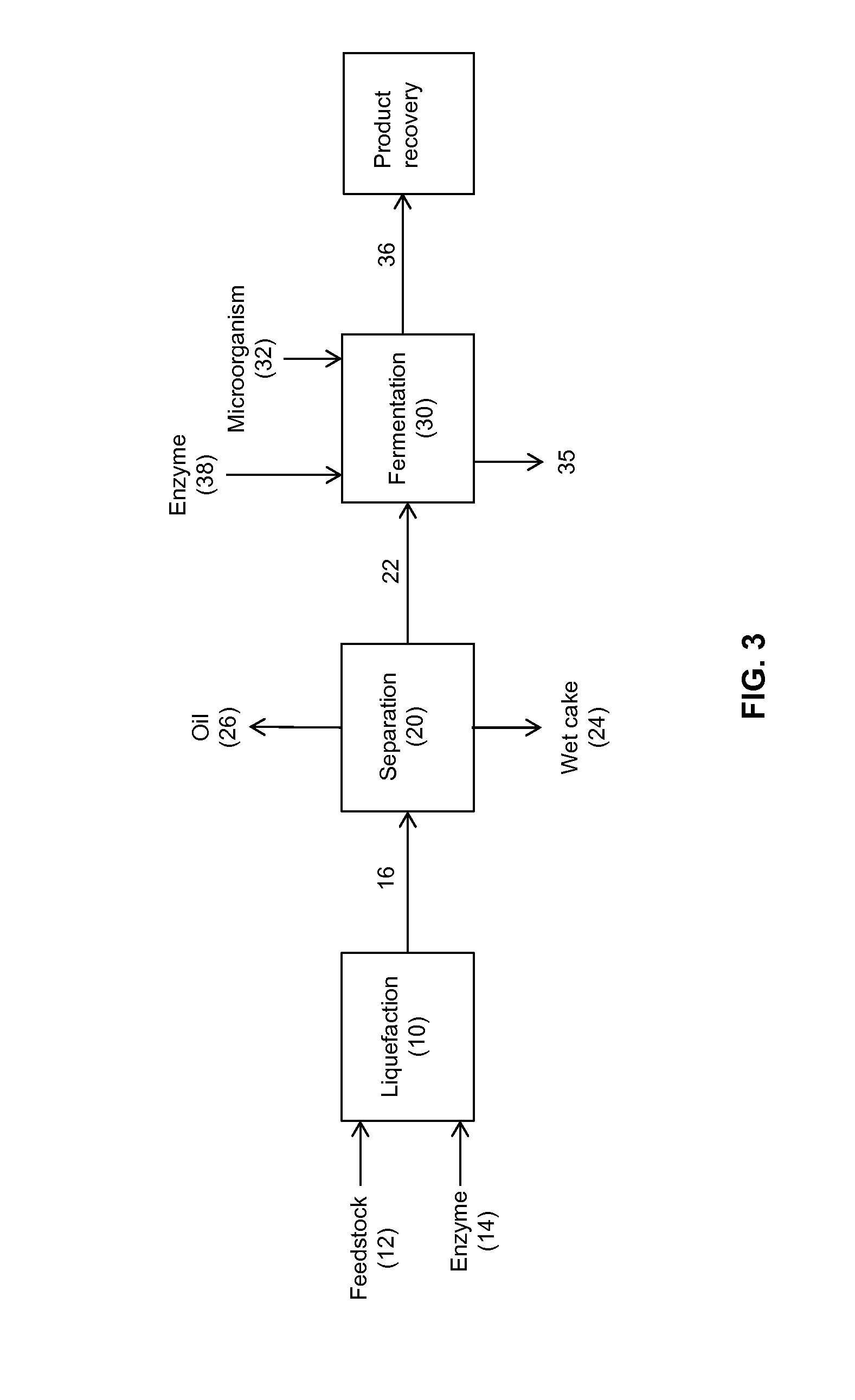

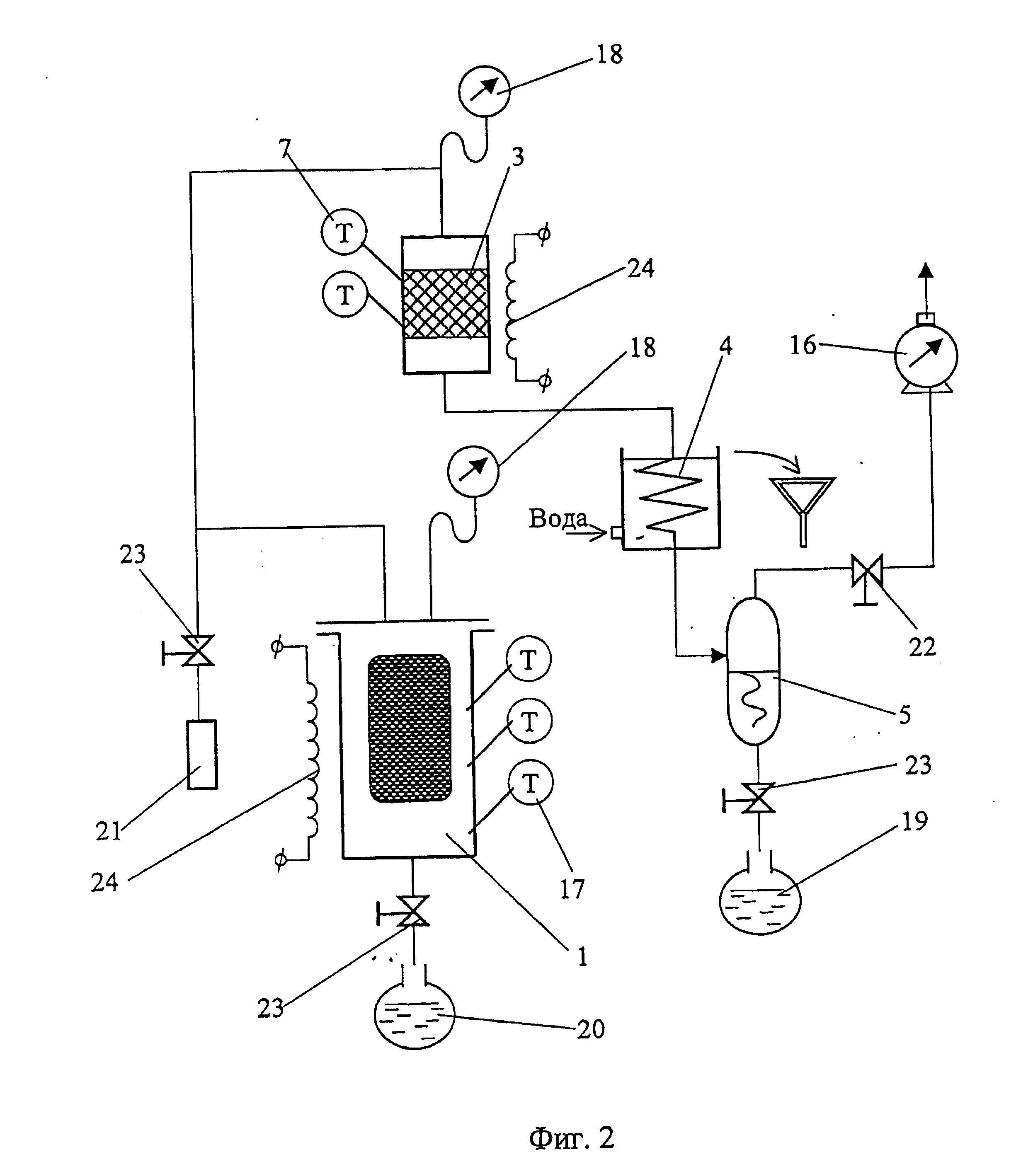

Processes and systems for the production of fermentative alcohols

InactiveUS20140024064A1Increasing biomass processing productivityImproving alcohol fermentation co-product profileBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholButanol

The present invention relates to processes and systems for the production of fermentative alcohols such as ethanol and butanol. The present invention also provides methods for separating feed stream components for improved biomass processing and productivity.

Owner:BUTAMAXTM ADVANCED BIOFUELS

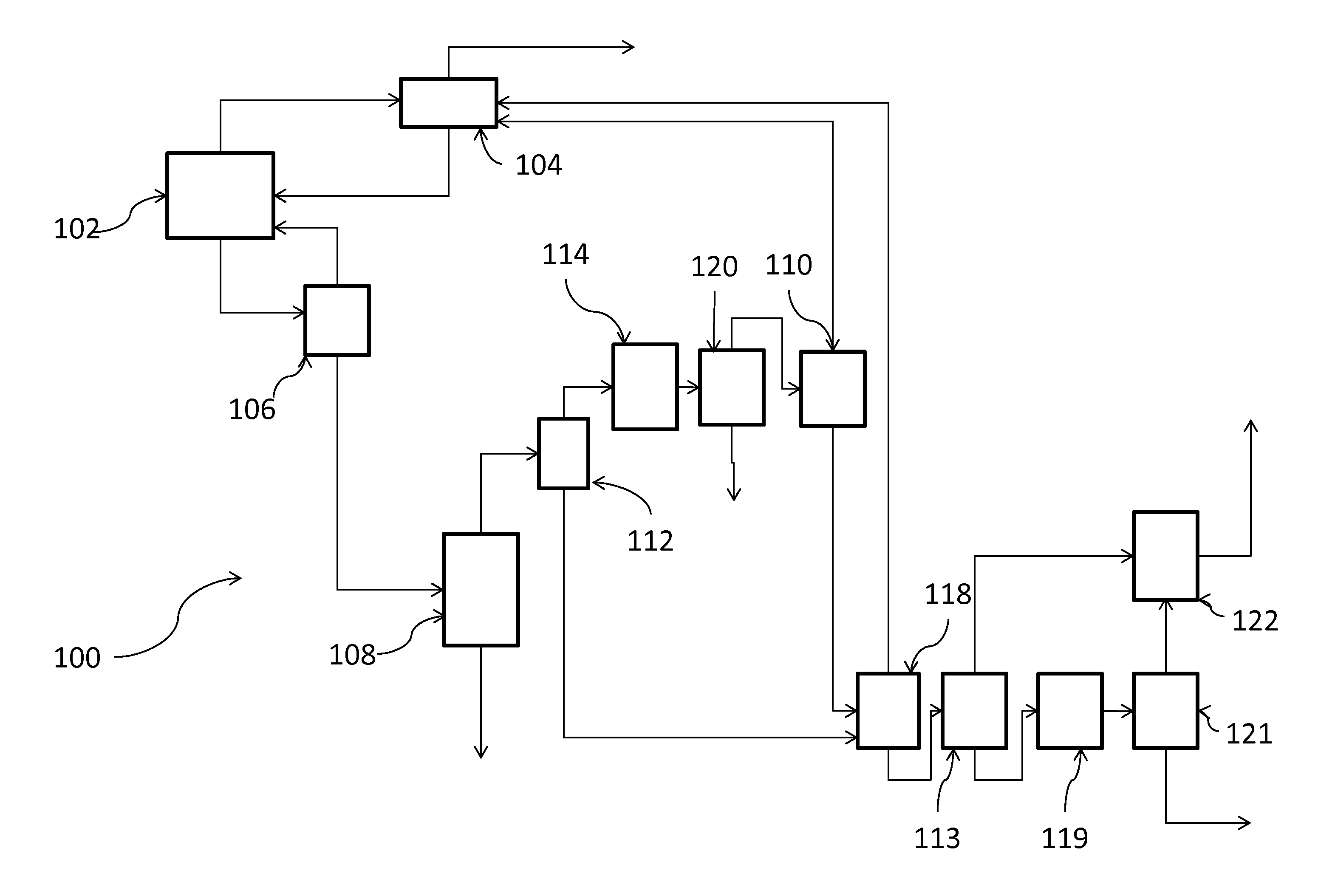

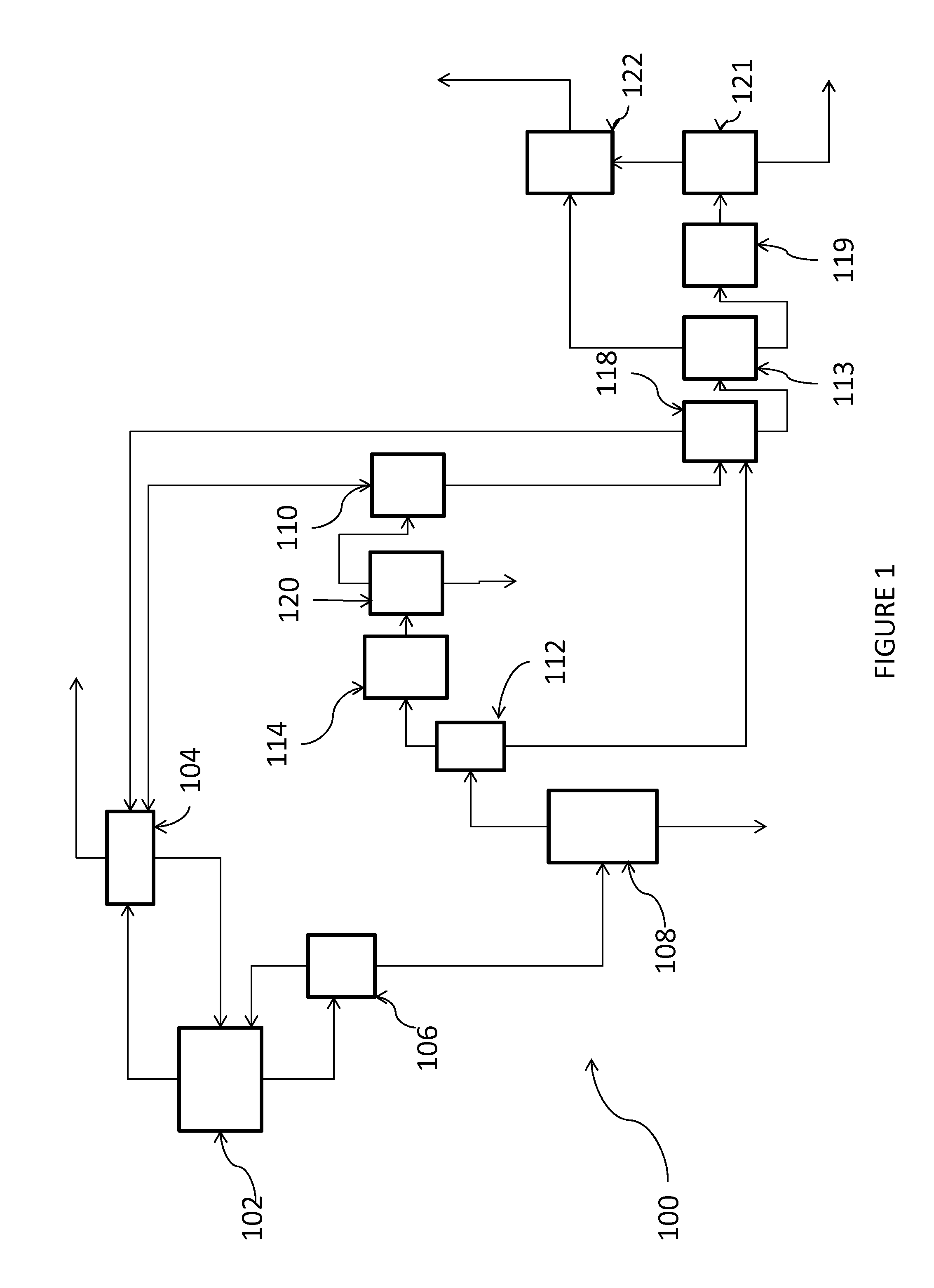

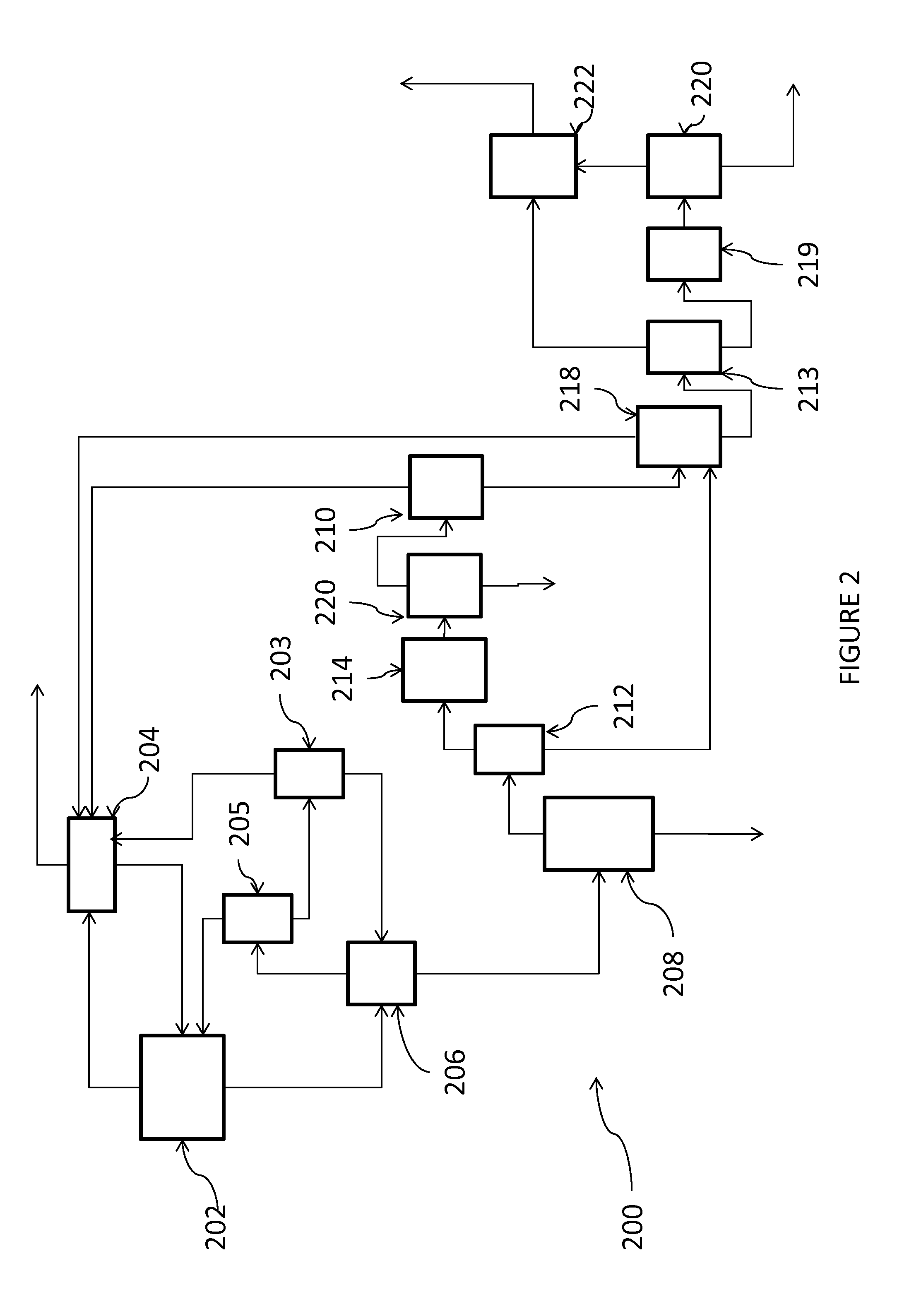

Processes and systems for the production of fermentation products

InactiveUS20140106419A1Improve machining productivityEnhance the imageBiological substance pretreatmentsOther chemical processesBiotechnologyAlcohol

The present invention relates to processes and systems for the production of fermentation products such as alcohols. The present invention also provides methods for separating feed stream components for improved biomass processing and productivity.

Owner:BUTAMAXTM ADVANCED BIOFUELS

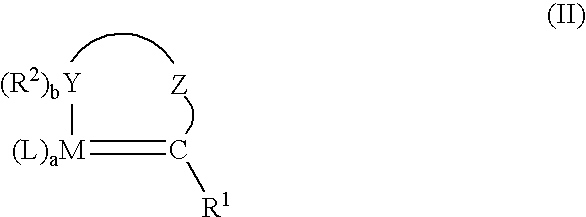

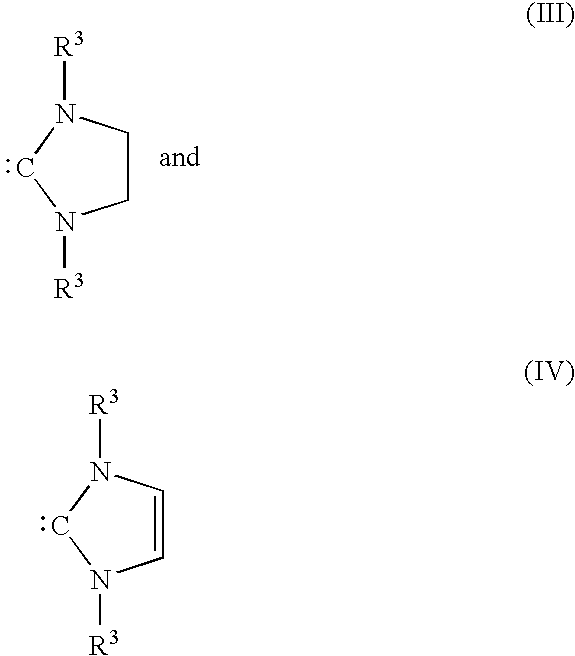

Membrane Separation Of A Metathesis Reaction Mixture

InactiveUS20080103346A1Reduces possibility of undesirableImprove efficiencySemi-permeable membranesCatalystsPolymer scienceCatalyst degradation

A process for separating a homogeneous metathesis catalyst and, optionally, one or more homogeneous metathesis catalyst degradation products from a metathesis reaction mixture containing in addition to said metathesis catalyst and said metathesis catalyst degradation product(s), one or more olefin metathesis products, one or more unconverted reactant olefins, and optionally, a solvent. The process involves contacting the metathesis reaction mixture with a nanofiltration membrane, such as a polyimide nanofiltration membrane, so as to recover a permeate containing a substantial portion of the olefin reaction products, the unconverted reactant olefins, and optional solvent, and a retentate containing the metathesis catalyst, and optionally, metathesis catalyst degradation product(s). In another aspect, this invention pertains to a continuous metathesis reaction-catalyst separation process, preferably, conducted in a nanofiltration membrane reactor.

Owner:DOW GLOBAL TECH LLC

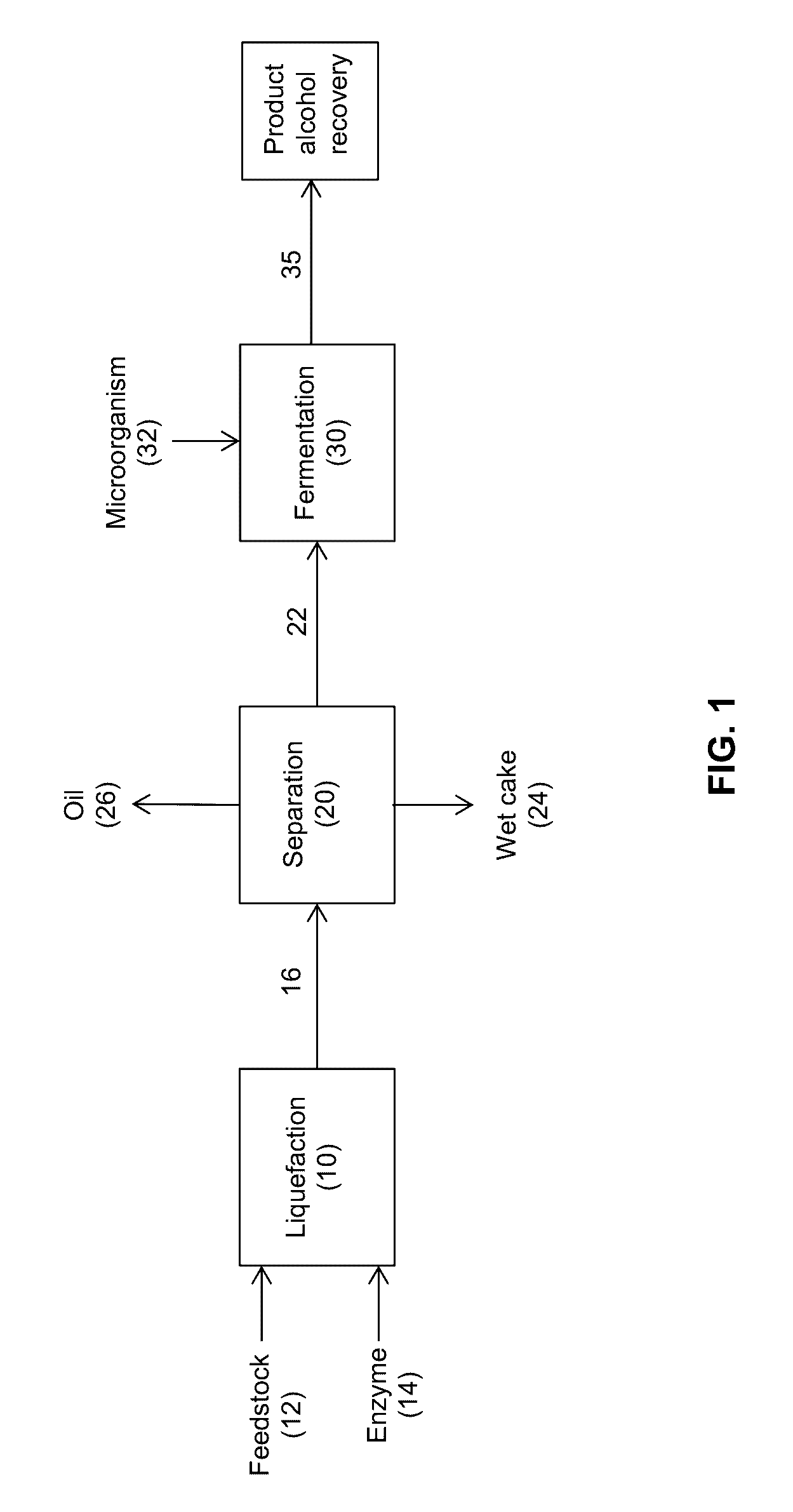

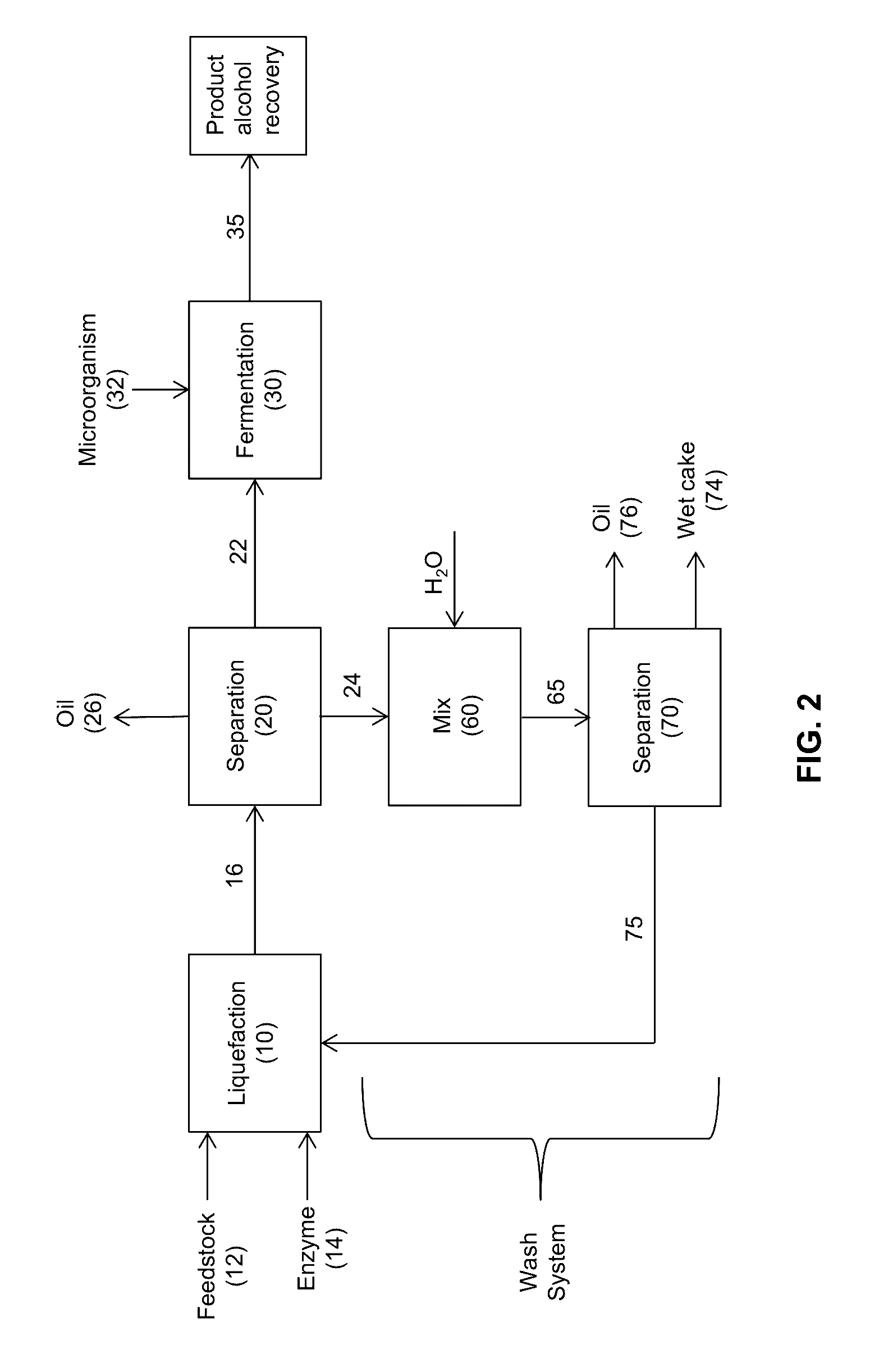

Processes and systems for the production of alcohols

ActiveUS20140273127A1Increasing biomass processing productivityEnhance the imageBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholButanol

The present invention relates to processes and systems for the production of fermentative products such as ethanol and butanol. The present invention also provides methods for separating feed stream components for improved biomass processing productivity.

Owner:GEVO INC

Oxidative Halogenation of C1 Hydrocarbons to Halogenated C1 Hydrocarbons

InactiveUS20080275279A1High selectivityReduce safety concernsHydrocarbon from carbon oxidesHydrocarbonsHalomethaneHalogen

An oxidative halogenation process involving contacting methane, a C1 halogenated hydrocarbon, or a mixture thereof with a source of halogen and a source of oxygen, at a molar ratio of reactant hydrocarbon to source of halogen in a feed to the reactor greater than 23 / 1, and / or at a molar ratio of reactant hydrocarbon to source of oxygen in a feed to the reactor greater than about 46 / 1; in the presence of a rare earth halide or rare earth oxyhalide catalyst, to produce a halogenated C1 product having at least one more halogen as compared with the C1 reactant hydrocarbon, preferably, methyl chloride. The process can be advantageously conducted to total conversion of source of halogen and source of oxygen. The process can be advantageously conducted with essentially no halogen in the feed to the reactor, by employing a separate catalyst halogenation step in a pulse, swing or circulating bed mode. The production of methyl halide can be integrated into downstream processes for manufacture of valuable commodity chemicals.

Owner:PODKOLZIN SIMON G +3

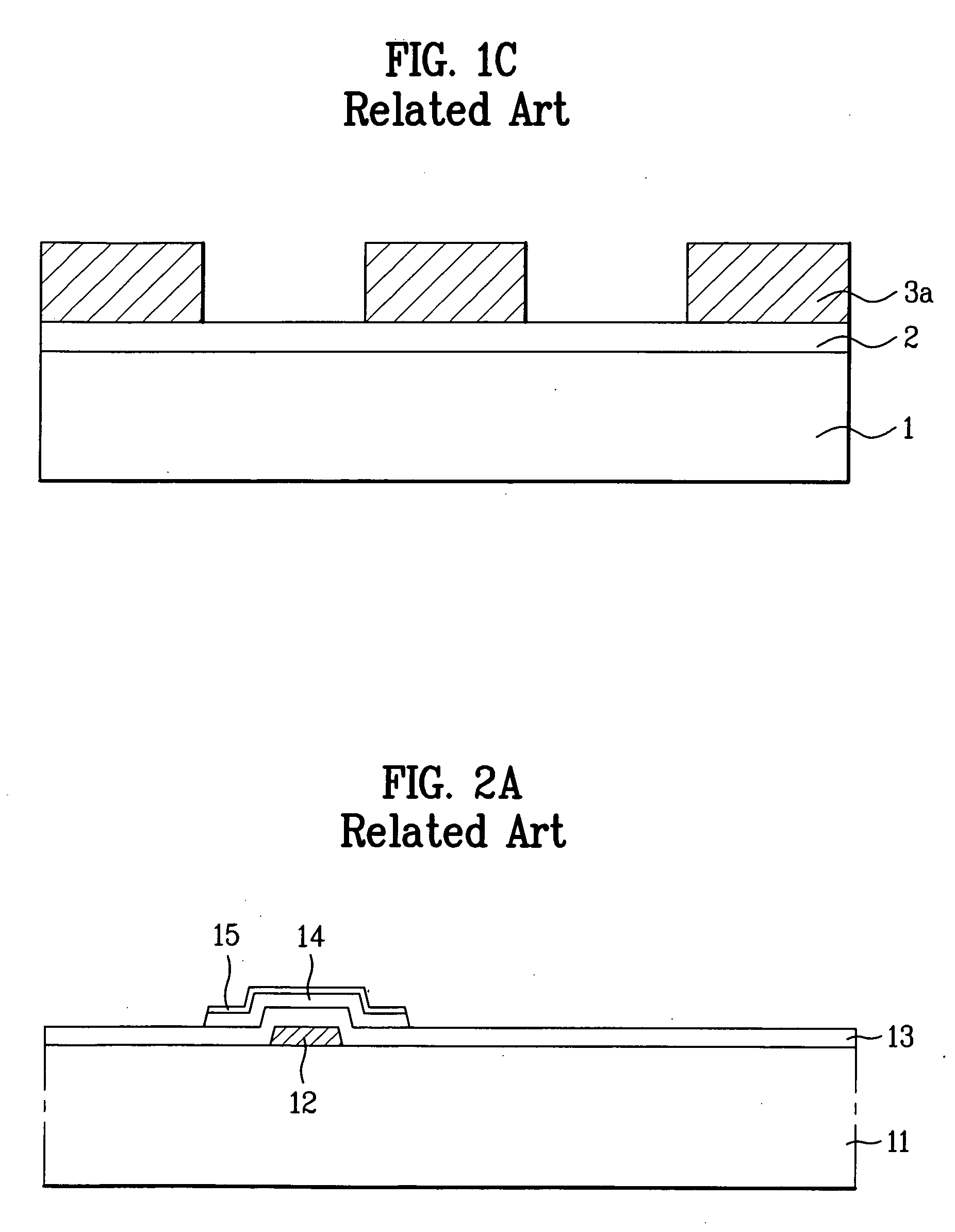

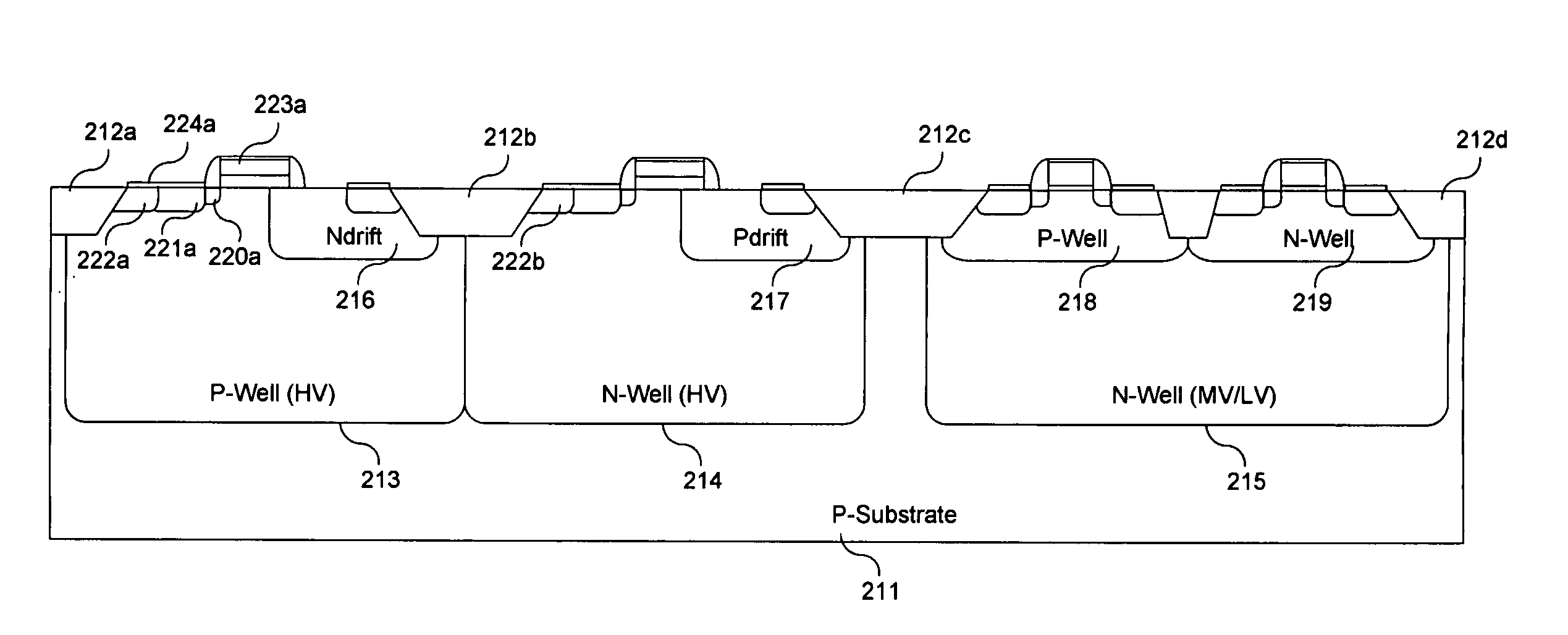

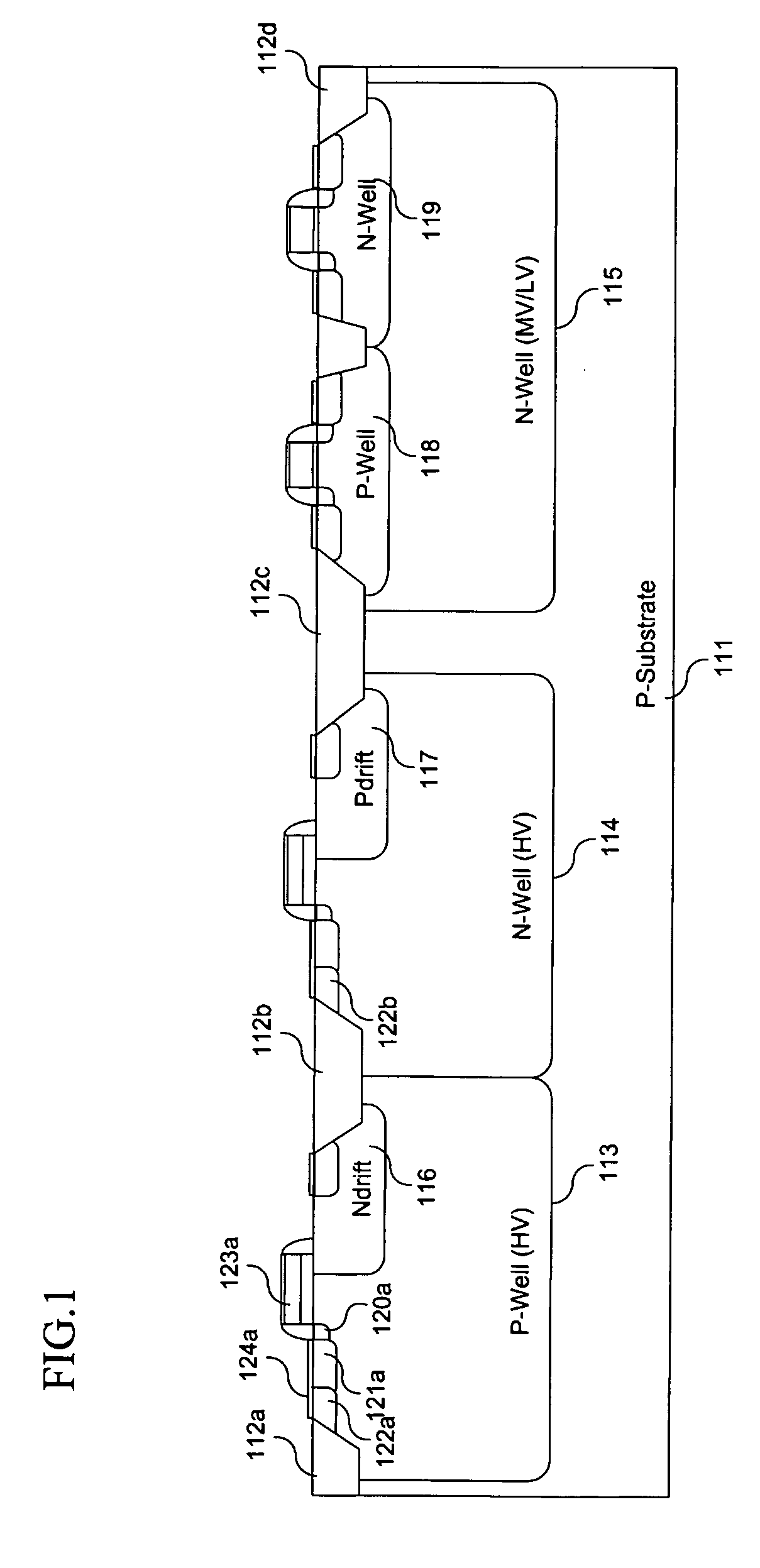

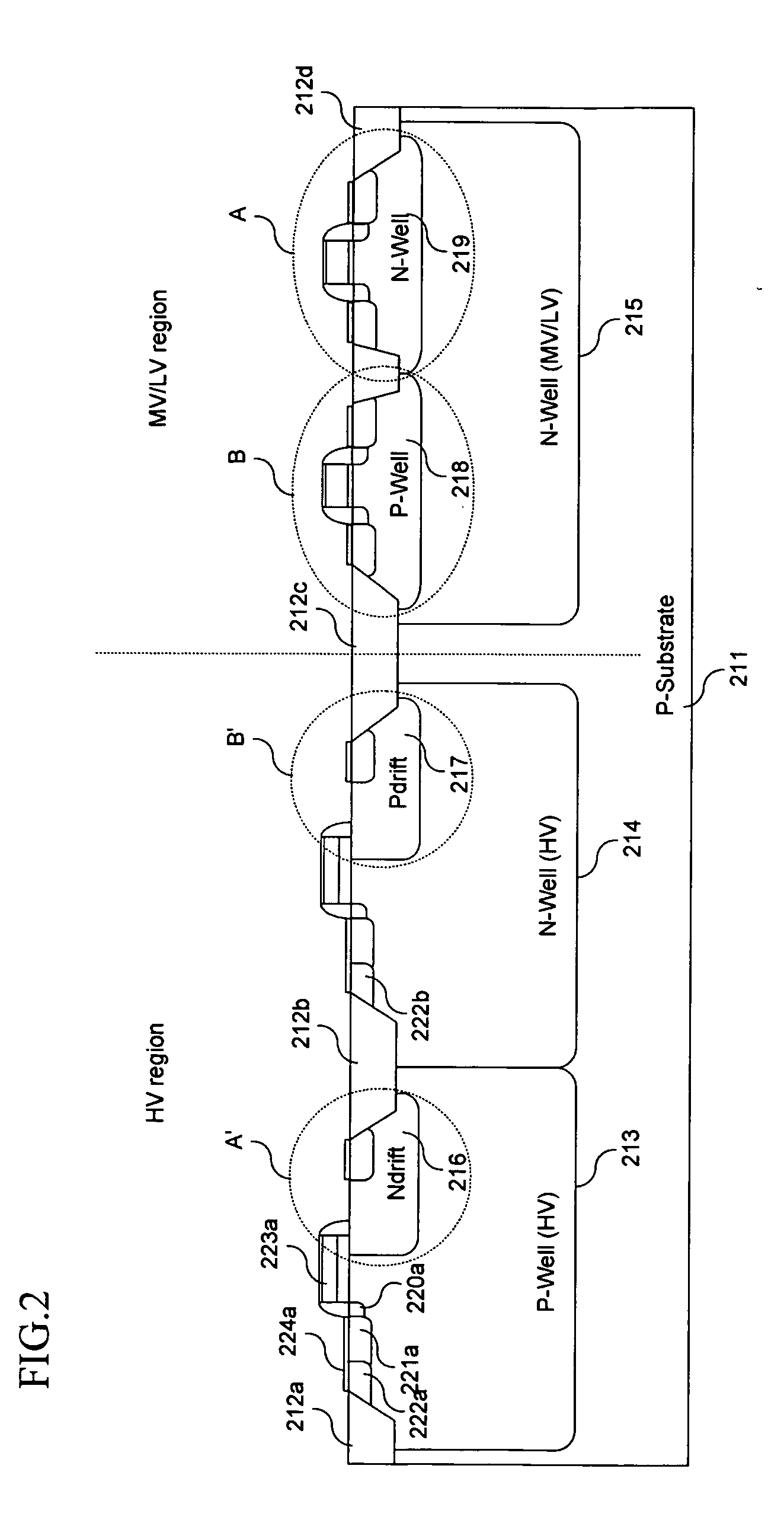

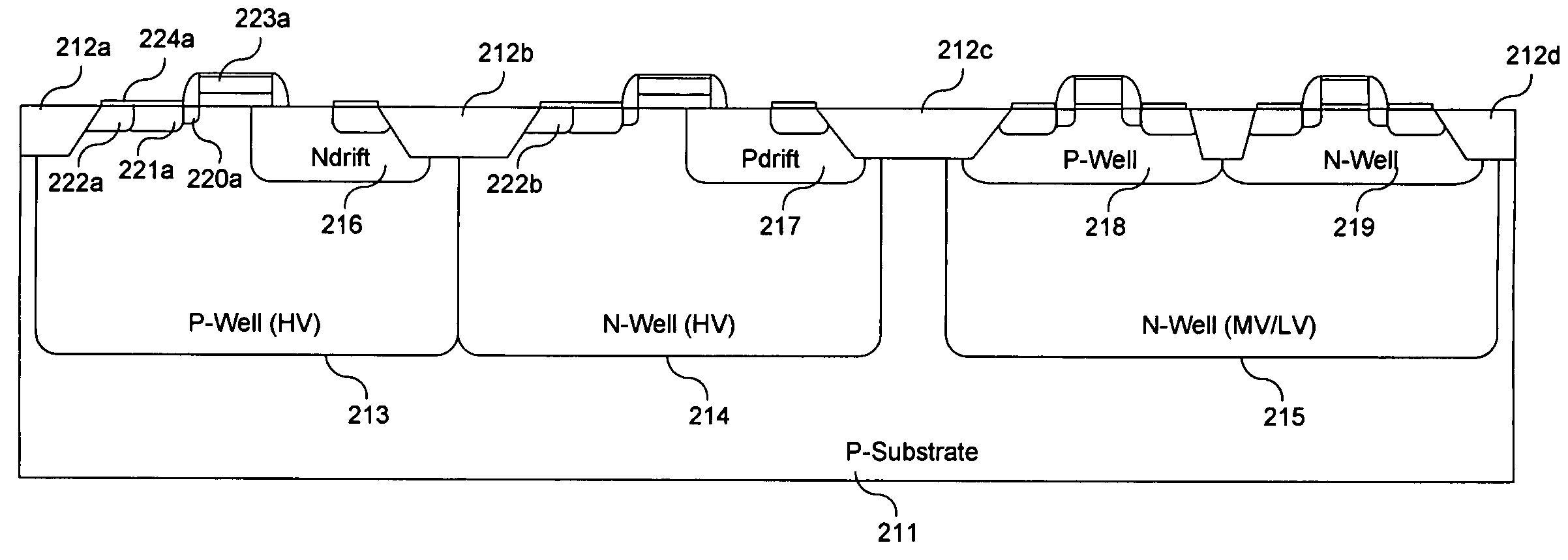

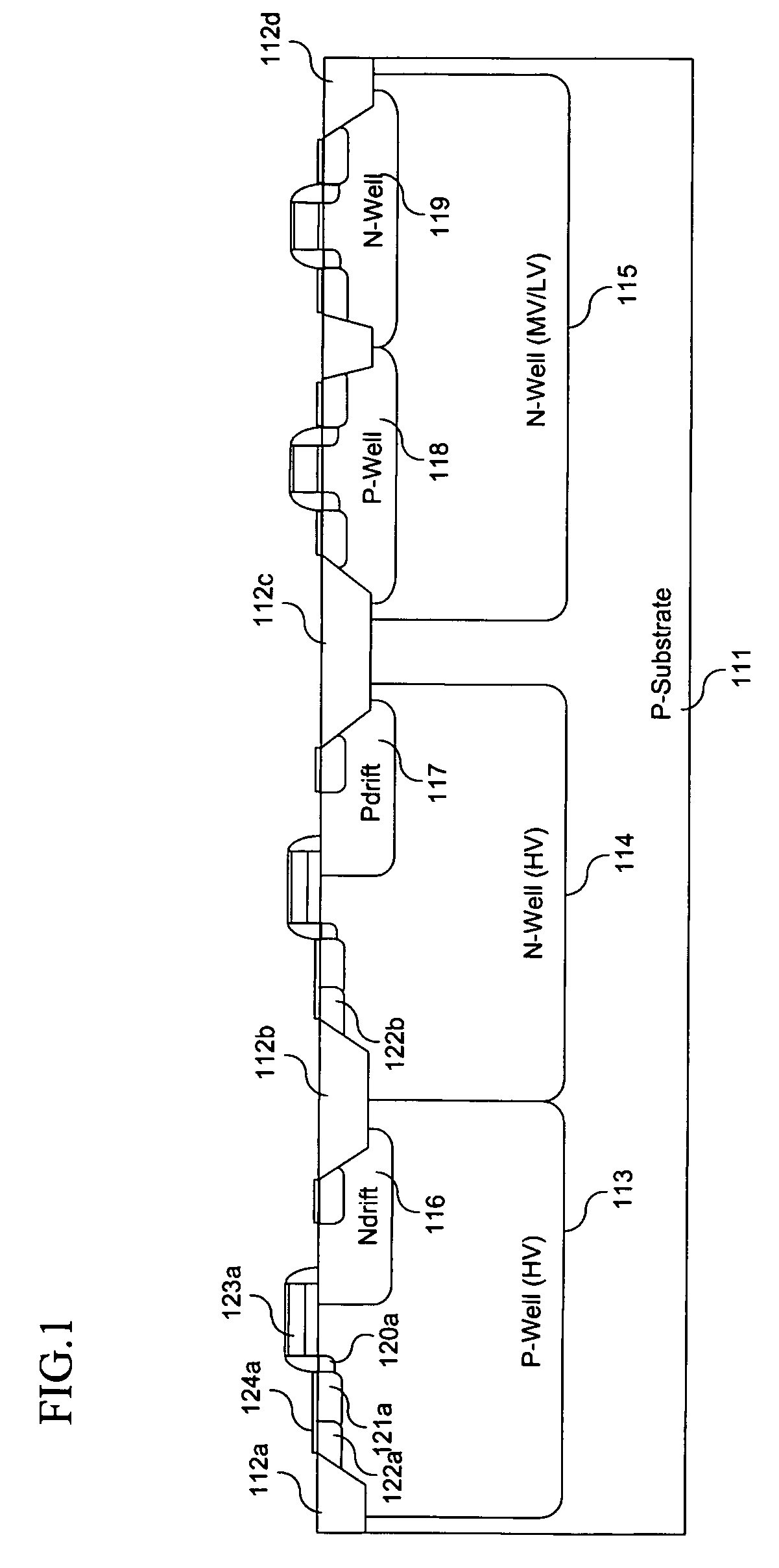

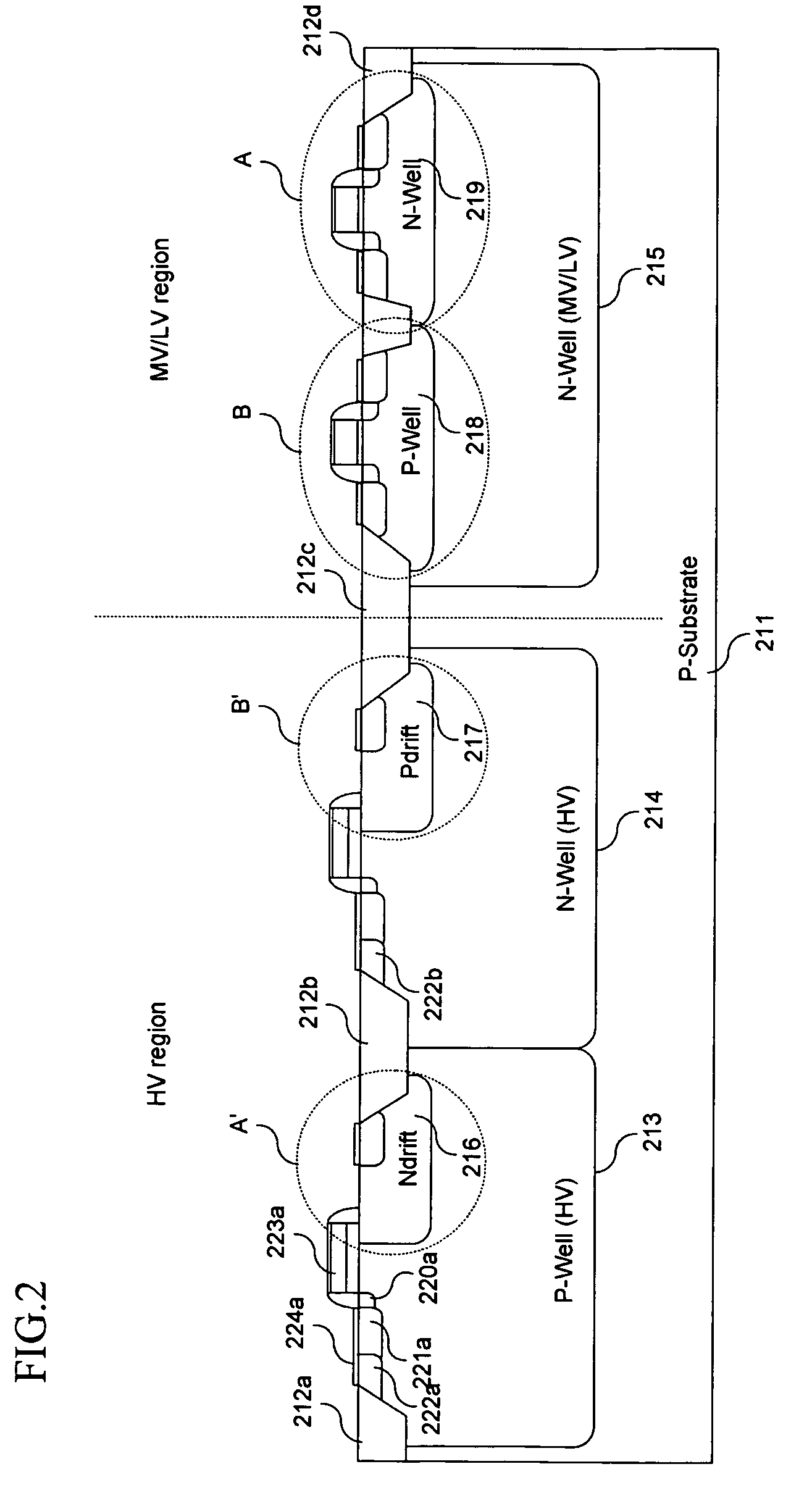

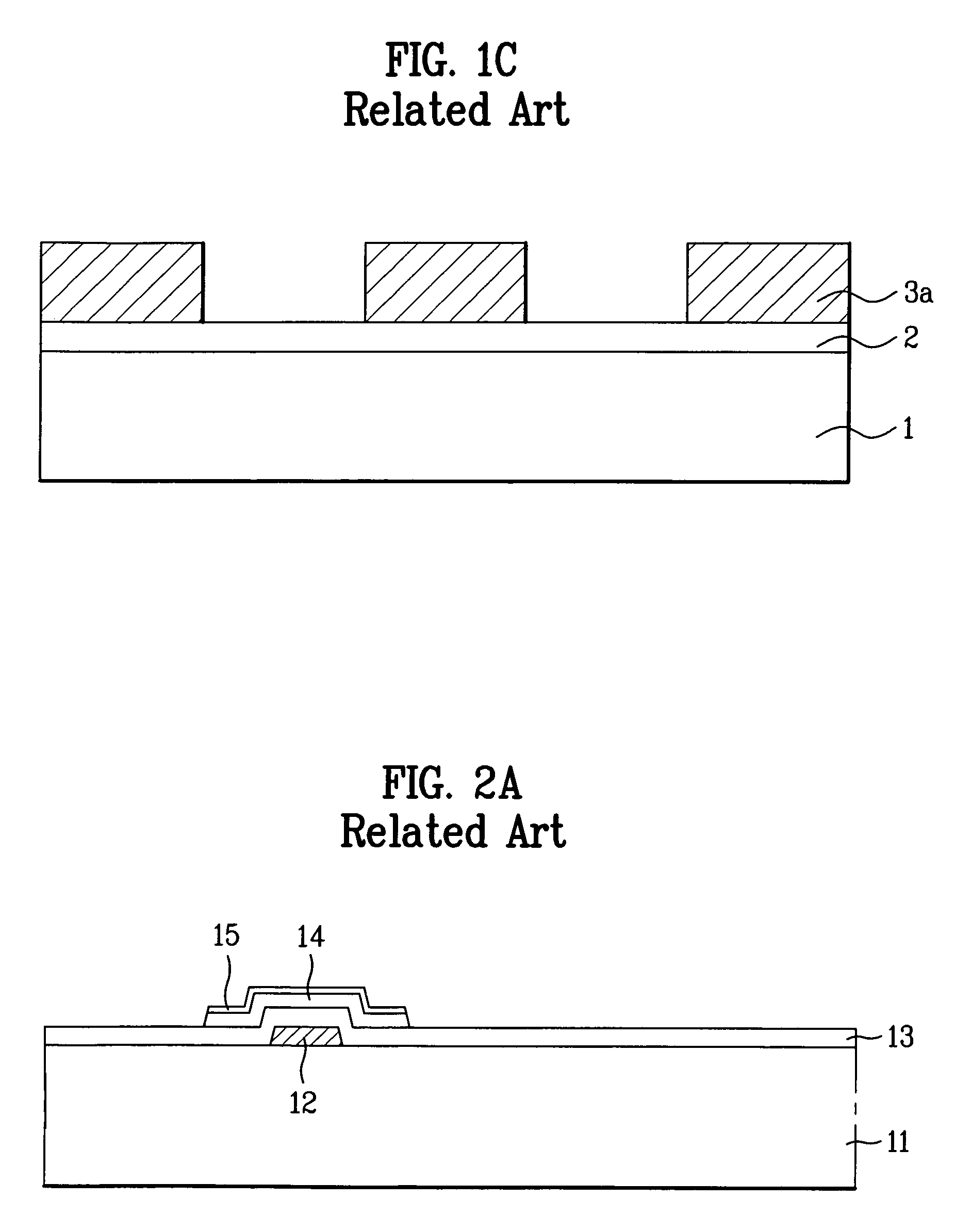

Method for manufacturing a semiconductor device

InactiveUS20060141714A1Improve machining productivityShorten production timeTransistorSolid-state devicesCMOSProduction rate

An exemplary method of manufacturing a semiconductor device according to an embodiment of the present invention includes forming a P-well and an N-well for high voltage (HV) devices and a first well in a low voltage / medium voltage (LV / MV) region for a logic device, in a semiconductor substrate; simultaneously forming a second well in the LV / MV region for a logic device and a drift region for one of the HV devices using the same mask; and respectively forming gate oxide layers on the semiconductor substrate in the HV / MV / LV regions. According to the present invention, the number of photolithography processes can be reduced by replacing or combining an additional mask for forming an extended drain region of a high voltage depletion-enhancement CMOS (DECMOS) with a mask for forming a typical well of a logic device, so productivity of the total process of the device can be enhanced.

Owner:COLUMBA TECH INC

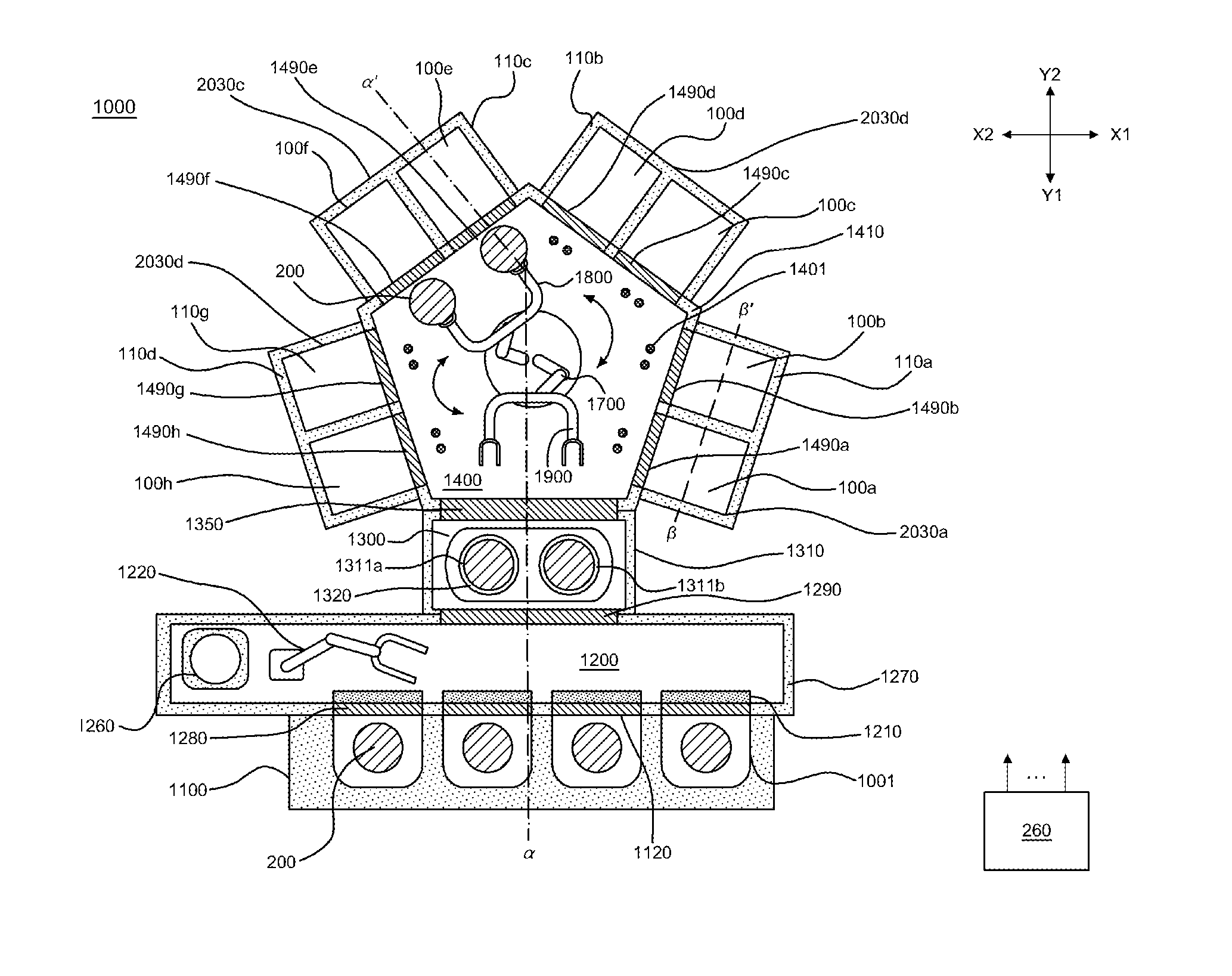

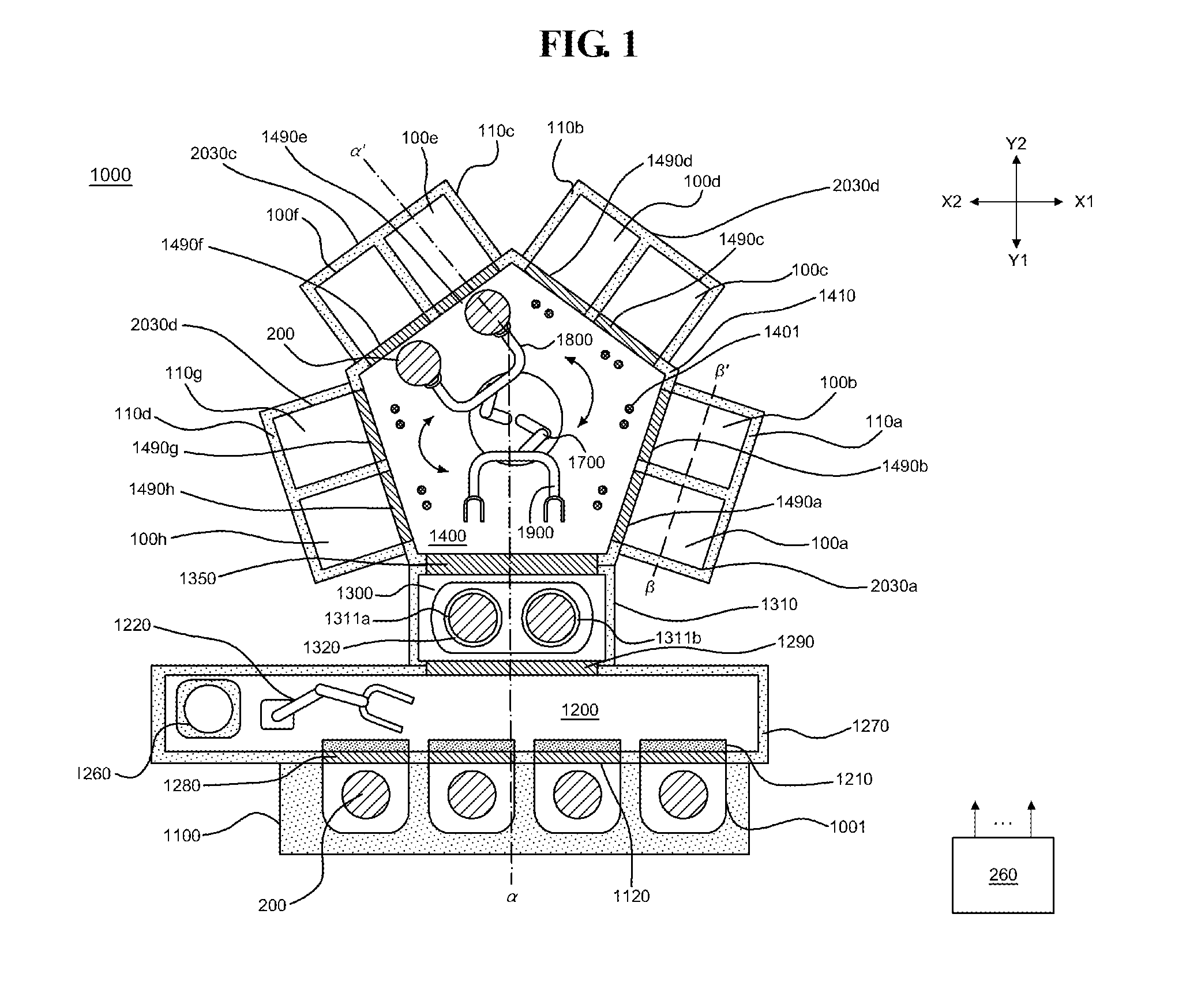

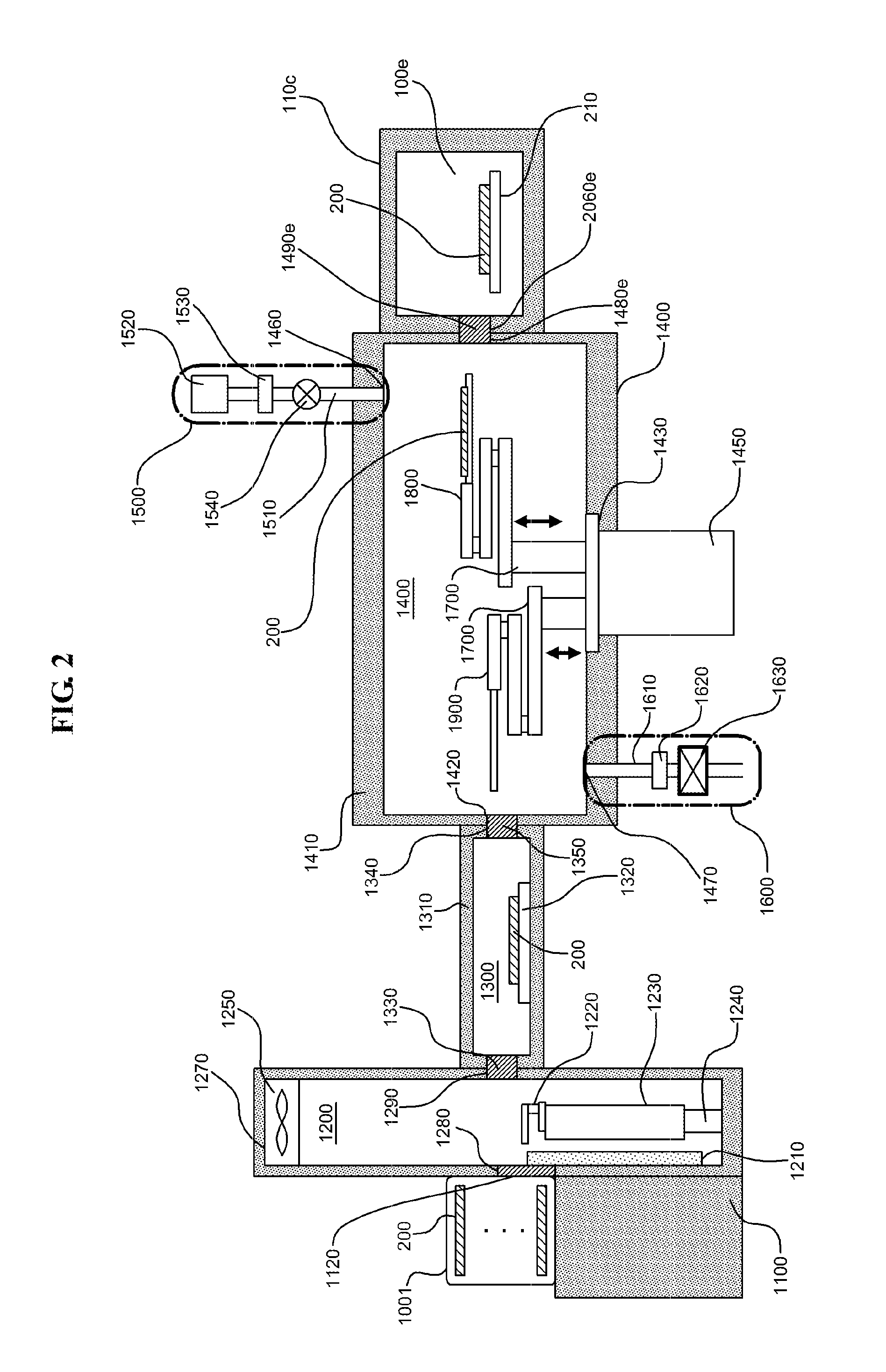

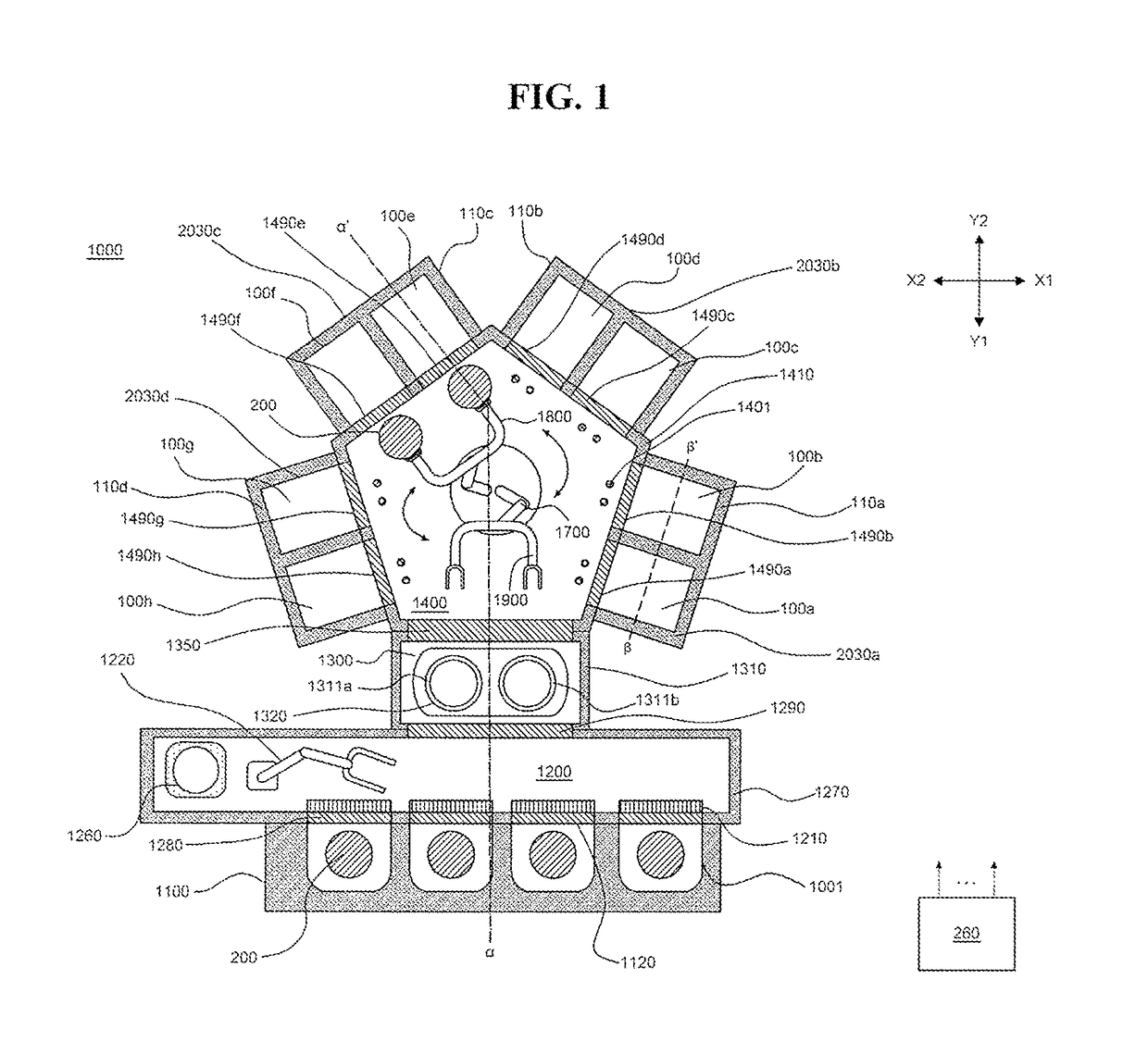

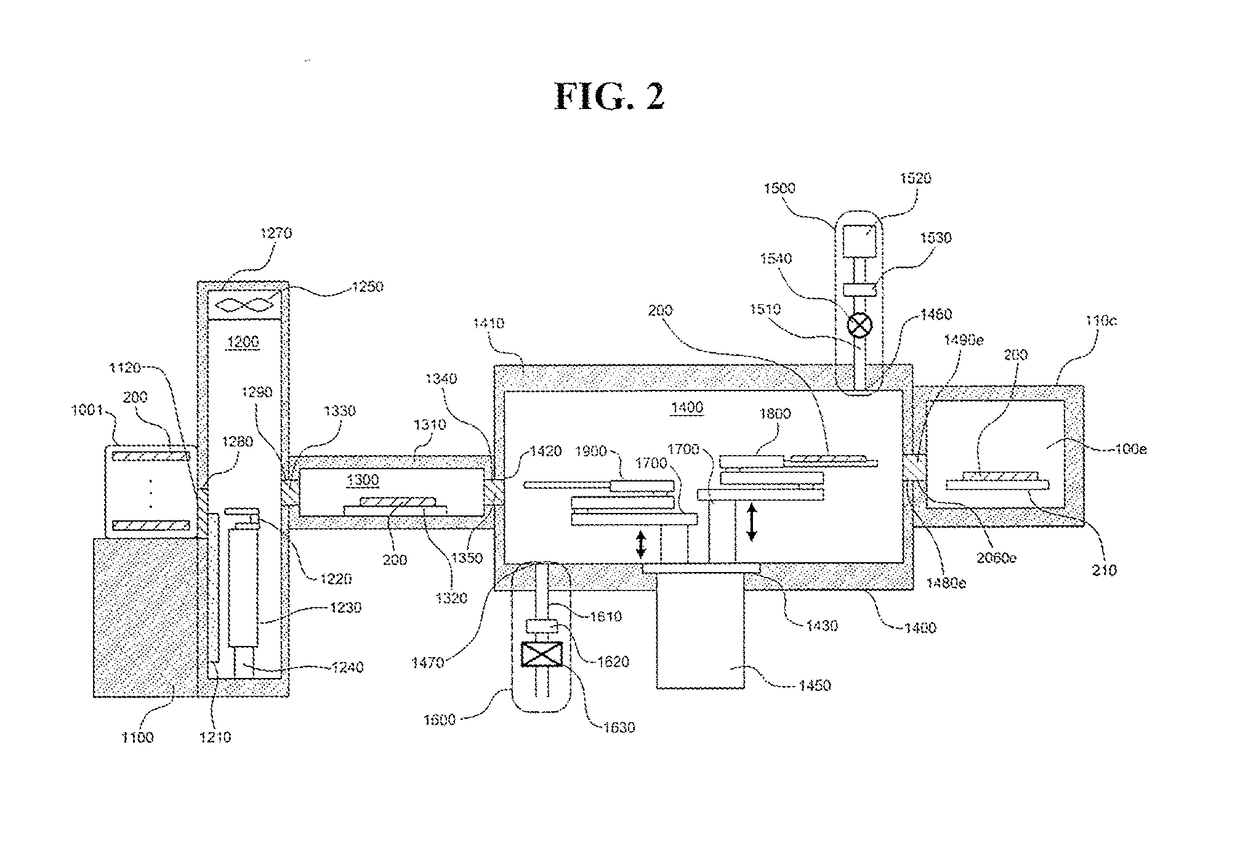

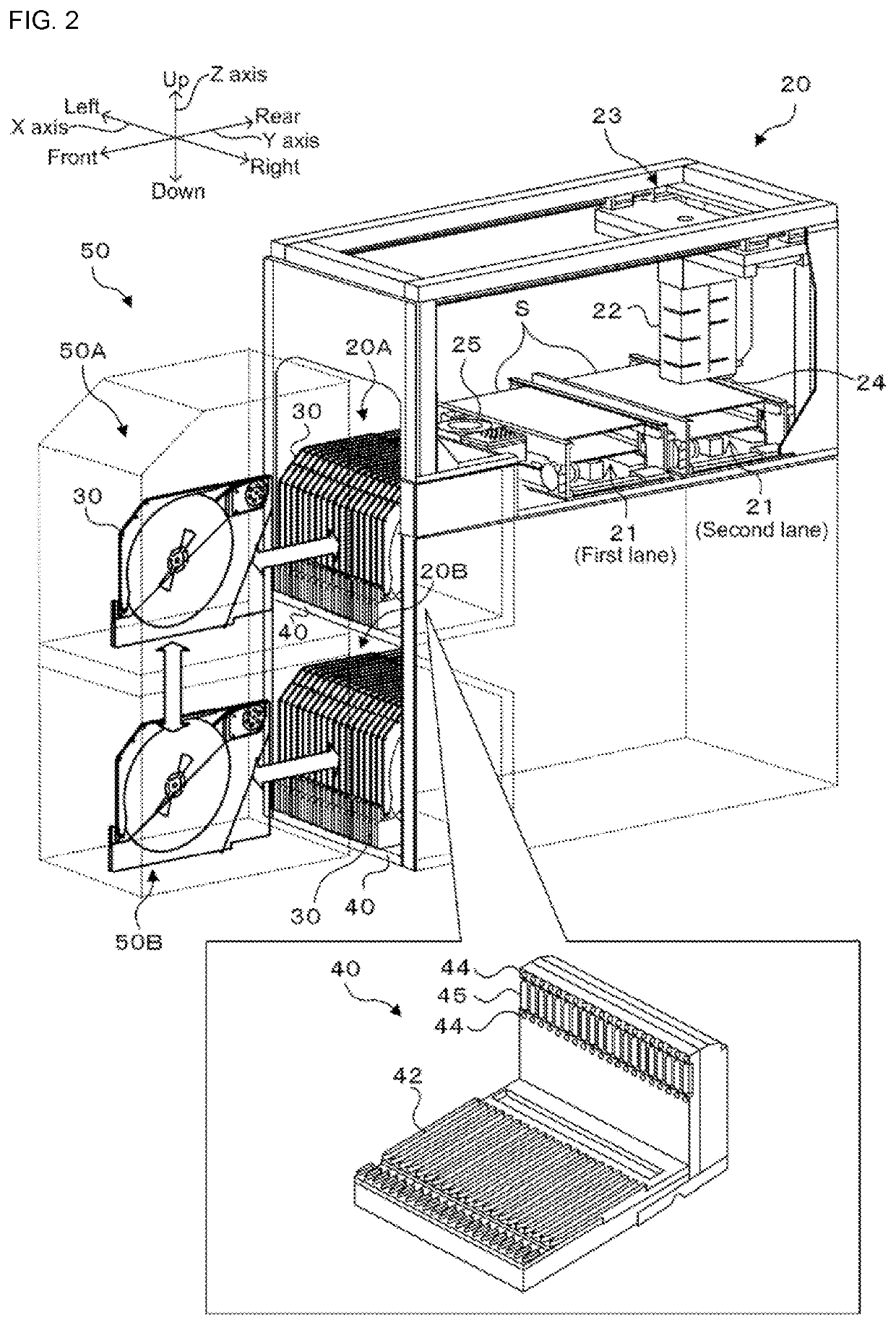

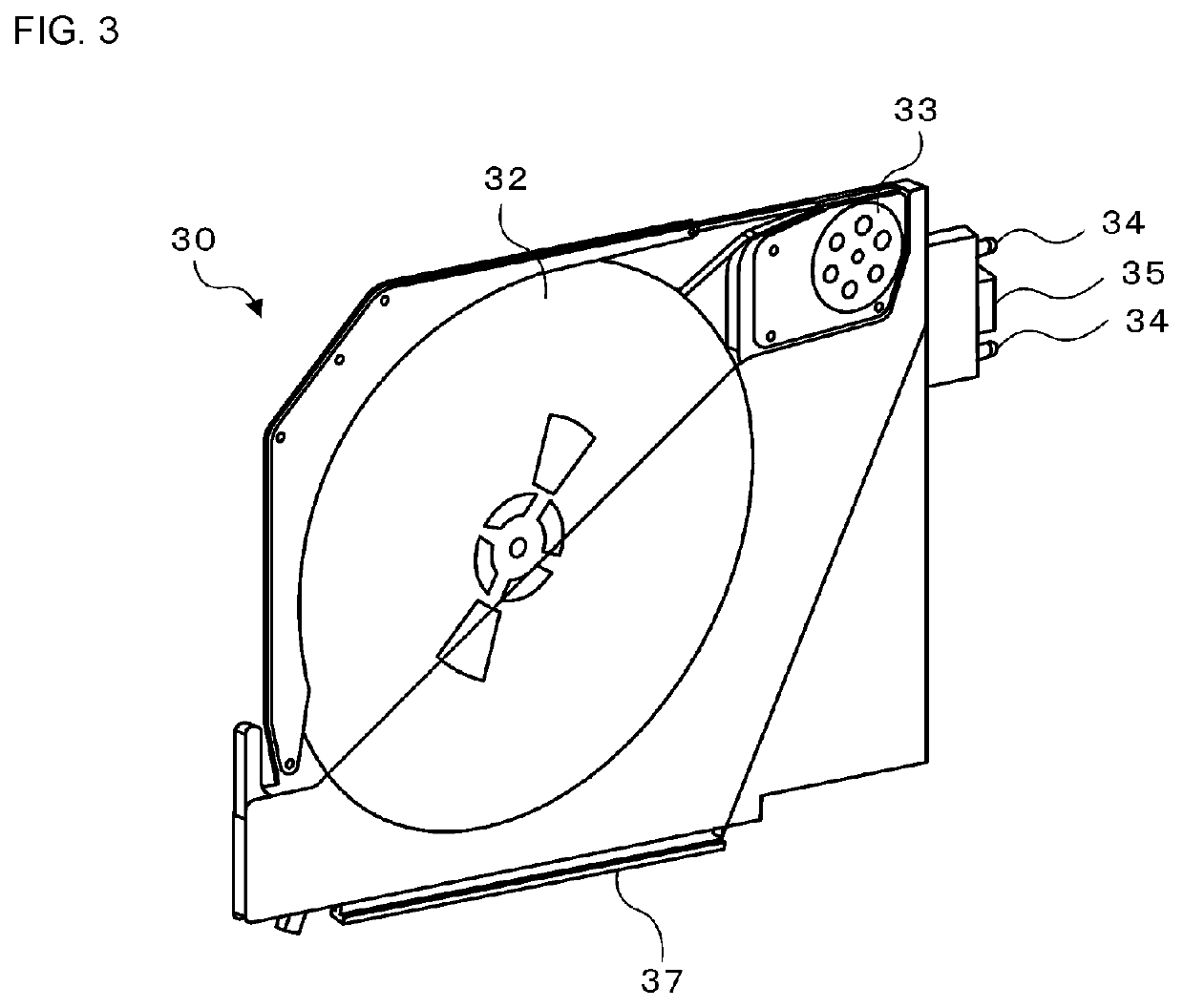

Substrate processing apparatus, method of manufacturing semiconductor device and non-transitory computer-readable recording medium

InactiveUS20170062254A1Decrease productivityImprove machining productivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

In the present invention, the productivity of a processing apparatus including a plurality of process chambers is improved. There is provided a substrate processing apparatus including a plurality of process chambers, a process gas supply unit configured to supply a process gas into each of the plurality of process chambers, a purge gas supply unit configured to supply a purge gas into each of the plurality of process chambers, an exhaust unit configured to exhaust each of the plurality of process chambers and a control unit configured to control the process gas supply unit, the purge gas supply unit and the exhaust unit to supply the process gas into a first process chamber of the plurality of process chambers to which a substrate is transferred while supplying the purge gas into process chambers other than the first process chamber and exhausting the plurality of process chambers.

Owner:KOKUSA ELECTRIC CO LTD

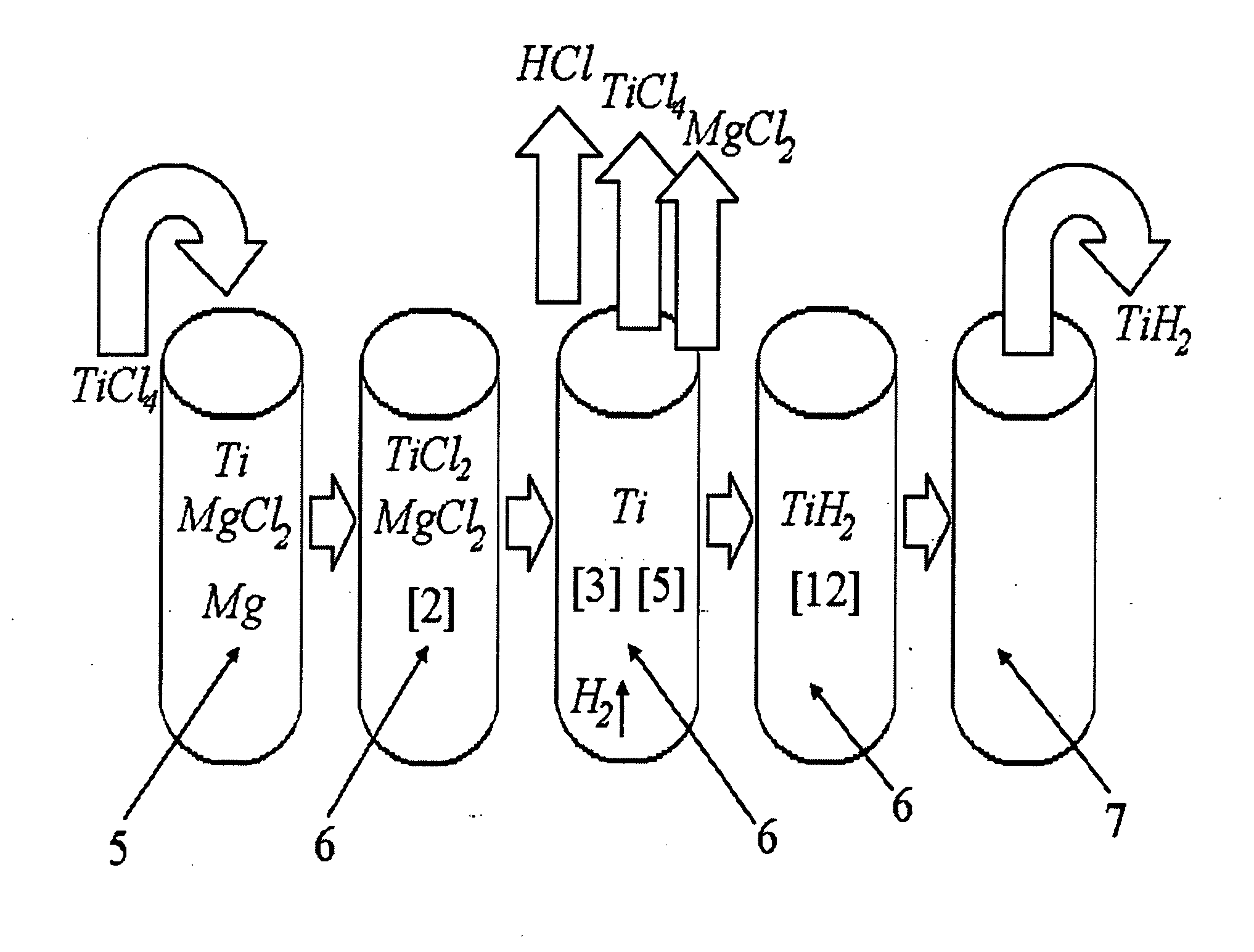

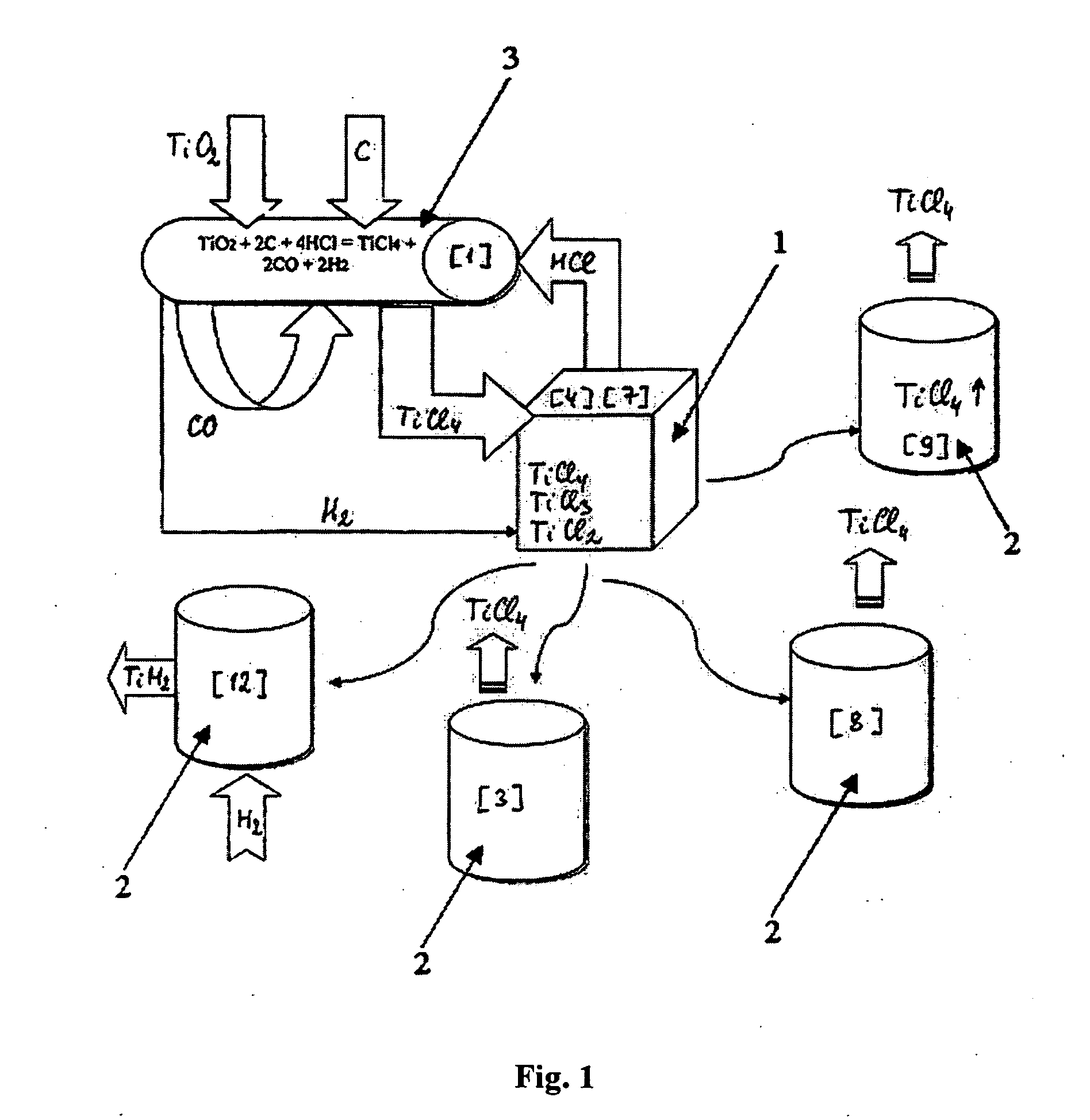

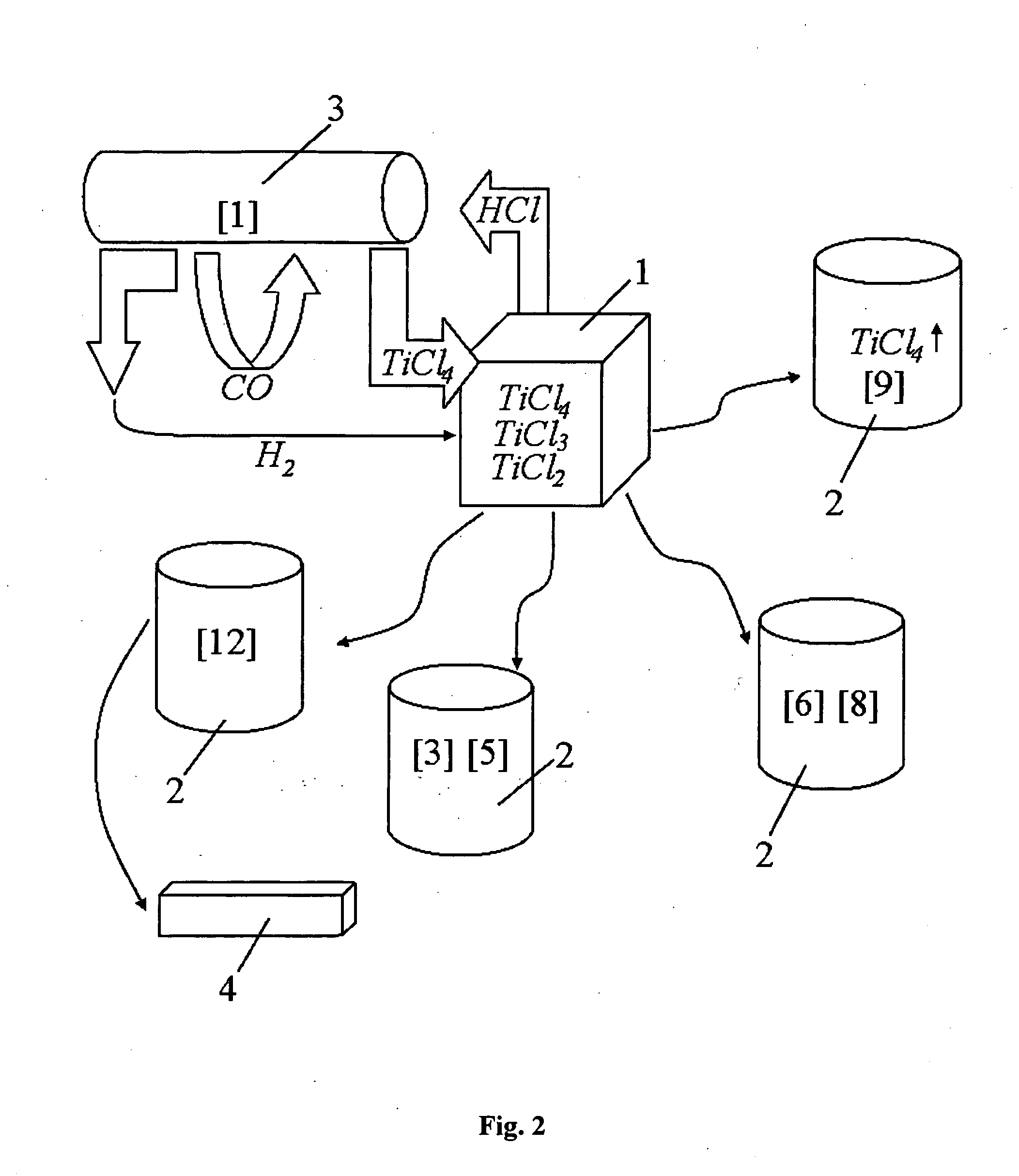

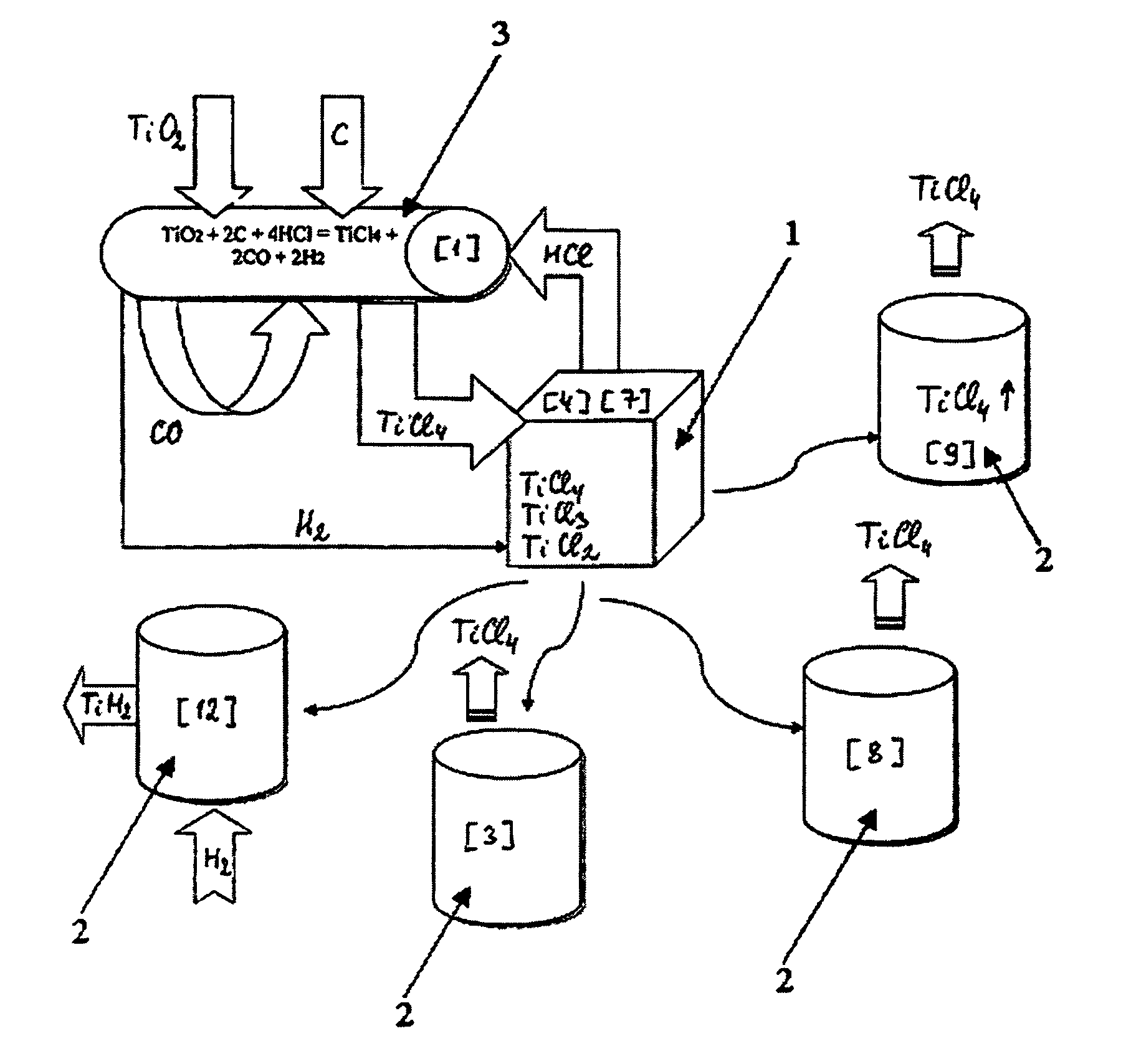

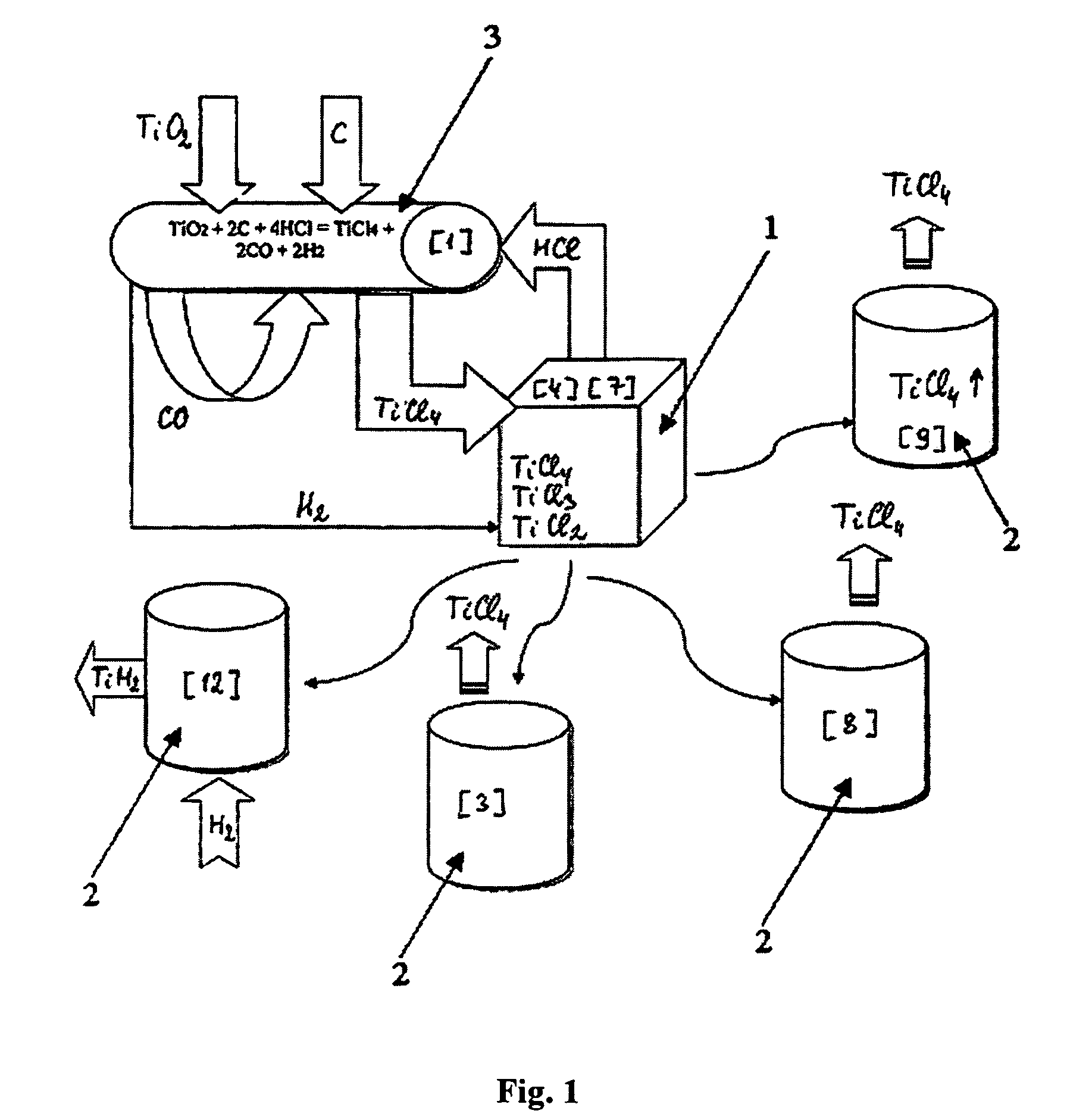

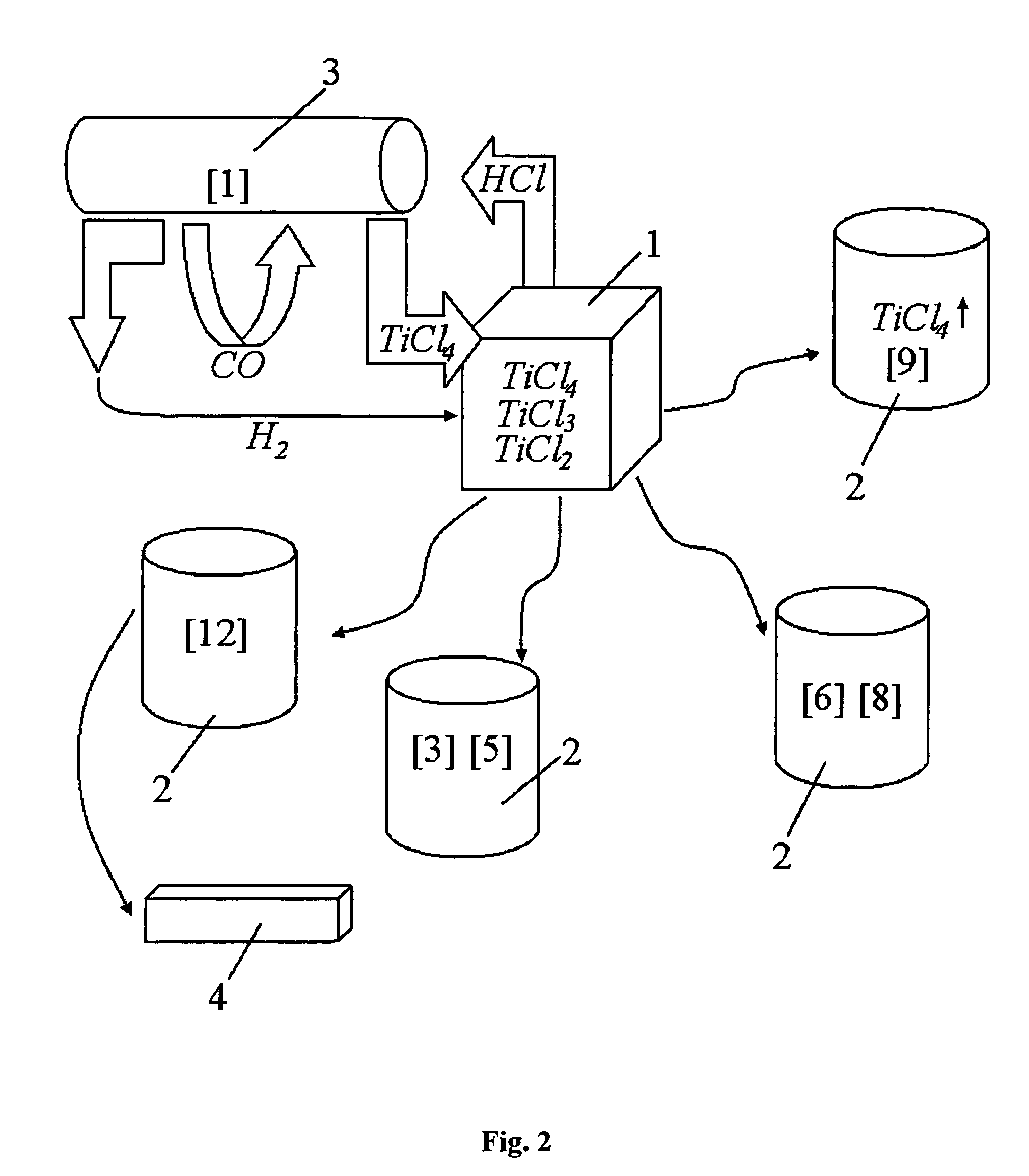

Continuous and semi-continuous process of manufacturing titanium hydride using titanium chlorides of different valency

InactiveUS20110171116A1Reduce manufacturing costCost-effective and highly-productive manufactureTransition element hydridesTitanium chlorideOxygen

The invention relates to the manufacture of titanium hydride powder using continuous or semi-continuous process, and using titanium slag or synthetic rutile as raw materials, while hydrogen, titanium tetrachloride, titanium trichloride, titanium dichloride, and hydrogen chloride are participate as intermediate reaction products. The continuous comprises: (a) reduction of TiCl4 to low titanium chlorides followed by cooling a mixture, (b) separating of residual TiCl4 from solid low chlorides by heating the mixture in argon or vacuum up to 150° C. followed by removing the titanium tetrachloride from the mixture, (c) dissociation of TiCl3 to TiCl2 at 450° C. in vacuum followed by removal of gaseous titanium tetrachloride from the reaction zone, condensation to the liquid, and returning back into the reaction retort, (d) dissociation of TiCl2 in vacuum at 750-850° C. to manufacture fine powder of metallic titanium and titanium tetrachloride, whereby hydrogen heated up to 1000° C. is used to accelerate this reaction, and (e) saturation of the fine titanium powder by hydrogen at 400-640° C. to manufacture final product of titanium hydride powder which is free of oxygen or nitrogen. The semi-continuous process includes the Kroll's process as the very first step.

Owner:ADMA PRODS

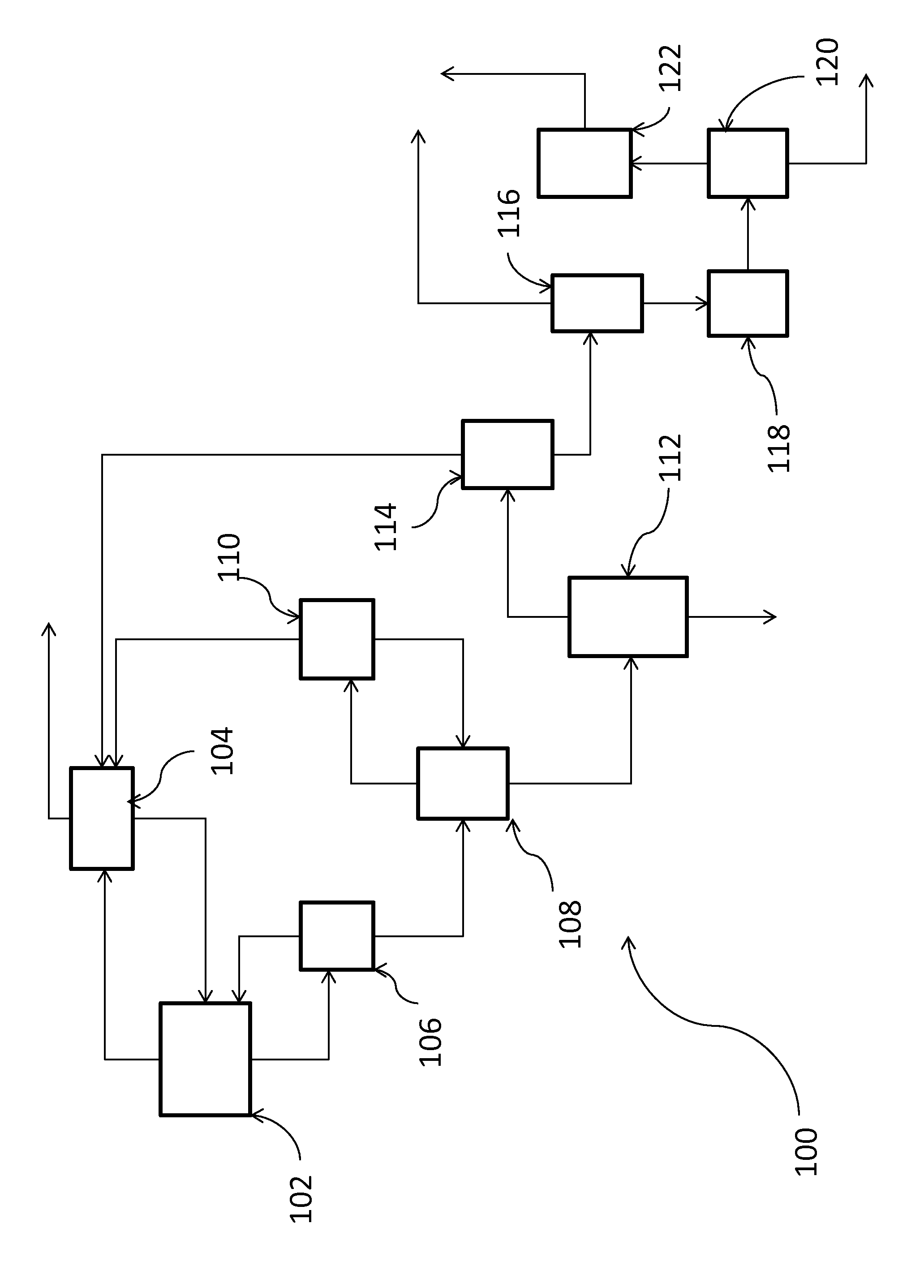

Processes and systems for the production of fermentation products

InactiveUS20150267225A1Increase productivityImprove profileBioreactor/fermenter combinationsBiological substance pretreatmentsBiomassChemistry

The present invention relates to processes and systems for the production of fermentation products such as alcohols. The present invention also provides methods for separating feed stream components for improved biomass processing and productivity.

Owner:BUTAMAXTM ADVANCED BIOFUELS

Improved wheel painting process

ActiveCN102284408AImprove machining productivityImprove appearance qualityPretreated surfacesCoatingsLacquerPre treatment

The invention discloses an improved wheel coating process which specifically comprises the steps of: pretreating, drying, bottom powder spraying, curing, colored paint spraying, masking lacquer spraying, curing, machining as well as lathing and polishing, pretreating, drying, and clear powder or lacquer spraying. According to the invention, spraying and curing process parameters are optimized so that the machining and producing efficiency of finish-turning and polishing a wheel is increased by one time, and the appearance quality is remarkably improved.

Owner:CITIC DICASTAL

Processes and systems for the production of alcohols

ActiveUS9523104B2Improve machining productivityEnhance the imageBiofuelsEnzymesBiochemical engineeringAlcohol ethyl

The present invention relates to processes and systems for the production of fermentative products such as ethanol and butanol. The present invention also provides methods for separating feed stream components for improved biomass processing productivity.

Owner:GEVO INC

Method for manufacturing a semiconductor device

An exemplary method of manufacturing a semiconductor device according to an embodiment of the present invention includes forming a P-well and an N-well for high voltage (HV) devices and a first well in a low voltage / medium voltage (LV / MV) region for a logic device, in a semiconductor substrate; simultaneously forming a second well in the LV / MV region for a logic device and a drift region for one of the HV devices using the same mask; and respectively forming gate oxide layers on the semiconductor substrate in the HV / MV / LV regions. According to the present invention, the number of photolithography processes can be reduced by replacing or combining an additional mask for forming an extended drain region of a high voltage depletion-enhancement CMOS (DECMOS) with a mask for forming a typical well of a logic device, so productivity of the total process of the device can be enhanced.

Owner:COLUMBA TECH INC

Process for the production of chlorinated propenes

ActiveUS20140163266A1Improve machining productivityLightweight productionPreparation by dehalogenationPreparation by hydrogen halide split-offWastewaterCost savings

Processes for the production of chlorinated propenes are provided. The present processes make use of a feedstock comprising 1,2,3-trichloropropane and chlorinates the 1,1,2,3-tetrachloropropane generated by the process prior to a dehydrochlorination step. Production of the less desirable pentachloropropane isomer, 1,1,2,3,3-pentachloropropane, is thus minimized. The present processes provide better reaction yield as compared to conventional processes that require dehydrochlorination of 1,1,2,3-tetrachloropropane prior to chlorinating the same. The present process can also generate anhydrous HCl as a byproduct that can be removed from the process and used as a feedstock for other processes, while limiting the production of waste water, thus providing further time and cost savings.

Owner:BLUE CUBE IP

Method of manufacturing semiconductor device

ActiveUS20170092517A1Decrease productivityImprove machining productivitySemiconductor/solid-state device manufacturingConveyor partsProduction rateDevice material

The present invention provides a technique for improving the productivity of a processing apparatus including a plurality of process chambers. There is provided a technique including a method for manufacturing a semiconductor device including: (a) transferring a last remaining substrate stored in an xth storage unit of a plurality of storage units to an empty nth chamber in an mth processing unit of a plurality of processing units; and (b) transferring a first one of a plurality of substrates stored in an (x+1)th storage unit of the plurality of storage units to one of chambers in an (m+1)th processing unit of the plurality of processing units (where x, m and n are natural numbers).

Owner:KOKUSA ELECTRIC CO LTD

Processes and systems for the production of fermentation products

InactiveUS20150211026A1Improve machining productivityEnhance the imageBioreactor/fermenter combinationsWater/sewage treatment by centrifugal separationBiotechnologyAlcohol

Owner:BUTAMAXTM ADVANCED BIOFUELS

Process for the production of chlorinated propenes

InactiveUS8907148B2High selectivityHigh yieldPreparation by dehalogenationPreparation by hydrogen halide split-offCost savingsEffluent

Processes for the production of chlorinated propenes are provided. The present processes make use of a feedstock comprising 1,2,3-trichloropropane and chlorinates the 1,1,2,3-tetrachloropropane generated by the process prior to a dehydrochlorination step. Production of the less desirable pentachloropropane isomer, 1,1,2,3,3-pentachloropropane, is thus minimized. The present processes provide better reaction yield as compared to conventional processes that require dehydrochlorination of 1,1,2,3-tetrachloropropane prior to chlorinating the same. The present process can also generate anhydrous HCl as a byproduct that can be removed from the process and used as a feedstock for other processes, while limiting the production of waste water, thus providing further time and cost savings.

Owner:BLUE CUBE IP

Continuous and semi-continuous process of manufacturing titanium hydride using titanium chlorides of different valency

InactiveUS8388727B2Cost-effective and highly-productive manufactureImprove machining productivityTransition element hydridesTitanium chlorideTitanium(II) chloride

Owner:ADMA PRODS

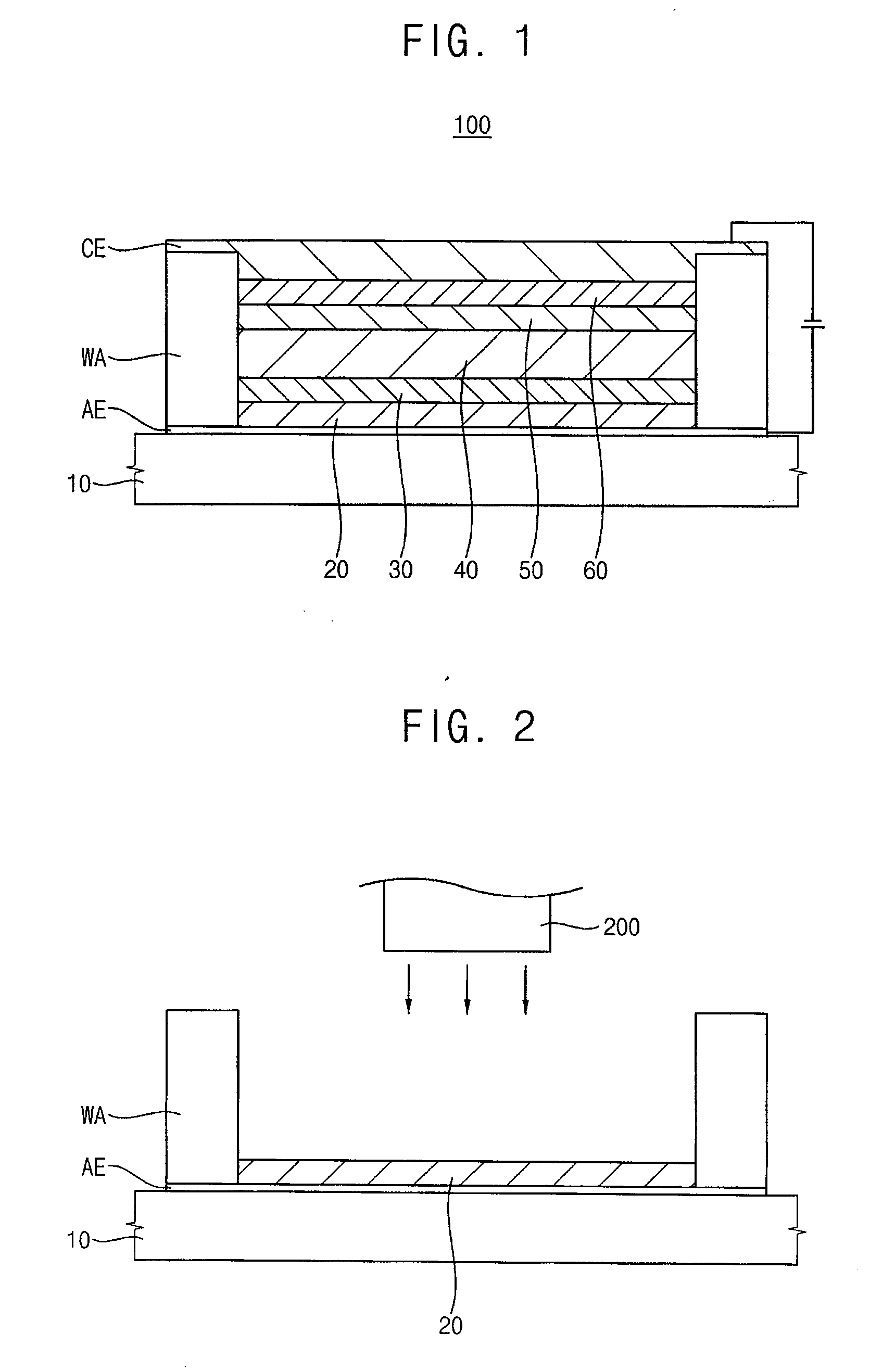

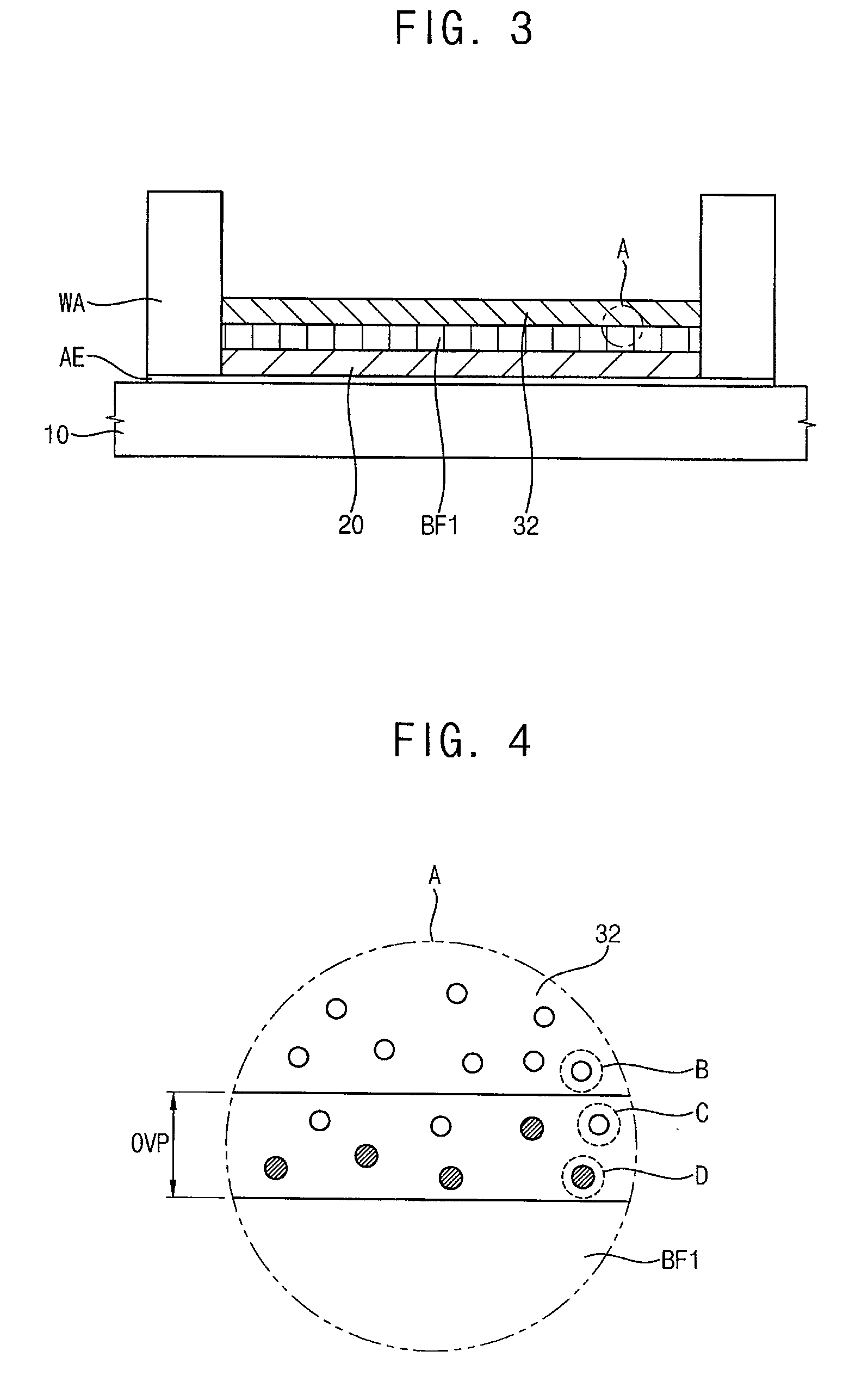

Method of manufacturing a light-emitting element and method of manufacturing a display substrate using the same

ActiveUS20090221209A1Increase productivityImprove reliabilitySolid-state devicesCold cathode manufactureProduction rateTransport layer

In accordance with one or more embodiments of the present disclosure, a method of manufacturing a light-emitting element includes forming an anode on a substrate, forming a first transport layer including one or more first polar compounds on the anode, forming a first non-polar solvent layer on the first transport layer, forming a first polar solution layer including one or more light-emitting compounds on the first non-polar solution layer, drying a polar solvent of the first polar solution layer and the first non-polar solvent layer so that a light-emitting layer including the one or more light-emitting compounds is formed on the first transport layer and forming a cathode on the light-emitting layer. The cathode is disposed opposite to the anode. As such, damage to the first transport layer may be reduced when forming the light-emitting layer, which may improve the reliability and productivity of a manufacturing process.

Owner:SAMSUNG DISPLAY CO LTD

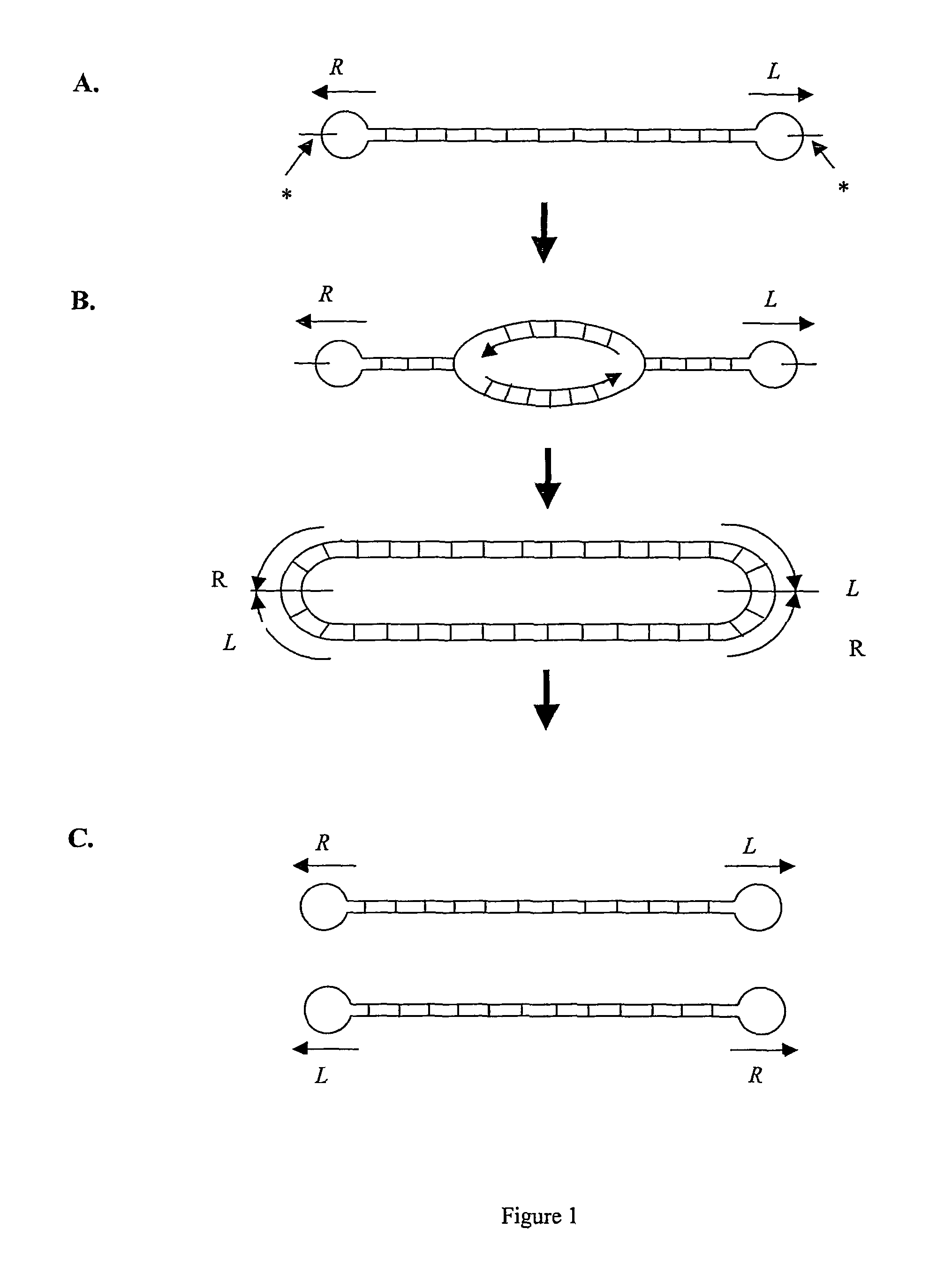

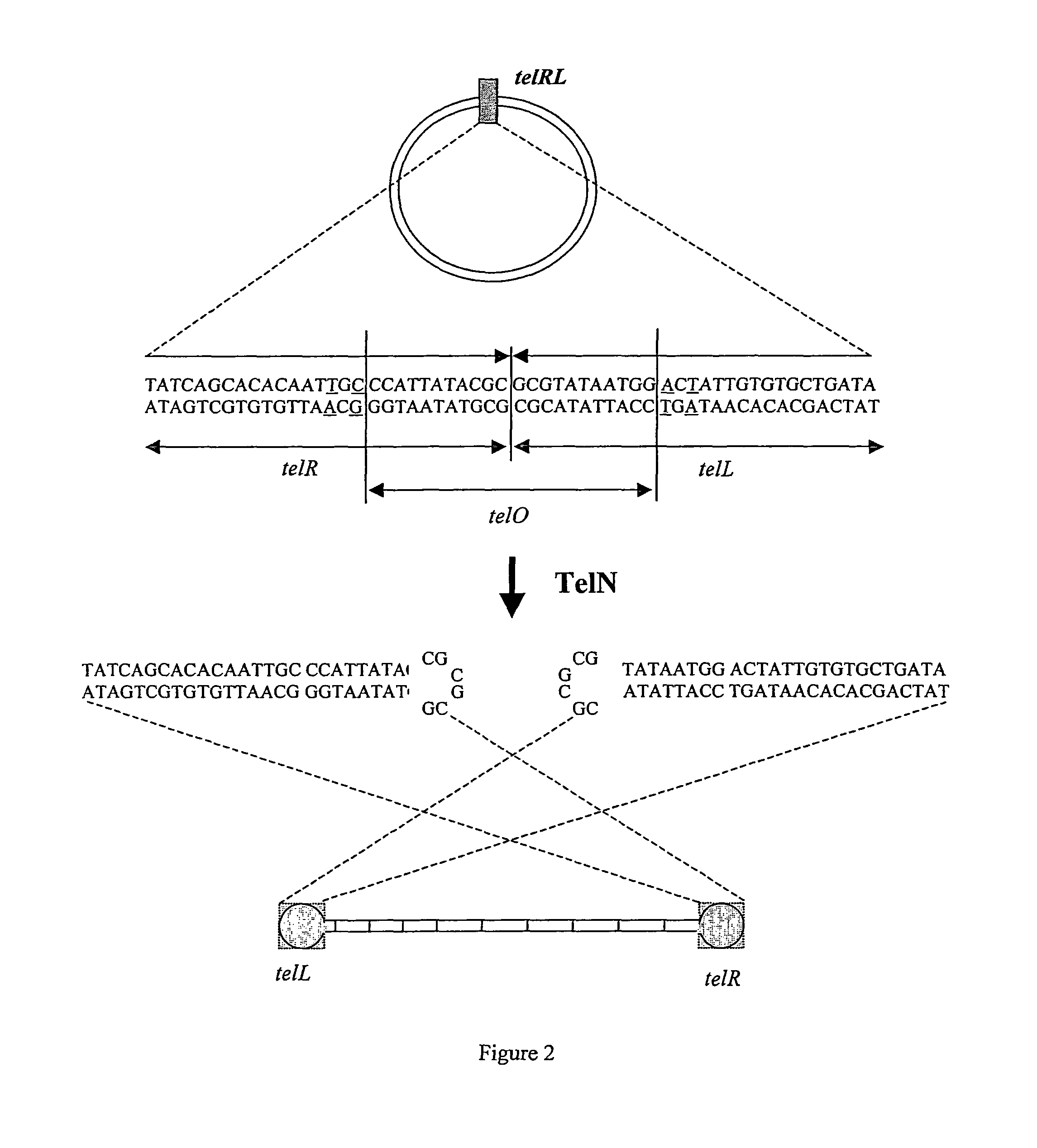

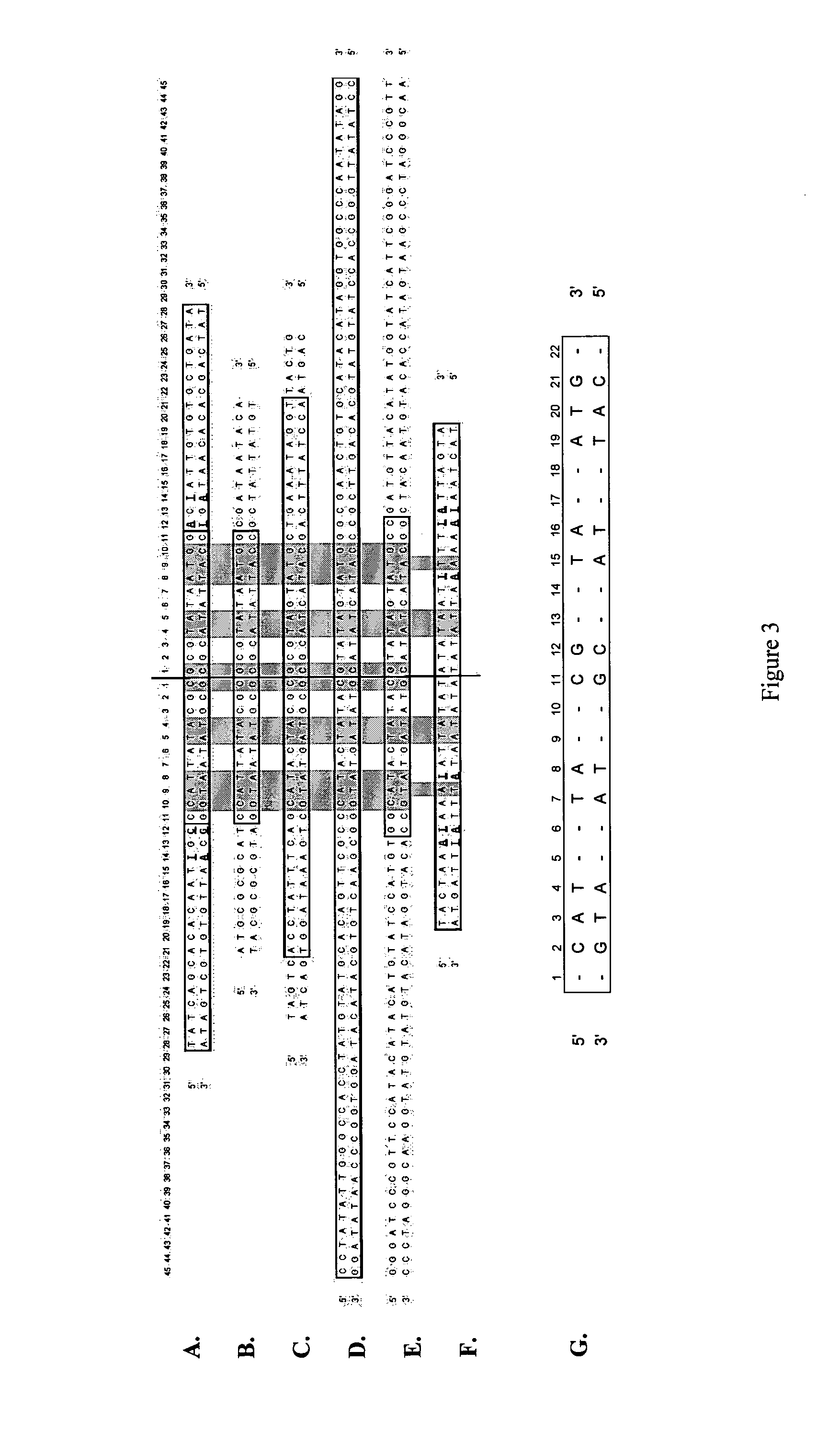

Production of closed linear DNA

ActiveUS9109250B2Increase productionLow costAntibacterial agentsOrganic active ingredientsTelomeraseA-DNA

An in vitro process for the production of closed linear deoxyribonucleic acid (DNA) comprises (a) contacting a DNA template comprising at least one protelomerase target sequence with at least one DNA polymerase in the presence of one or more primers under conditions promoting amplification of said the template; and (b) contacting amplified DNA produced in (a) with at least one protelomerase under conditions promoting production of closed linear DNA. A kit provides components necessary in the process.

Owner:TOUCHLIGHT IP LTD

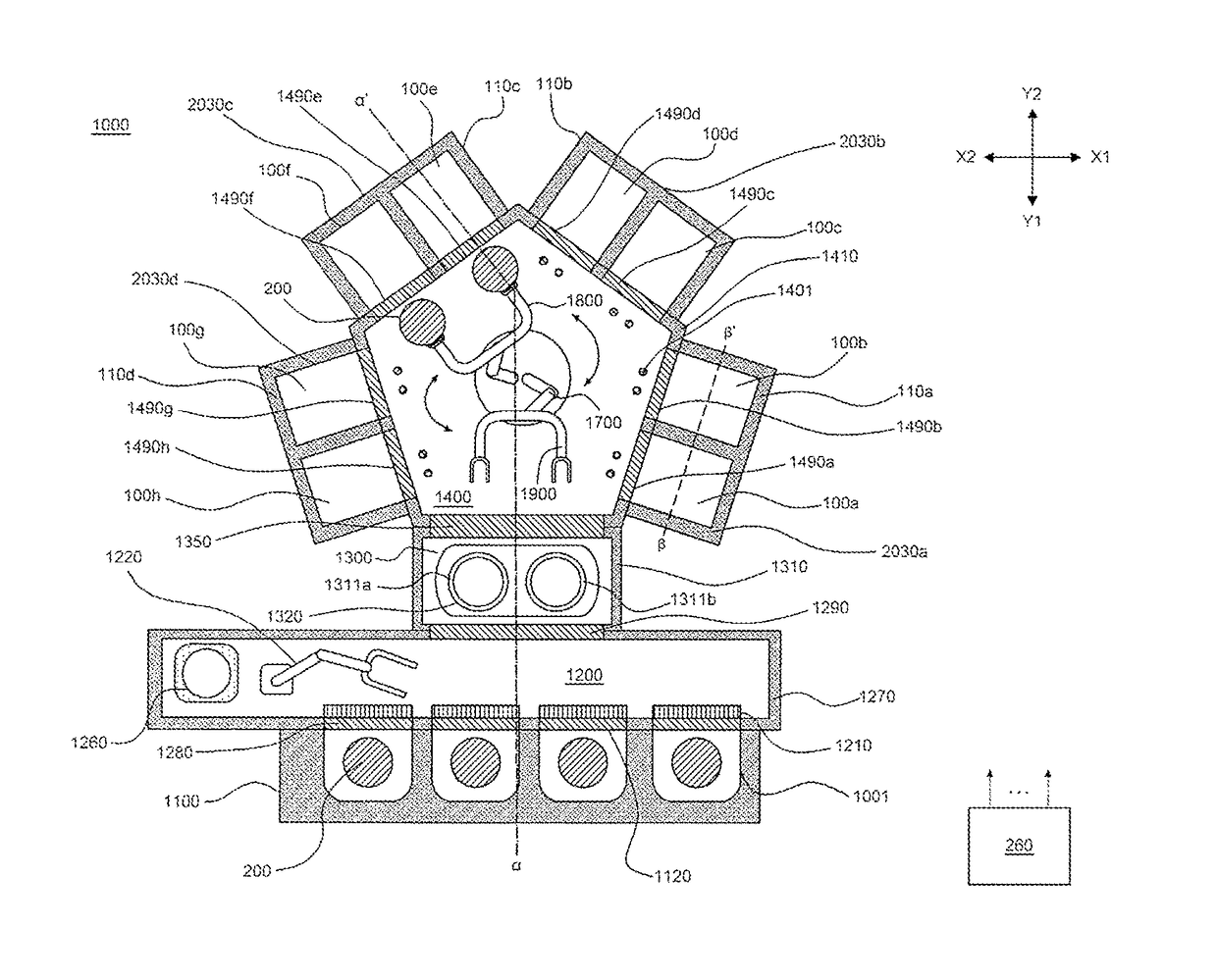

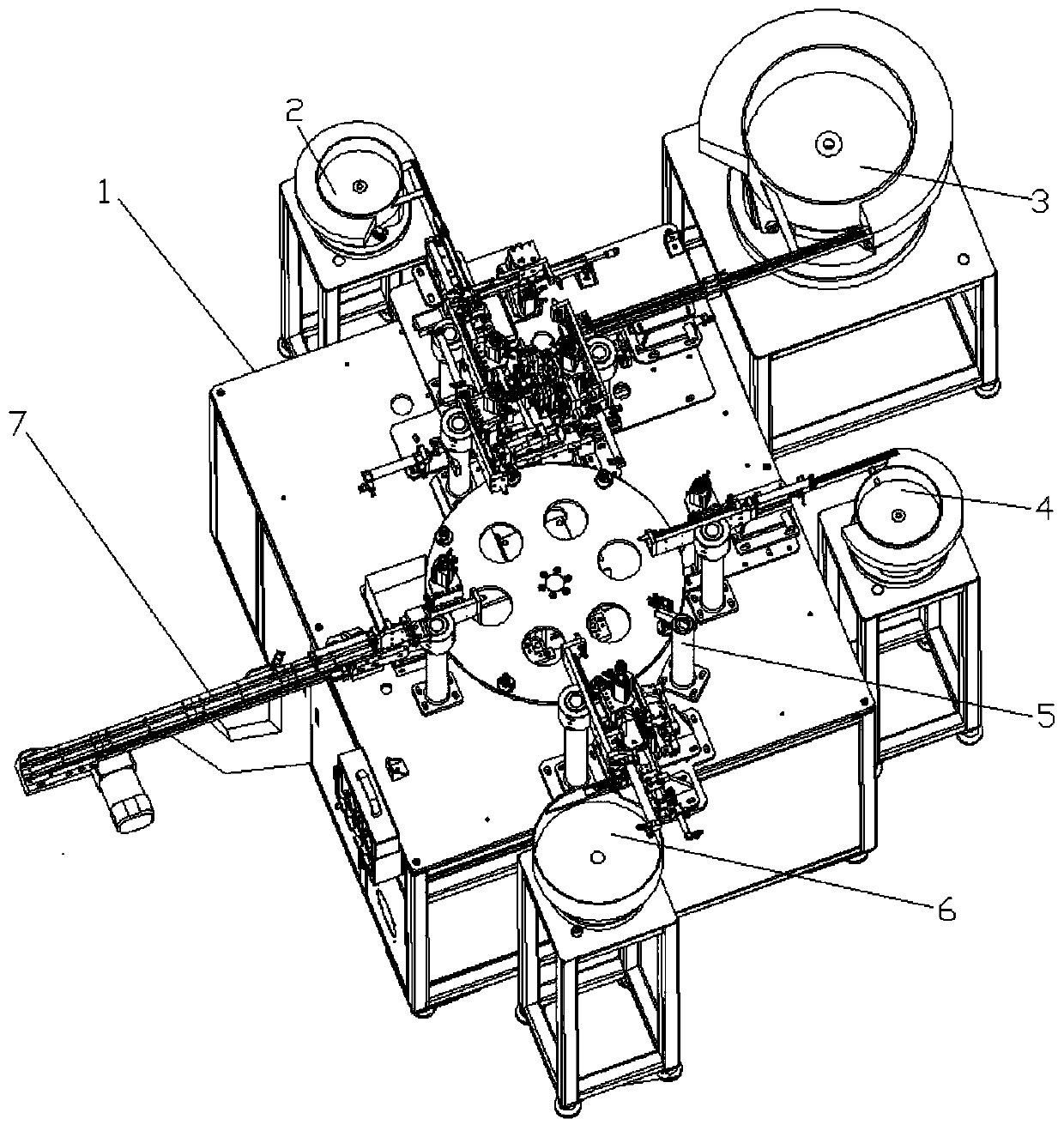

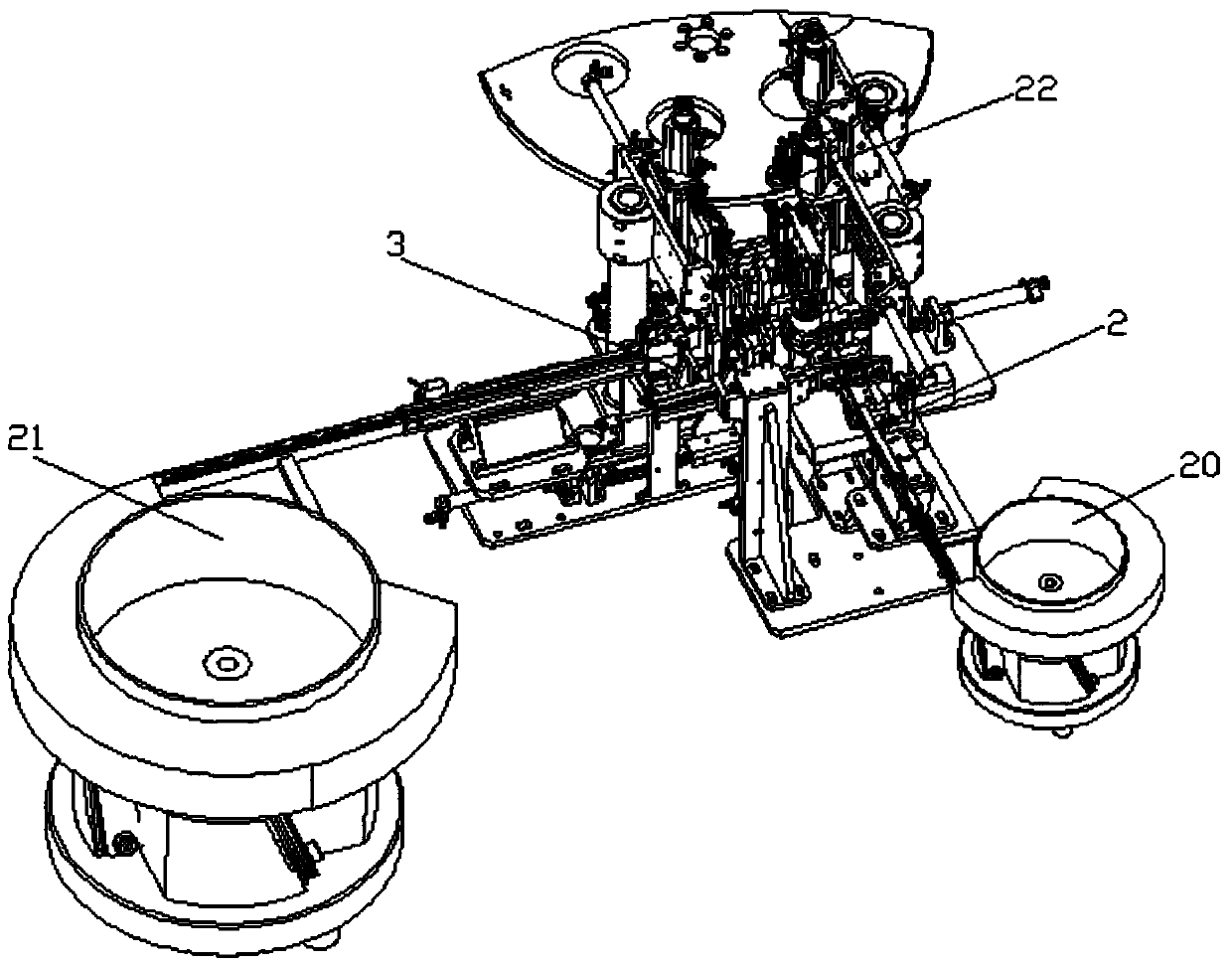

Full-automatic automobile valve assembly machine

InactiveCN107932058AReduce wearImprove accuracyAssembly machinesMetal working apparatusDistribution controlEngineering

The invention relates to a fully automatic automobile valve assembly machine, which includes a frame and a power distribution control box arranged in the frame, a turntable device is arranged above the frame, and the turntable device includes a turntable transmission motor fixed on the frame and cooperating with each other And the turntable, the turntable carrier is evenly arranged along the ring on the turntable, and the key block conveying device, the pipe jacking conveying device, the funnel installation device, the pressing device, the sealing Ring installation device and blanking device; the present invention extends the inner ring of the sealing ring through the sealing ring thimble, and expands the inner diameter of the sealing ring under the action of the sealing ring sleeve, and when the inner diameter of the sealing ring is larger than the sealing ring sleeve, the sealing ring slides upwards to the sealing ring casing, and then move to the top of the turntable carrier, the product casing cooperates with the jacking pipe, and the telescopic cylinder of the installation sleeve stretches out, driving the sealing ring installation sleeve to push the sealing ring into the groove of the jacking pipe, thereby greatly reducing The degree of wear of the sealing ring.

Owner:DONGGUAN UNIV OF TECH

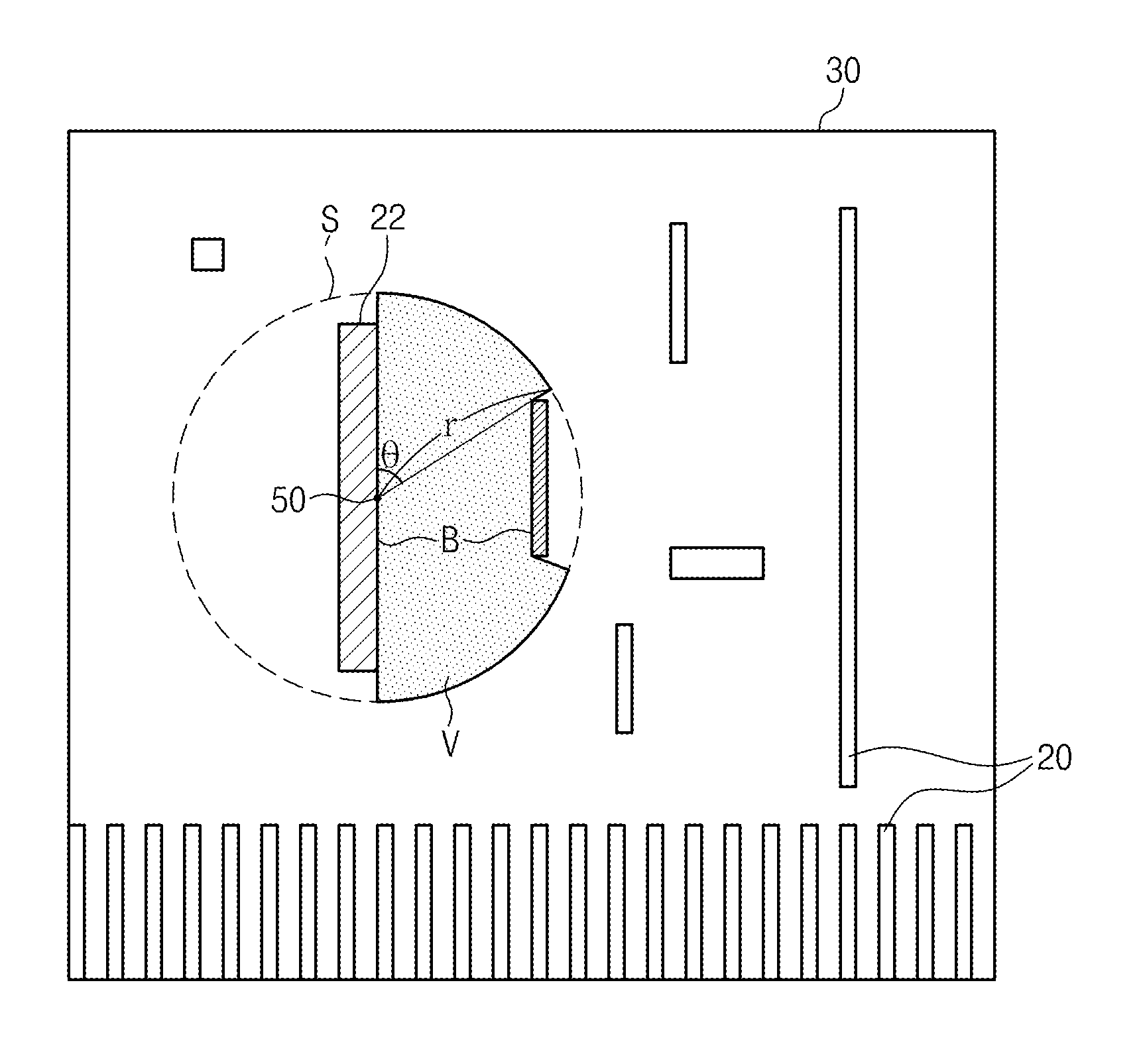

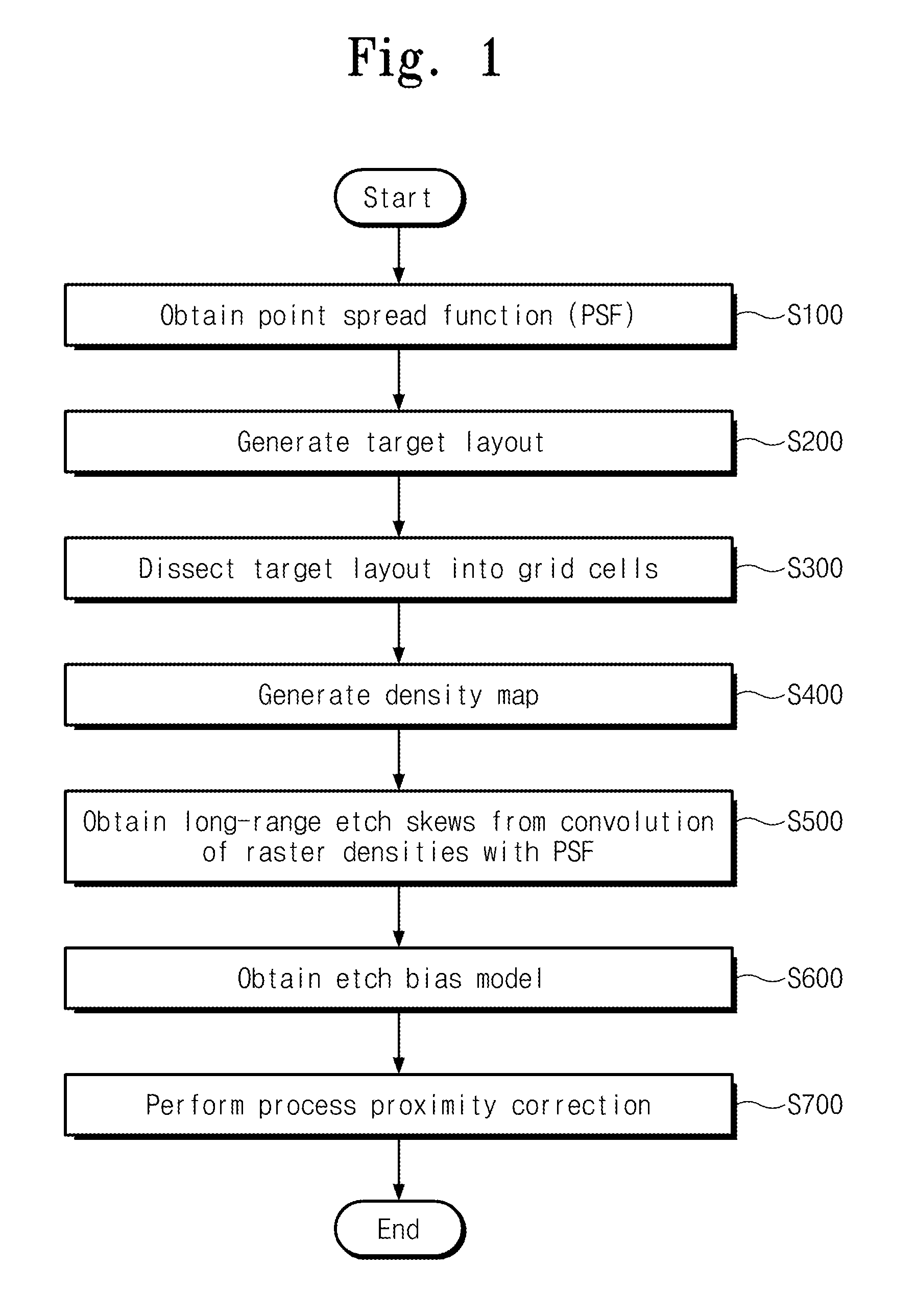

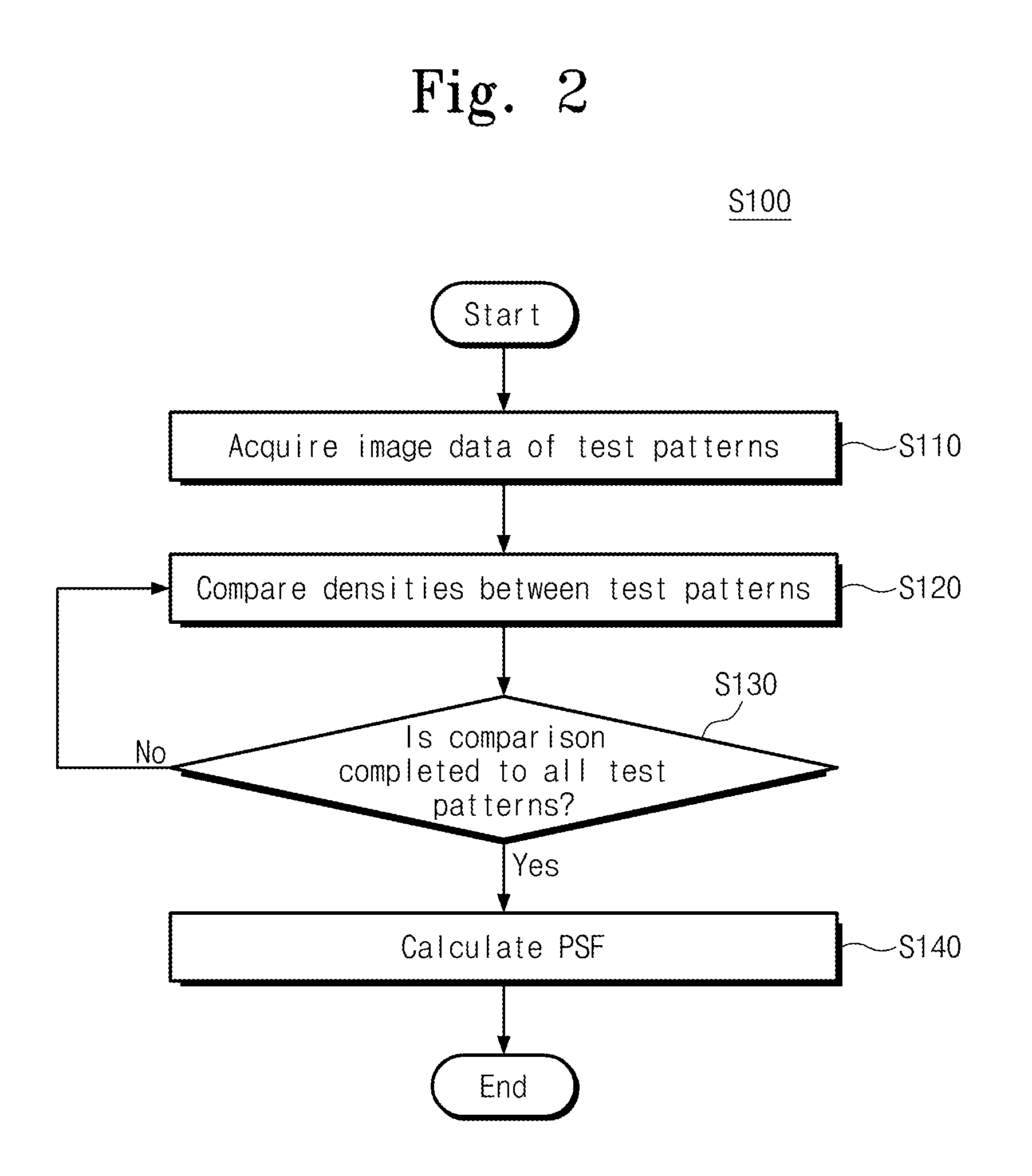

Method for process proximity correction

ActiveUS20130219349A1Improve accuracyImprove machining productivityOriginals for photomechanical treatmentSpecial data processing applicationsPoint spread functionGrid cell

A method for process proximity correction may include obtaining a point spread function (PSF) from test patterns, the test patterns including an etching process performed thereon, generating a target layout with polygonal patterns, dividing the target layout into grid cells, generating a density map including long-range layout densities, each of the long-range layout densities being obtained from the polygonal patterns located within a corresponding one of the grid cells, performing a convolution of the long-range layout densities with the PSF to obtain long-range etch skews for the grid cells, and generating an etch bias model including short-range etch skews and the long-range etch skews, each of the short-range etch skews being obtained from a neighboring region of a target pattern selected from the polygonal patterns in each of the grid cells.

Owner:SAMSUNG ELECTRONICS CO LTD

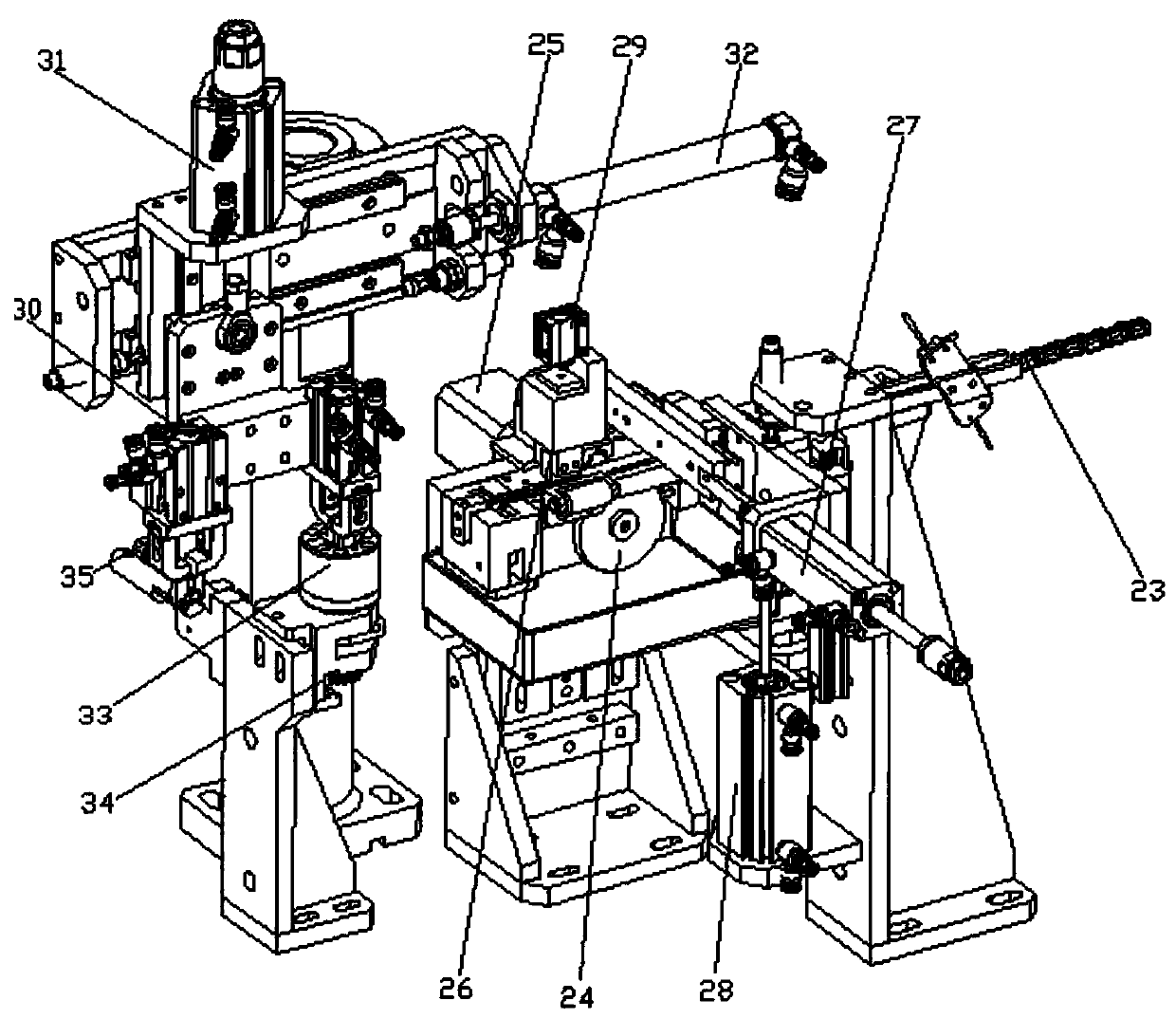

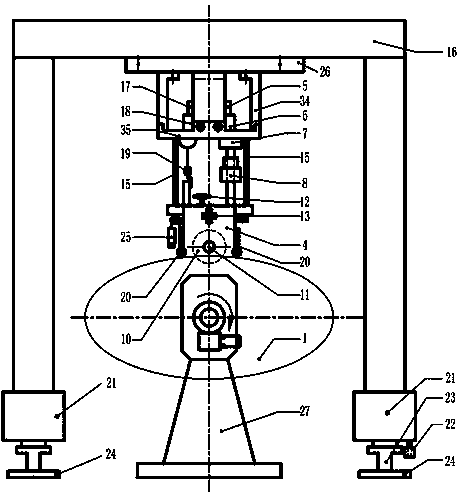

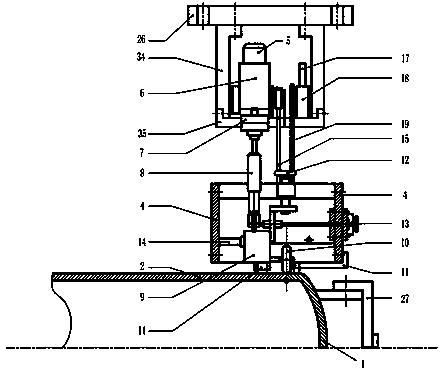

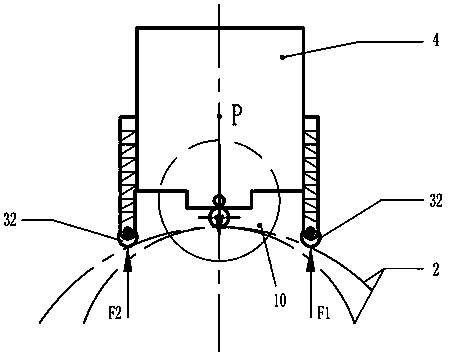

Integrated milling equipment for welding groove of large irregular medium plate structure

InactiveCN104028817AImprove machining productivityEnsure Consistency and ReliabilityMilling equipment detailsWeld seamStructural engineering

The invention discloses integrated milling equipment for a welding groove of a large irregular medium plate structure. The integrated milling equipment comprises a milling cutter system component, a fixed-depth profile modeling component, a milling cutter adjusting component, a normal-direction support component, a horizontal tracking component, a milling cutter box floating component, a 90-degree reversing component, a height raising component, a groove length displacement component and a milling cutter box body. Firstly, separated weldments are assembled into an integrated weldment; afterwards, the welding groove is integrally machined; finally, welding is performed; in this way, the machining productivity of the welding groove is increased to at least double. With regard to integrated machining of the welding groove, the welding groove is machined through one milling cutter at a time, and therefore the consistency and reliability of the size of welding seams of the welding groove integrally machined are higher; the integrated milling equipment is quite beneficial to assembly quality guarantee of the weldments and the dimensional accuracy of the welded product; the machining cost of the welding groove is lower; the dimensional consistency of the welding groove is quite high, and single-sided weld with double-sided formation can usually be achieved; in this way, the welding productivity is further increased, and the production cycle is further shortened.

Owner:武汉纳瑞格智能设备有限公司

Thin film etching method and method of fabricating liquid crystal display device using the same

ActiveUS7491557B2Simple processImprove machining productivitySolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

A thin film etching method includes forming a layer on a substrate, aligning a mask having a pattern defined thereon above the layer, and removing a portion of the layer by irradiating the substrate with a femtosecond laser through the mask.

Owner:LG DISPLAY CO LTD

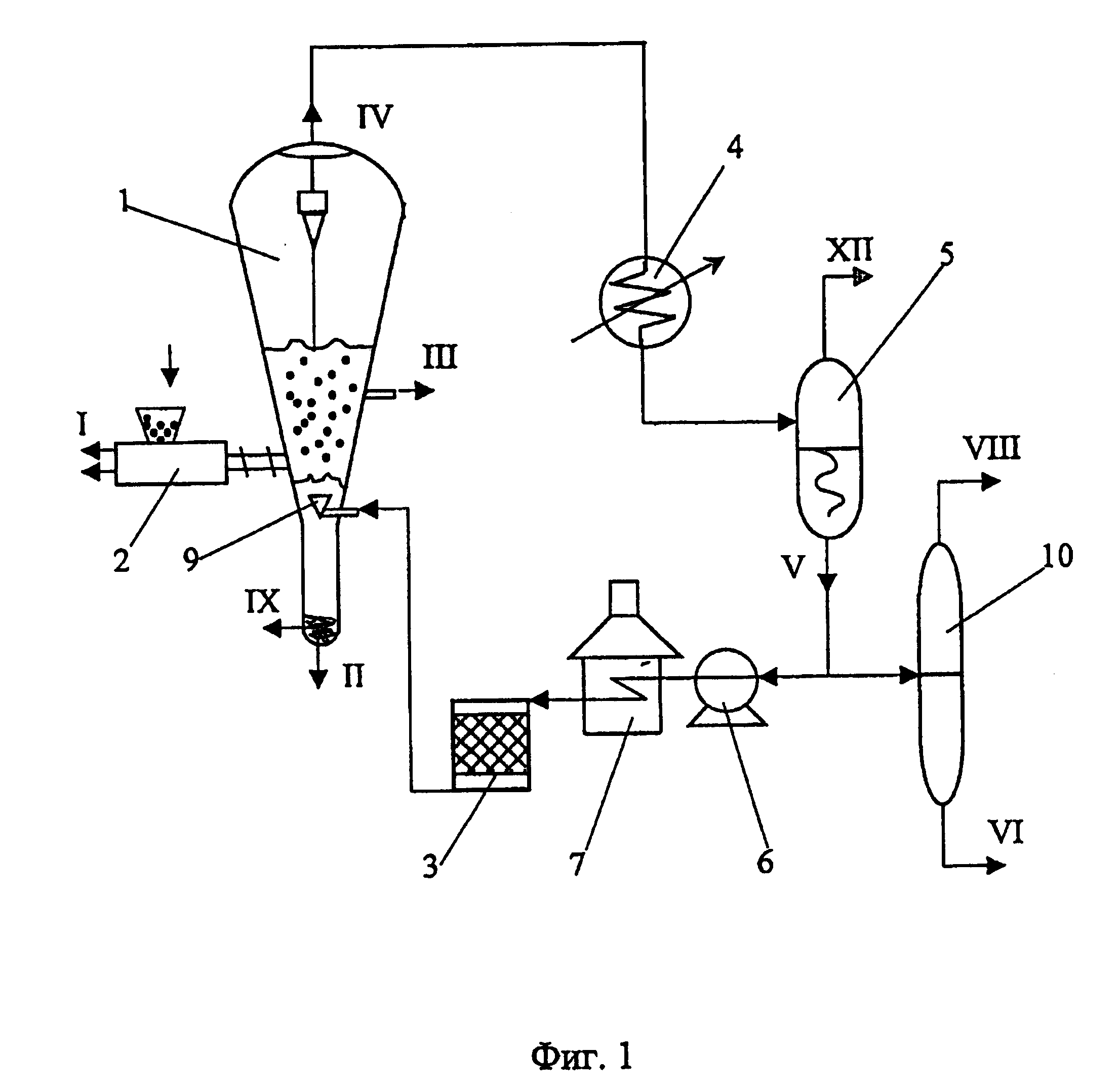

Method for recycling rubber-containing wastes

InactiveUS20060281956A1Speed up the processSimple technologyTreatment with plural serial stages onlyCatalytic naphtha reformingCatalytic reformingBenzene

The inventive method includes thermal liquefaction of wastes in an organic solvent at a temperature above 270° C. and a pressure up to 6 MPa. The liquid fraction is separated from the undissolved product. The liquid fraction is distilled into the fraction with the boiling temperature below 220° C. and the fraction with the boiling temperature above 220° C. Alkyl benzene or the gasoline fraction with a boiling temperature below 220° C. is used as an organic solvent at the start-up of the process. Thermal liquefaction of a batch of wastes is carried out in an organic solvent at a temperature from 280° C. to 435° C. and a pressure at least 2.9 MPa, the organic solvent-waste weight ratio being more than 1.0. The liquid fraction with the boiling temperature below 220° C. is subjected to catalytic reforming. A part of the liquid fraction, as subjected to catalytic reforming, with the boiling temperature below 220° C. is used as the target product, and the remaining part of the liquid fraction, as subjected to catalytic reforming, with the boiling temperature below 220° C. is used as a solvent and returned for thermal liquefaction of a new batch of wastes at a temperature from 280° C. to 435° C. and a pressure at least 2.9 MPa, the solvent-waste weight ratio being more than 1.0. The process of thermal liquefaction is continued in the said conditions of thermal liquefaction and catalytic reforming for the next and subsequent batches of wastes, while a part of the liquid fraction, as subjected to catalytic reforming, with the boiling temperature below 220° C. being returned for thermal liquefaction.

Owner:OBSCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU N T D TAMANNO

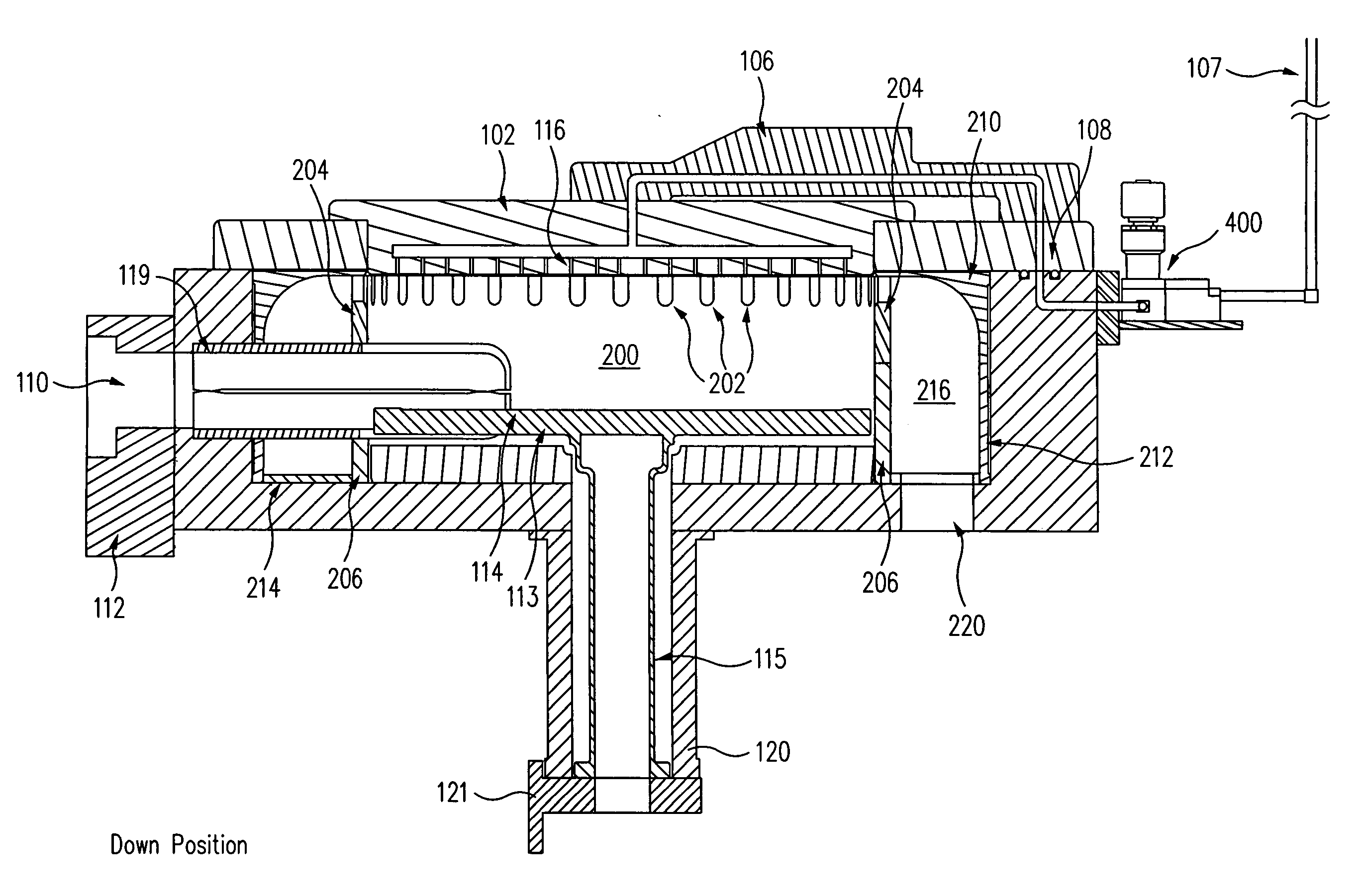

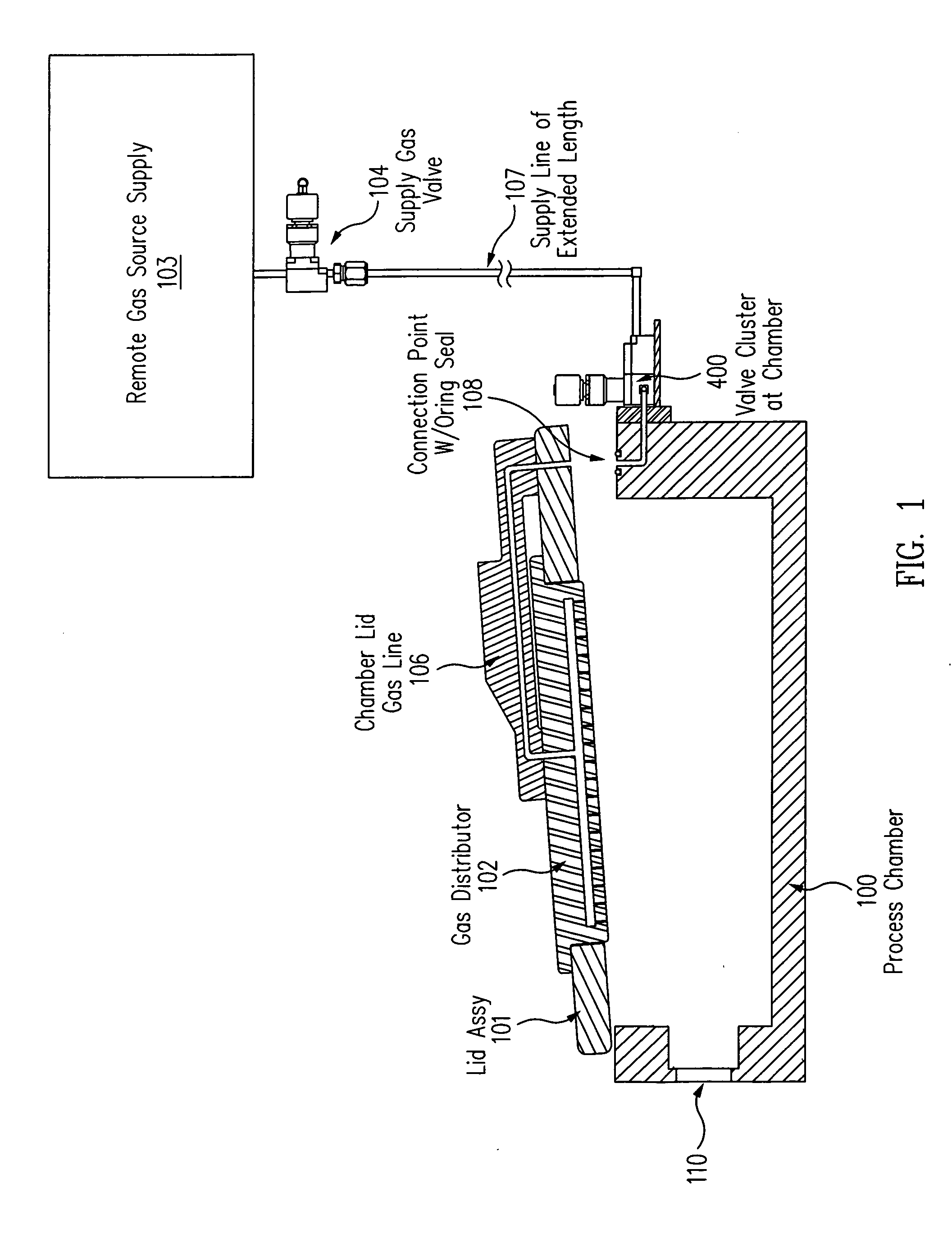

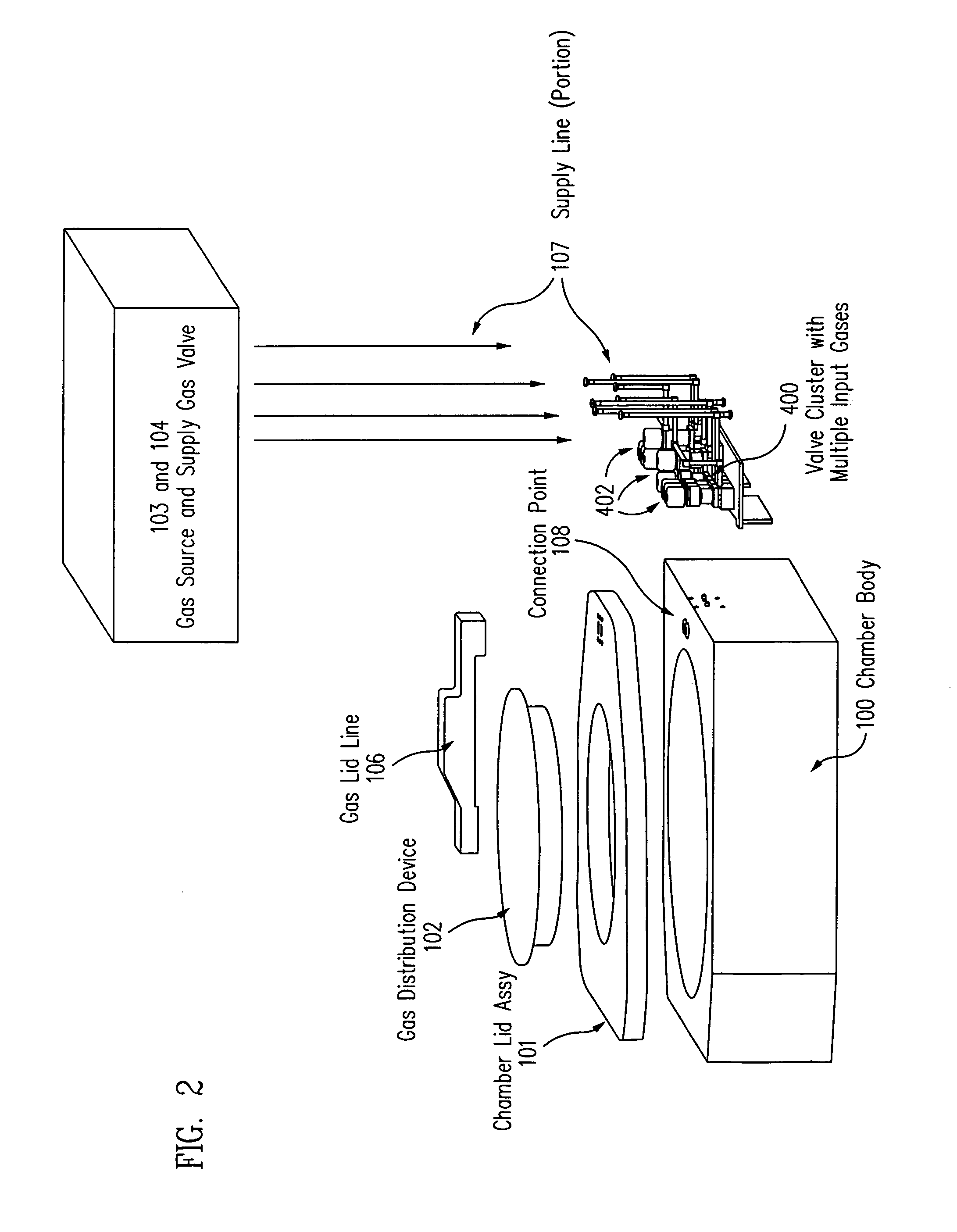

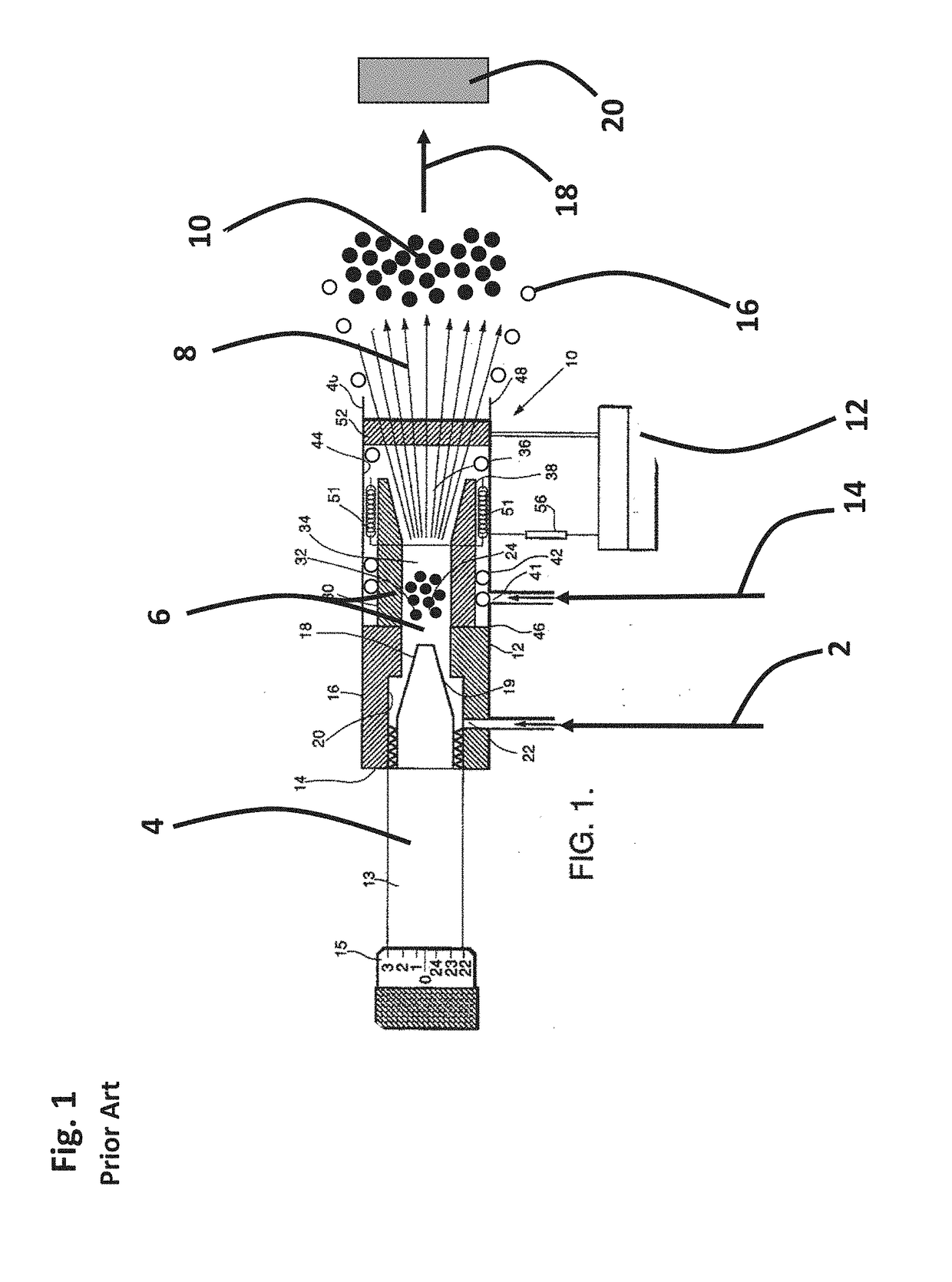

Gas manifold valve cluster

InactiveUS20070028838A1Promote fast actuationShorten the lengthVacuum evaporation coatingSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor

The present invention relates generally to a deposition apparatus for semiconductor processing. More specifically, embodiments of the present invention relate to a gas manifold valve cluster and deposition apparatus. In some embodiments of the present invention a gas manifold valve cluster and system are provided that promotes reduced length and volumes of gas lines that will be exposed to atmosphere during cleaning which minimizes the time required to perform process chamber maintenance and therefore increase the productivity of the process chamber. In other embodiments a gas manifold valve cluster and ALD deposition apparatus are provided.

Owner:AVIZA TECHNOLOGY INC

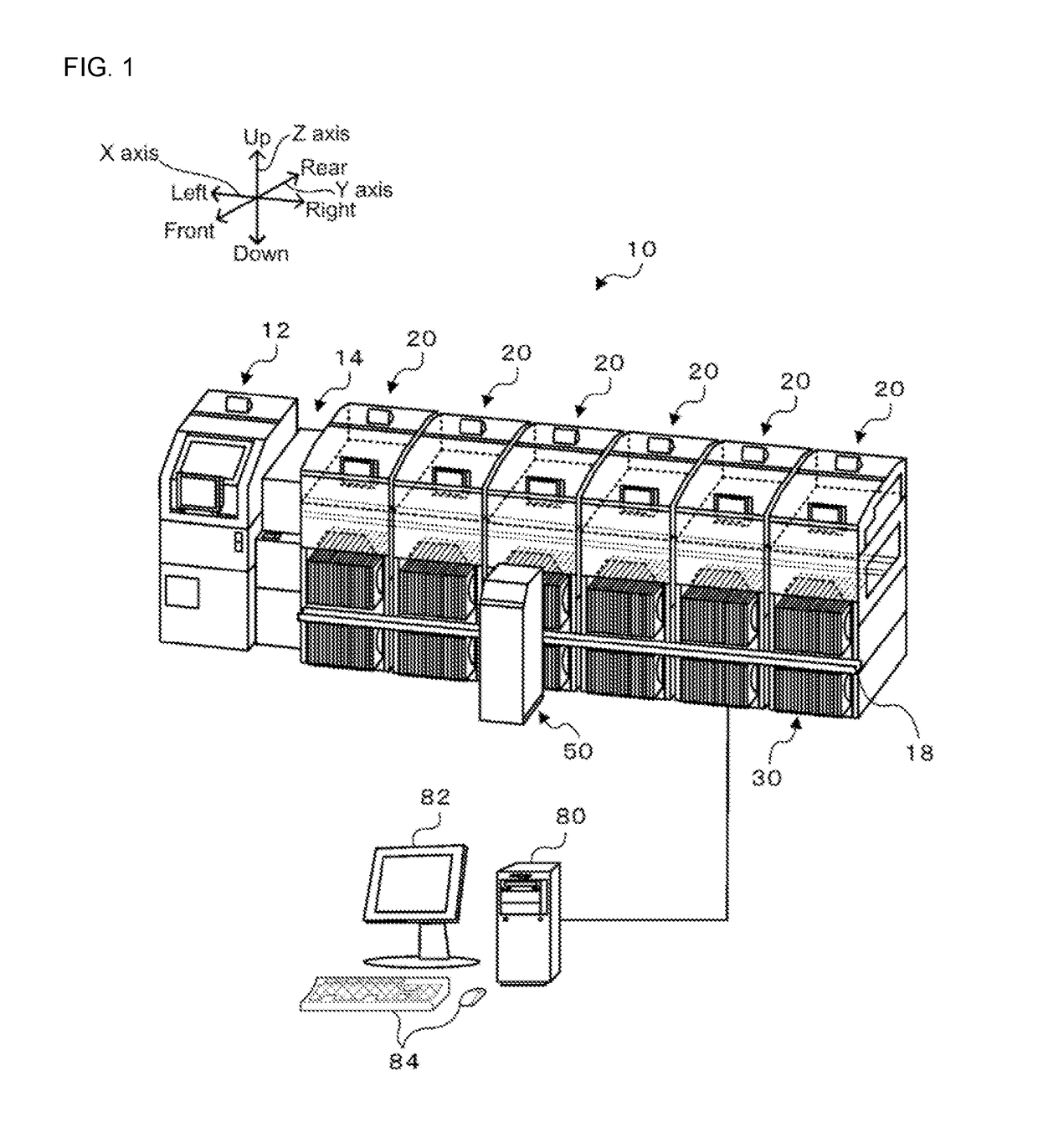

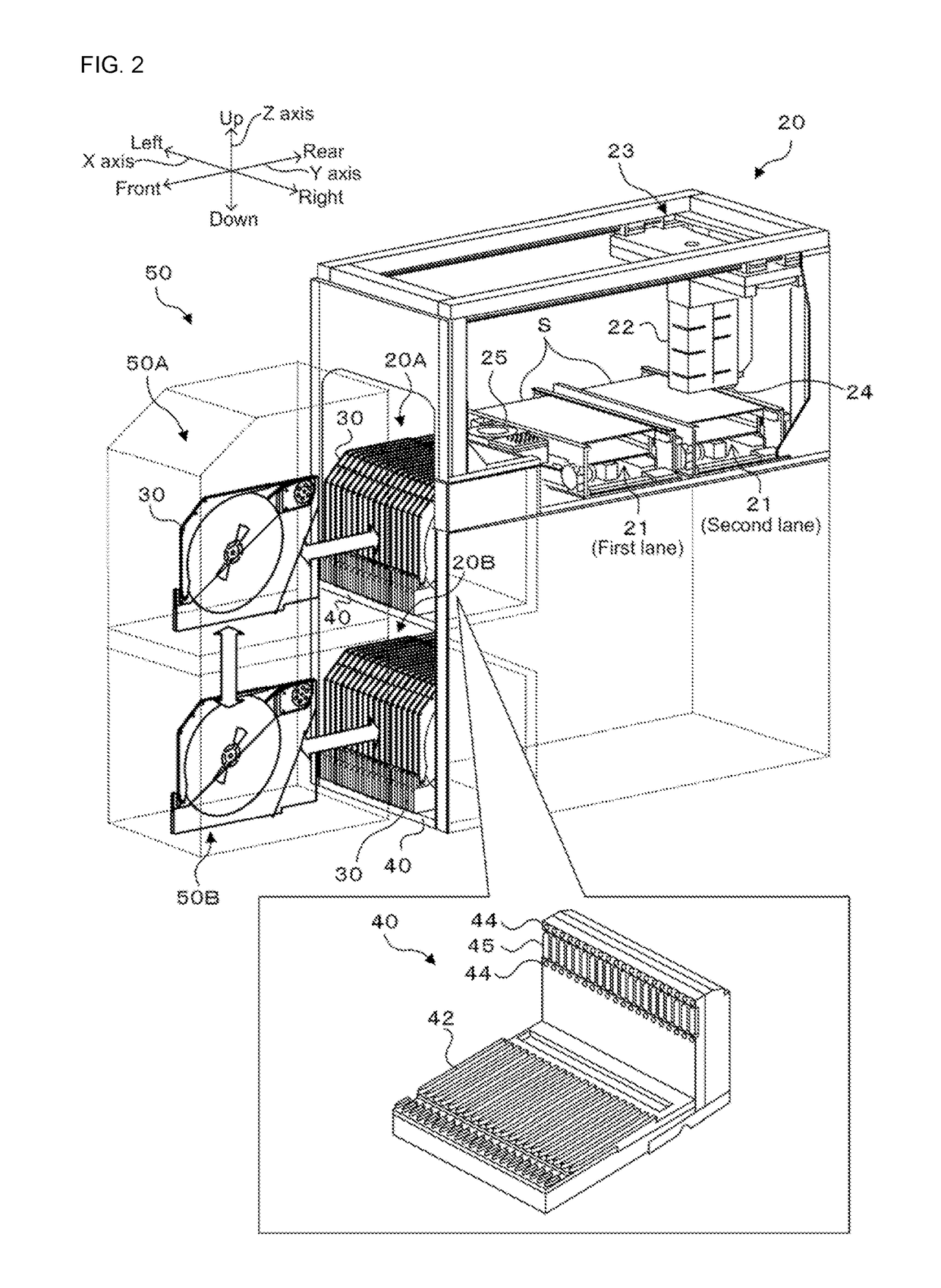

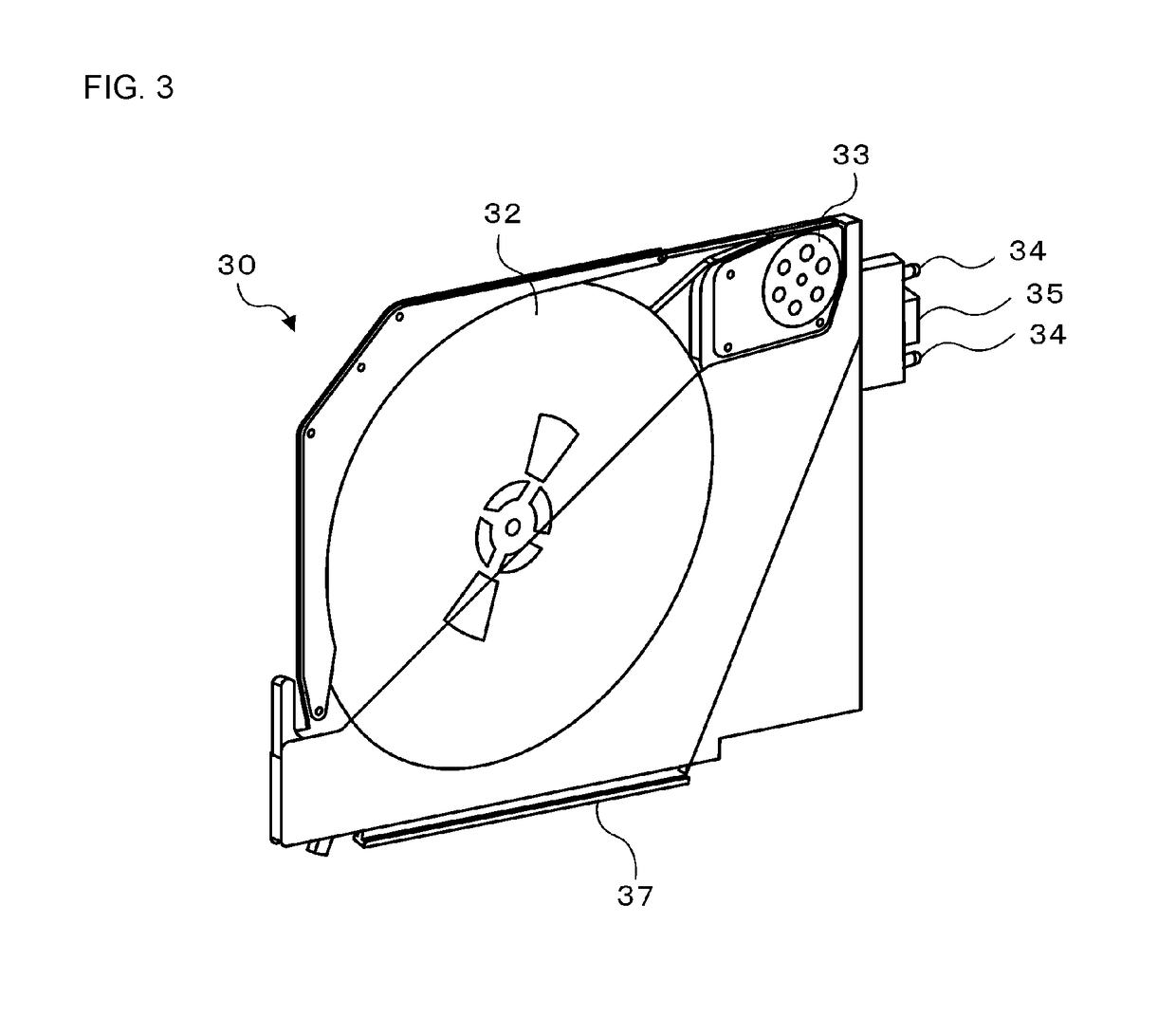

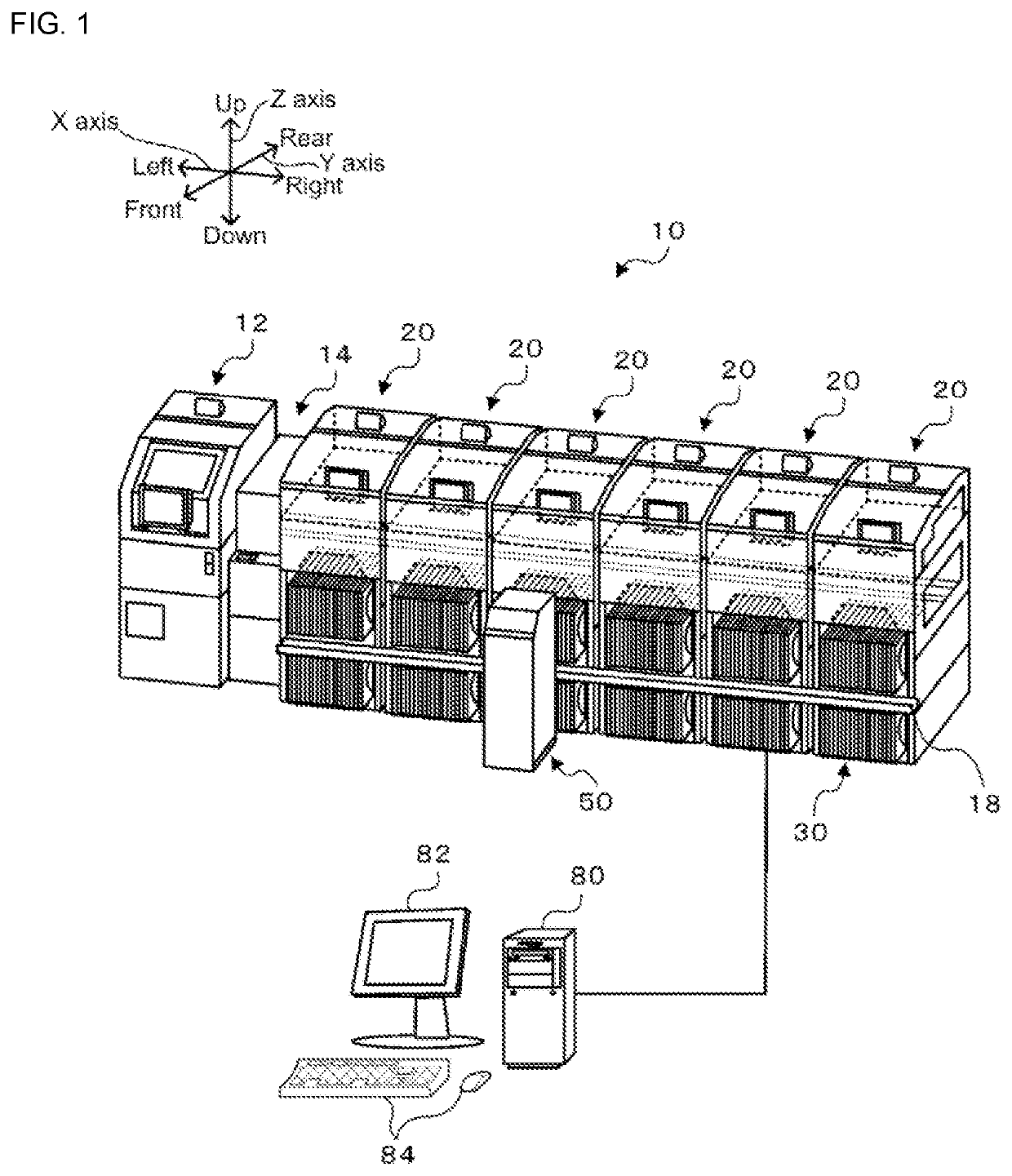

Mounting processing method, mounting system, exchange control device, and component mounter

ActiveUS20180376635A1Improve machining productivityQuick conversionCoupling device connectionsCoupling device engaging/disengagingMonoboardEngineering

A component mounting system starts mounting processing in a state in which a portion of the initial set target feeders of the multiple feeders required for mounting processing are set in supply area of component mounter, and in which remaining feeders are not set in supply area of component mounter. Mounting processing is performed while switching feeders that have finished supplying components with remaining feeders using exchange robot during mounting processing of a single board. By this, because it is possible to perform mounting processing while exchanging required feeders within the range of the upper limit loading quantity of component mounter, it is possible to improve the efficiency of mounting processing.

Owner:FUJI CORP

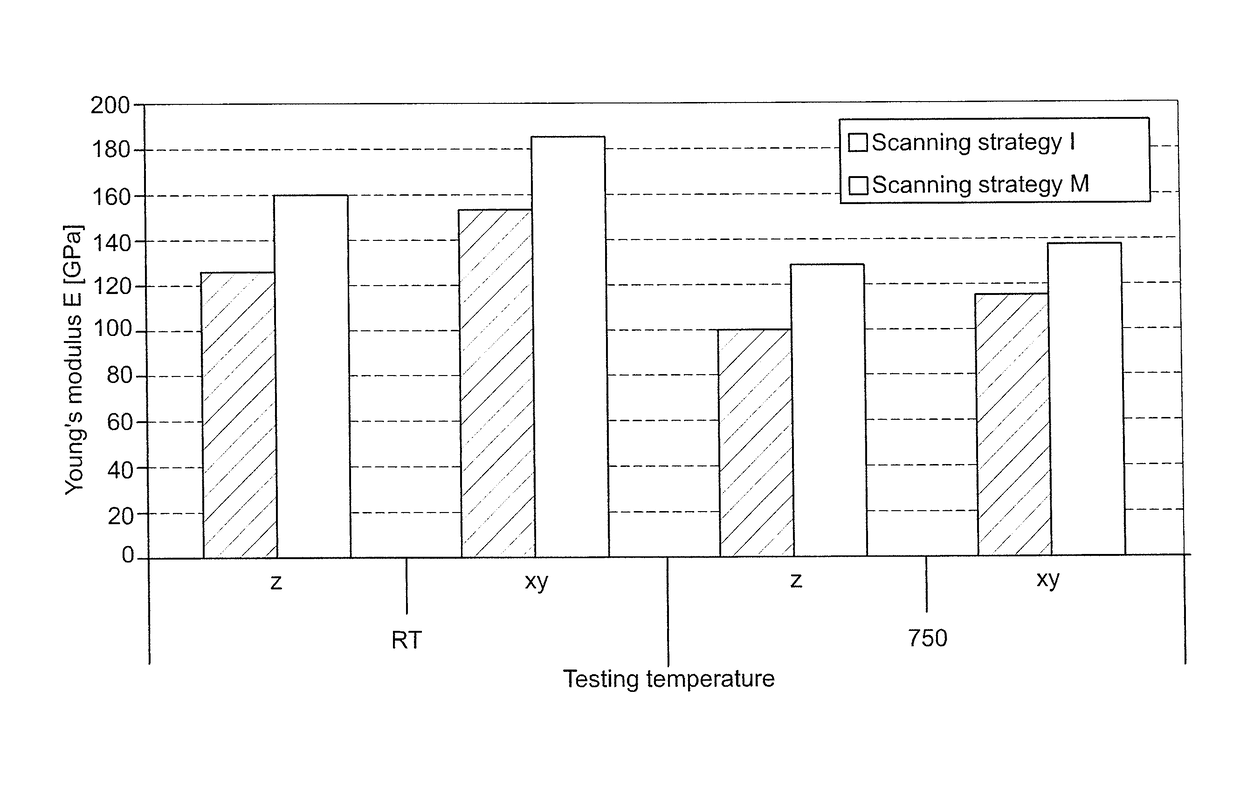

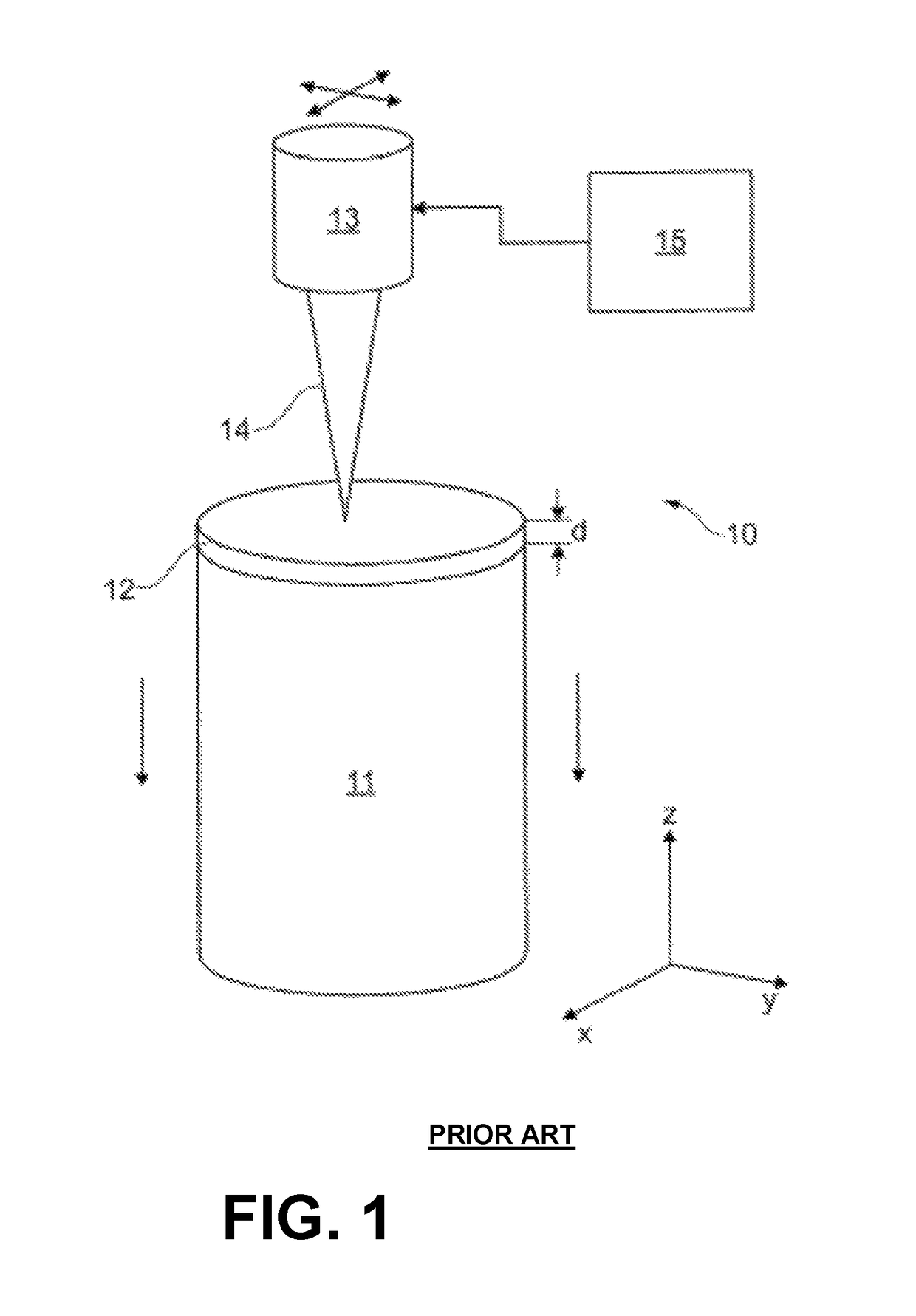

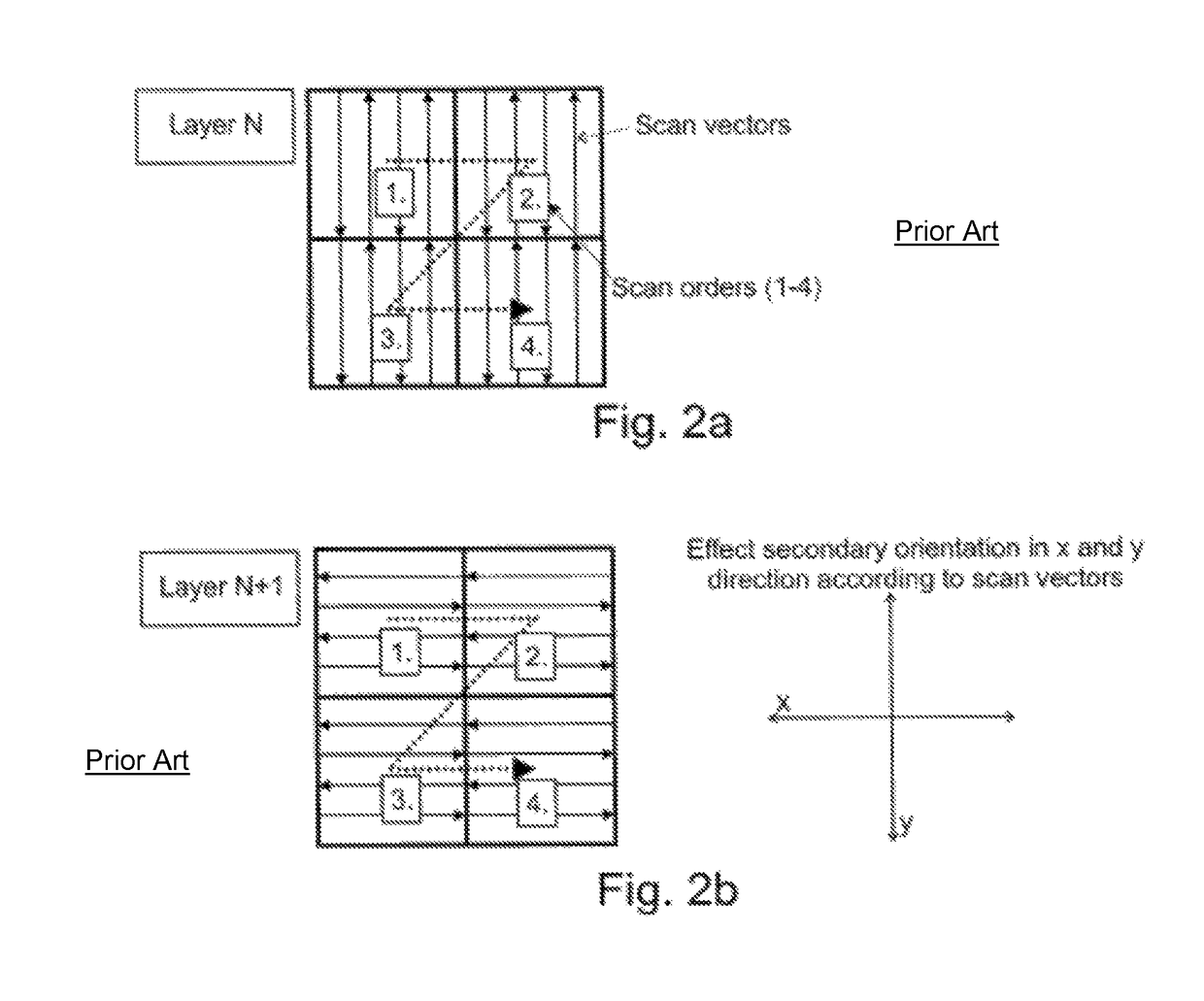

Method for manufacturing a hybrid component

InactiveUS9764423B2Improve machining productivityLow costTurbinesAdditive manufacturing apparatusGrain orientationCrystallite

The invention refers to a method for manufacturing a hybrid component including the following steps of manufacturing a preform as a first part of the hybrid component, then successively building up on that preform a second part of the component from a metallic powder material by means of an additive manufacturing process by scanning with an energy beam, thereby establishing a controlled grain orientation in primary and in secondary direction of at least a part of the second part of the component. The controlled secondary grain orientation is realized by applying a specific scanning pattern of the energy beam, which is aligned to the cross section profile of the component or to the local load conditions for the component.

Owner:ANSALDO ENERGIA IP UK LTD

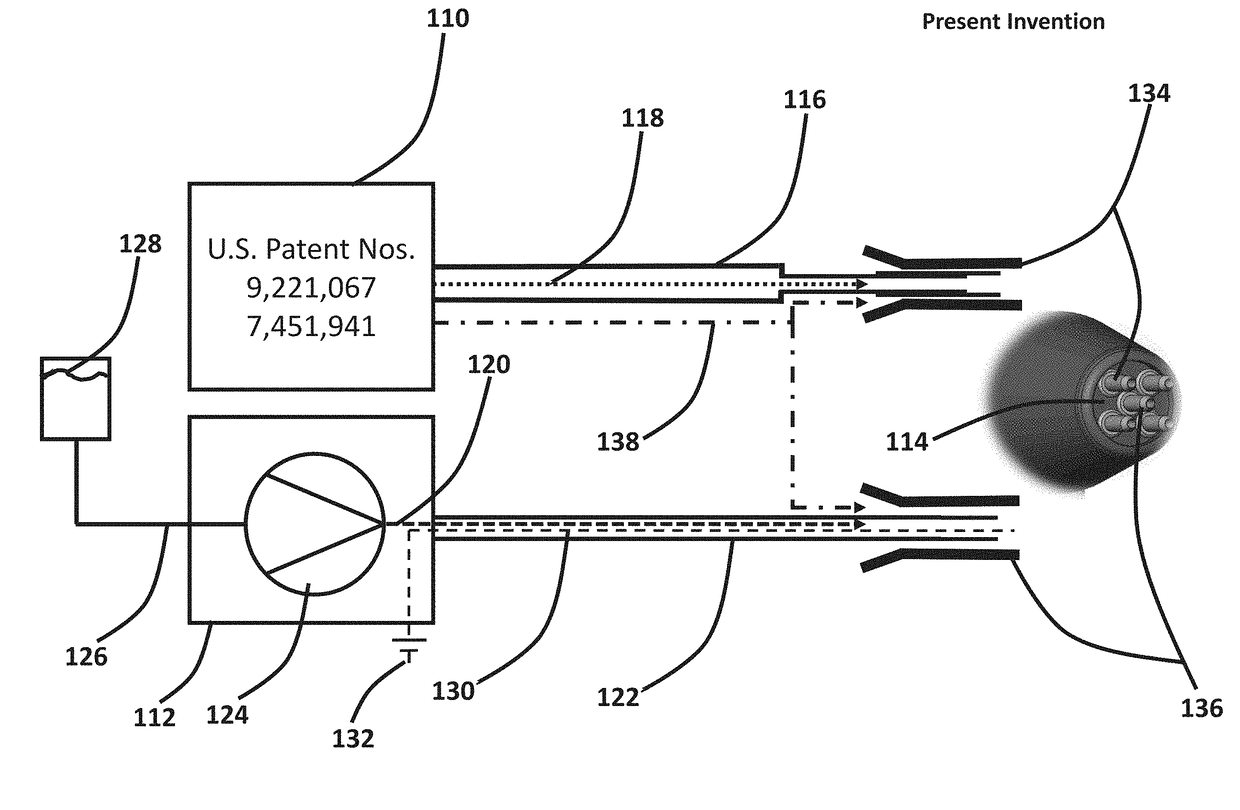

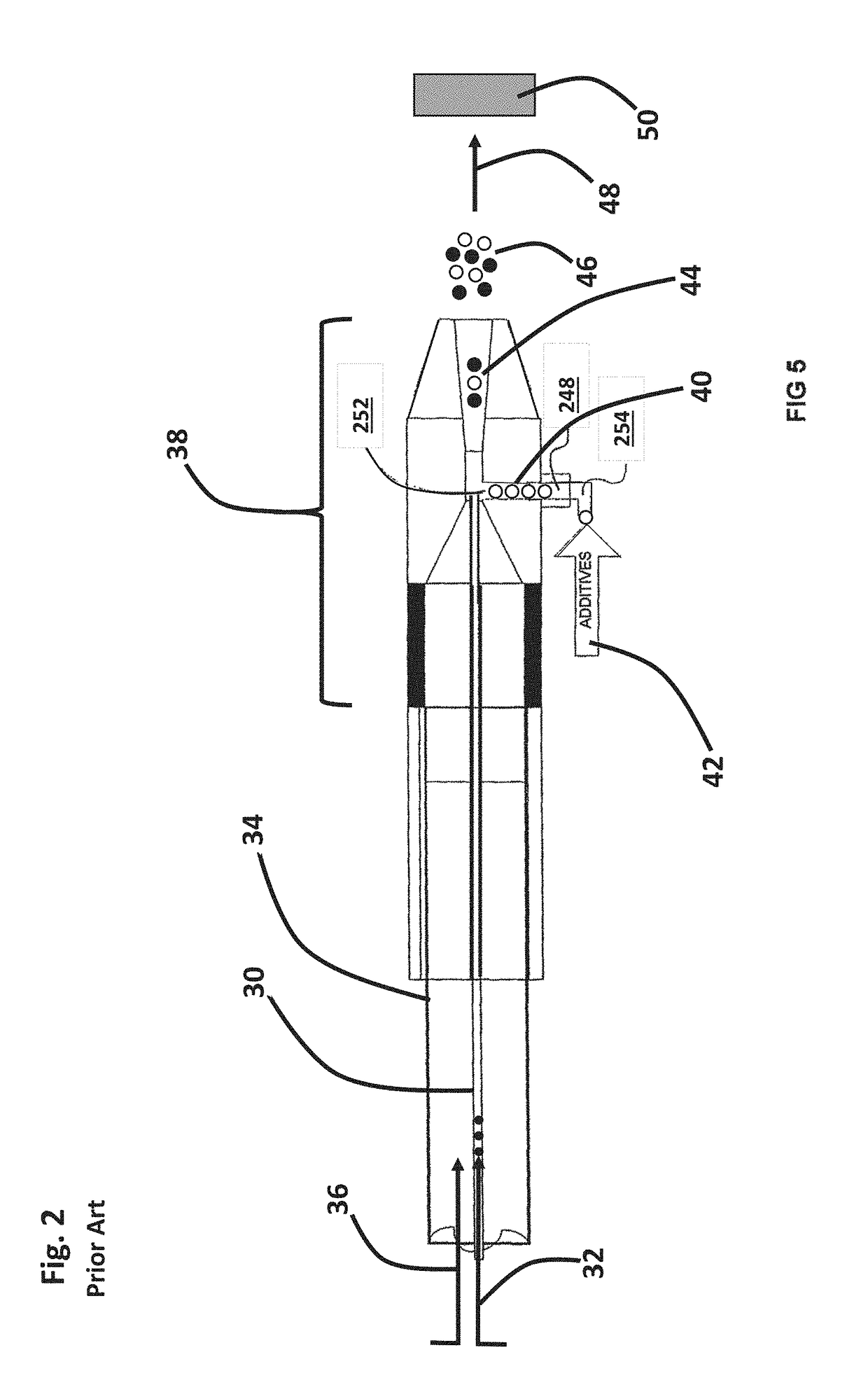

Passive Electrostatic CO2 Composite Spray Applicator

ActiveUS20180280998A1Eliminate distractionsOvercome limitationsLiquid supply arrangementsAbrasion apparatusInjection airHigh velocity

An electrostatic spray application apparatus and method for producing an electrostatically charged and homogeneous CO2 composite spray mixture containing an additive and simultaneously projecting at a substrate surface. The spray mixture is formed in the space between CO2 and additive mixing nozzles and a substrate surface. The spray mixture is a composite fluid having a variably-controlled aerial and radial spray density comprising pressure- and temperature-regulated propellant gas (compressed air), CO2 particles, and additive particles. There are two or more circumferential and high velocity air streams containing passively charged CO2 particles which are positioned axis-symmetrically and coaxially about an inner and lower velocity injection air stream containing one or more additives to form a spray cluster. The axis-symmetrical CO2 particle-air streams are passively tribocharged during formation, and the spray clustering arrangement creates a significant electrostatic field and Coanda air mass flow between and surrounding the coaxial flow streams.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com