Method for recycling rubber-containing wastes

a technology of rubber-containing wastes and wastes, which is applied in the field of recycling rubber-containing wastes, can solve the problems of high energy intensity, very actual polymer wastes, and use of wastes from synthetic rubber production, and achieve the effects of improving process productivity, simplifying technology, and speeding up process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

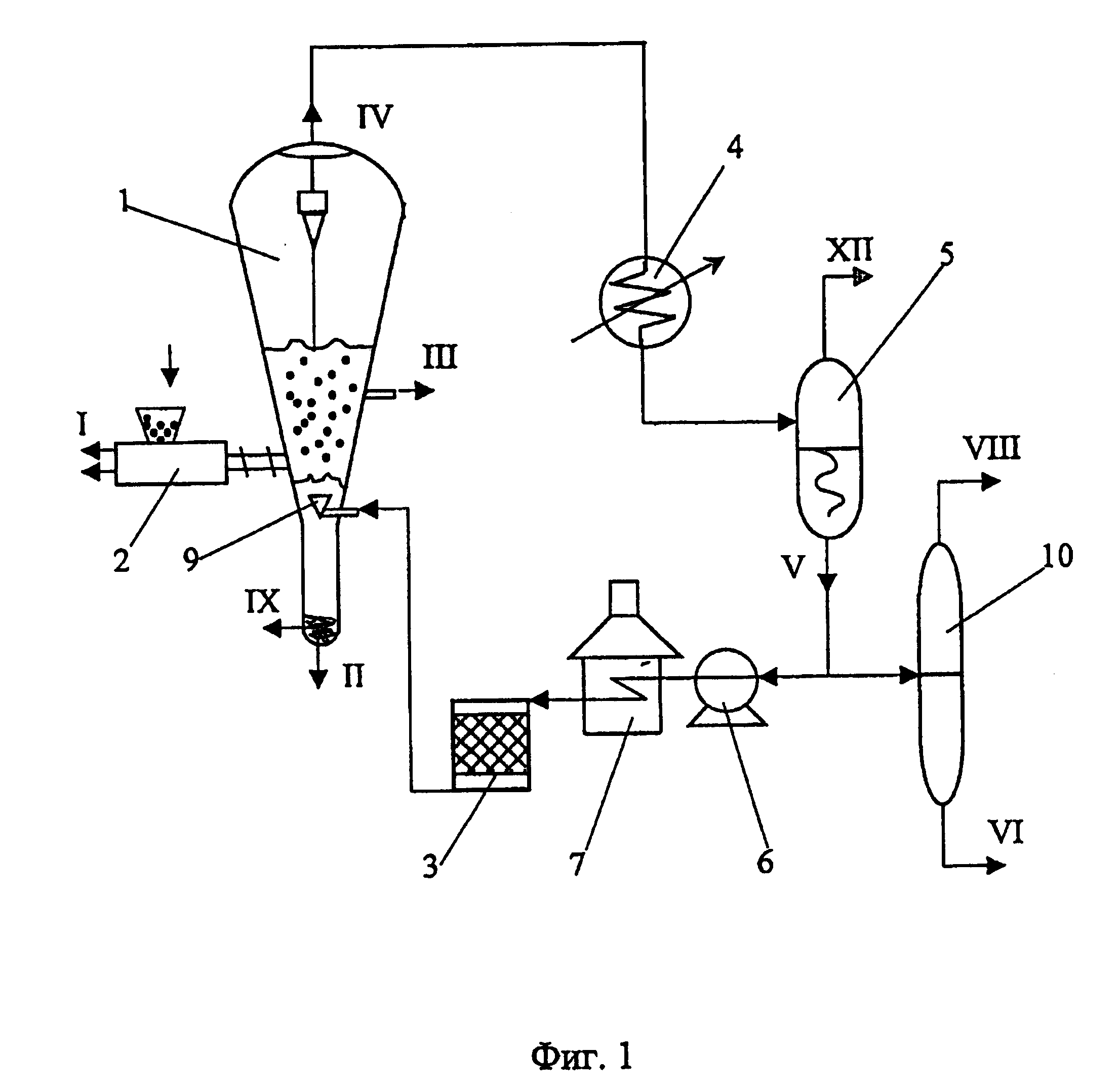

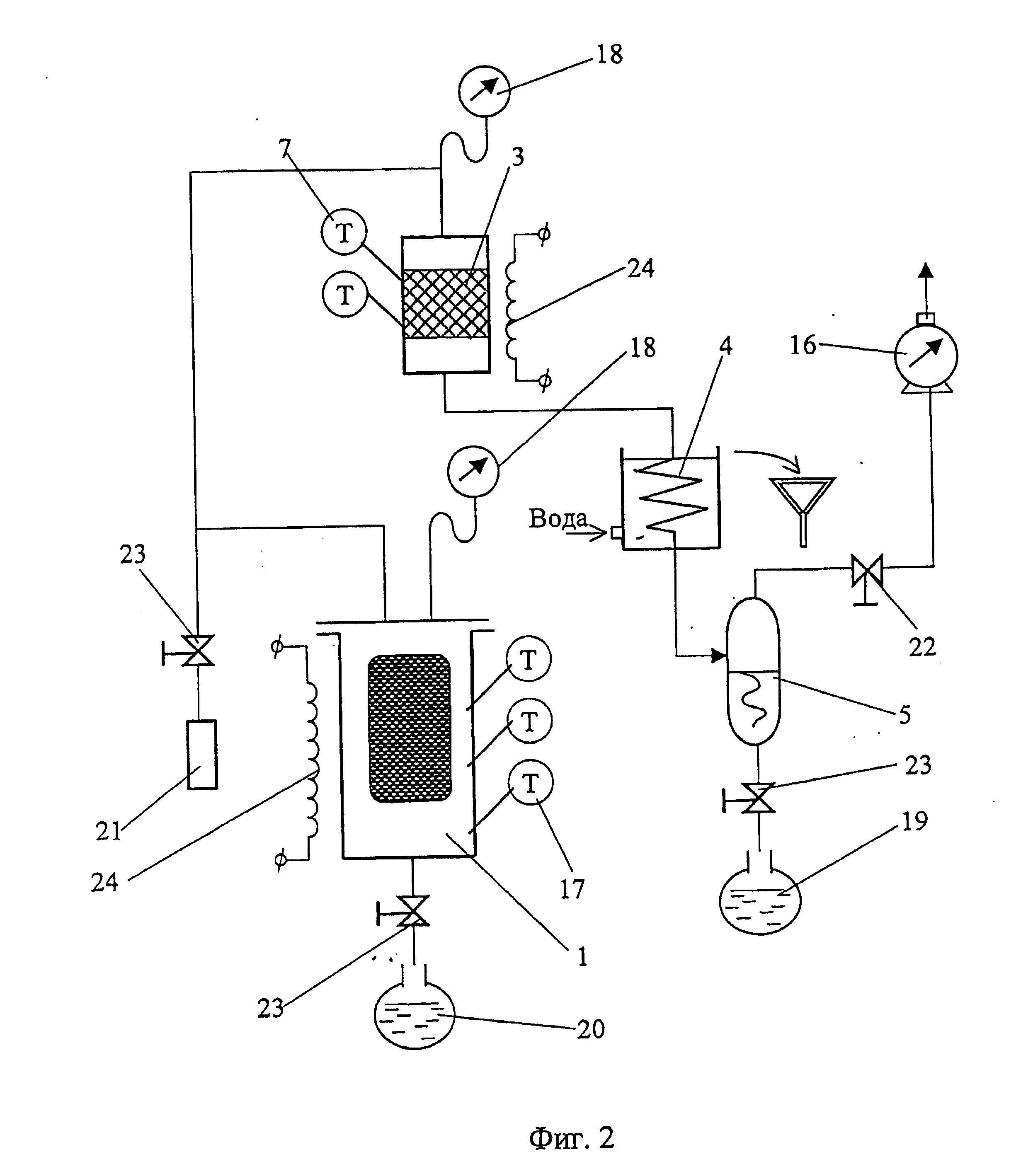

[0041]FIG. 1 schematically shows: a thermolysis reactor 1, a unit 2 for preparation and feeding of rubber-containing wastes, a reforming reactor 3, a cooler-condenser 4, a gas-liquid separator 5, a pump 6, a pipe furnace 7, a distributive device 9, a rectifying column 10.

[0042] The production process of thermal liquefaction (thermolysis) of rubber-containing wastes begins with waste preparation, e.g., worn tires. Rubber-containing wastes are washed, milled and separated from the slime I (steel cord, textile, dirt) in the unit 2 and afterwards are fed into the reactor 1 (conical) with a fluidized bed of rubber crumb and technical carbon in a solvent, which are is a state close to pseudo-critical.

[0043] Thermolysis of rubber and its conversion to the thermolysis products is carried out in the pseudo-fluidized bed of the solvent:

[0044] II—liquid heavy hydrocarbons having a boiling temperature above 220° C.;

[0045] III—powder technical carbon removed from the reactor 1 with the use o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com