Substrate processing apparatus, method of manufacturing semiconductor device and non-transitory computer-readable recording medium

a processing apparatus and semiconductor technology, applied in the direction of conveyor parts, transportation and packaging, coatings, etc., can solve the problem of reducing productivity and achieve the effect of reducing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0021]Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

[0022]Hereinafter, a substrate processing system according to the present embodiment will be described.

[0023](1) Configuration of Substrate Processing System

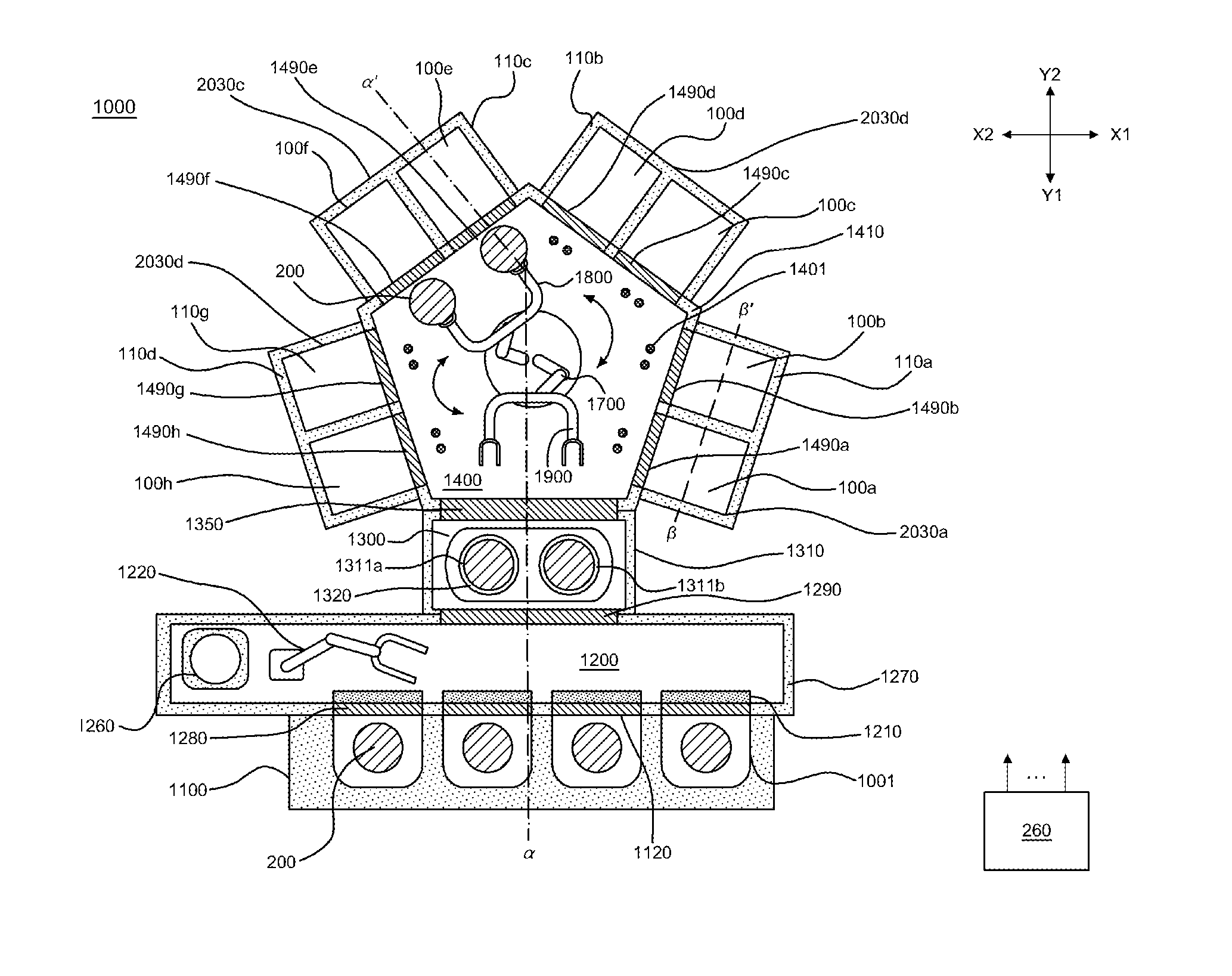

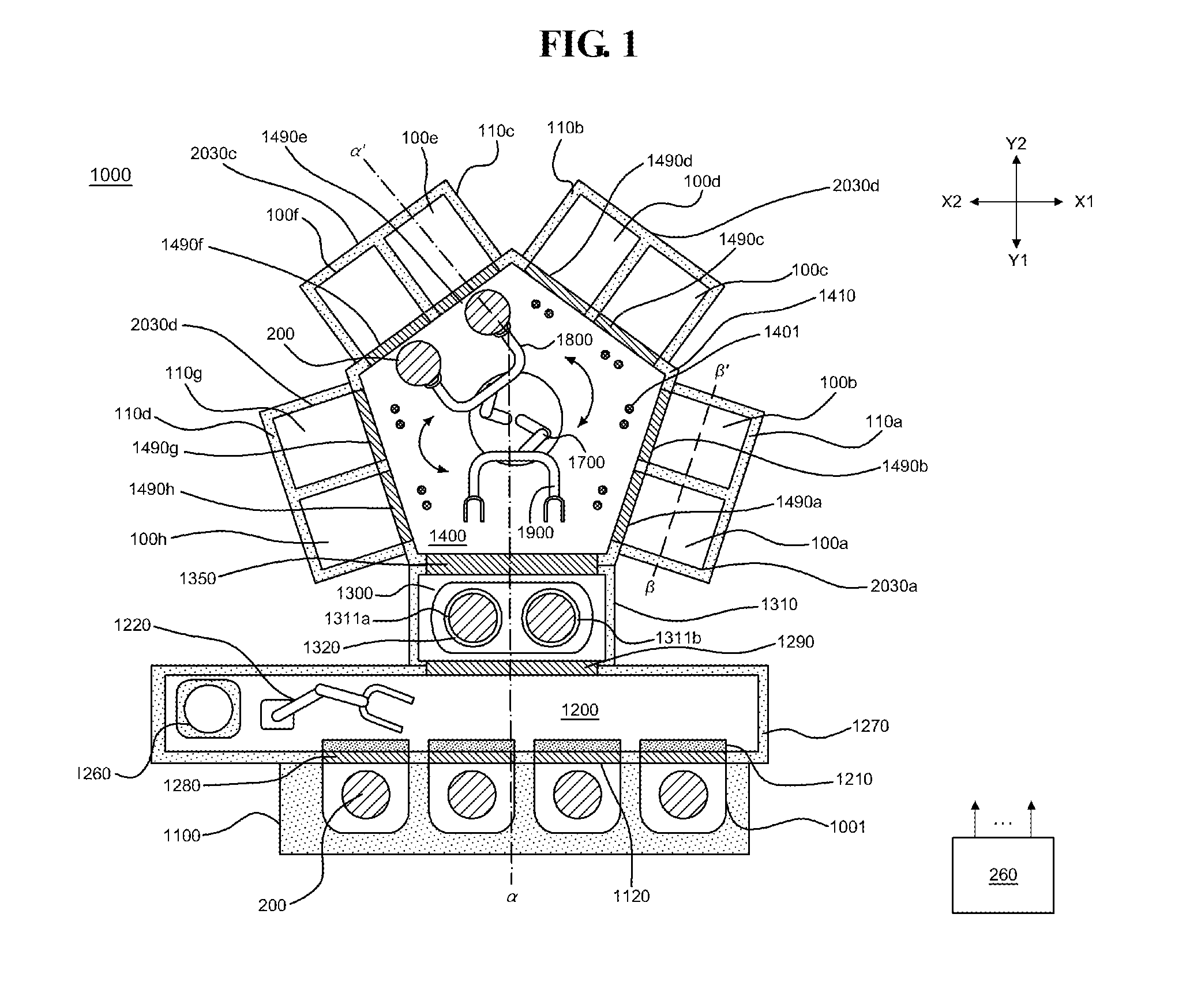

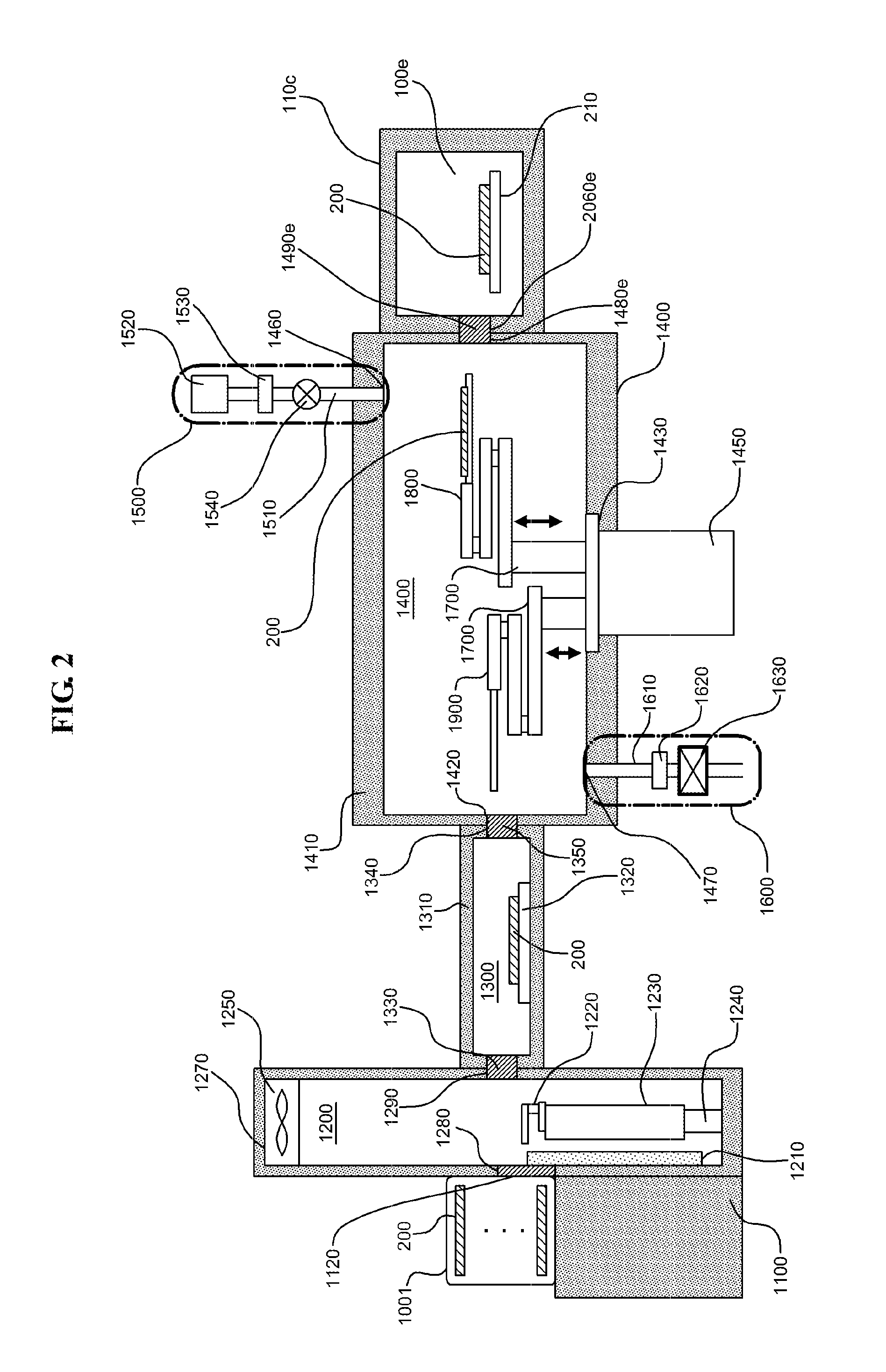

[0024]A configuration of a substrate processing system according to an embodiment of the present invention will be described with reference to FIGS. 1 through 4. FIG. 1 is a cross-sectional view illustrating the configuration of the substrate processing system according to the present embodiment. FIG. 2 is a vertical cross-sectional view taken along line α-α′ of FIG. 1 that illustrates the configuration of the substrate processing system according to the present embodiment. FIG. 3 is an explanatory diagram for describing in detail an arm of FIG. 1. FIG. 4 is a vertical cross-sectional view taken along line β-β′ of FIG. 1 and an explanatory diagram for describing a gas supply system that supplies a gas to a process modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com