Full-automatic automobile valve assembly machine

A fully automatic, valve group technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of easy defective products, high cost, low degree of automation, etc., to improve processing productivity, reduce wear, improve The effect of feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

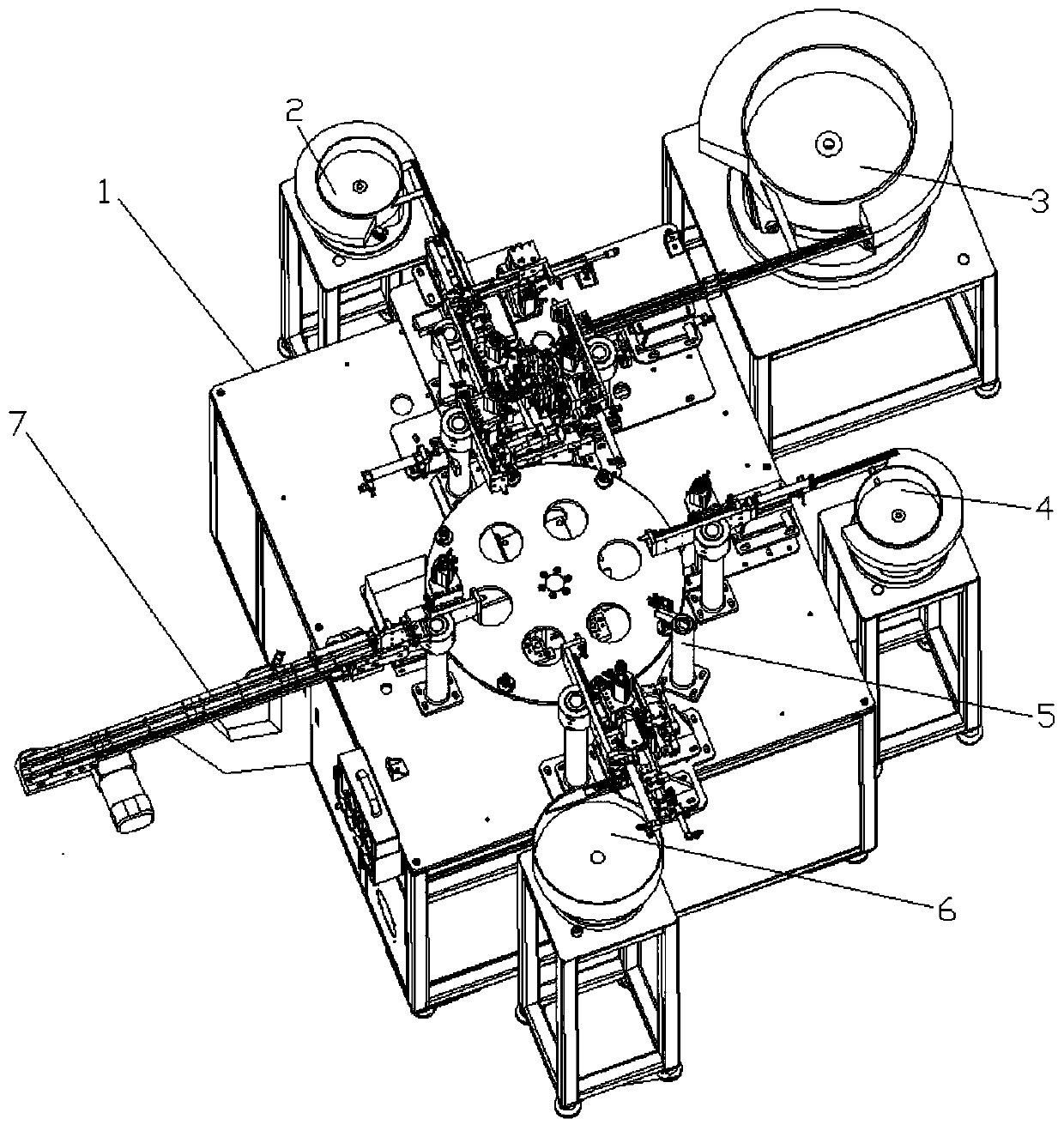

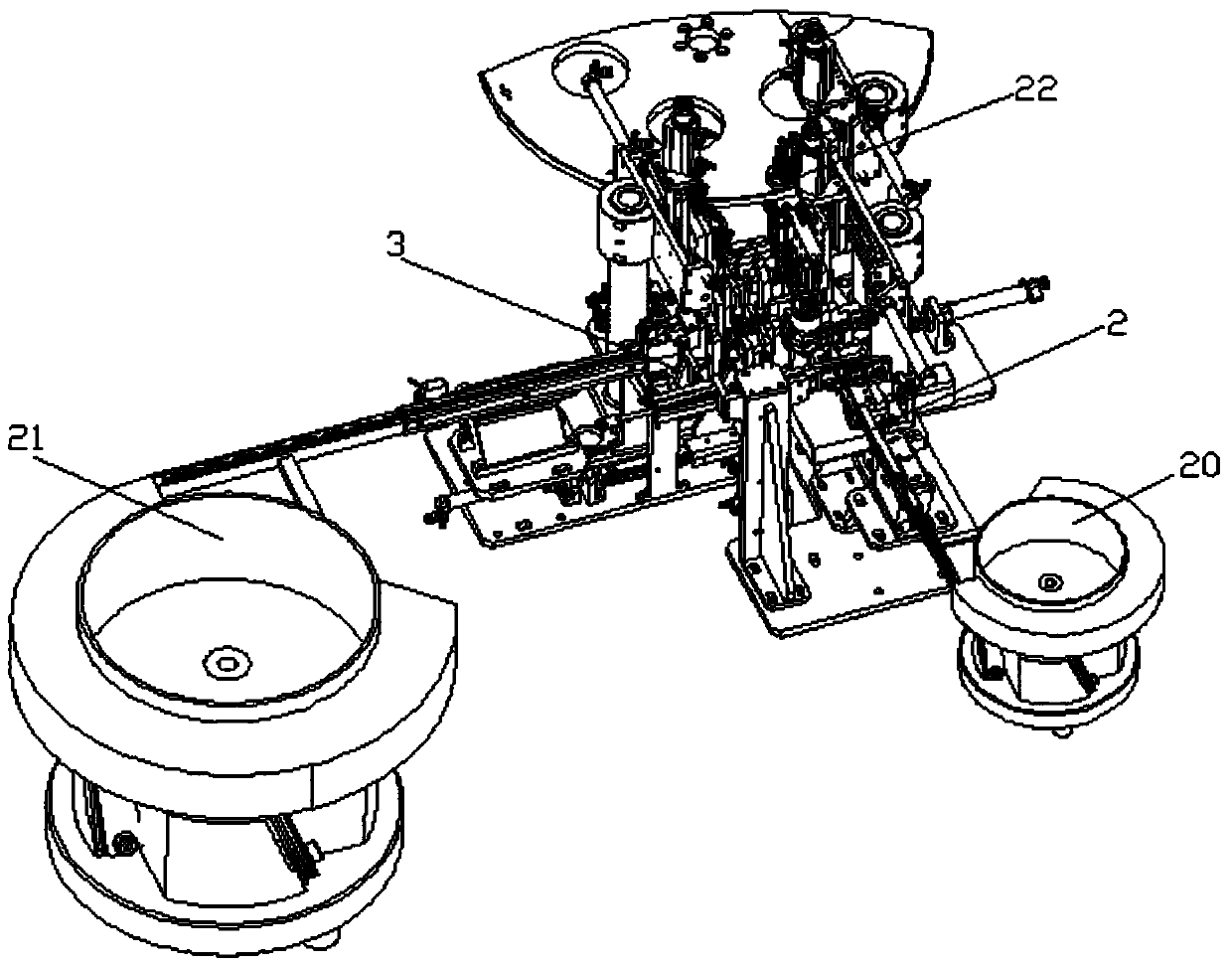

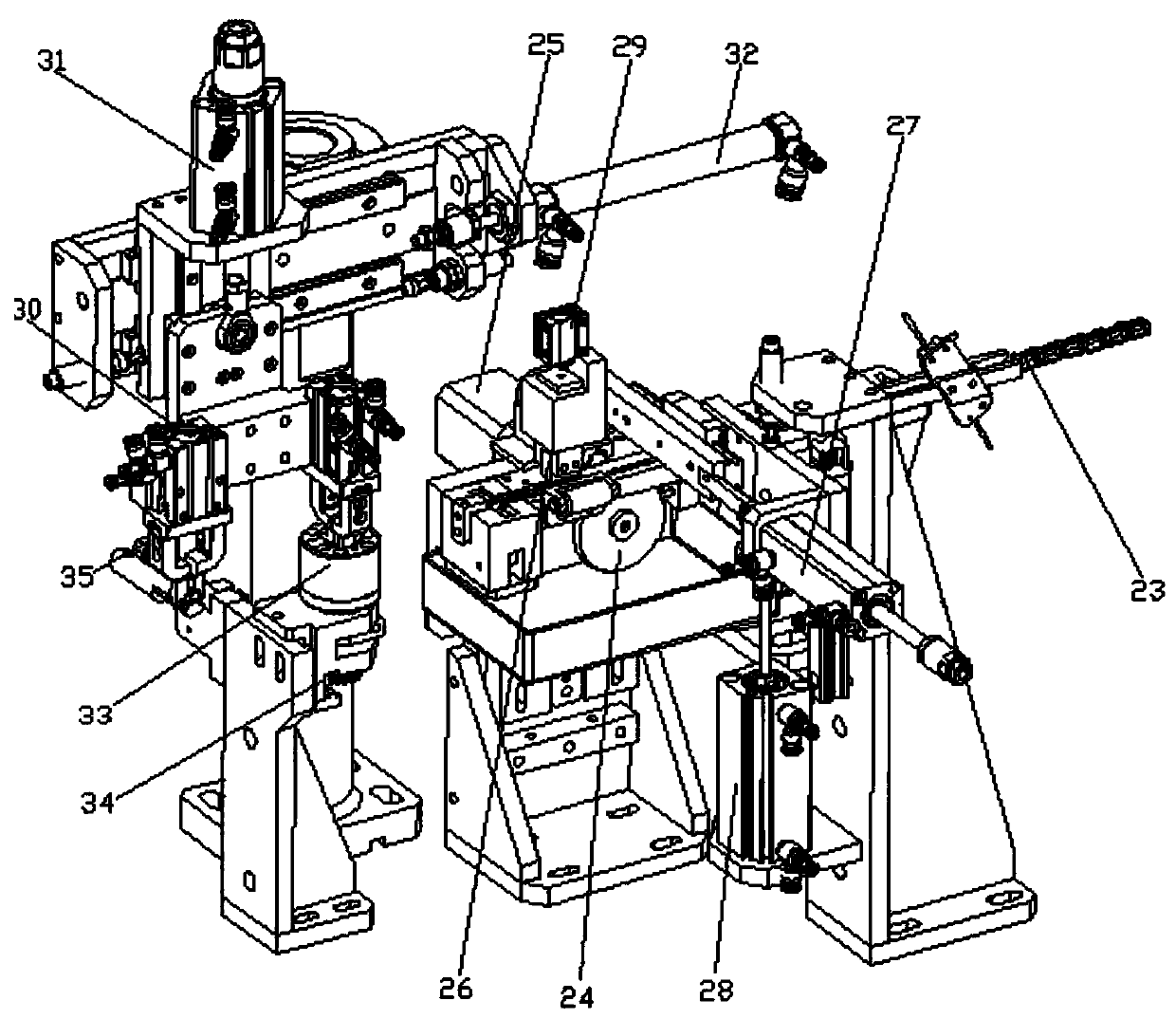

[0040] Such as Figure 1-Figure 14 As shown, the structure of the present invention is: a fully automatic automobile valve assembly machine, which includes a frame 1 and a power distribution control box arranged in the frame 1, and the middle part above the frame 1 is provided with a turntable device 8, so The turntable device 8 includes a turntable drive motor 61 and a turntable 60 that are fixed on the frame 1 and cooperate with each other. The turntable carrier 22 is uniformly arranged on the turntable 60 along the ring. The direction of rotation is sequentially provided with a key piece conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com