Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

A vitrified bond and metal technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of easy formation of vibration marks and poor impact resistance, and reduce cracks, wear resistance and shape Good retention, excellent wetting and firm holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

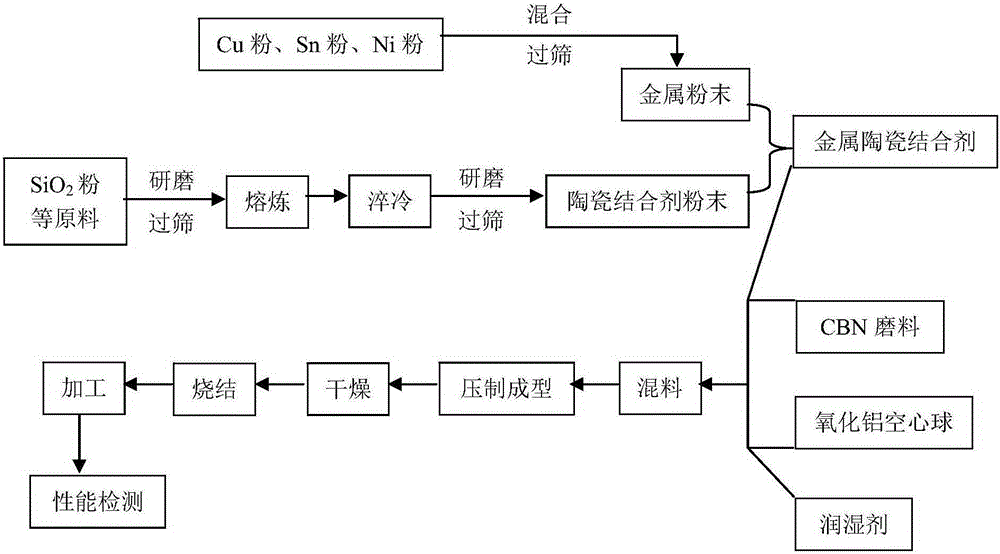

Method used

Image

Examples

Embodiment 1

[0033] The cermet bond of this embodiment is made up of a ceramic component with a mass fraction of 90% and a metal component with a mass fraction of 10%; the ceramic component is made up of the following components in percentage by weight: SiO 2 52%, B 2 o 3 26%, Al 2 o 3 10%, Na 2 O5%, CaO0.5%, K 2 O4%, MgO0.5%, TiO 2 2%; the metal component is composed of the following components in weight percentage: Cu70%, Sn18%, Ni12%.

[0034] The preparation method of the metal-ceramic bond of the present embodiment comprises the following steps:

[0035] 1) SiO 2 Powder, B 2 o 3 Powder, Al 2 o 3 Powder, Na 2 O powder, CaO powder, K 2 O powder, MgO powder, TiO 2 Grind the powder through a 40-mesh sieve, put it into a corundum crucible, and heat it up to 1400°C at a rate of 10°C / min through a high-temperature electric furnace, keep it warm for 2 hours to fully clarify and homogenize, and obtain a melt;

[0036] 2) Pour out the melt obtained in step 1), water-quench into g...

Embodiment 2

[0044] The cermet bond of this embodiment is composed of a ceramic component with a mass fraction of 92% and a metal component with a mass fraction of 8%; the ceramic component is composed of the following components in weight percentage: SiO 2 40%, B 2 o 3 8%, Al 2 o 3 11%, Na 2 O18%, CaO5%, K 2 O10%, MgO2%, TiO 2 6%; the metal component is composed of the following components in weight percentage: Cu55%, Sn30%, Ni15%.

[0045] The preparation method of the metal-ceramic bond of the present embodiment comprises the following steps:

[0046] 1) SiO 2 Powder, B 2 o 3 Powder, Al 2 o 3 Powder, Na 2 O powder, CaO powder, K 2 O powder, MgO powder, TiO 2 The powder is ground through a 40-mesh screen and put into a corundum crucible, and the temperature is raised to 1300°C by a high-temperature electric furnace at a rate of 10°C / min, and kept for 2 hours to fully clarify and homogenize to obtain a melt;

[0047] 2) Pour out the melt obtained in step 1), water-quench in...

Embodiment 3

[0055] The cermet bond of this embodiment is composed of a ceramic component with a mass fraction of 88% and a metal component with a mass fraction of 12%; the ceramic component is composed of the following components in weight percentage: SiO 2 60%, B 2 o 3 8%, Al 2 o 3 20%, Na 2 O6%, CaO0.5%, K 2 O3%, MgO0.5%, TiO 2 2%; the metal component is composed of the following components in weight percentage: Cu65%, Sn15%, Ni20%.

[0056] The preparation method of the metal-ceramic bond of the present embodiment comprises the following steps:

[0057] 1) SiO 2 Powder, B 2 o 3 Powder, Al 2 o 3 Powder, Na 2 O powder, CaO powder, K 2 O powder, MgO powder, TiO 2 The powder is ground through a 40-mesh sieve and put into a corundum crucible, and the temperature is raised to 1400°C by a high-temperature electric furnace at a rate of 10°C / min, and kept for 2 hours to fully clarify and homogenize to obtain a melt;

[0058] 2) Pour out the melt obtained in step 1), water-quench ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com