High-precision efficient automatic grinding and detecting production line and high-precision efficient automatic grinding and detecting production method

A production line and grinding technology, which is used in measuring/indicating equipment, metal sawing equipment, tool manufacturing for sawing machines, etc. to the expected effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

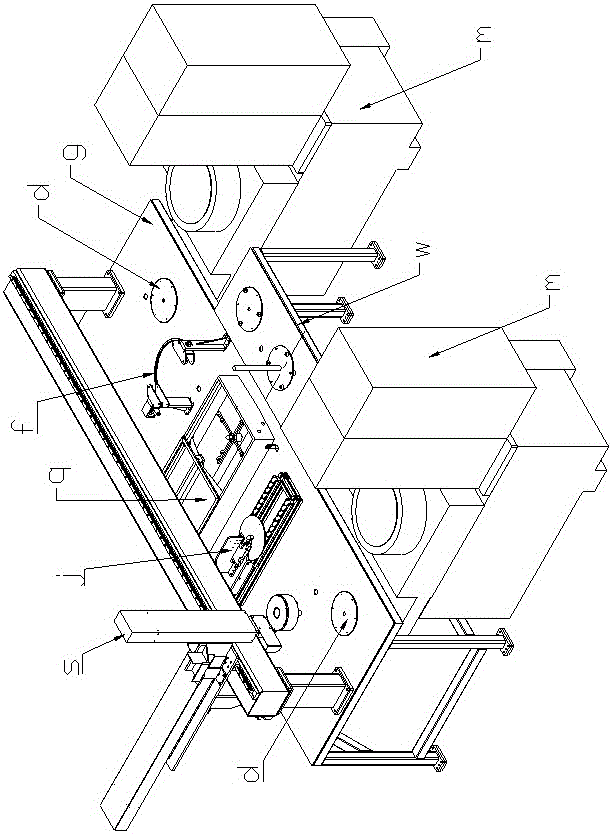

[0046] Such as figure 1 As shown, the three-degree-of-freedom manipulator inspection and cleaning automatic production line includes a three-degree-of-freedom manipulator mechanism s, a cleaning mechanism q, a turning mechanism f, a detection mechanism j, a worktable g, a material table w, and two sets of machines arranged at both ends of the workbench g grinder m. The working table g is used to install the three-degree-of-freedom manipulator mechanism s, the cleaning mechanism q, the turning mechanism f, the detection mechanism j, the material table w and the area to be processed d. There are two areas d to be processed, which are located in front of the two grinding machines m. The material table w is used to place workpieces.

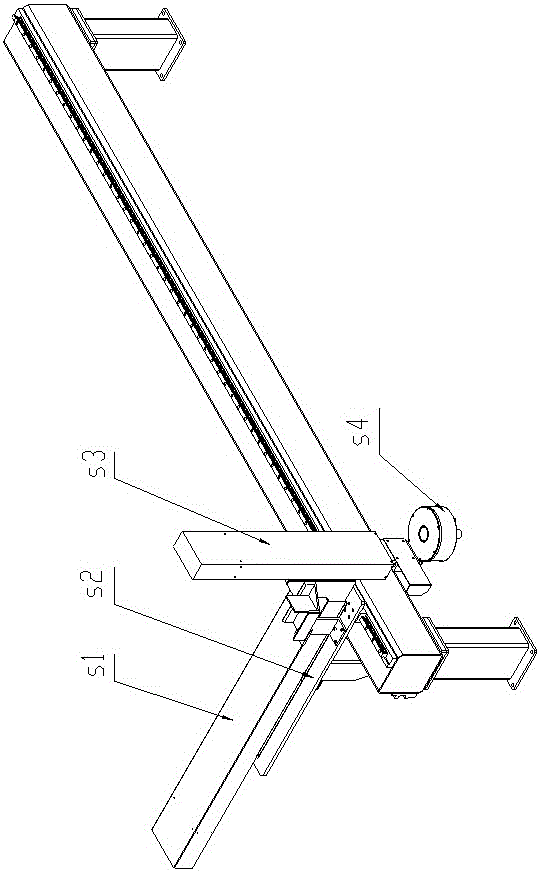

[0047] Such as figure 2 As shown, the three-degree-of-freedom manipulator mechanism s include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com