OpenCV-based high-reflection bottle cap defect detection method

A defect detection and high-reflection technology, applied in measuring devices, material analysis through optical means, image analysis, etc., can solve problems such as poor detection effect and high labor intensity, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

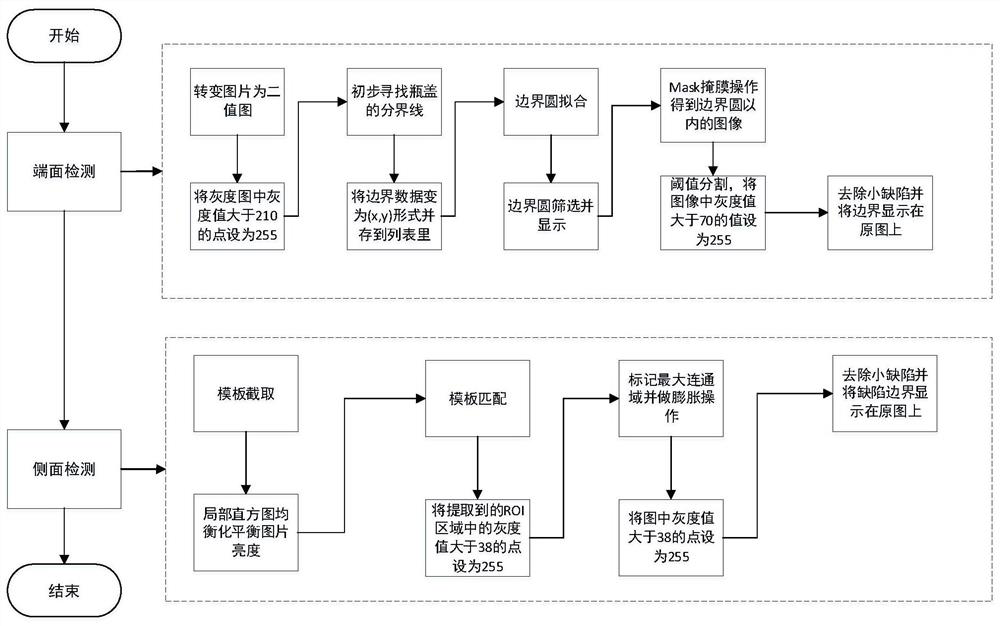

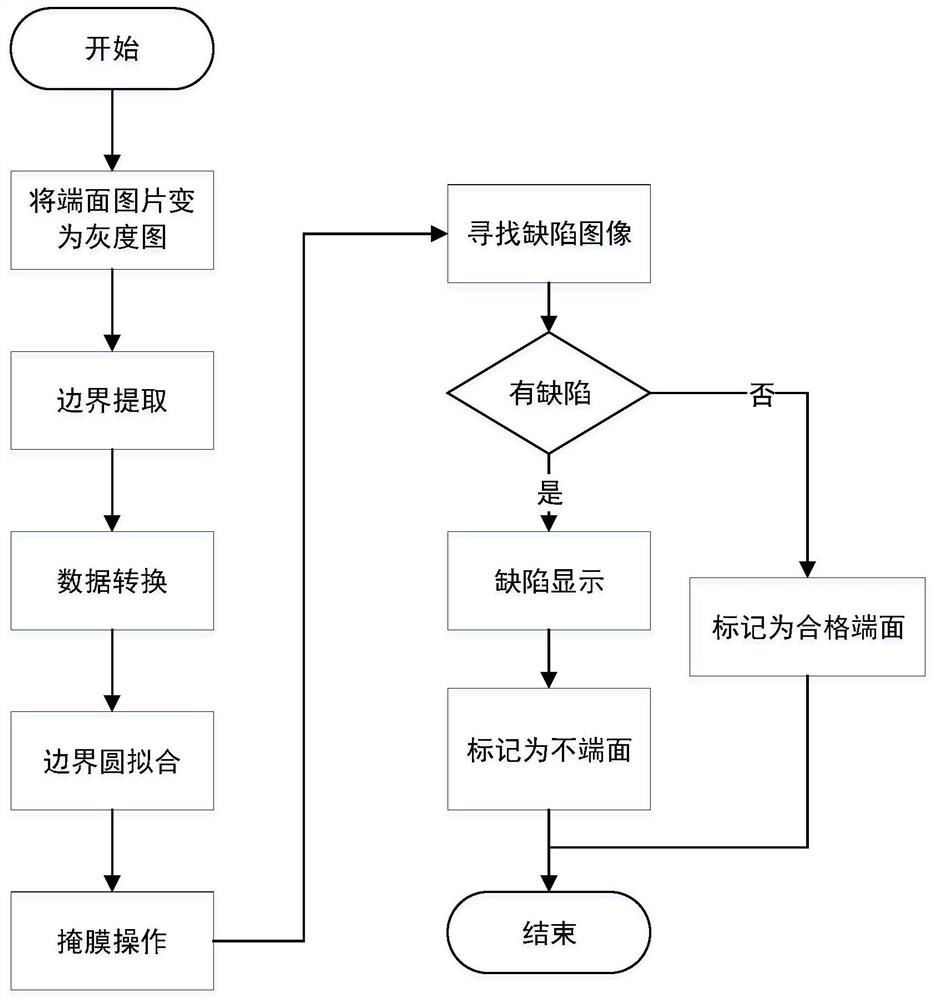

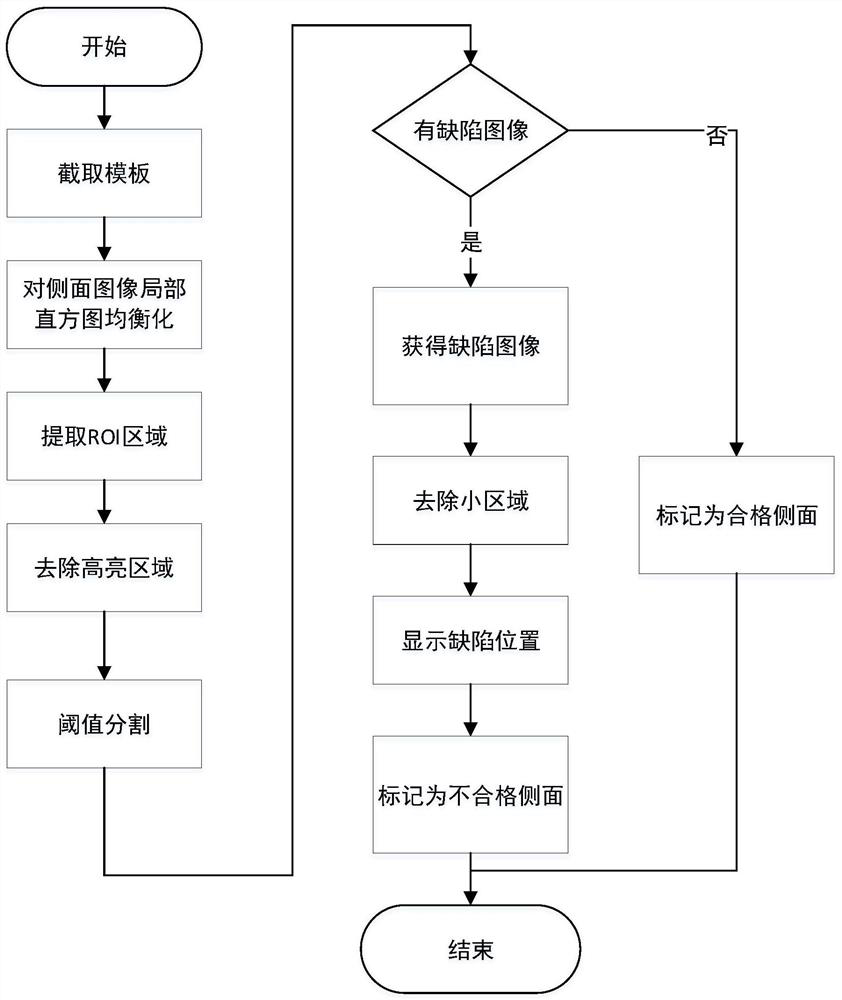

[0053] The present invention proposes an OpenCV-based intelligent detection method for defects on the outer surface of a highly reflective plastic bottle cap. The detection is divided into end face detection and side detection. The flow chart of end face detection is as follows figure 2 As shown, the flow chart of side detection is as follows image 3 shown. Mainly use the library function that comes with OpenCV to process the captured image of the bottle cap and then get the position of the defect on the bottle cap.

[0054] The flaws in the existing highly reflective plastic bottle cap inspection are mainly detected by naked eyes manually, which has high work intensity but low detection efficiency. Therefore, the present invention proposes a defect detection algorithm for highly reflective plastic bottle caps based on OpenCV to realize the highly reflective surface. Autonomous identification and localization of defects on plastic bottle caps.

[0055] Such as Figure 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com