Automatic detection device for touch screen

An automatic detection device, touch screen technology, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problem of not being able to fully detect the functional integrity of the touch screen, save detection costs, achieve structural design, and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

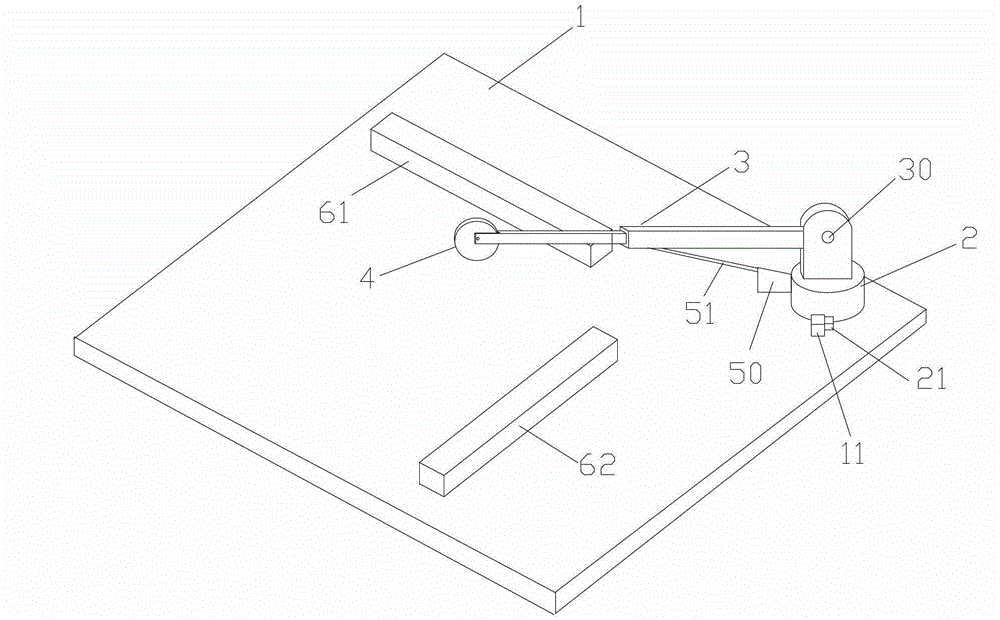

[0023] The embodiment of the present invention provides a touch screen automatic detection device, such as figure 1 As shown, it includes a detection platform 1, a rotating column 2, a telescopic rod 3, and a detection roller 4. The rotating column 2 is rotatably mounted on the detection platform, and one end of the telescopic rod 3 is pivotally connected to the rotating column through a pivot 30 2, and can be rotated in a direction perpendicular to the detection platform 1. The other end of the telescopic rod 3 is rotatably installed with the detection roller 4 and the rotation axis of the detection roller 4 is parallel to the detection platform 1. A driving motor (not shown in the figure) drives to rotate around an axis perpendicular to the detection platform, and the telescopic rod 3 is driven by a second driving motor (not shown in the figure) to move closer to or away from the rotation The direction of the column is telescopic, and the rotating column 2 is also provided wit...

Embodiment 2

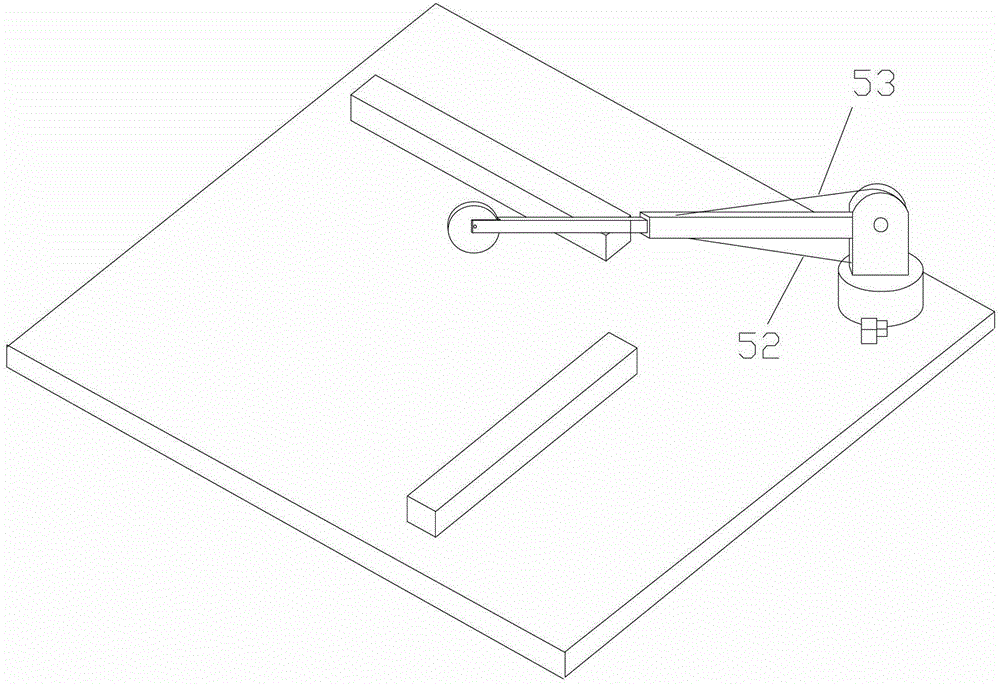

[0037] The difference between the embodiment of the present invention and the first embodiment is the driving device, such as figure 2 As shown, the driving device in the embodiment of the present invention includes a first wire 52, a second wire 53, a first wire winder (not shown in the figure), and a second wire winder (not shown in the figure). One end of the first pull wire 52 is connected to the rear half of the side of the telescopic rod far away from the detection platform, the other end of the first pull wire 52 is wound on the first winder, and one end of the second pull wire 53 is connected to the telescopic rod Approaching the back half of one side of the detection platform, the other end of the second pull wire is wound on the second winder, the first winder and the second winder are respectively located on the rotating column on the upper and lower sides of the pivot . The first winder pulls the telescopic rod from above the pivot (the telescopic rod is pivotally...

Embodiment 3

[0041] The difference between the embodiment of the present invention and the first embodiment above is still in the driving device. The driving device in the embodiment of the present invention is a third driving motor, and the third driving motor is synchronously connected with the pivot to drive the pivot. Rotate.

[0042] In order to realize the synchronous connection between the third drive motor and the pivot, the output shaft of the third drive motor can be coaxially connected with the pivot, and only a side wall of the rotating column needs to be provided for fixing the third drive motor Then, the output shaft of the third drive motor and the pivot shaft are coaxially fixedly connected.

[0043] Of course, the third drive motor can also be synchronously connected through a transmission belt, a transmission chain, or a transmission gear. These synchronous connection modes are known to those skilled in the art, and will not be repeated here.

[0044] It can be understood that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com