Self-adaptive adjustment method and system based on digital twinborn body

An adaptive and twinning technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problem of the gap between the application research of assembly simulation simulation and digital twin technology, to improve the efficiency of assembly and debugging, and to achieve broad application prospects. , The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

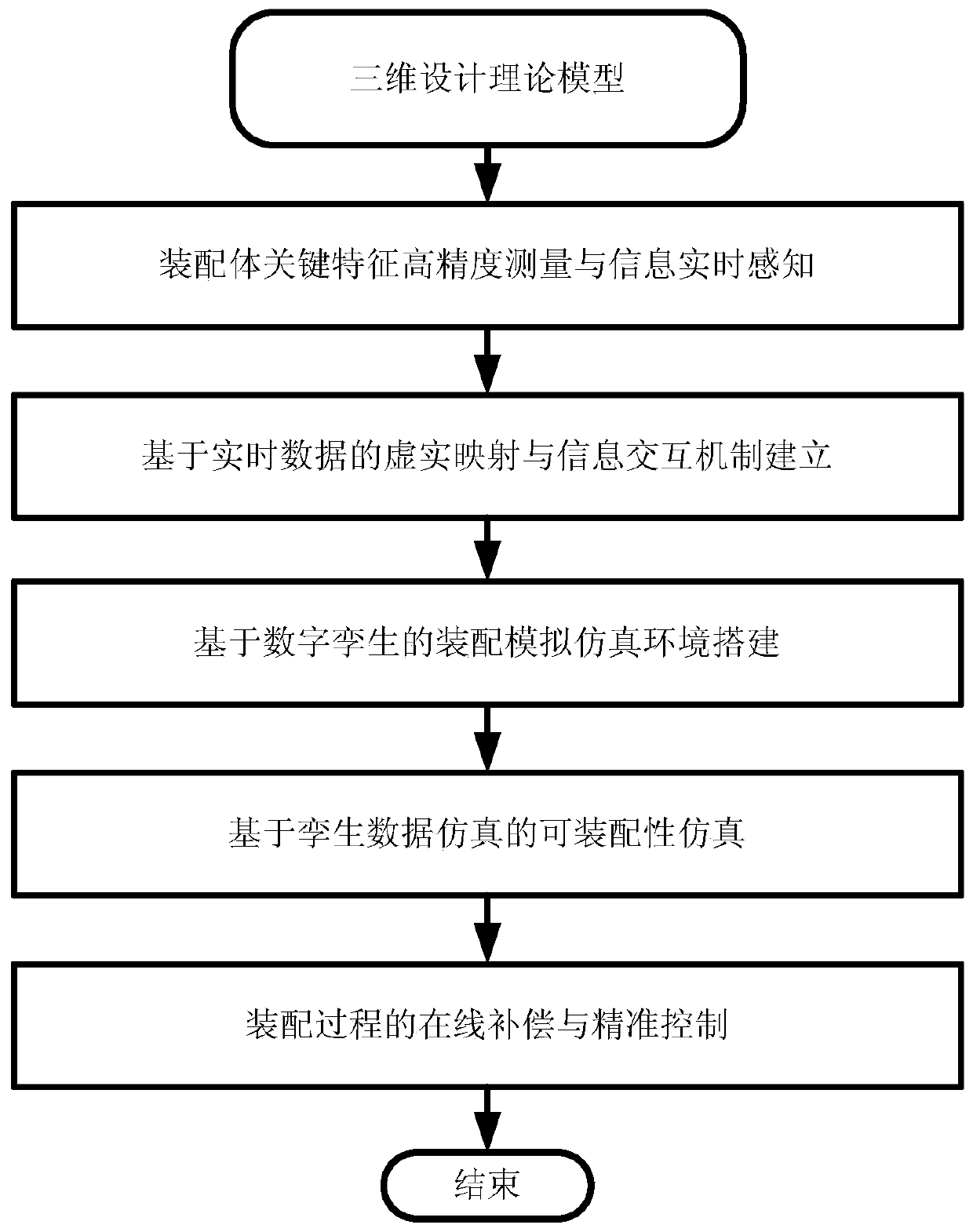

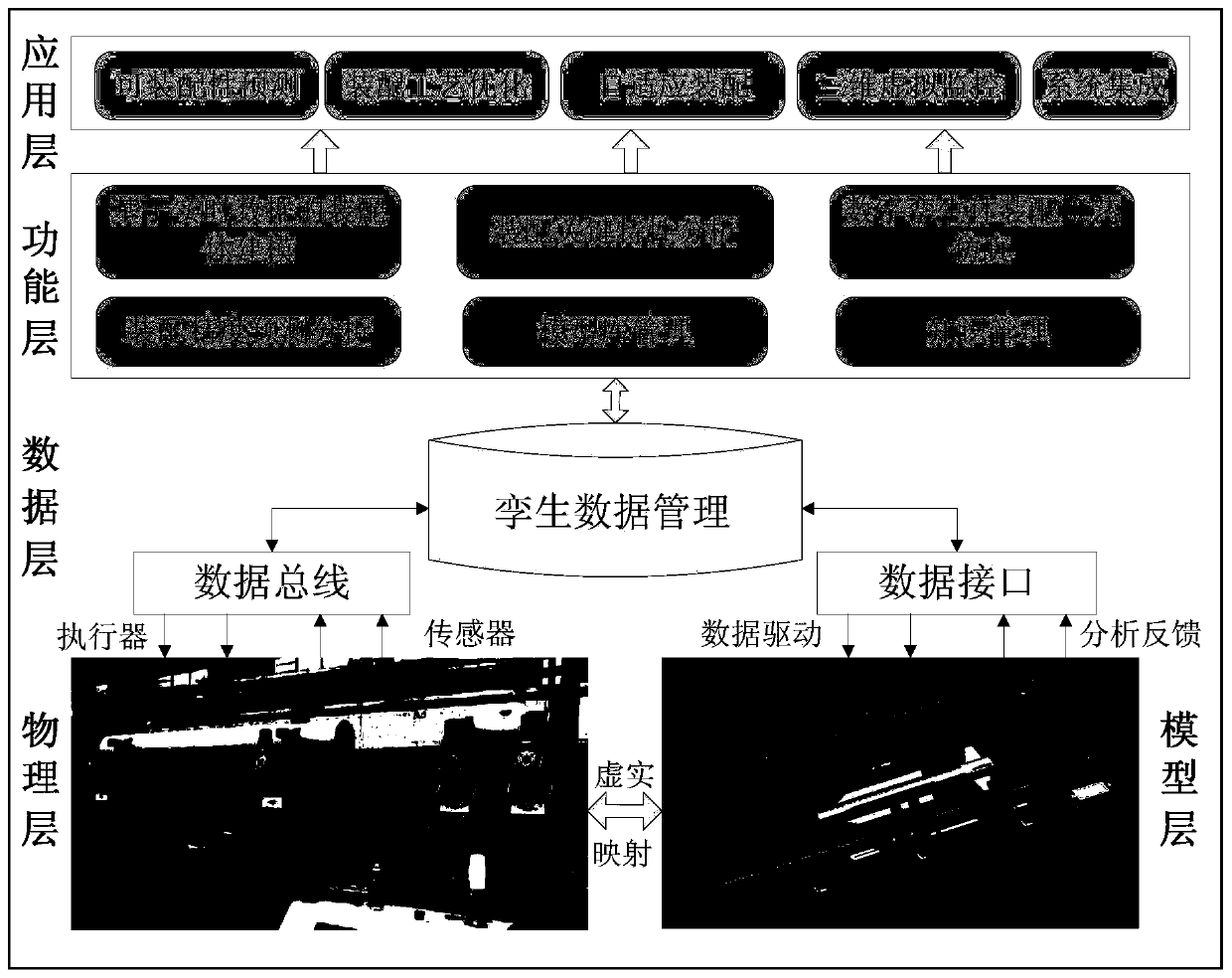

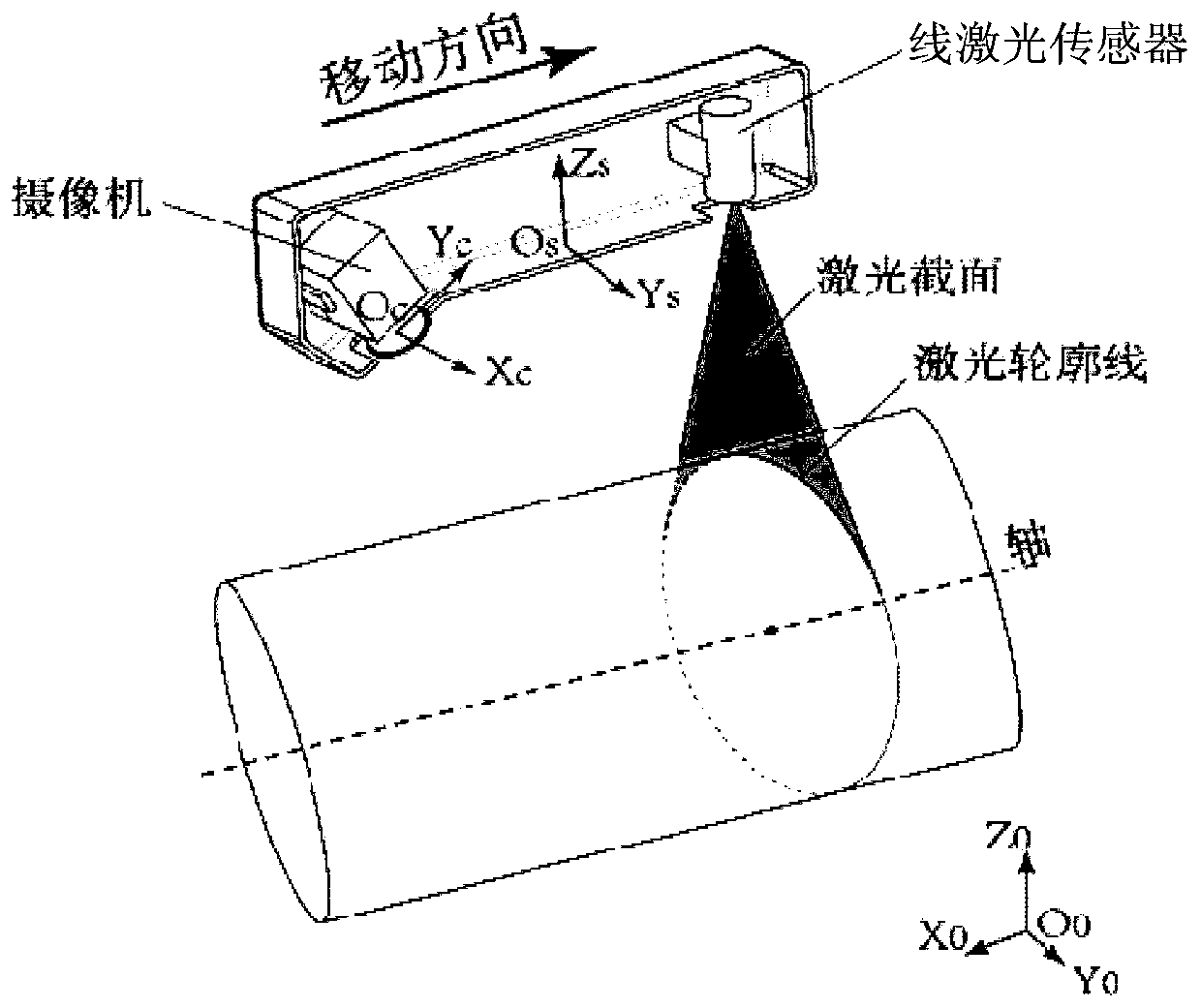

[0039] The present invention is an adaptive adjustment method based on digital twins, which uses a line laser sensor and a camera to digitally measure the outline of a cylindrical assembly and the positioning pin on the end face, and fits the axis of the cylindrical assembly and the pin hole; Adjust the position of the cylindrical assembly, control the alignment of the axis of the assembly, and realize adaptive assembly and adjustment based on the virtual monitoring of the digital twin. With the help of digital twin technology, build an assembly simulation environment based on the fusion of virtual and real, and use the manufacturing system Internet of Things as a carrier to realize the interconnection between the physical world and the information world in the assembly process. Accurate simulation, monitoring, diagnosis, prediction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com