Pressure reduction type backflow preventing device

A backflow preventer and pressure reducing valve technology, applied in the direction of control valve, functional valve type, engine components, etc., to achieve the effects of stable performance, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

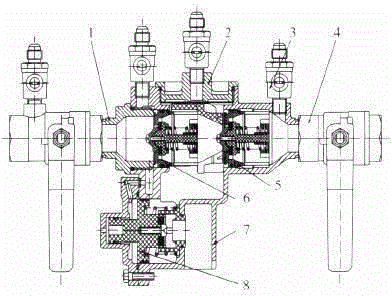

Embodiment 1

[0014] A decompression backflow preventer. The decompression backflow preventer is composed of two check valves that work independently. A differential pressure relief valve is connected externally between the two valves. Directly connect two ball valves for maintenance and four elastic sealing test ball valves to form a complete decompression backflow preventer. In the case of water supply, the water in the main water pipeline is decompressed from the check valve at the inlet position. The outlet of the check valve at the position from the area to the outlet supplies water to the user, and the high-pressure water imported by the check valve at the inlet position is directly connected to the upper chamber of the diaphragm of the pressure reducing valve, while the lower chamber of the diaphragm communicates with the inlet of the check valve at the outlet position. A certain pressure difference pushes the diaphragm to the right, the pressure reducing valve closes, and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com