Fiber-optic gyroscope optical path assembly method based on tail fiber stress monitoring

A fiber optic gyroscope and stress monitoring technology, which is used in Sagnac effect gyroscopes, measuring devices, and force measurement by measuring the change of optical properties of materials when they are stressed. Pigtail stress and other problems, to achieve the effect of improving the assembly qualification rate, avoiding the instability of the gyro output signal or the short working cycle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

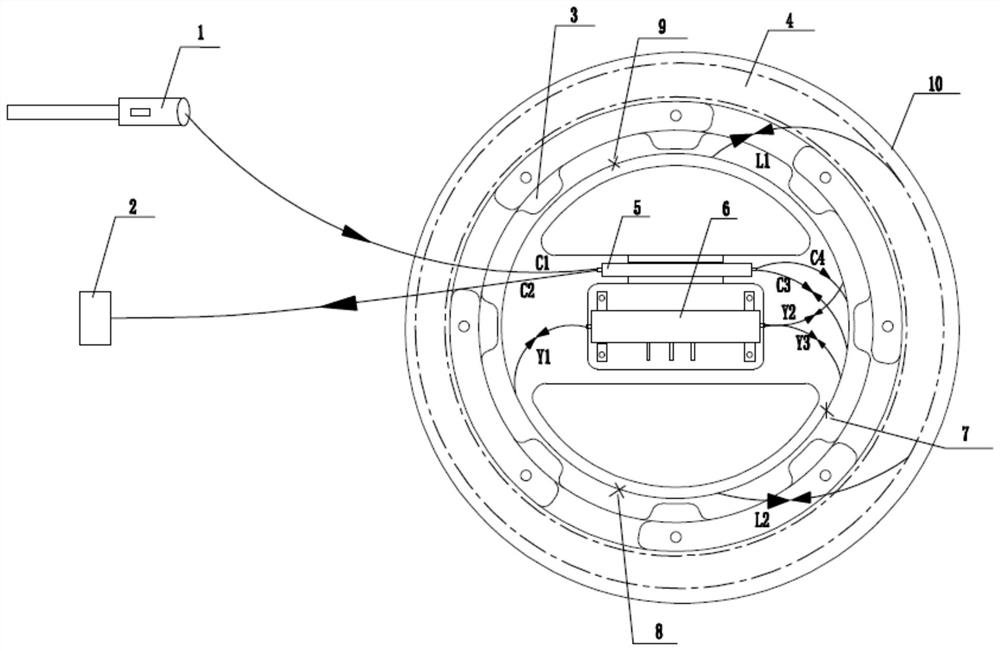

[0021] The invention is assembled based on the monitoring of the tail fiber stress during the optical path assembly of the optical fiber gyroscope. The design is reasonable and the operation is simple. It has been practically applied in the optical path assembly of a high-precision optical fiber gyroscope, which improves the qualified rate of one assembly and solves the mass production of optical fiber gyroscopes. key technologies in.

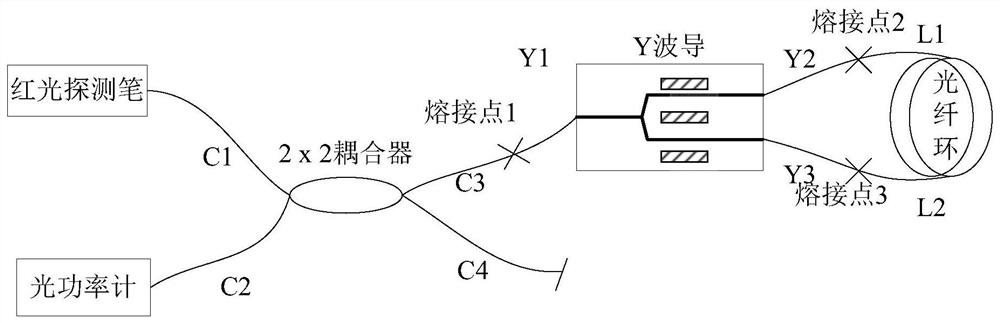

[0022] figure 1 For the test principle of the optical path pigtail stress of the present invention, the devices used for pigtail stress monitoring include a red light detection pen, a 2 × 2 fiber coupler, an optical fiber ring, a Y waveguide and an optical power meter, wherein the red light detection pen is used as the emission source of the optical path .

[0023] Described assembly method comprises the steps:

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com