Optical fiber ceramic core automatic grinder and automatic grinding method

A ceramic ferrule and grinding machine technology, which is applied to machine tools, grinders, and grinding/polishing equipment suitable for grinding workpiece planes, can solve the problem of uneven grinding of the end face of optical fiber ceramic ferrules, difficult to control down pressure, and difficult to control. Meet the 3D requirements of the end face of the fiber ceramic ferrule, and achieve the effect of avoiding instability, high precision and high grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

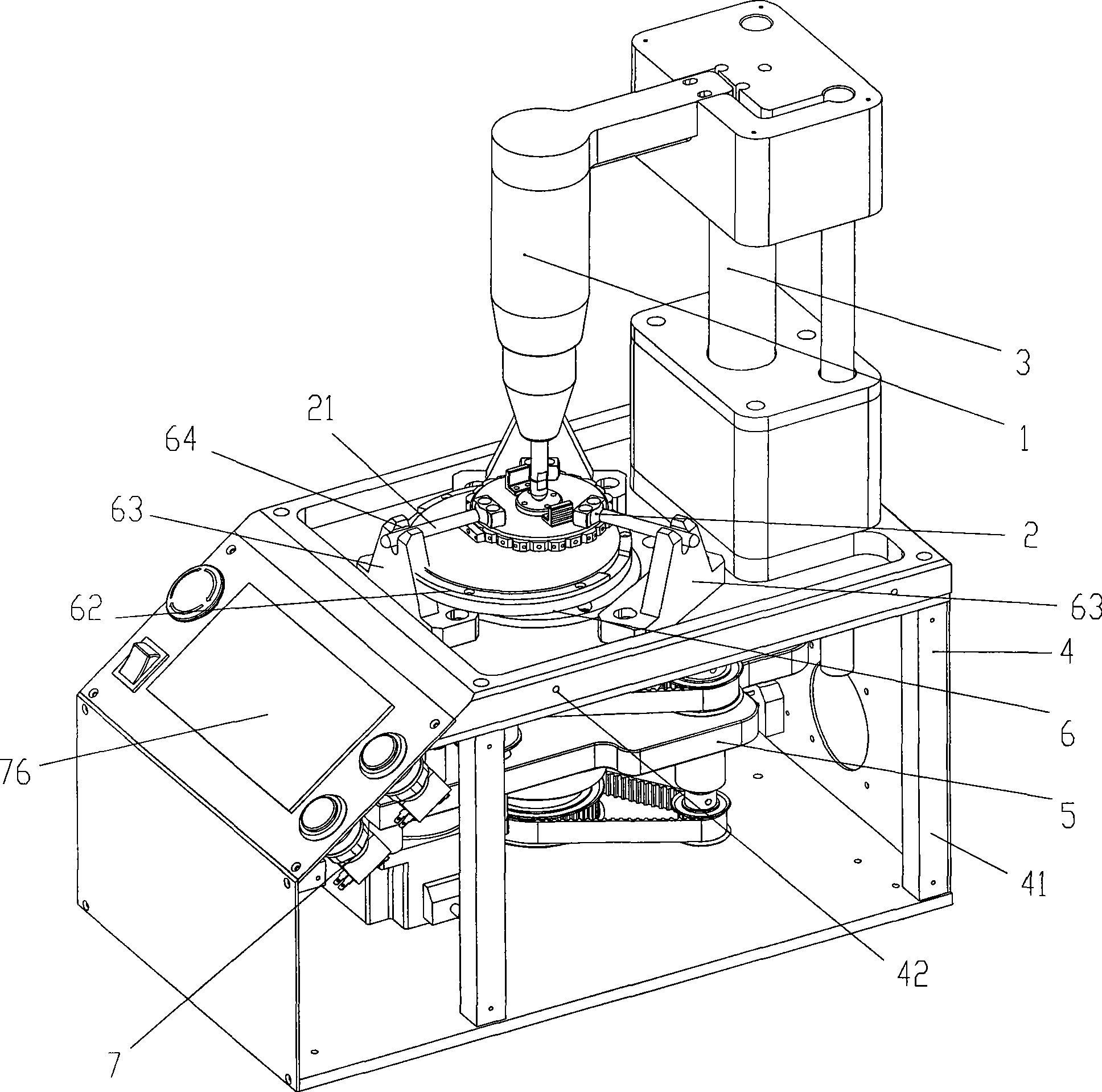

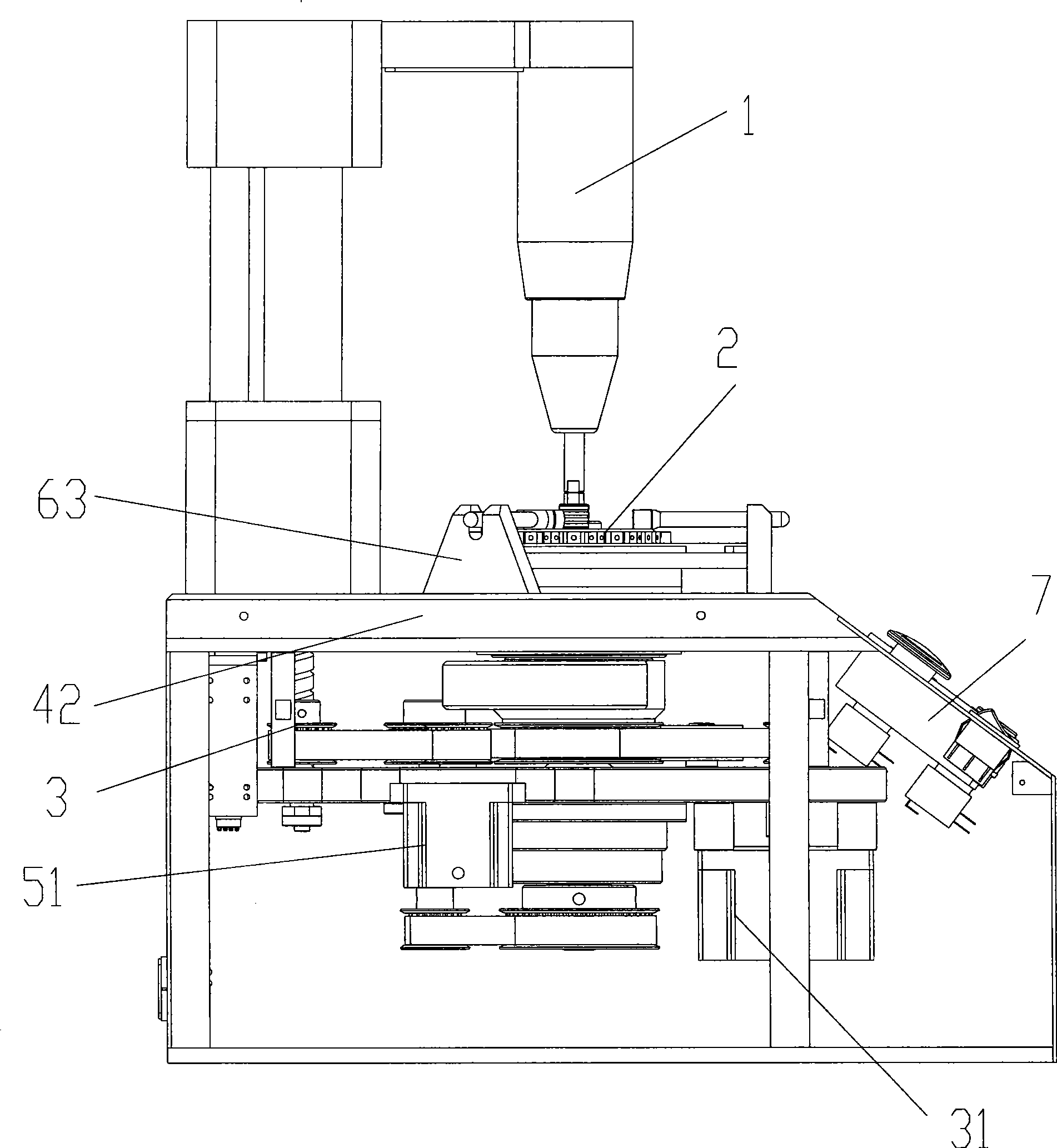

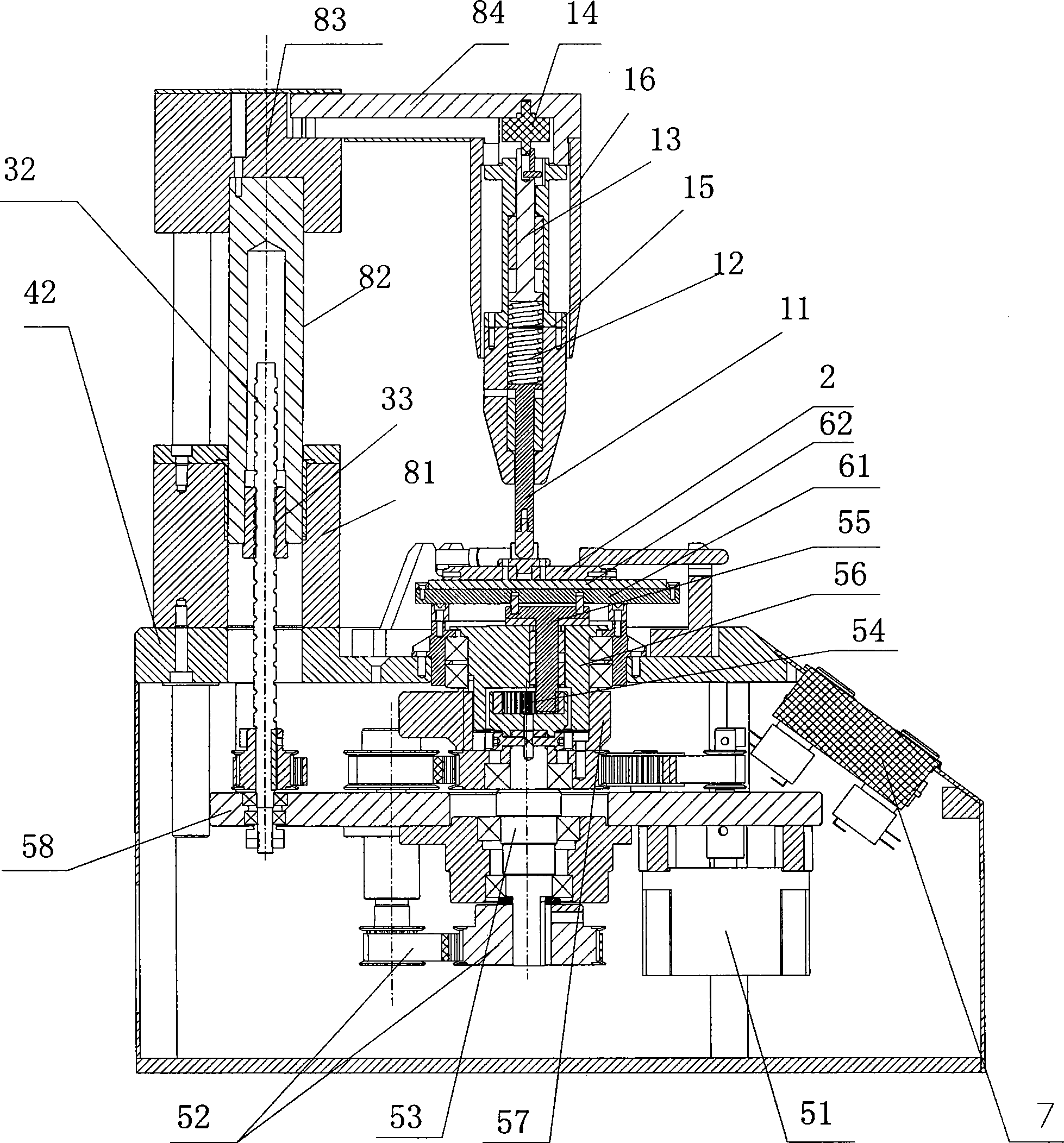

[0031] Such as Figure 1 to Figure 4 As shown, it is an embodiment of the fiber ceramic ferrule automatic grinding machine of the present invention, comprising a frame 4, a power system 5 installed on the frame 4, a grinding system 6 driven by the power system 5, and a power system installed on the frame 4 The upper lifting system 3, the pressure system 1 driven up and down by the lifting system 3, and the control system 7 that controls the lifting system 3 to rise or fall according to the pressure change of the pressure system 1 and / or the change of the grinding time.

[0032] In this embodiment, the frame 4 includes a plurality of columns 41 arranged vertically, and an upper base plate 42 installed on the columns 41 . Further, a connecting base plate is installed on the lower side of the upper base plate 42 for installation of the power system 5 and the lifting system 3 .

[0033] The power system 5 includes a drive motor (brushless DC motor 51 ) and a transmission mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com