Radiation unit matching block assembling device and method

A technology of radiation unit and assembly device, applied in radiation element structure, metal processing, metal processing equipment and other directions, can solve the problems of narrow operating space and difficult assembly of matching blocks, etc., to ensure distance dimensional accuracy and improve the qualification rate of one-time assembly , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

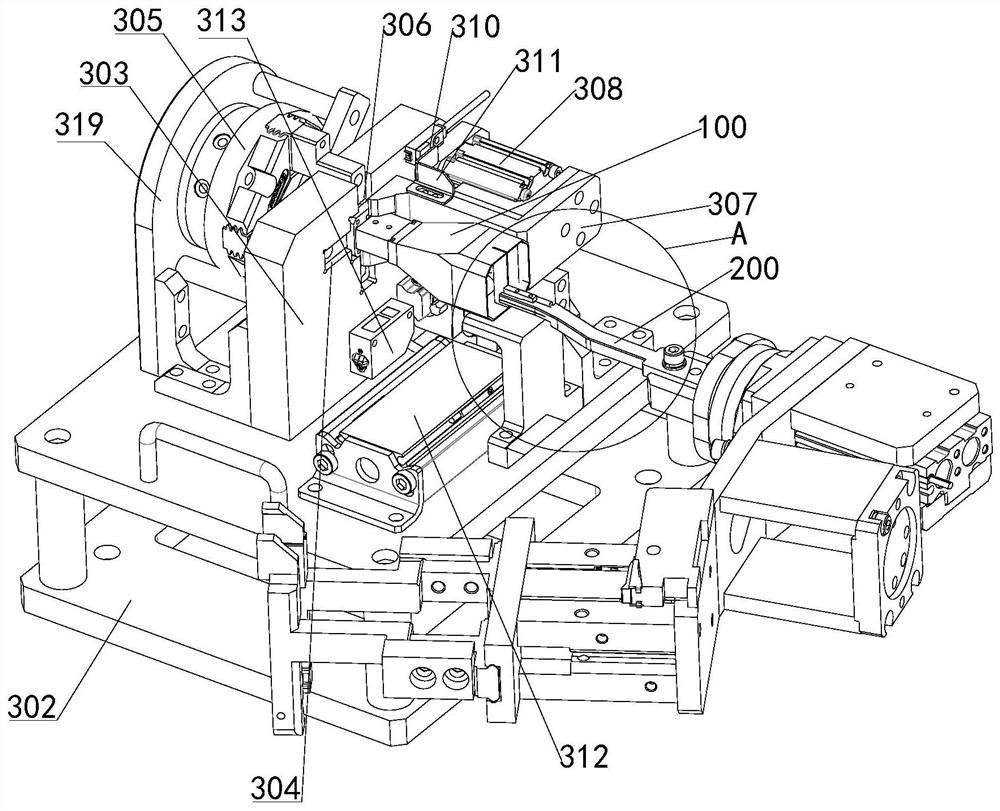

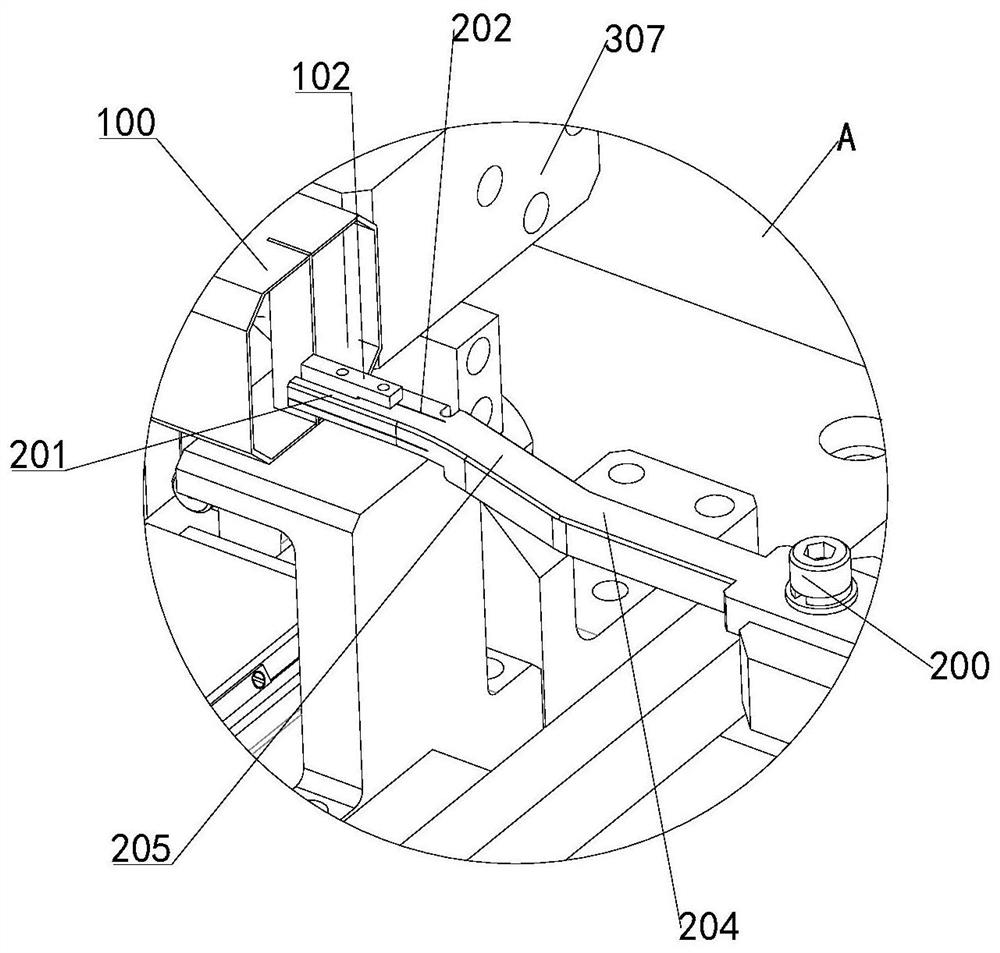

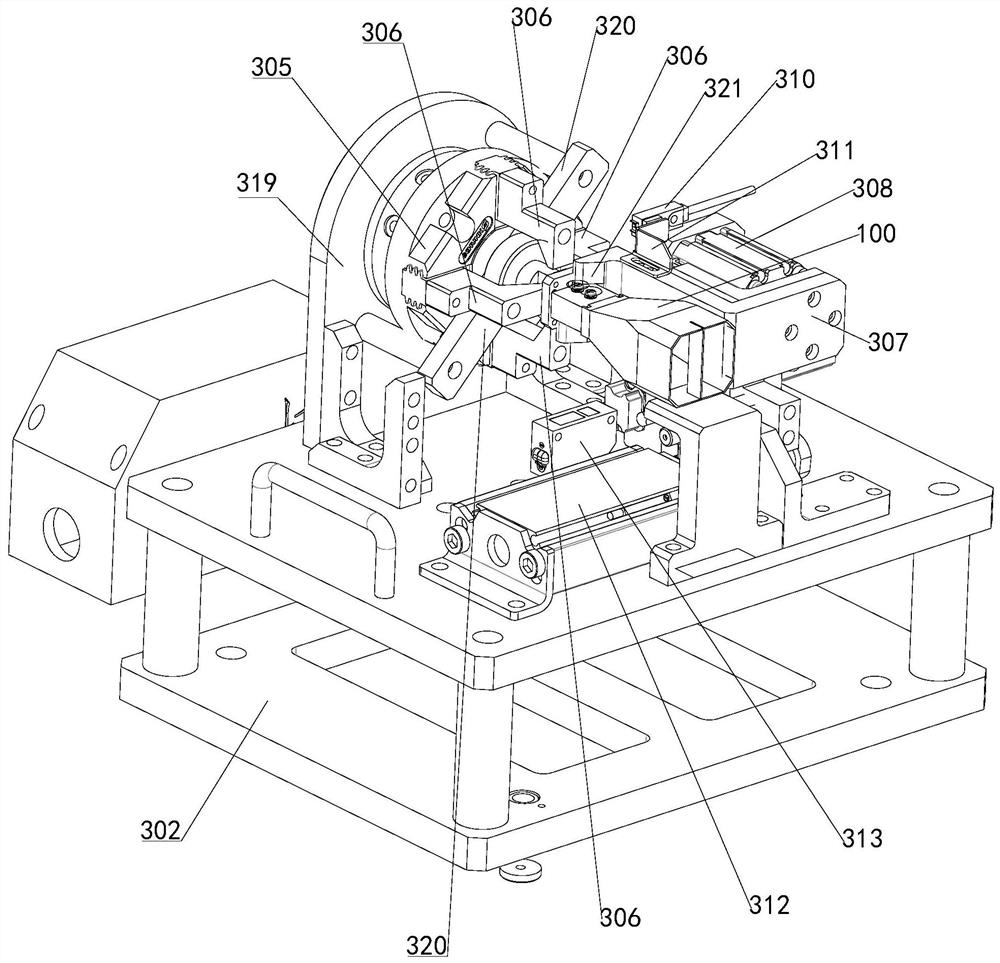

[0050]Such asFigure 1 - Figure 6 As shown, a radiation unit matching block assembly device of the present embodiment includes a matching block clamp 200 and a radiating unit clamp 300, and the radiating unit jig 300 is provided with an elastic pin 301, and the matching block clamp is close to the end. The position of the portion is provided with a block limit slot 201, and the upper surface of the matching block clamp 200 is provided with a limiting port in communication with the matching block limit groove 201; wherein the matching block clamp 200 drives a block. When the radiation unit 100 is in the radiation unit 100, the elastic pin 301 in the radiating unit holder 300 extends from the limit bits into the matching block limit slot 201 and abuts one end of the matching block 102.

[0051]This embodiment passes the matching block into the radiation unit clamp, and utilizes the matching block in the matching block of the matching block to limit the fast installation of the matching bl...

Embodiment 2

[0053]Such asFigure 1 - Figure 6 As shown, a radiation unit matching block assembly device of the present embodiment includes a matching block clamp 200 and a radiating unit clamp 300, and the radiating unit jig 300 is provided with an elastic pin 301, and the matching block clamp is close to the end. The position of the portion is provided with a block limit slot 201, and the upper surface of the matching block clamp 200 is provided with a limiting port in communication with the matching block limit groove 201; wherein the matching block clamp 200 drives a block. When the radiation unit 100 is in the radiation unit 100, the elastic pin 301 in the radiating unit holder 300 extends from the limit bits into the matching block limit slot 201 and abuts one end of the matching block 102.

[0054]Such asfigure 2 As shown, the matching block limit groove 201 of the present embodiment is a step slot that is adapted to the matching block 102. The matching block can be performed on the matching ...

Embodiment 3

[0066]Such asFigure 13 As shown, the radiation unit matching block assembly device mounting device is mounted in addition to the assembly apparatus including Example 1 or Embodiment 2, including three-axis module 314 and a locking gun 318, an assembly device, a three-axis mold. The group 314 and the lock nail gun 318 are mounted on the mounting platform 103, and the lock nail gun 318 is mounted on the three-axis module 314 and moves in XYZ three directions under the three axis module 314. The three-axis module 314 includes an X to modules 315, Y to modules 316, and the Z to module 317, the X to module 315 is mounted on the mounting platform 103, the Z-to module 317 installation On the X-to-module 315, the Y, the module 316 is mounted on the Z-to-module 317, and the locking gun 318 is mounted on the Y to module 316, the assembly device located in the Y, below the module 316, using a three-axis module to drive the lock nail gun 318 from the screw arrangement machine 323 to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com