A radiation unit matching block assembly device and method

A technology of radiation unit and assembly device, which is applied in the structural form of radiation element, metal processing equipment, metal processing, etc., can solve the problems of difficult assembly of matching blocks and narrow operating space, so as to improve the qualification rate of one-time assembly and ensure the accuracy of distance and dimension. , the effect of quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

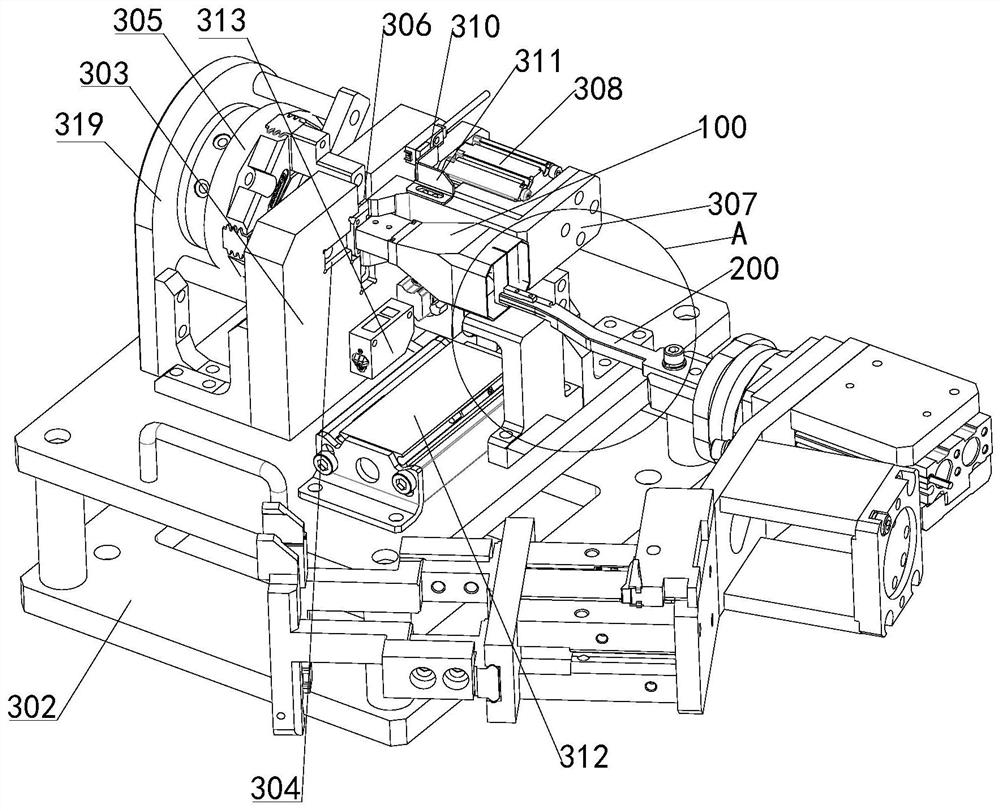

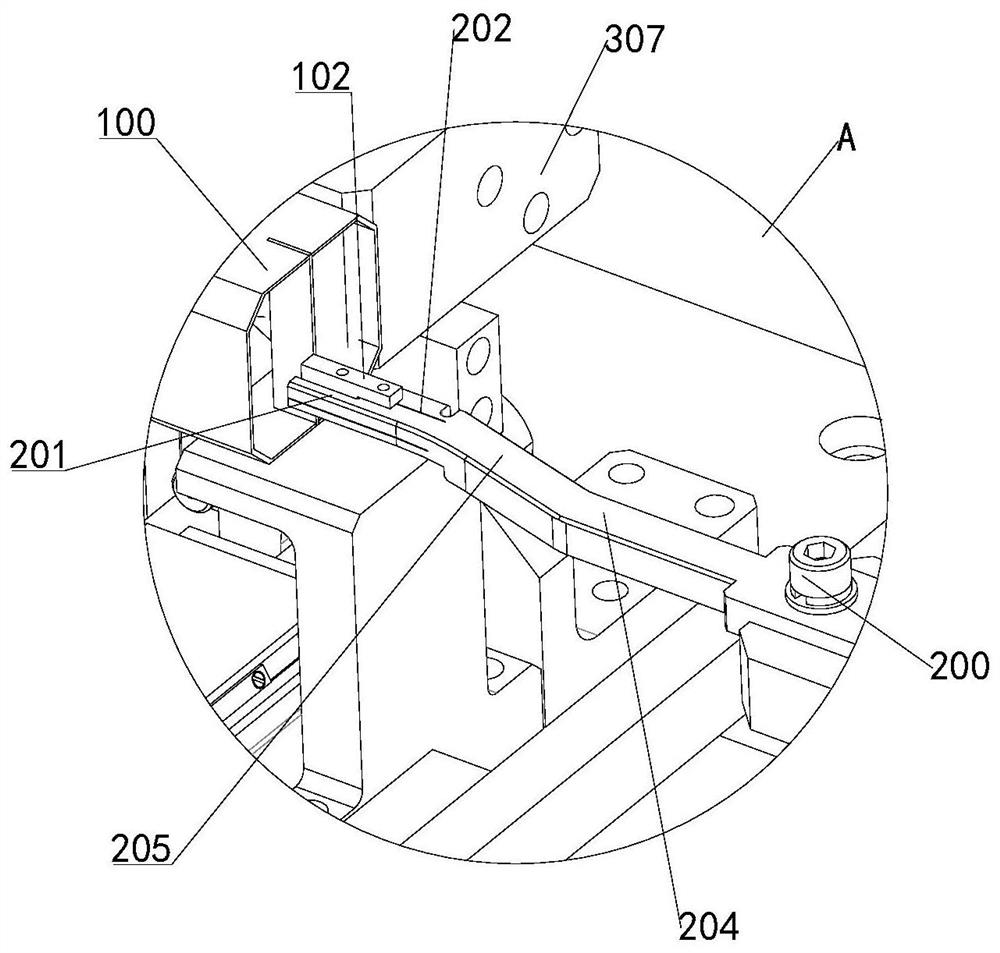

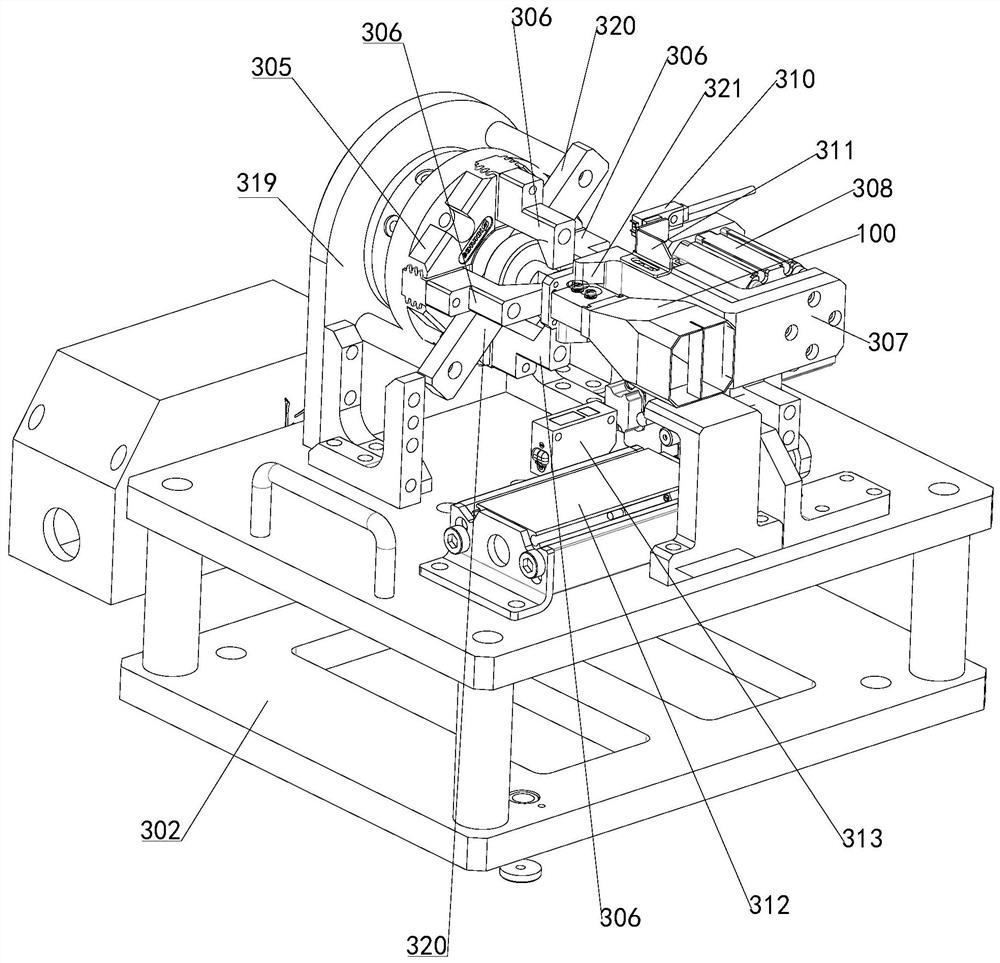

[0050] Such as Figure 1-Figure 6 As shown, a radiation unit matching block assembly device in this embodiment includes a matching block clamp 200 and a radiation unit clamp 300, the radiation unit clamp 300 is provided with an elastic pin 301, and one side of the matching block clamp 200 is close to the end A matching block limit groove 201 is provided at the position of the upper part, and one end surface of the matching block clamp 200 is provided with a first limit port communicating with the matching block limit groove 201; wherein, when the matching block clamp 200 drives the matching When the block extends into the radiation unit 100 , the elastic pin 301 in the radiation unit fixture 300 extends from the first limiting opening into the matching block limiting slot 201 and abuts against one end of the matching block 102 .

[0051] In this embodiment, the matching block is sent into the radiation unit fixture through the matching block fixture, and the matching block in ...

Embodiment 2

[0053] Such as Figure 1-Figure 6 As shown, a radiation unit matching block assembly device in this embodiment includes a matching block clamp 200 and a radiation unit clamp 300, the radiation unit clamp 300 is provided with an elastic pin 301, and one side of the matching block clamp 200 is close to the end A matching block limit groove 201 is provided at the position of the upper part, and one end surface of the matching block clamp 200 is provided with a first limit port communicating with the matching block limit groove 201; wherein, when the matching block clamp 200 drives the matching When the block extends into the radiation unit 100 , the elastic pin 301 in the radiation unit fixture 300 extends from the first limiting opening into the matching block limiting slot 201 and abuts against one end of the matching block 102 .

[0054] Such as figure 2 As shown, the matching block limiting groove 201 in this embodiment is a stepped groove matching the matching block 102 . ...

Embodiment 3

[0066] Such as Figure 13 As shown, the installation station of the radiation unit matching block assembly device in this embodiment, in addition to the assembly device in Embodiment 1 or Embodiment 2, also includes a three-axis module 314 and a nail gun 318, the assembly device, the three-axis mold The group 314 and the nail gun 318 are installed on the installation platform 103 respectively, and the nail gun 318 is installed on the three-axis module 314 and moves in three directions of XYZ under the drive of the three-axis module 314 . The three-axis module 314 includes an X-direction module 315, a Y-direction module 316 and a Z-direction module 317, the X-direction module 315 is installed on the installation platform 103, and the Z-direction module 317 is installed On the X-direction module 315, the Y-direction module 316 is installed on the Z-direction module 317, the locking nail gun 318 is installed on the Y-direction module 316, and the assembly device is located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com