A tempering method and tempering device for glass with holes

A perforated glass and tempering technology, which is applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve the problem of explosive edges of perforated glass, and achieve convenient equipment maintenance, reduce temperature difference, and good adhesion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described below in conjunction with the accompanying drawings.

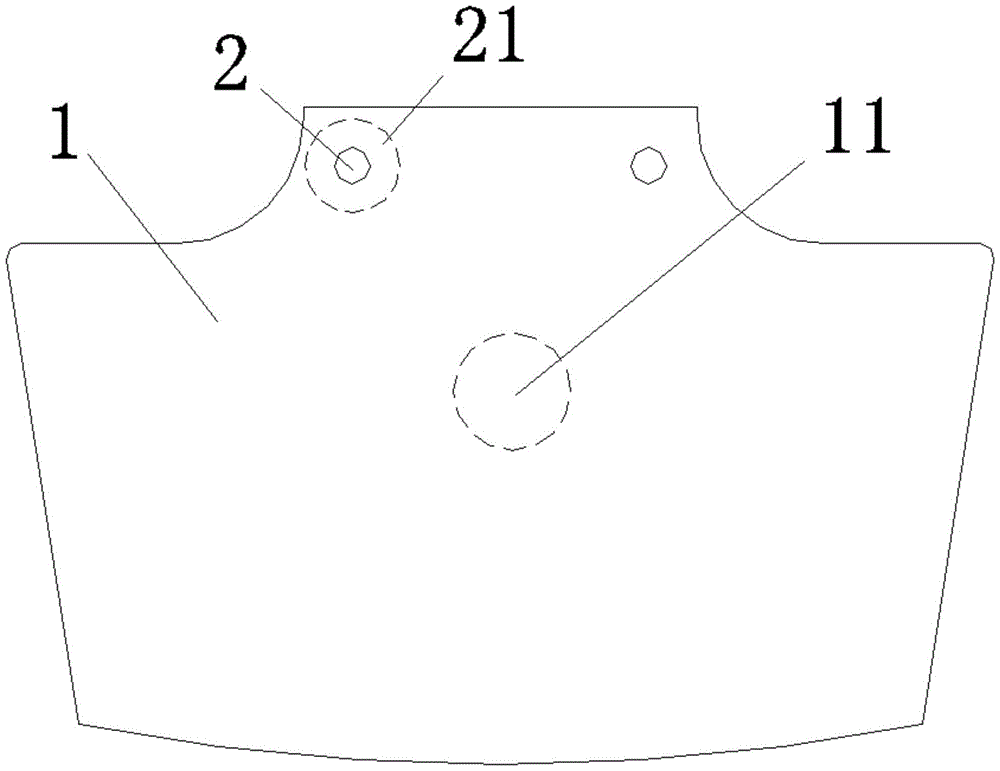

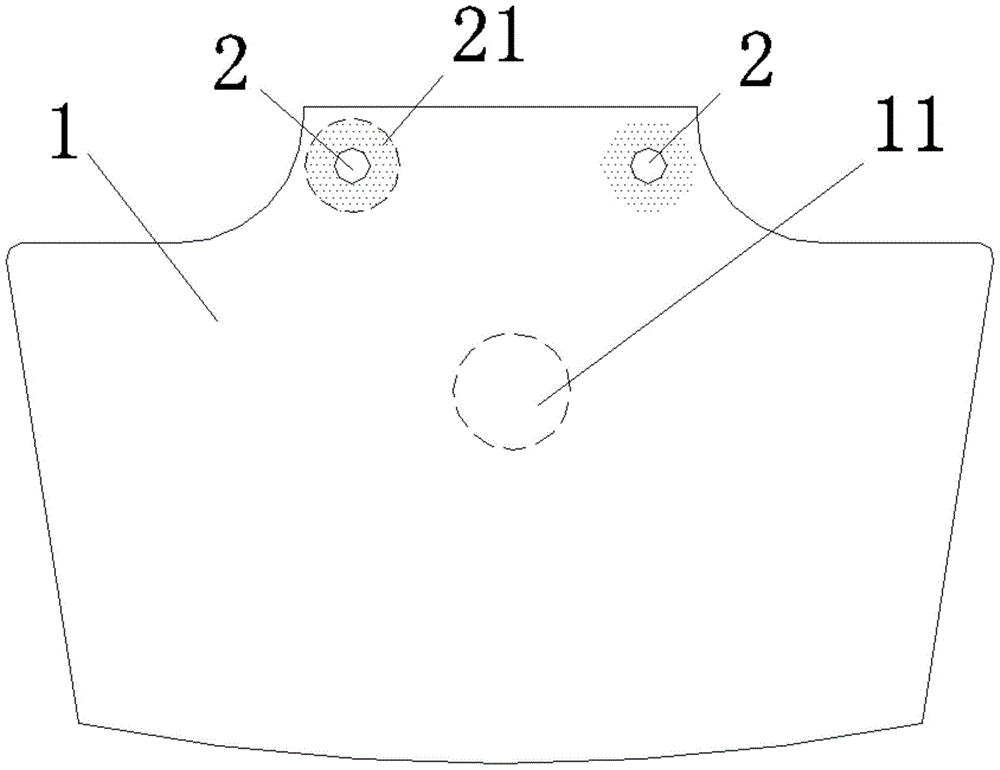

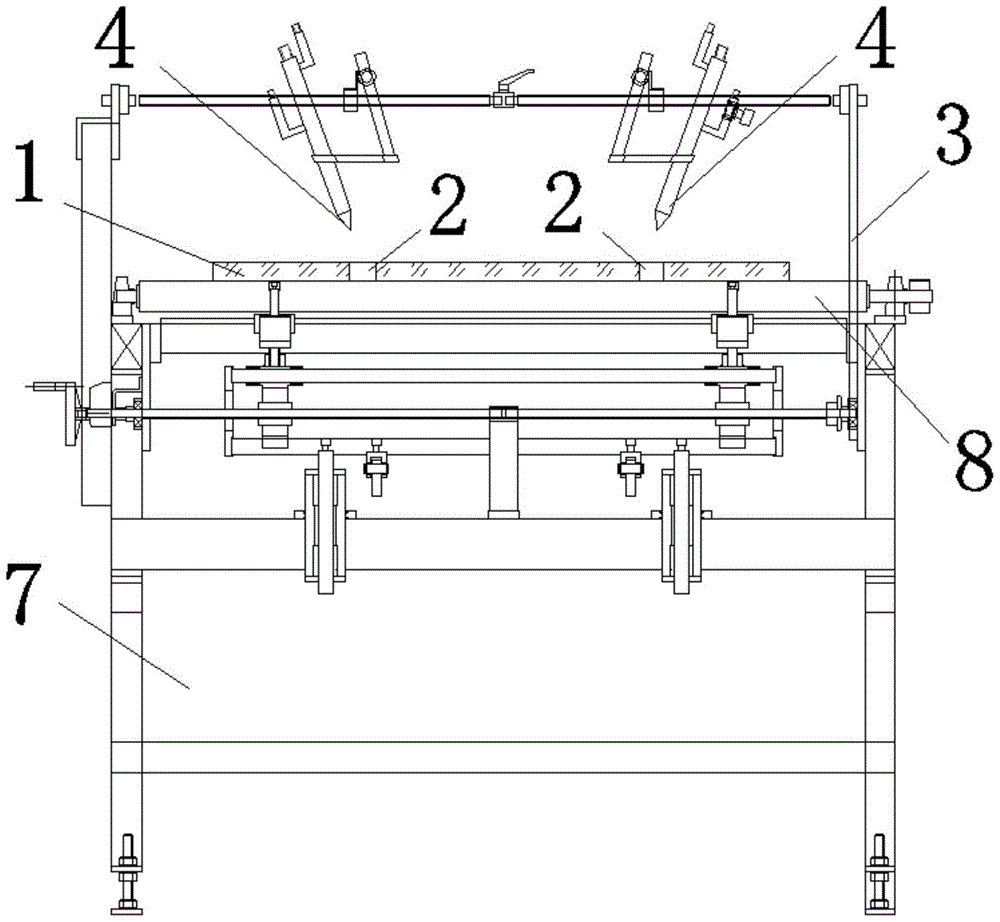

[0029] Such as Figure 2~4 As shown, a method for tempering glass with holes described in the present invention includes the following steps: Step 1: Place the pretreated glass plate 1 on the upper segment 7 for transmission; the pretreatment includes cutting, edging, Drilling, washing, drying and other steps; step 2: transfer the glass plate 1 from the upper segment 7 to the heating section, and heat it to the temperature required for tempering; step 3: transfer the glass plate 1 from the heating section to the The forming section is tempered and quenched; step 4: transfer the glass plate 1 from the forming section to the cooling section for cooling, and finally obtain the finished tempered glass; it is characterized in that: when the glass plate 1 is placed on the upper section 7 When using the torch 4, the flame of the hydrocarbon industrial gas is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com