Corrugated paper wrinkle removing device and method

A corrugated paper and belt conveyor technology, applied in the direction of mechanical processing/deformation, can solve the problems of corrugated paper surface wrinkles and affect the flatness of corrugated paper, and achieve the effect of eliminating surface wrinkles, smooth and beautiful surface, and improving surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

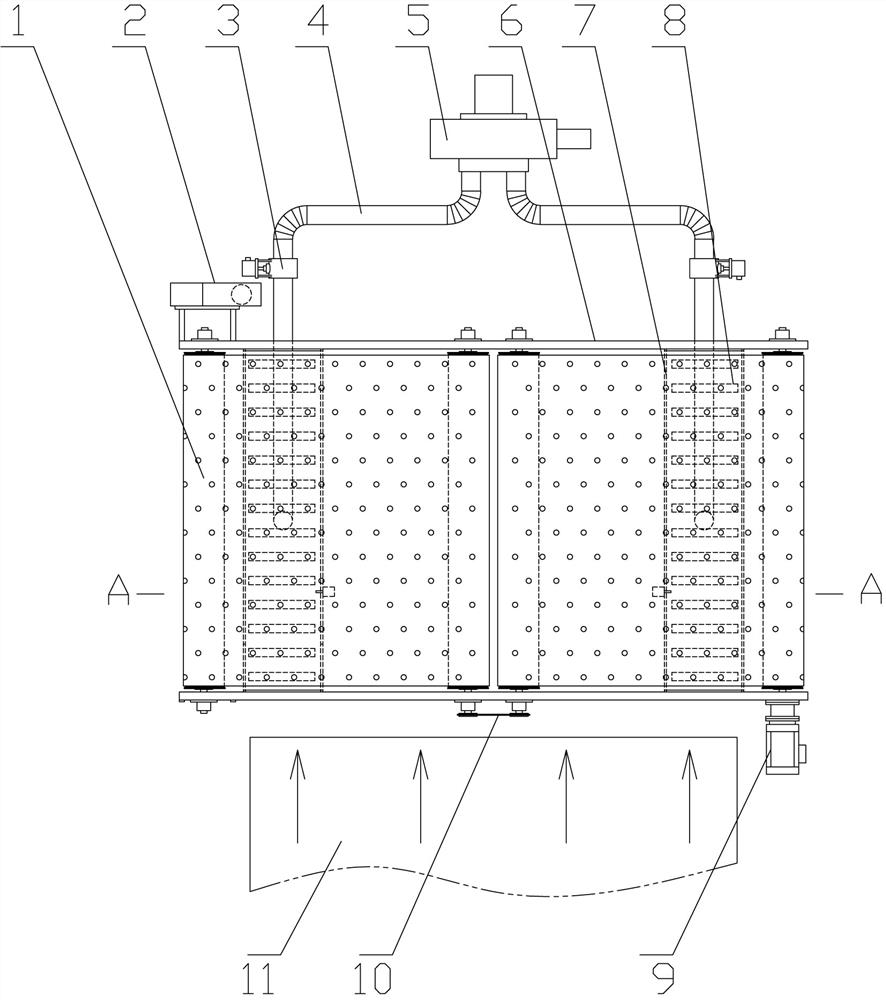

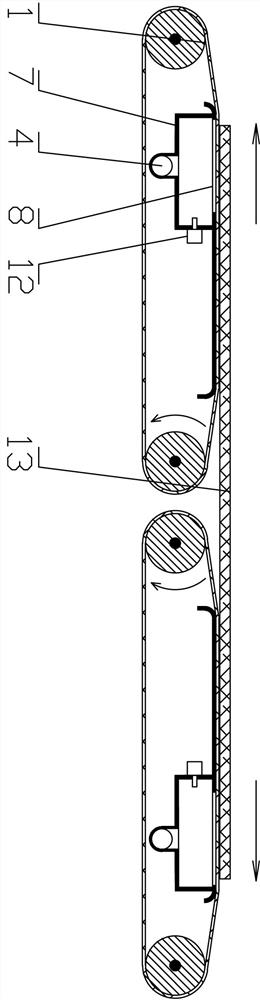

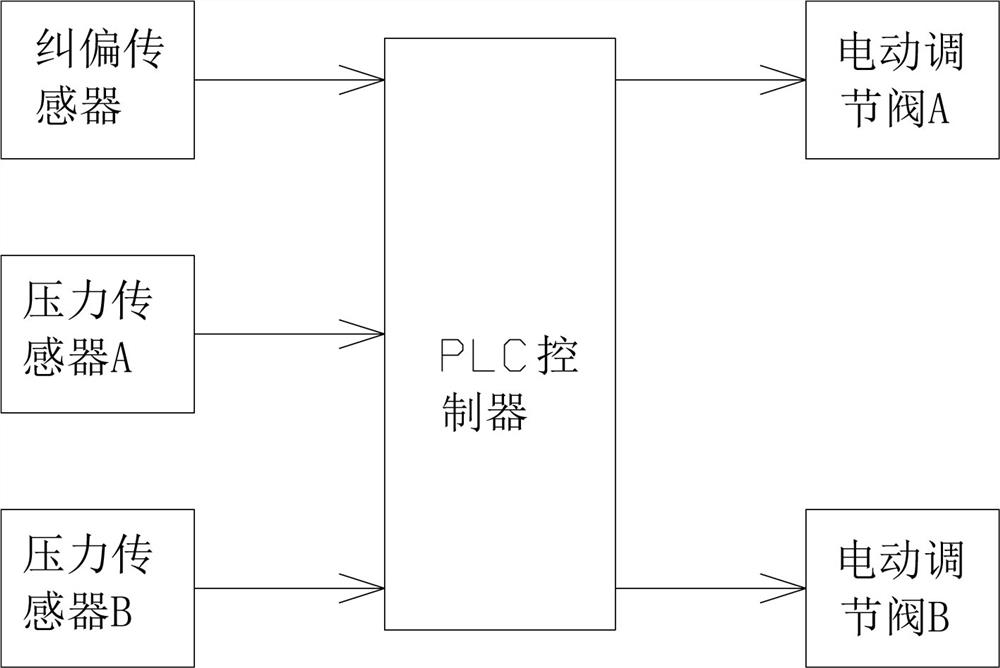

[0017] Such as Figures 1 to 3 As shown, a corrugated paper wrinkle removing device and method includes a frame 6 and an air pump 5, and two sets of suction leveling mechanisms are arranged in the frame 6, and the suction leveling mechanism includes a perforated belt conveyed in the frame 6 The machine 1 is provided with an air extraction box 7 in the perforated belt conveyor 1, and a plurality of air extraction holes 8 are provided on the surface of the air extraction box 7, and the air extraction pump 5 is connected to the air extraction box 7 through the air extraction pipe 4, and two sets of suction leveling mechanisms The conveying direction of two perforated belt conveyors 1 is opposite, and the two air extraction boxes 7 are located at both sides of the frame 6 .

[0018] Such as figure 1 As shown, after the surface of the corrugated paper is glued, the corrugated paper moves forward against the surface of two perforated belt conveyors 1. After the air pump 5 is starte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com