Patents

Literature

147results about How to "Smooth and beautiful surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

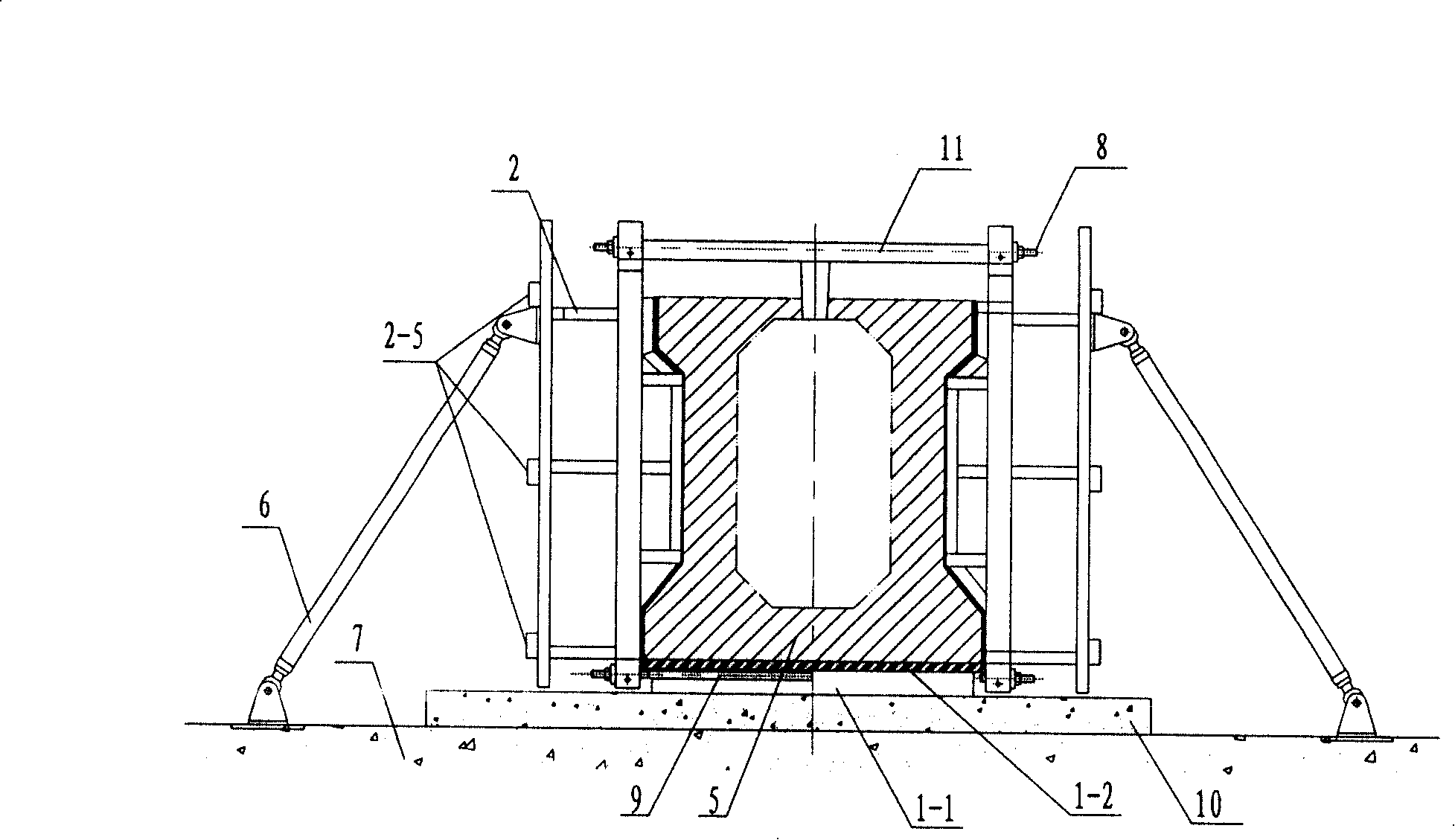

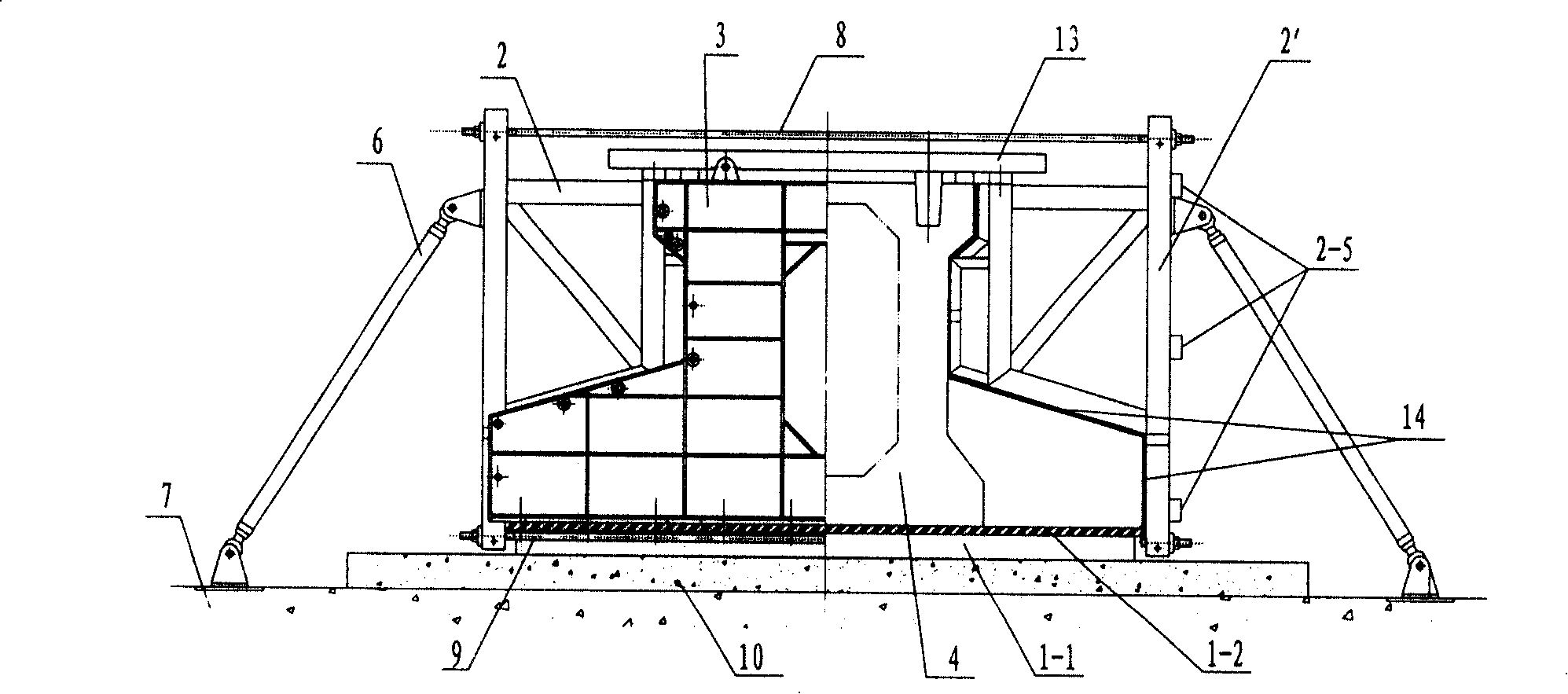

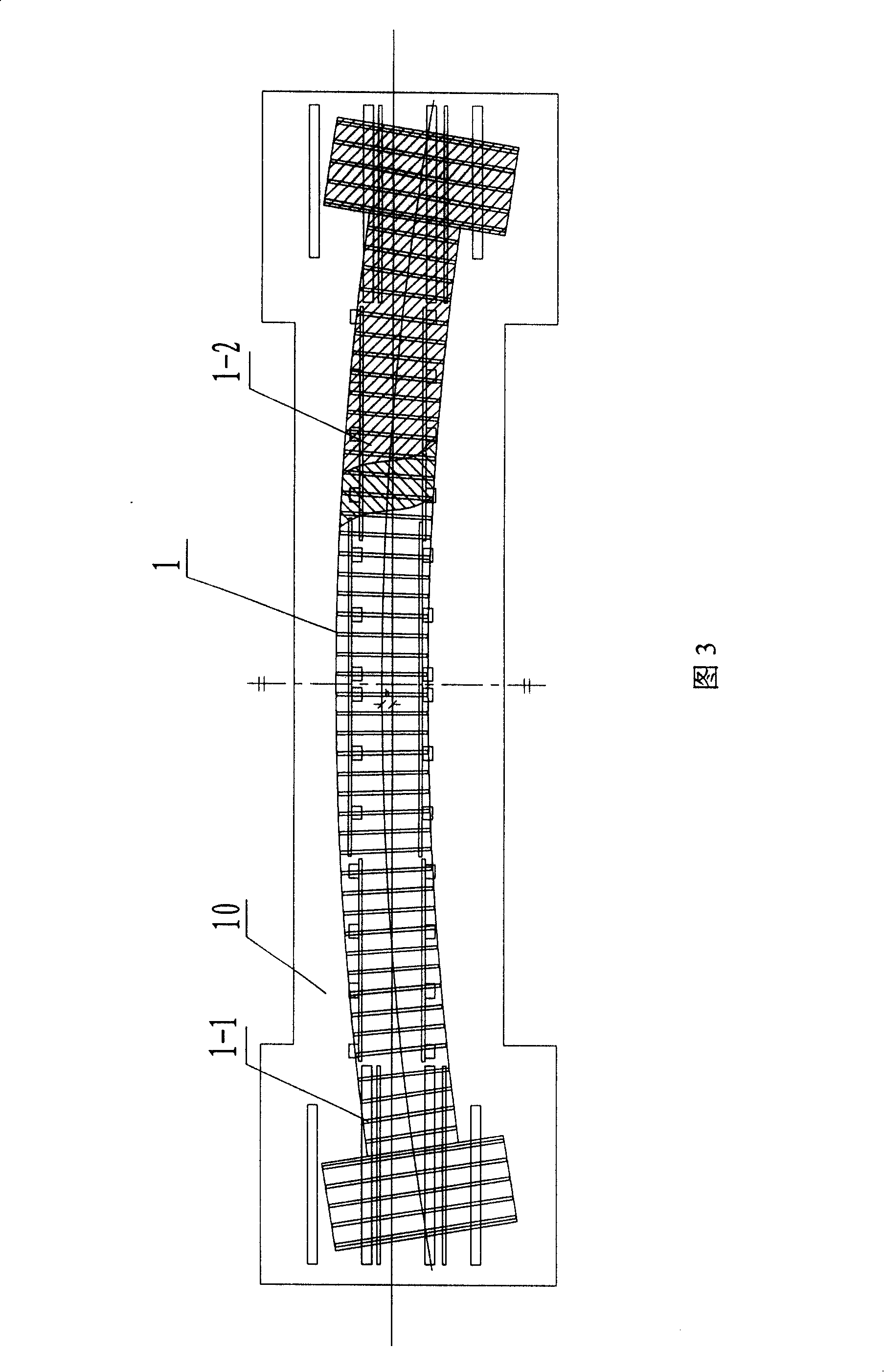

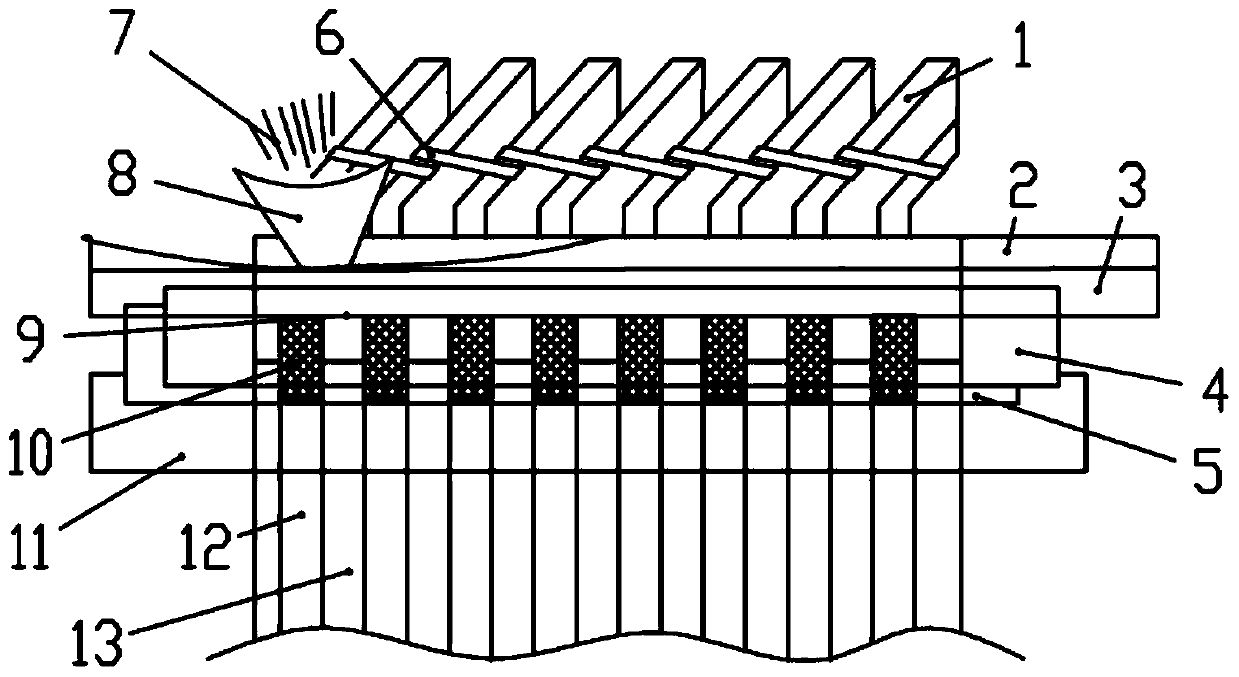

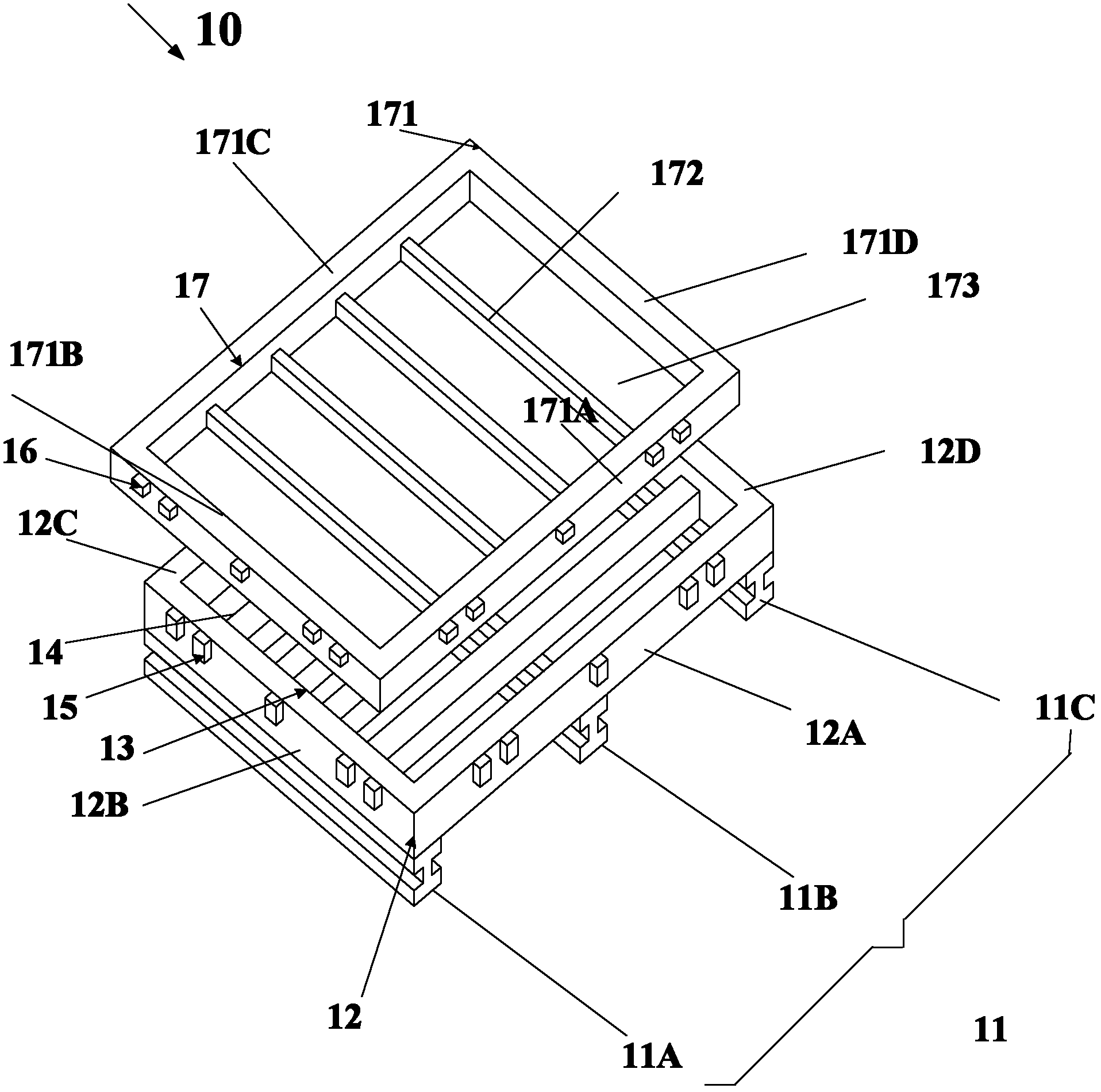

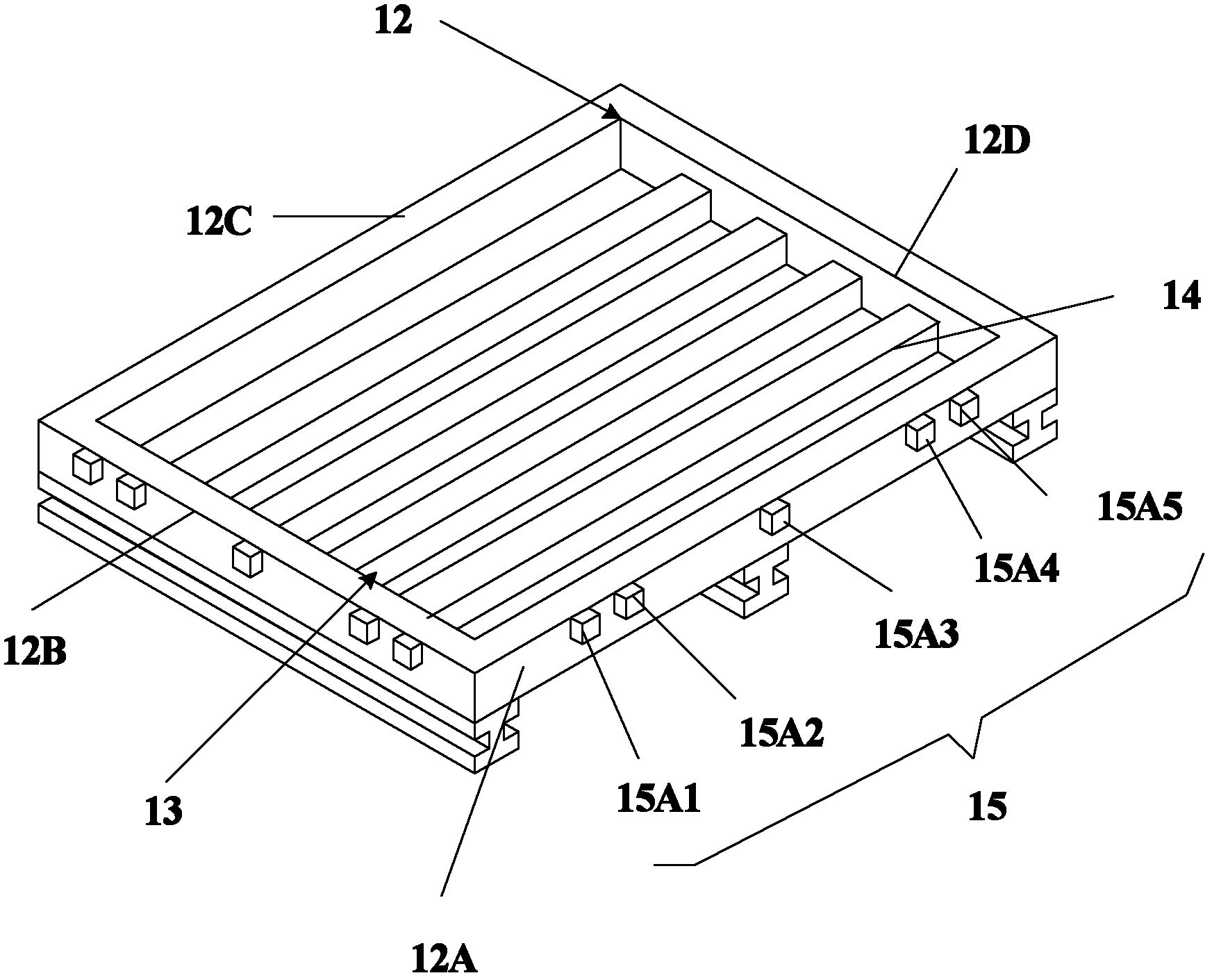

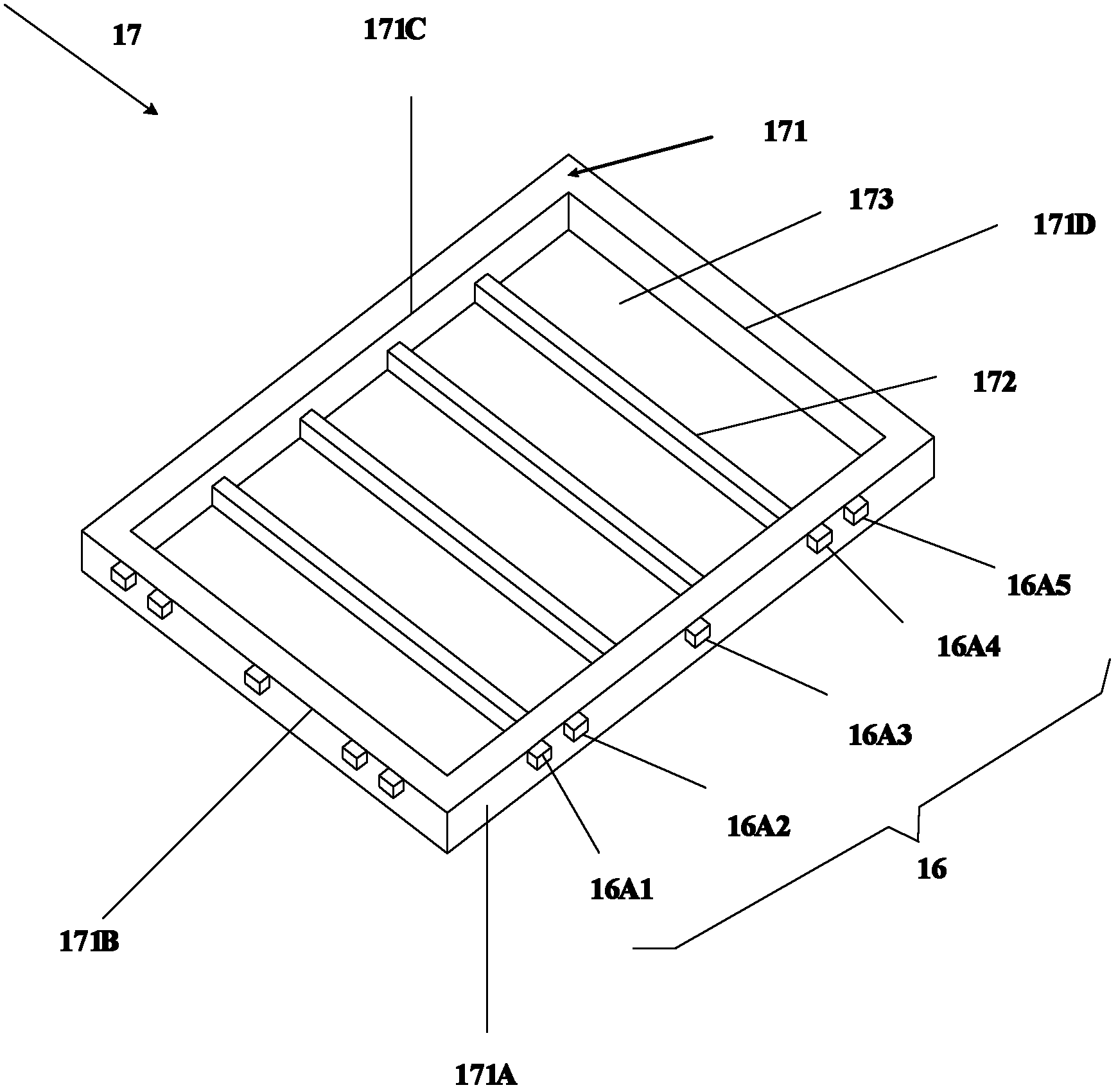

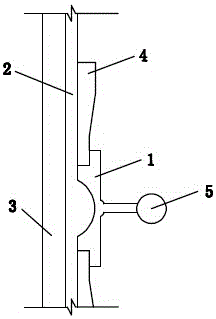

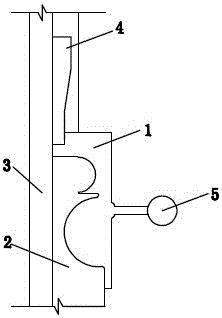

Curvature radius adjustable prefabricated box-beam mold and construction method thereof

ActiveCN101181796ASmooth and beautiful surfaceReduce manufacturing costMould separation apparatusMouldsEngineeringPeriod length

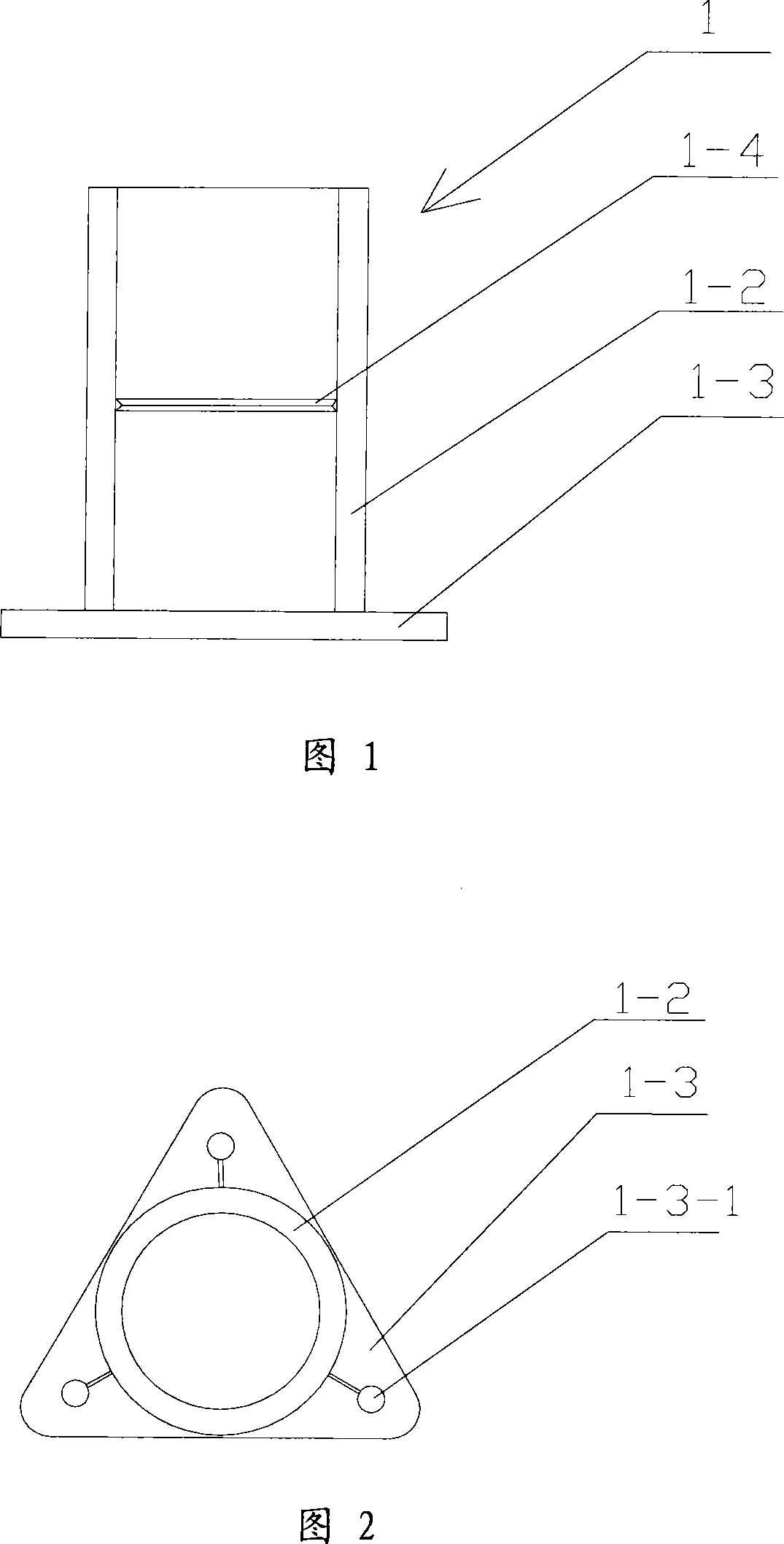

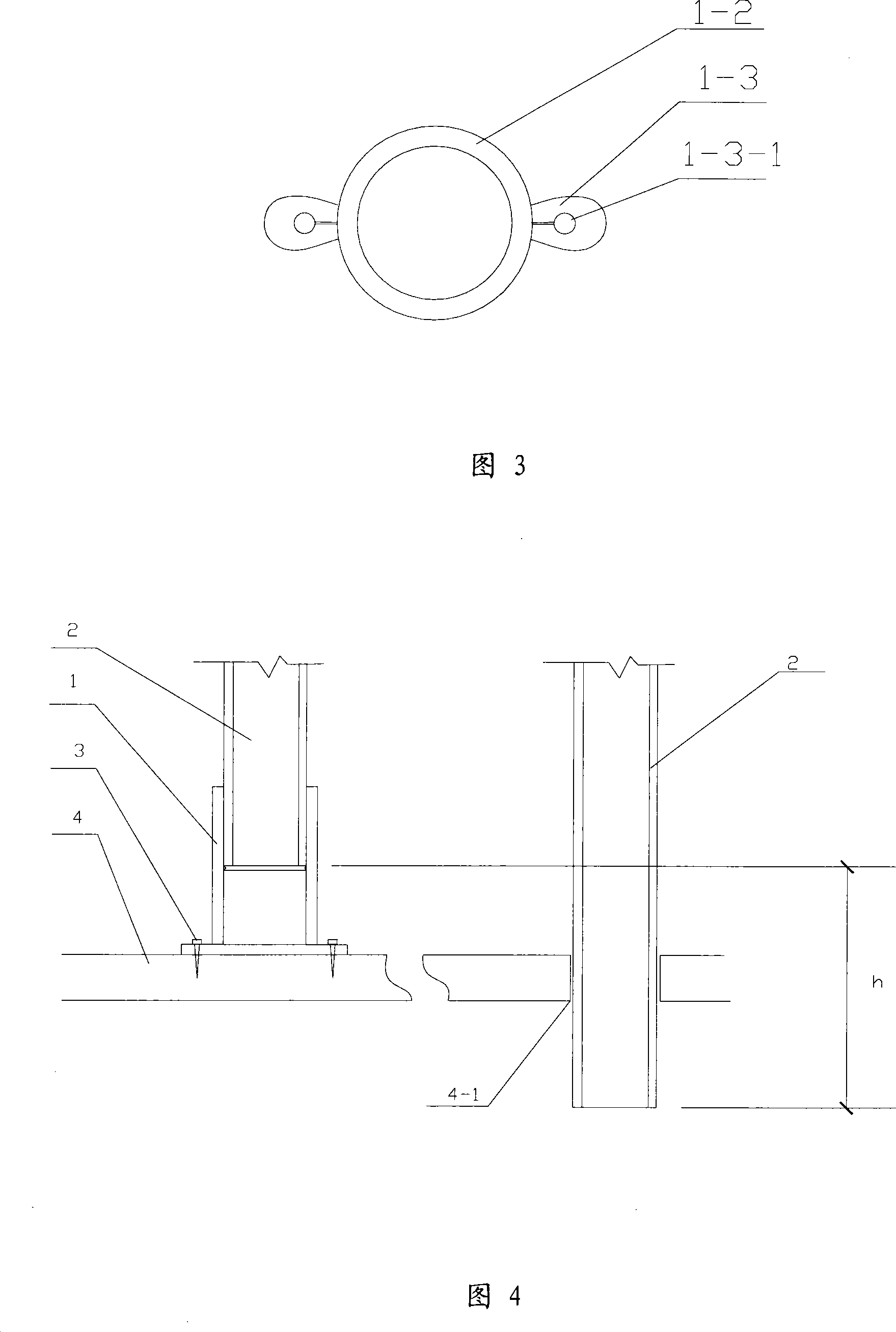

The invention discloses a prefabricated box girder mold with adjustable curvature radius and an installation and construction method of the mold. The invention adopts the concept of replacing the curved line with a folded line of a fixed length, and accurately sets out the bottom mold, so that the side mold is designed by It is composed of several fixed-length fixed sections. An elastic change section is set between the fixed-length fixed sections, and an adjustment link rod is set between the fixed-length fixed sections to realize the function of adjusting the curvature of the fixed-length broken line. At the same time, the adjustment insert section is embedded in the side mold The adjustment of inner and outer arc length changes can not only meet the needs of fixed section and variable curvature prefabricated building components, but also meet the production or construction needs of continuous variable section and variable curvature prefabricated building components. The prefabricated box girder mold with adjustable curvature radius of the present invention can not only meet the overall needs and accuracy requirements of the design curvature change, but also has a smooth and beautiful surface, with as few or no traces of template joints as possible.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

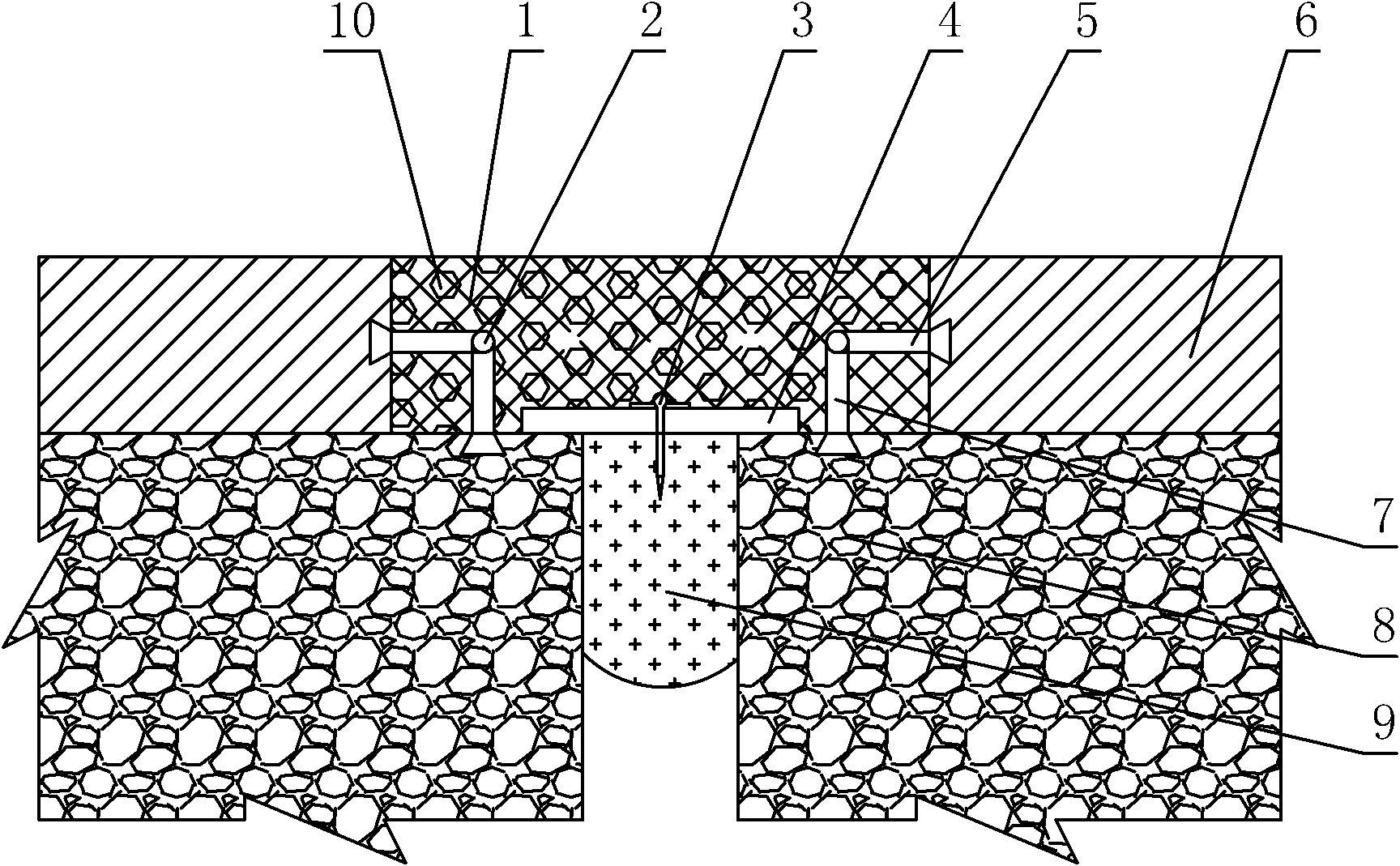

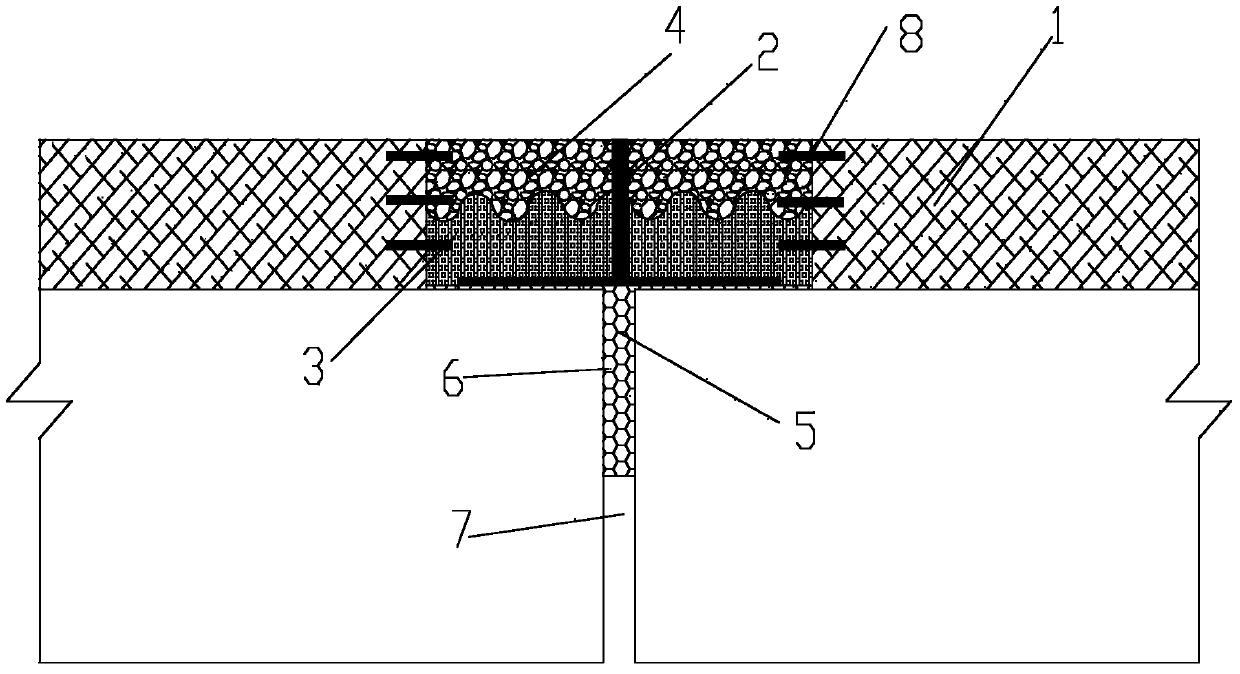

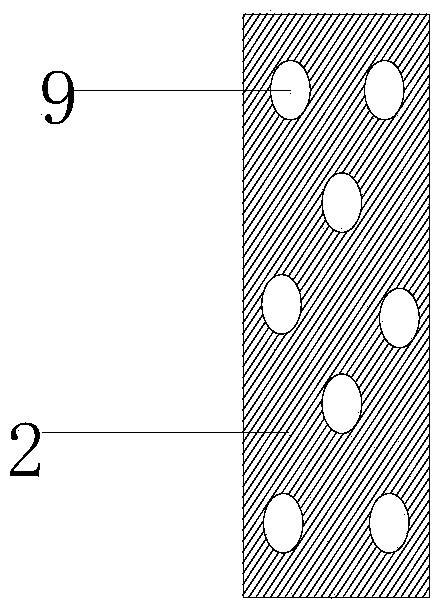

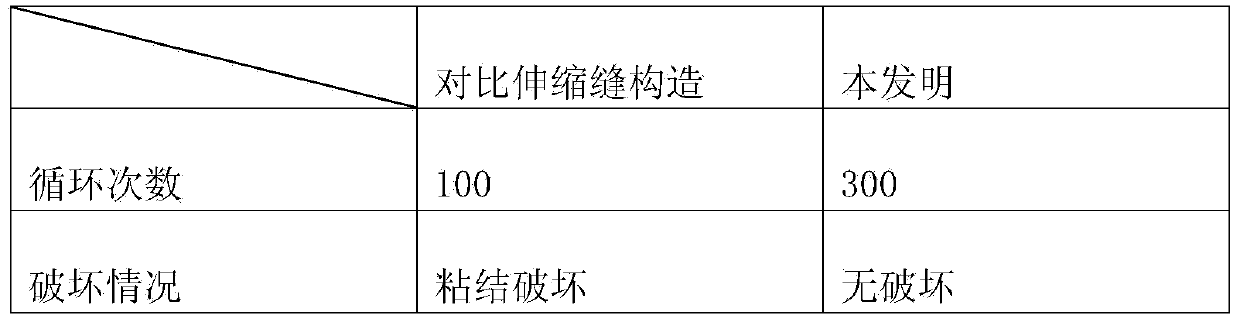

Elastoplastic device for expansion joints in buildings and road engineering

InactiveCN101985846ASimple structureReasonable designArtificial islandsPaving detailsElastomerRoad engineering

The invention discloses an elastoplastic device for expansion joints in buildings and road engineering. The elastoplastic device comprises a cast-in-place concrete layer and a bituminous concrete pavement layer arranged on the upper end of the cast-in-place concrete layer, wherein the center of the cast-in-place concrete layer is provided with an expansion joint filled with sponges or foams; the center of the bituminous concrete pavement layer is provided with a notch which is filled with expansion elastomers and broken stones and is internally provided with a cover plate; lower expansion bolts are symmetrically arranged around the upper part of the cast-in-place concrete layer; lateral expansion bolts are symmetrically arranged around the inner side of the bituminous concrete pavement layer; and steel bars are arranged between the end parts of the lateral expansion bolts and the lower expansion bolts. The device disclosed by the invention has the advantages of simple structure and reasonable design, and is convenient and rapid in construction; the performance requirements of the expansion joints can be met, special expansion members are not needed to be arranged, and the problem of short service life of other expansion devices under small stroke can be effectively solved; and the device disclosed by the invention has the characteristics of good elasticity and neat and beautiful appearance, and can bear vehicle load.

Owner:西安达盛隔震技术有限公司

Emulsified paraffin release agent and manufacturing method thereof

InactiveCN101812362AGood release effectSmooth and beautiful surfaceLubricant compositionParaffin waxProcess engineering

The invention discloses an emulsified paraffin release agent and a manufacturing method thereof. The emulsified paraffin release agent comprises the following raw materials in portions by weight:10 portions of paraffin, 2 portions of stearic acid, 1 portion of borax, 0.5 portion of HPMC, 0.6 portion of peregal, 0.1 portion of triethanolamine, 85.8 portions of water and adequate defoamer. The manufacturing method comprises the following steps: heating to dissolve the paraffin and the stearic acid at 80-90 DEG C, and keeping the temperature for later use; adding water into a reaction kettle, heating the borax to 40-50 DEG C under continuous stirring condition, slowly adding the HPMC while quickly stirring, heating to 80-85 DEG C, pouring the transparent emulsifying agent peregal solution, and slowly pouring the paraffin and stearic acid which are molten by heating into the transparent solution while stirring quickly; and finally, adding the triethanolamine, and stirring for several minutes. The invention can replace expensive machine oil, can be freely diluted with water, and can be sprayed or coated. The invention has the advantages of good film release performance and wide application range, and can enable the surface to be smooth and beautiful.

Owner:河南省绿韵建材有限公司

Method for laying protection layer on surface of iron storage tank

InactiveCN102991024AImprove bindingExtended use timeSynthetic resin layered productsGlass/slag layered productsGlass fiberSand blasting

The invention discloses a method for laying a protection layer on the surface of an iron storage tank. The technical scheme of the invention is characterized in that the method comprises the following steps: carrying out sand blast treatment of the metal surface to make the surface reach an Sa2.5 grade effect, carrying out isodirectional brush coating of a primer resin of the metal surface, allowing the obtained coat to solidify, carrying out isodirectional brush coating of the primer resin again, allowing the obtained new coat to solidify, laying a layer of a resin mortar on the surface of the coat, laying a reinforcement layer obtained through laying glass fiber clothes in an alternated manner to a required thickness of 3-5mm, laying a resin-rich layer, laying a layer of a plastic film on the surface, allowing to solidify, and uncovering the plastic film. The method for laying the protection layer on the surface of the iron storage tank has the characteristics of strong adhesion of the metal and the glass fiber reinforced plastic protection layer, long use time, no cracking, no exfoliation, and flattened and beautiful surface.

Owner:JIANGXI COPPER

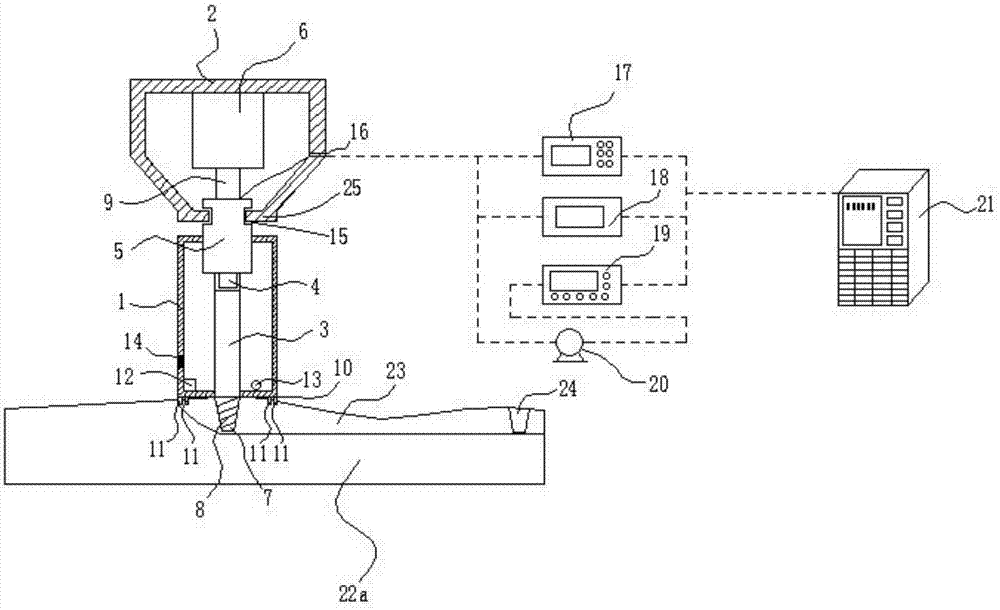

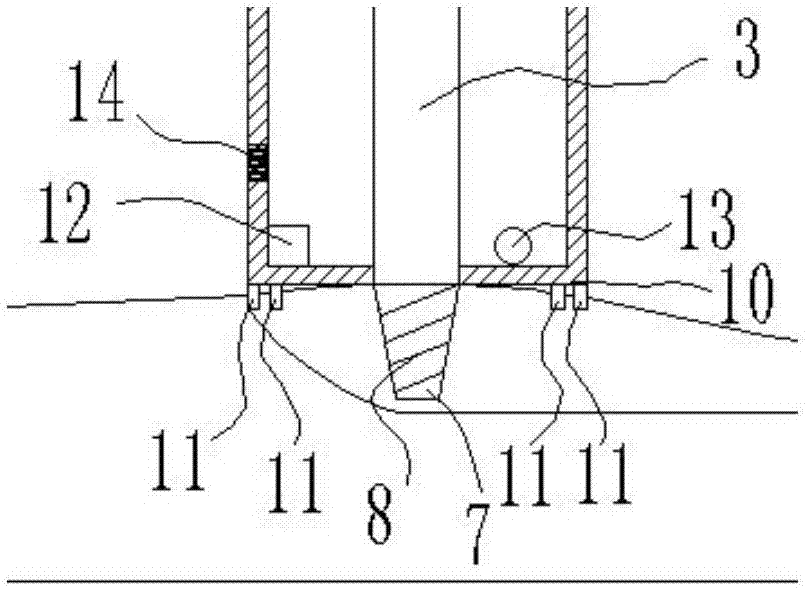

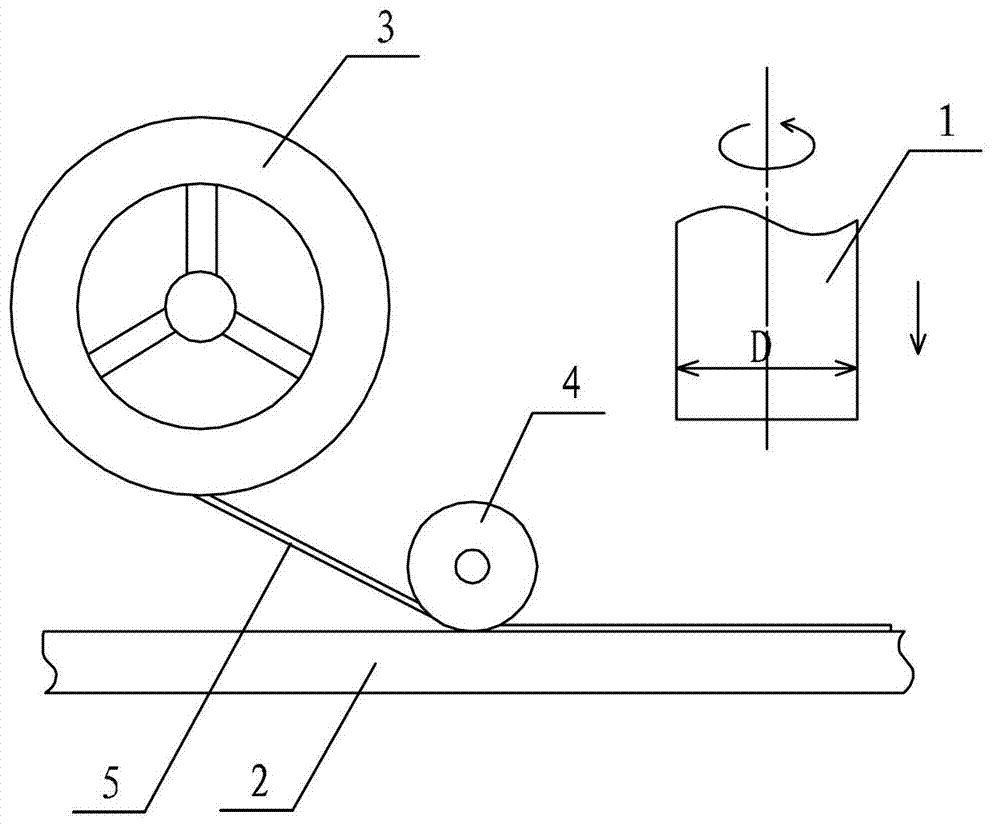

Friction stir welding device with adjustable stirring pin length and welding method

ActiveCN107470773AOvercome the problem of limited welding depth and unsatisfactory welding effectSmooth and beautiful surfaceNon-electric welding apparatusHydraulic pumpEngineering

The invention provides a friction stir welding device with the adjustable stirring pin length and a two-sided welding method. The friction stir welding device with the adjustable stirring pin length comprises a friction stir welding device main body, a clamping part, a micro hydraulic oil cylinder, a driving motor, a temperature sensor, an ultrasonic probe, an ultrasonic detector, a temperature display, a hydraulic controller, a hydraulic pump and an operation controller. The friction stir welding device main body is mounted below the clamping part and is hollow. A stirring pin is arranged in the friction stir welding device main body. A stirring head is arranged on the lower portion of the stirring pin. A rotary joint is connected with the upper portion of the stirring pin. The micro hydraulic oil cylinder is mounted between the stirring pin and the rotary joint. The friction stir welding device can automatically adapt to various welding depths and welding demands of variable cross-section components, welded surfaces are smoother and more attractive, the welding strength is higher, the welding effect is better, and the friction stir welding device is high in automation degree and easy and convenient to operate and control.

Owner:BEIJING FSW TECH

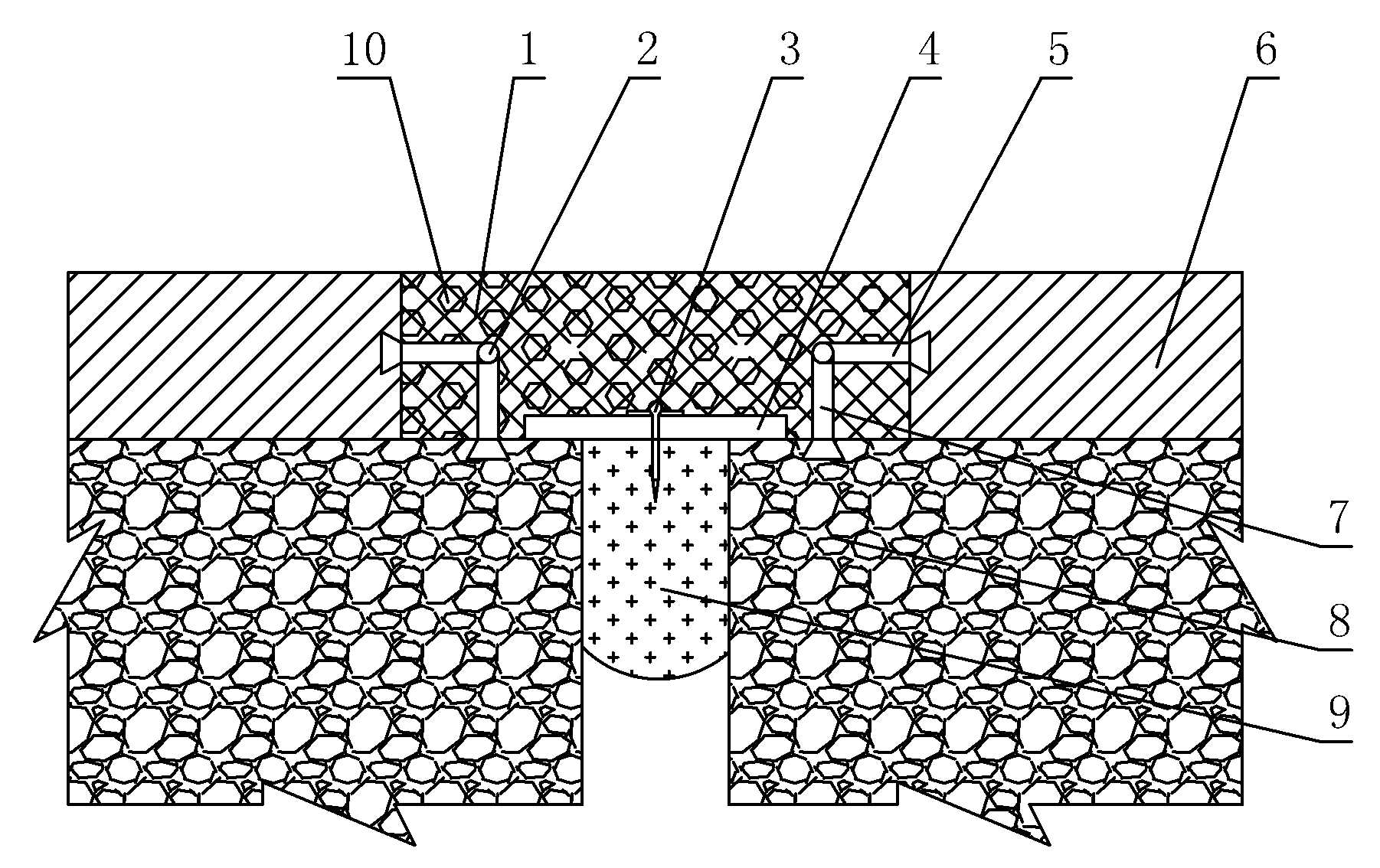

Road and bridge expansion joint structure

InactiveCN103669202AEasy constructionReasonable designBridge structural detailsStress conditionsIn vehicle

The invention discloses a road and bridge expansion joint structure. The road and bridge expansion joint structure comprises an inverted-T-shaped plate component with the bridge longitudinal cross section being in an inverted T shape. Two wing plates of the inverted-T-shaped plate component transversely extend into a base body of a bridge pavement layer. A web extends upwards to be flush with the upper surface of the bridge pavement layer. Each wing plate is sequentially provided with a cushion layer and a protection wear-resisting layer from bottom to top in a laying mode and is longitudinally connected with the bridge pavement layer. An expansion joint notch and the two sides of the expansion joint notch are filled with elastic layers to be sealed. The road and bridge expansion joint structure has the advantages of being convenient to construct, reasonable in design, high in efficiency, good in vehicle load bearing performance, good in elasticity, smooth and attractive in surface, and good in waterproofing, anti-aging, anti-fatigue, shock resistance and corrosion resistance. In accordance with the characteristics of an expansion joint, three materials of different components and matching ratios are adopted, layered pavement is conducted according to different stress conditions and states, good durability is achieved, construction is rapid and simple, and the expansion joint performance requirement can be well met.

Owner:孟献春

Sodium-potassium citrate chewing tablet and preparation method thereof

ActiveCN102429887AStable and controllable qualityCool tasteOrganic active ingredientsMetabolism disorderCelluloseMagnesium stearate

The invention provide a sodium-potassium citrate chewing tablet, of which the prescription is composed of the following components by mass percent: 33.0-33.1% of potassium citrate, 27.8-27.9% of sodium citrate, 28-32% of filling agent, 0.05-0.3% of adhesive, 1-1.5% of lubricant, 3-5% of flavoring agent, 0.1-0.3% of aromatizer and 3-4% of moistureproof film coating agent, wherein the filling agentis mannitol or a mixture of mannitol and sorbitol or xylitol; the adhesive is hydroxypropyl methylcellulose or polyvidone K30; the lubricant is magnesium stearate or a mixture of magnesium stearate and micropowder silica gel; the flavoring agent is citric acid or a mixture of citric acid and sodium saccharin, aspartame or steviosin; and the aromatizer is pharmaceutically acceptable essence. The invention also provides a preparation method of the sodium-potassium citrate chewing tablet. The preparation method is simple and convenient to operate, low in cost and suitable for industrial production. The obtained tablet has stable and controllable quality, fresh and cool mouthfeel, sourness and sweetness in taste, mint fragrance or fruit fragrance, smooth and beautiful surface, uniform color, moderate hardness and rapid dissolution, and has good application prospects in treatment of gout and hyperuricemia as well as improvement of children and adult in vivo acidosis symptom and other aspects.

Owner:SOUTHWEST UNIV

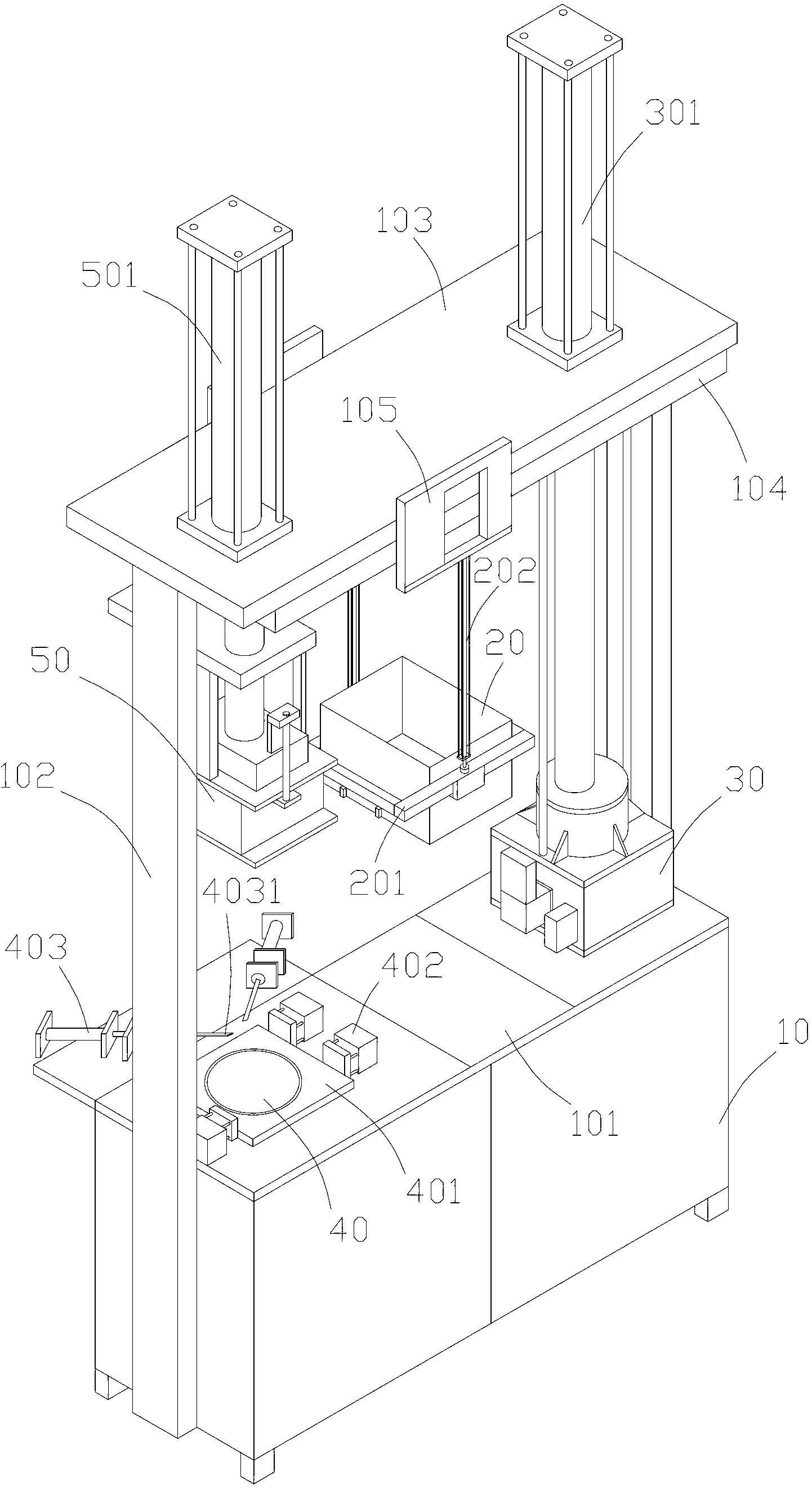

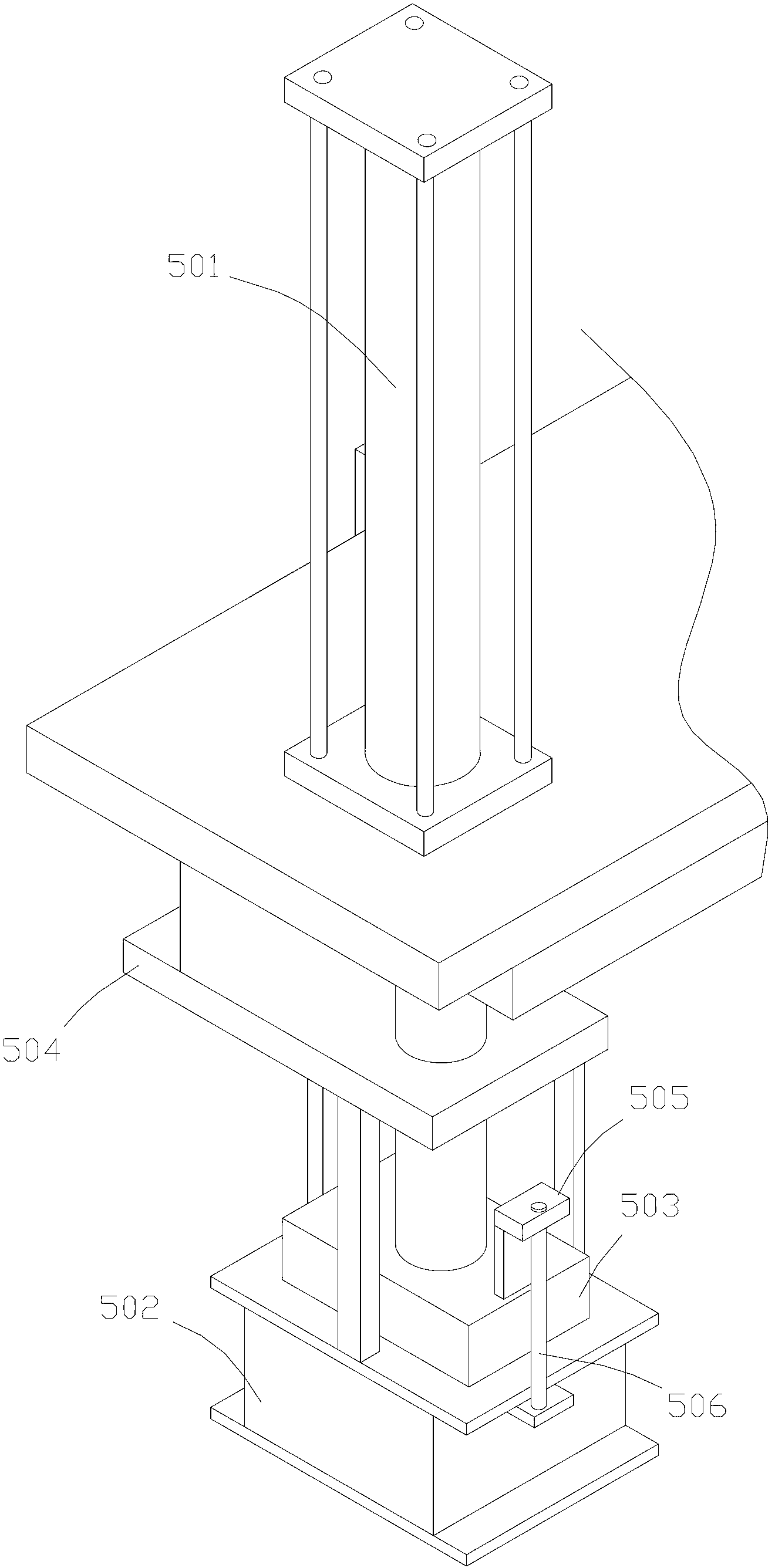

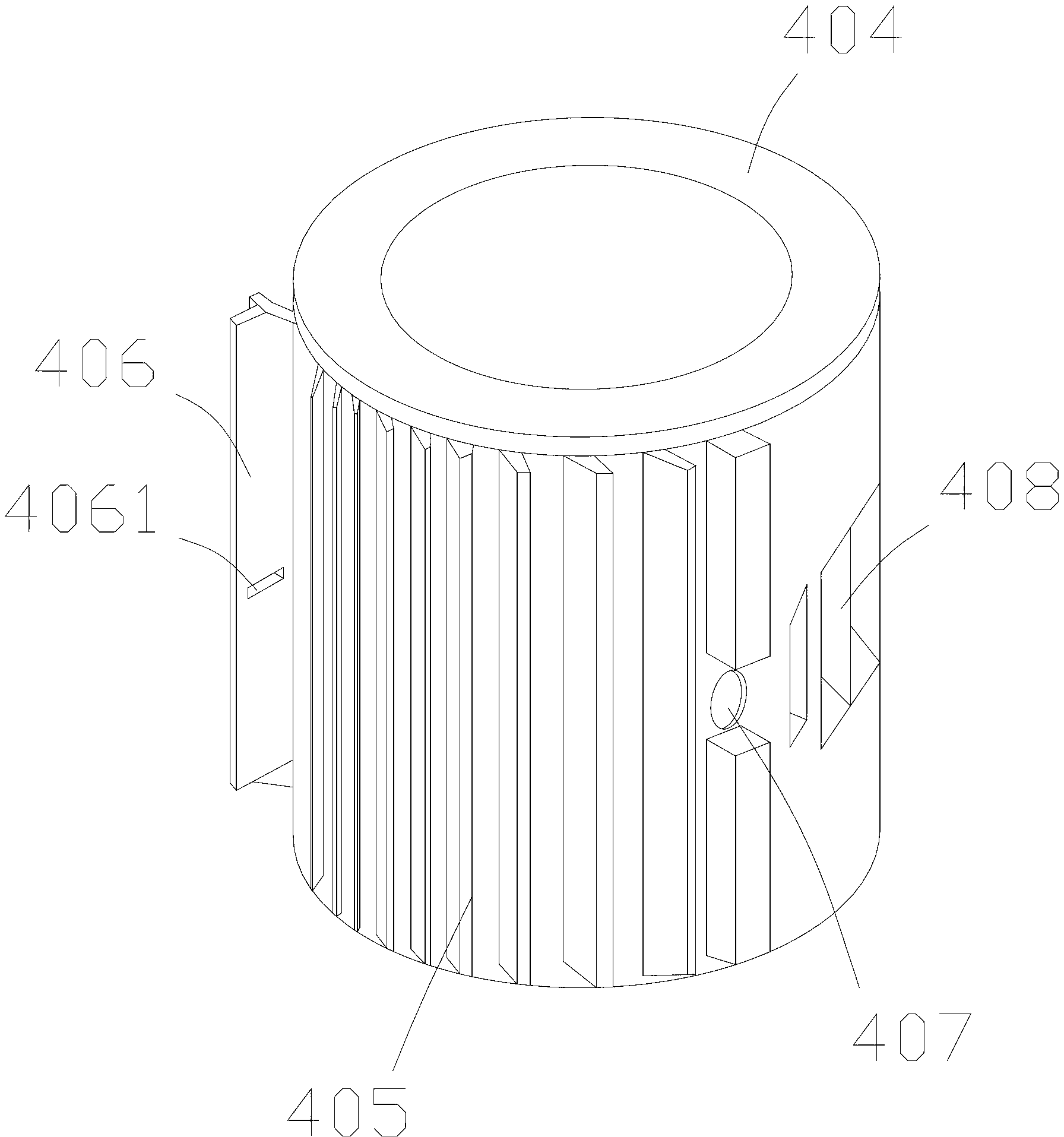

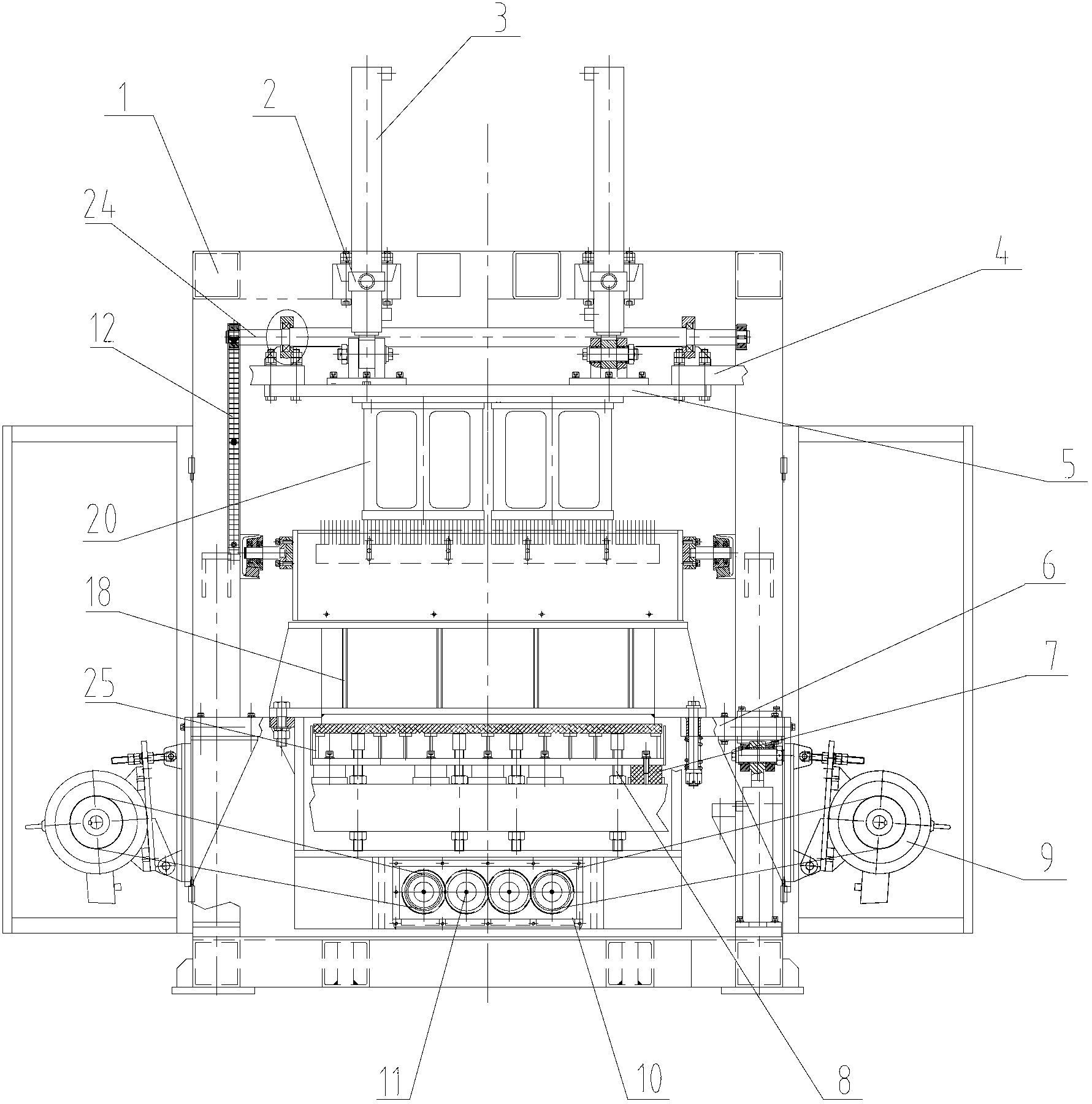

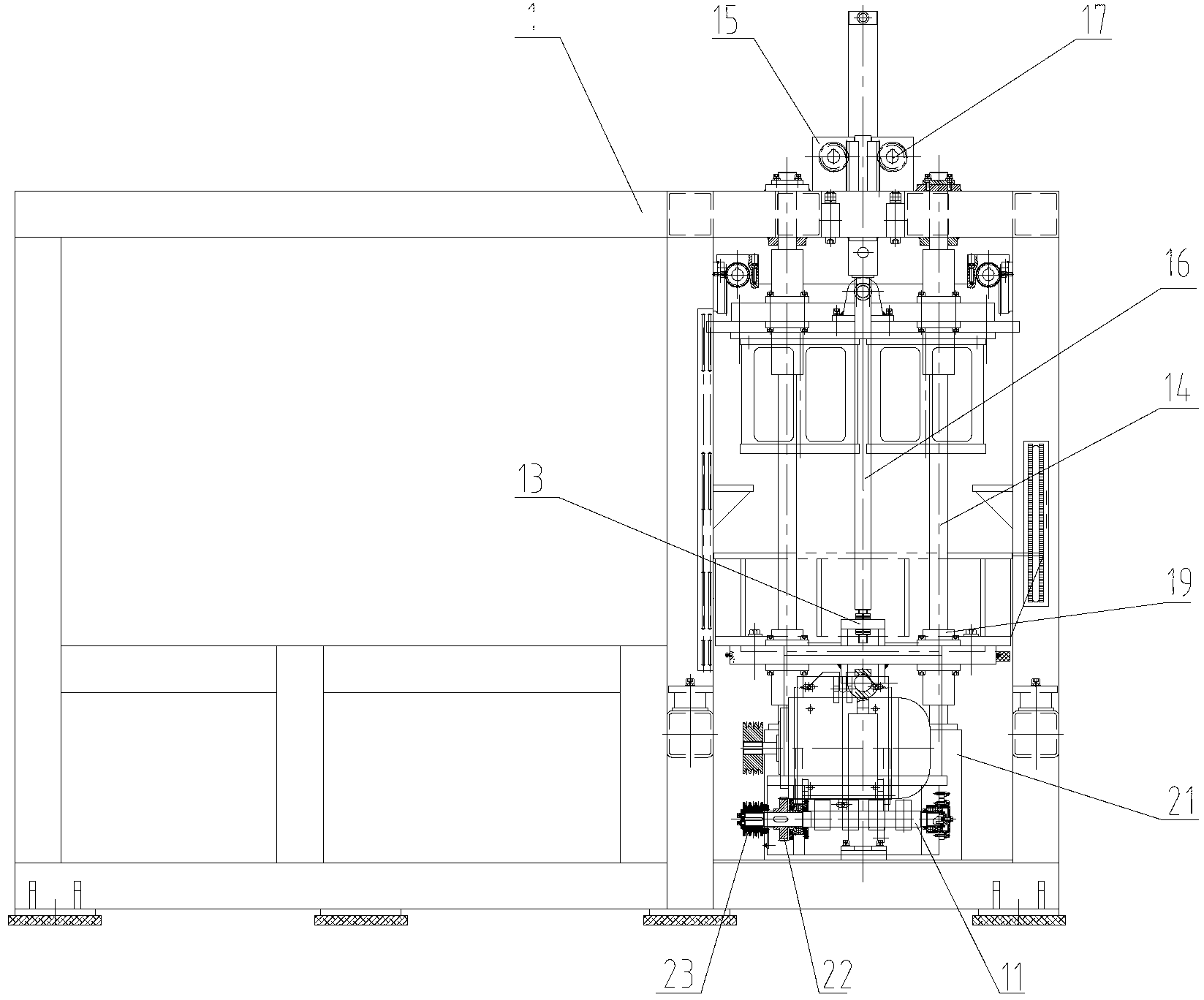

Automatic seamless motor housing molding machine

ActiveCN103231027AEasy to useNo lossFoundry mouldsMoulding machinesManufacturing technologyMolding machine

The invention relates to an automatic seamless motor housing molding machine, and relates to a motor manufacturing technology. The machine comprises a frame and a workbench arranged on the frame. Supporting rods extend upwards from two sides of the frame. A cross beam is connected on the upper ends of the supporting rods. Slide rod assemblies are arranged on two sides of the cross beam. An inner shape sand box is arranged below the cross beam. A rectangular connection piece is fixedly connected on the periphery of the inner shape sand box. Gas cylinders are connected on two sides of the rectangular connection piece. The ends of piston rods on the front ends of the gas cylinders are fixed on the rectangular connection piece. The back ends of the gas cylinders are slidably connected on the slide rod assemblies through sliding parts. An inner shape molding mold elevation groove is arranged on one side of the workbench, and an outer shape molding mold accommodation recess is arranged on the other side of the workbench. An outer shape mold is arranged on the outer shape molding mold accommodation recess. An elevation gas cylinder is connected to an outer-upper pressing plate on the outer shape mold. A sand feeding pipe is connected to the outer shape mold. An elevation mechanism is arranged on the bottom of the inner shape molding mold elevation groove. An inner shape molding mold is fixed on the elevation mechanism. An ejection-pressing device is arranged above the inner shape molding mold, and is connected to an ejection-pressing gas cylinder which is arranged on the cross beam. With the machine provided by the invention, a manufactured product has no crack caused by mold seam of a splicing-type mold. The surface of the product is more smooth and beautiful.

Owner:狄海串 +1

Ice-crack-shaped polished crystal tile and manufacturing method thereof

The invention discloses an ice-crack-shaped polished crystal tile comprising a ceramic tile blank, a coloured glaze layer, an ice crack layer and a transparent frit layer, wherein the coloured glaze layer comprises the following components in percentage by mass: printing glaze, glaze pigment, kaolin, methylcellulose and sodium tripolyphosphate; the ice crack layer is made of ice flower crystals with crystal glaze as the main material. The ice-crack-shaped polished crystal tile is manufactured sequentially through the steps: manufacturing a flower net; blending coloured glaze; pushing-printing the coloured glaze and ice flower crystal powder; pushing-printing frit particles; firing; and polishing. According to the invention, a crystal effect liked by people is integrated into the transparent frit layer of the polished crystal tile to form a snowflake-like natural, clean and varied embedded crystal effect, so that the tile with the novel technology has stronger decorative performance; the manufacturing method of the ice-crack-shaped polished crystal tile is simple and rapid, capable of realizing large-batch mechanical production under the condition of no great change of the original equipment, extremely simple in operation and capable of realizing flexible production for tiles with different deigned styles.

Owner:FOSHAN MAY ROSE CERAMIC

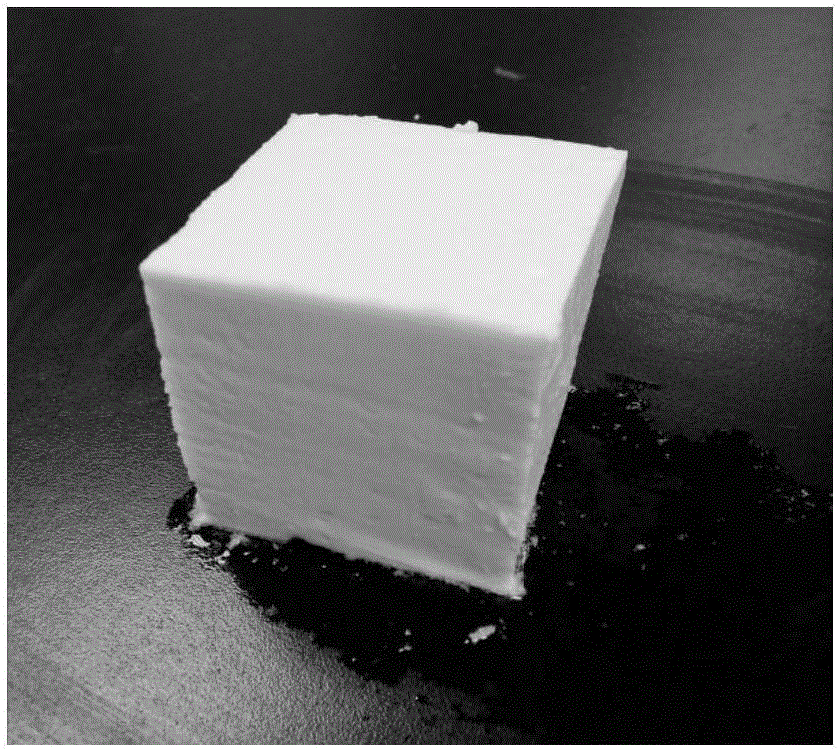

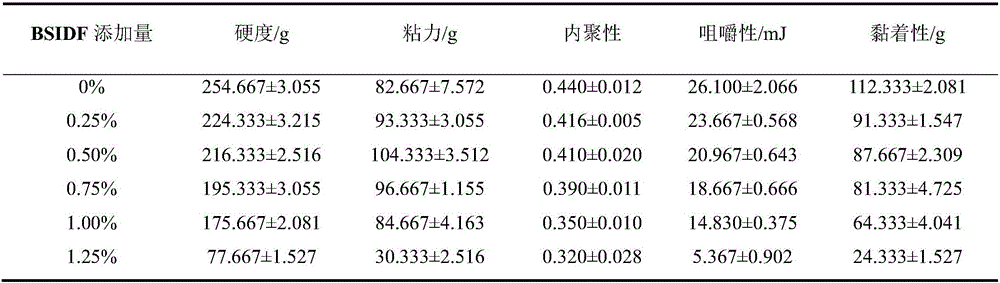

Manufacture method of bamboo shoot dietary fiber bean curds and product thereof

InactiveCN106720449ARaw materials are easy to getSimple processCheese manufactureFlavorDietary fiber

The present invention relates to a manufacture method of bamboo shoot dietary fiber bean curds and a product thereof. The preparation method is simple. By using wastes produced in the processing of bamboo shoots as a raw material and a variety of modern food high technologies, the bamboo shoot dietary fibers with a high purity are prepared by using compound enzymolysis, ultrafine grinding and other technologies, glucolactone is supplemented as a coagulator, and the bean curds containing the bamboo shoot dietary fibers are prepared. The prepared products are in square shapes (10cmx10cmx10cm), present milky white, smooth and beautiful in surface, uniform in color and luster, moderate in hardness, qualified in flexibility, and tender and smooth in taste, has unique flavor of the bamboo shoots, is free of other smell, and has good market development prospects.

Owner:SOUTHWEST UNIVERSITY

Heat-resistant antistatic coating

InactiveCN101993647AEasy to cleanEasy maintenanceEpoxy resin coatingsElectrically-conductive paintsEpoxySolvent

The invention relates to a heat-resistant antistatic coating which is especially applicable to working at high temperature. The heat-resistant antistatic coating provided by the invention can maintain good electrical conductivity and does not influence the properties of manufactured products. The heat-resistant antistatic coating is prepared from 55-65% of polyester resin, 55-65% of epoxy resin, 27-40% of filling material, 4-5% of leveling agent, 3-4% of curing agent, 40-70% of resin, 20-40% of electrically conductive powder, 1-20% of solvent, 1-3% of dispersing aid, 1-5% of titanium white, 0.1-0.3% of coupling agent, 35-55% of acrylic emulsion, 1-4% of graphite powder, 1-4% of carbon black and 45-65% of diluent.

Owner:杨紫萱

Novel mould vibrating brick making machine

InactiveCN103009457AImprove compact strengthThe surface is smooth and beautifulCeramic shaping apparatusBrickEngineering

The invention relates to a novel mould vibrating brick making machine which comprises a main machine and a matched device. A main frame of the main machine is internally provided with an upper moving mechanism, a column part, a lower moving mechanism, a vibrating mechanism, a layer board platform, a lower balancing mechanism and a power device. The novel mould vibrating brick making machine is characterized in that the main machine is internally provided with a lower mould frame of the lower moving mechanism, the vibrating mechanism, the lower balancing mechanism and the power device which are connected with a lower moving base and driven by a lower mould oil cylinder to move up and down simultaneously. The vibrating force is directly transferred from a vibrating box to the lower mould frame, and when the lower mould frame vibrates up and down, a high frequency beating process exists between raw materials and the layer board platform. The novel mould vibrating brick making machine integrates characteristics of mould vibration and table vibration, the vibrating effect is good, the movements are synchronous and consistent, the compact strength of bricks is high, and the surface of the brick is smooth and attractive.

Owner:WUHAN BANDAO HEAVY IND

Insoluble medicine tablet and preparing process thereof

InactiveCN1451373AAvoid clumpingSmooth and beautiful surfacePharmaceutical non-active ingredientsPill deliveryCarboxymethyl starchSolubility

A tablet of the insoluble medicine is prepared through mixing said medicine with lactose, pulverizing, sieving, mixing with microcrystal cellulose powder and carboxymethyl starch sodium, preparing soft material with povidone K30 solution, granulating, drying at 50-80 deg.C, mixing with lubricant, and tabletting. Its advantage is high solubility of medicine (more than 90%).

Owner:YANGTZE RIVER PHARM GRP CO LTD

Normal temperature manufacturing process for MMA high-intensity artificial stone special-shaped pot/trough

InactiveCN101474827AWell mixedEfficient mixingStone-like material working toolsMechanical propertyMaterials science

The present invention discloses a technique for manufacturing MMA high-strength artificial stone special-shaped basin / groove at normal temperature. The methyl methacrylate resin, arenaceous quartz, accelerating agent and solidifying agent are executed with mixing, injection molding and solidifying forming. The mixing is vacuum mixing which is executed in a mixer with a vacuum degree of 8MPa. The vibration is executed while the squeezing is executed for pouring into the mold for completing injection molding. The mould is closed to a static solidifying exothermic peak, and mould removing and baking are executed. The invention aims at the disadvantages of high cost and hard mould removing of prior art. The invention provides a technique for manufacturing MMA high-strength artificial stone special-shaped basin / groove at normal temperature. The cost is reduced on one hand. On the other hand the mechanical property of product is increased. The technique of the invention has the following remarkable effects: adoption of normal temperature pouring for replacing the previous high temperature pouring, low energy consumption and convenient construction; and 2. adoption of vacuum mixing, excellent texture of finished product, and beautiful external appearance.

Owner:SHANGHAI MOERSHU CORP DEVING

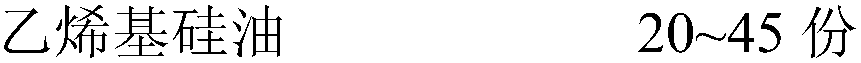

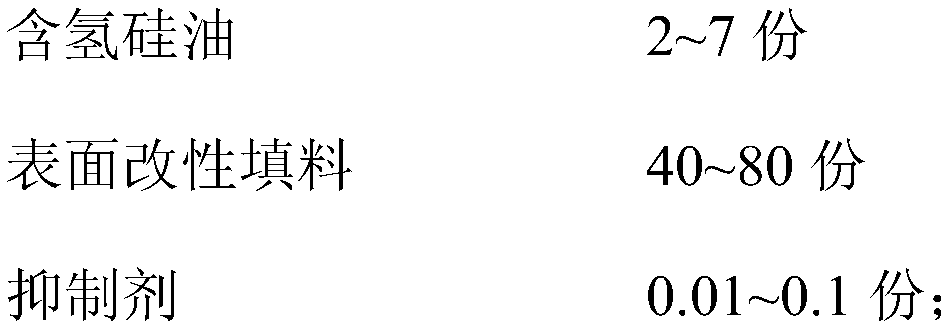

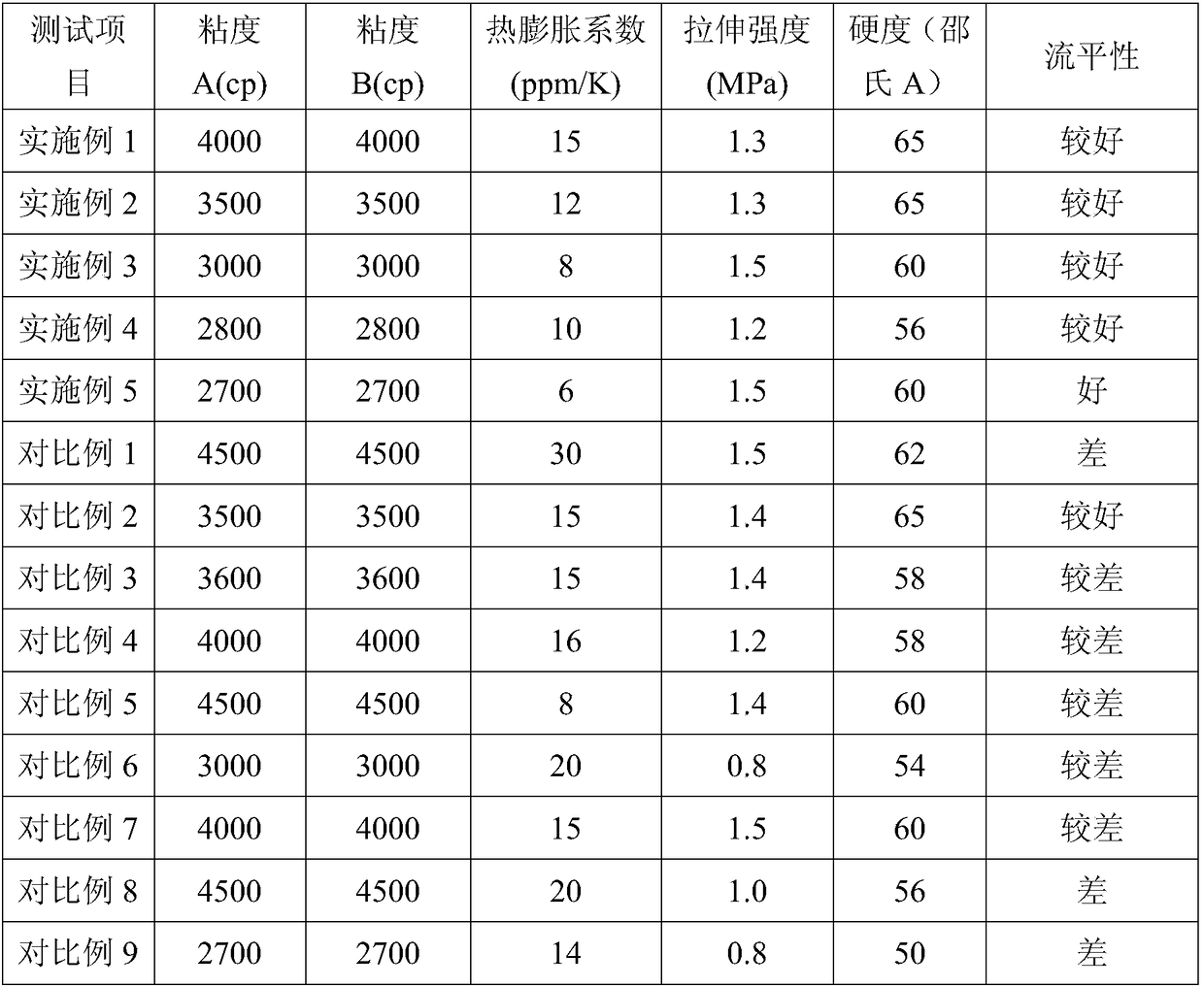

Encapsulating silica gel and preparation method and application thereof

ActiveCN108410416AEffective protectionImprove the level ofNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsHot weatherHydrogen

The invention provides an encapsulating silica gel and a preparation method and application thereof. The encapsulating silica gel is prepared from a component A and a component B, wherein the component A is prepared from the following components in parts by weight: 20 to 45 parts of vinyl silicone oil, 2 to 7 parts of hydrogen-containing silicone oil, 40 to 80 parts of surface-modified filler, and0.01 to 0.1 part of inhibitor; the component B is prepared from the following components in parts by weight: 20 to 45 parts of vinyl silicone oil, 30 to 70 parts of surface-modified filler, and 0.05to 0.2 part of catalyst. The encapsulating silica gel prepared by the preparation method has a low expansion coefficient, a good leveling property during curing, a smooth surface, and an attractive appearance, a good encapsulating effect can be kept in severe cold and hot weather environments, the components can be prevented from being cracked or damaged, and the encapsulating silica gel can be widely used in the encapsulation of electronic components such as a LED power supply and a dry type transformer, which require high temperature stability.

Owner:深圳天鼎新材料有限公司

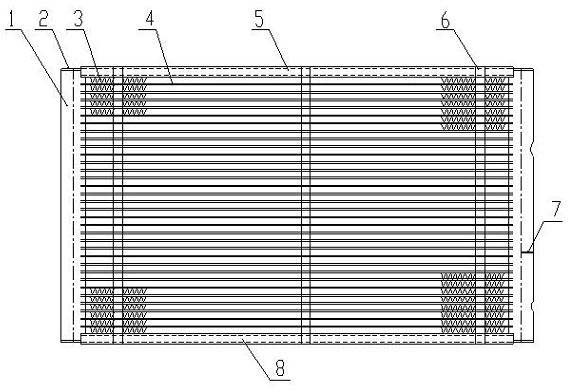

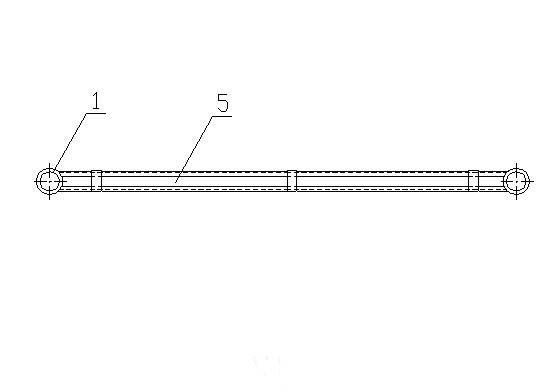

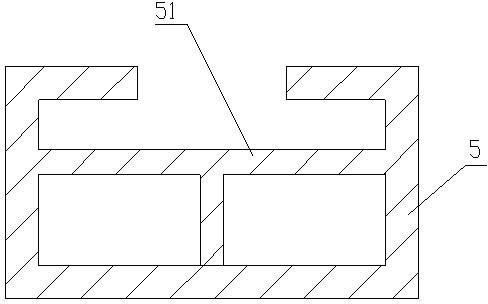

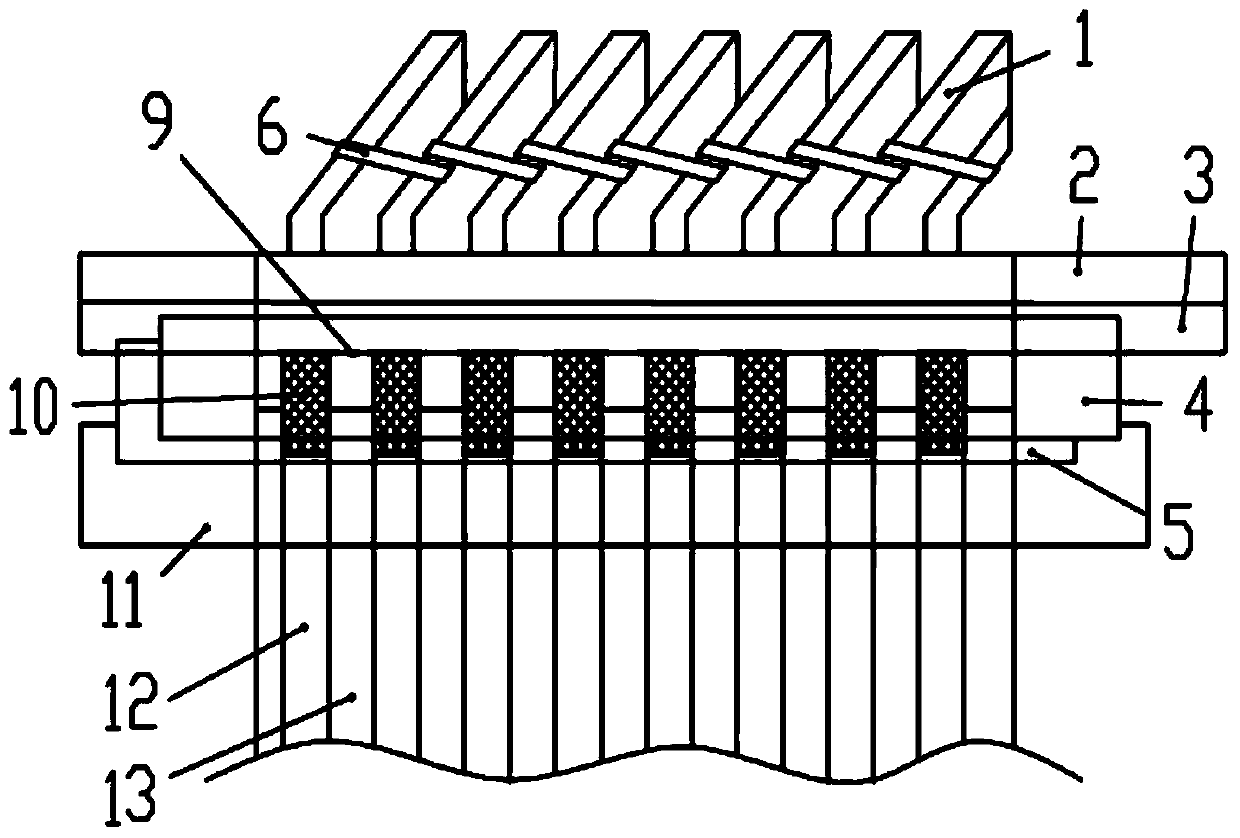

Method for producing and assembling micro-channel heat exchanger

ActiveCN102628654ALow costSolve the defect of deformationStationary conduit assembliesHeat exchanger casingsPlate heat exchangerNitrogen

The invention relates to a micro-channel heat exchanger technology, in particular to a method for producing and assembling a micro-channel heat exchanger. According to the method, the problems of deformation of a core body protective plate and oxidized black residues attached to the protective plate caused by that the core body of the micro-channel heat exchanger is reinforced by a stainless steel square pipe before braze welding are solved. The method is characterized in that porous flat pipes are arranged between collecting pipes on two sides uniformly in parallel; a radiating belt is arranged between the adjacent porous flat pipes; the end parts of the parallel and symmetrical collecting pipes are plugged by end covers; partition boards are arranged in the collecting pipe; the porous flat pipes are arranged on the inner sides of the radiating belts on the edge of the length direction of the collecting pipes; upper protective plates or lower protective plates are arranged on the outer sides of the radiating belts; the protective plates and the lower protective plates are bundled by a plurality of steel belts; the core body, bundled by the steel belts, of the micro-channel heat exchanger is conveyed to a nitrogen protection high-temperature brazing furnace to be welded; and after the core body of the micro-channel heat exchanger moves out of the nitrogen protection high-temperature brazing furnace, the steel belts are removed. According to the method, no deformation defect exists, the surface is smooth, clean and attractive, and production efficiency is high.

Owner:浙江康盛热交换器有限公司

Locating sleeve buried beforehand for electrical installation project

The invention discloses a pre-embedded locating conduit for electrical installation engineering, comprising a base and a conduit body on the base. An inner cavity matched with the sleeved pre-embedded conduit is arranged in the conduit body. Screw holes are arranged on the base. The prior art has the problems that electrical installation pre-embedding procedure damages the formwork, the verticality of the pre-embedded conduit can not be controlled, and the casting quality of concrete surrounding the pre-embedded conduit is bad. However, the pre-embedded locating conduit for electrical installation engineering has the advantages of solving the problems of the prior art, no damaging the template, effectively controlling the position and the verticality of the pre-embedded conduit, improving the concrete quality. The pre-embedded locating conduit for electrical installation engineering has also the advantages of low cost, and convenient manufacture.

Owner:RONGHUA CONSTR GRP CO LTD

Tunnel lightweight inorganic fireproof composite material

ActiveCN101200380AMeet construction requirementsSignificantly reduce drynessLayered productsFiberFireproofing

The invention provides a light inorganic fireproofing composite material for tunnel, which is compounded by three layers of materials from inside to outside; the first layer is spray inorganic fireproofing material, the components of which comprise inorganic fireproofing fiber, expanded vermiculite powder, expanded graphite powder and ordinary Portland cement; the second layer is surface fireproofing material, the components comprises ordinary Portland cement, mica powder, gypsum and talcum powder; the third layer is fireproofing decorative material, which is a fire-retardant single-side composite aluminum foil. The composite material has the advantages that: the fire endurance is high; the thermal conductivity in hydrocarbon fire scene is extremely low; the fireproofing result is excellent; the self quality loss in fire is less without melting and dropping; the weight is light; the weathering is good; the sound-absorbing is good and the high-frequency drying reduction is obvious; the cost is low; the construction strength is less and the charge is low; furthermore, the ornament is good and the surface is smooth and beautiful surface, thereby the invention can mainly be used in the fire protection for the tunnel wall.

Owner:应急管理部四川消防研究所

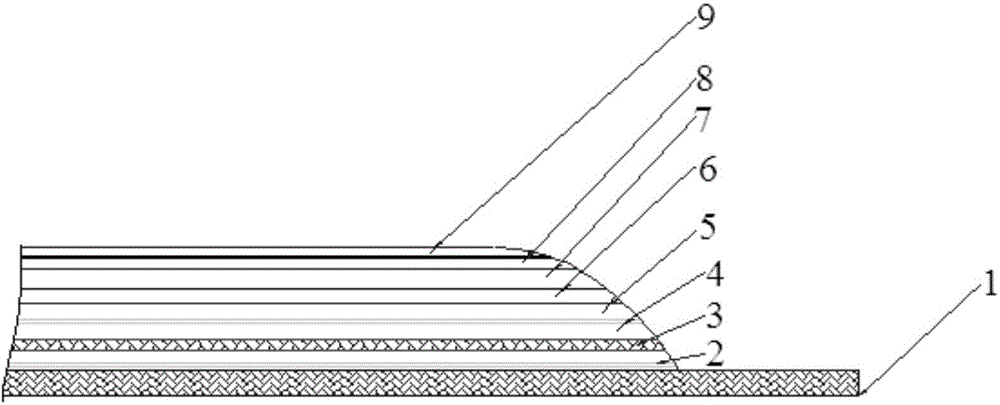

Method for integrally forming light automobile floor

The invention relates to a method for integrally forming a light automobile floor. The method comprises the following steps: firstly, mold laying-up operation is carried out, wherein bottom layer glass fabric, a PET foam core sandwich, upper layer glass fabric, release cloth, an isolation film with holes, a PP punching plate, a flow guide net and a vacuum bag film are sequentially laid on the surface of a mold, one end of a winding pipe stretches into the interior of the vacuum bag film, the other end of the winding pipe is connected with an external vacuum pump, one end of a resin injecting pipe is connected to the flow guide net, and the other end of the resin injecting pipe is connected with an external resin tank; secondly, the vacuum pump is started to carry out vacuum pressure maintaining; and thirdly, thermosetting resin is poured from the resin tank to enter the interior of the bottom layer glass fabric, the interior of the PET foam core sandwich and the interior of the upper layer glass fabric, excess thermosetting resin is sucked out through the winding pipe, mold releasing is achieved after curing treatment, and the light automobile floor formed by the bottom layer glass fabric, the PET foam core sandwich, the upper layer glass fabric and the thermosetting resin poured into the bottom layer glass fabric, the PET foam core sandwich and the upper layer glass fabric is obtained. Compared with the prior art, the automobile floor obtained through the method is flat and attractive in surface, light, difficult to combust, dampproof, corrosion-resisting and good in weather resistance.

Owner:SHANGHAI YUEKE COMPOSITE

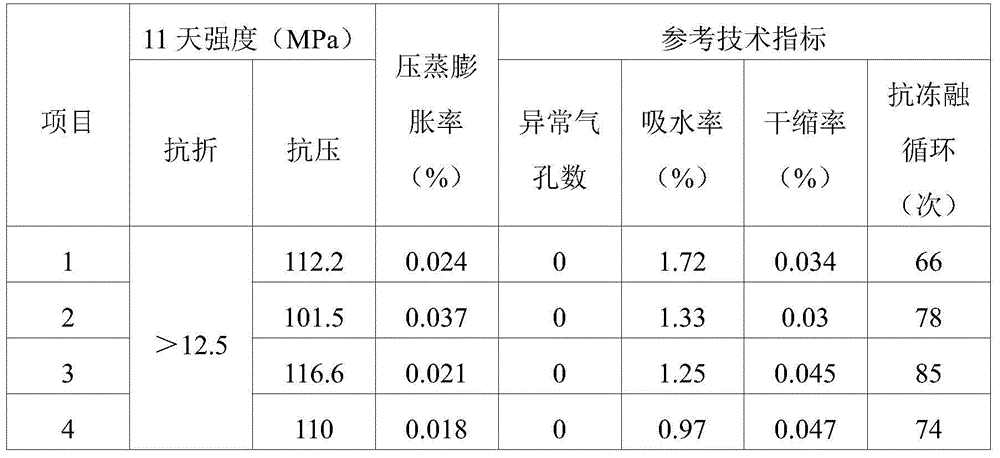

Cement base insulator adhesive

The invention discloses a cement base adhesive for an electric porcelain insulator. The cement base adhesive comprises the following components in percentage by mass: 22-42% of cement, 5.5-12.5% of mineral powder, 2-7.5% of silicon micro powder, 35-64% of quartz sand, 0.25-0.7% of a polycarboxylic acid water reducer, 0.015-0.099% of lithium carbonate, 0.025-0.06% of a defoaming agent and 7-15% of water. The cement base insulator adhesive disclosed by the invention is composed of Portland cement, a mineral admixture, an additive and the like, and has good working performance, mechanical properties and durability. The compression strength of 3 days can reach 75MPa, the compression strength of 11 days can reach 100MPa, the compression strength of 28 days can reach 122MPa, and the flexural strength of each stadium is greater than 12.5MPa.

Owner:WUHAN UNIV OF TECH

Production method of multi-layer composite adhesive fabric

ActiveCN103360982AGuaranteed compactnessImprove the protective effectNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementChemistry

The invention relates to a production process of an adhesive fabric, particularly relates to a production method of a multi-layer composite adhesive fabric, and solves the technical problem that the adhesive fabric is loose and coarse in surface and extremely poor in protection property due to the fact that bubble, pinhole and sponge phenomena often exist on the surface of the adhesive fabric as a result of identical curing points of each adhesive layer in the multi-layer adhesive fabric production process in the prior art. The production method of a multi-layer composite adhesive fabric comprises the following steps: 1, component preparation: preparing components of two adhesives; 2, compounding: respectively compounding the two adhesives; 3, adhesive cement preparation: preparing adhesive cements of the two adhesives; 4, adhesive coating: coating the adhesive cement of a second adhesive on two faces of a nylon fabric, and then coating the adhesive cement of a first adhesive on one face of the nylon fabric; and 5, curing to obtain the multi-layer composite adhesive fabric. According to the formula of the process provided by the invention, the quality of the product is greatly improved; and the product is smooth and beautiful in surface, and has very good protection property against various corrosive substances.

Owner:SHANXI XINHUA CHEM

2MW wind turbine notch potting process

ActiveCN104218750APrevent leakageSmooth and beautiful surfaceManufacturing dynamo-electric machinesGlass fiberEngineering

The invention provides a 2MW wind turbine notch potting process. The process includes the steps of sticking a double-sided foam adhesive and the lower edge of the outer surface of transparent composite foil in a parallel and level mode and closely winding and tensioning a round of the notched edge of the outer circle of a stator with the double-sided foam adhesive; cutting a glass fiber mat into rectangular pieces to be filled onto the surface of a groove wedge and tightly sticking and fixing the upper end of the glass fiber mat to the lower end of the double-sided foam adhesive with a transparent adhesive tape; filling potting adhesive to the bottom of the transparent composite foil to complete potting. According to the 2MW wind turbine notch potting process, the glass fiber mat is used for filling the surface of the groove wedge, and then the transparent adhesive tape is used for sticking and fixing for further enabling the entire outer surface of the 2MW stator to approximately have the surface of a cylinder, so that potting adhesive leakage during the potting of a 2MW direct drive permanent magnet wind turbine notch can be effectively prevented, and the surface formed through curing with the notch potting adhesive is smooth and attractive in appearance.

Owner:JIANGSU CRRC ELECTRIC CO LTD

Sputtering target packaging box

ActiveCN102502043AReduce the chance of damageHigh strengthBio-packagingRigid containersEngineeringBody positions

The invention provides a sputtering target packaging box, which comprises an enclosed box, a protection body positioned in an accommodating space, a bottom plate and a cover plate, wherein the enclosed box comprises side plates which are connected end to end and are integrally molded; the accommodating space is defined by the side plates; two sides of the protection body are supported on the side plates; the bottom plate is arranged on the protection body and is positioned in the enclosed box; the cover plate is arranged on the top of the enclosed box and has a shape of a frame; each frame of the cover plate is provided with a locking hole or a buckle; and the side plates are correspondingly provided with buckles or locking holes which are matched with the locking holes or the buckles of the cover plate. The sputtering target packaging box does not deform due to external force, and the target damage rate is reduced; the packaging box can be repeatedly detached and mounted multiple times and is convenient to carry and flexible to use; and the bearing capacity is high, the packaging box can be laminated in multiple layers, and the storage space of a target is saved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

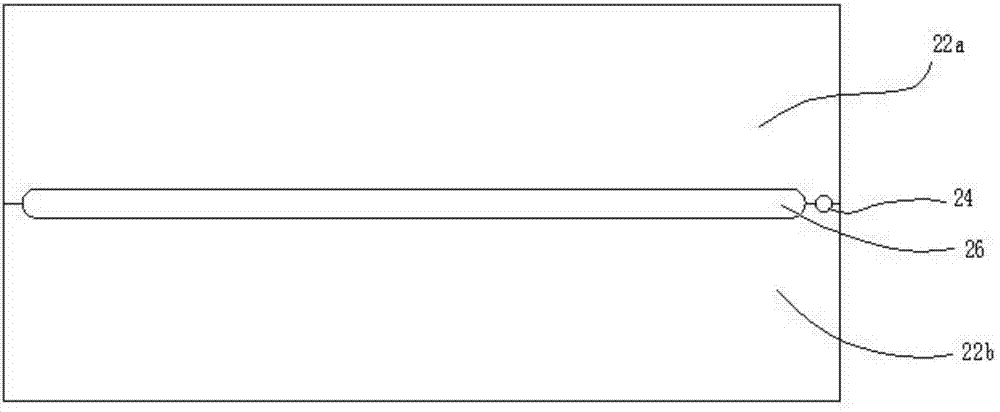

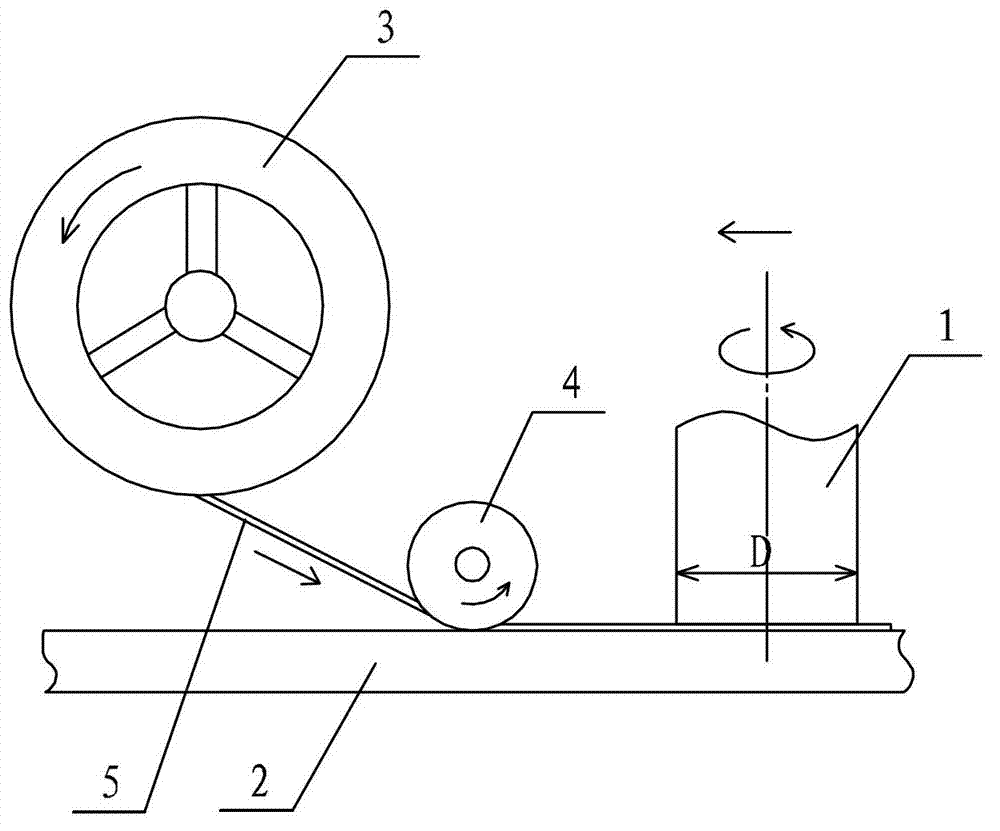

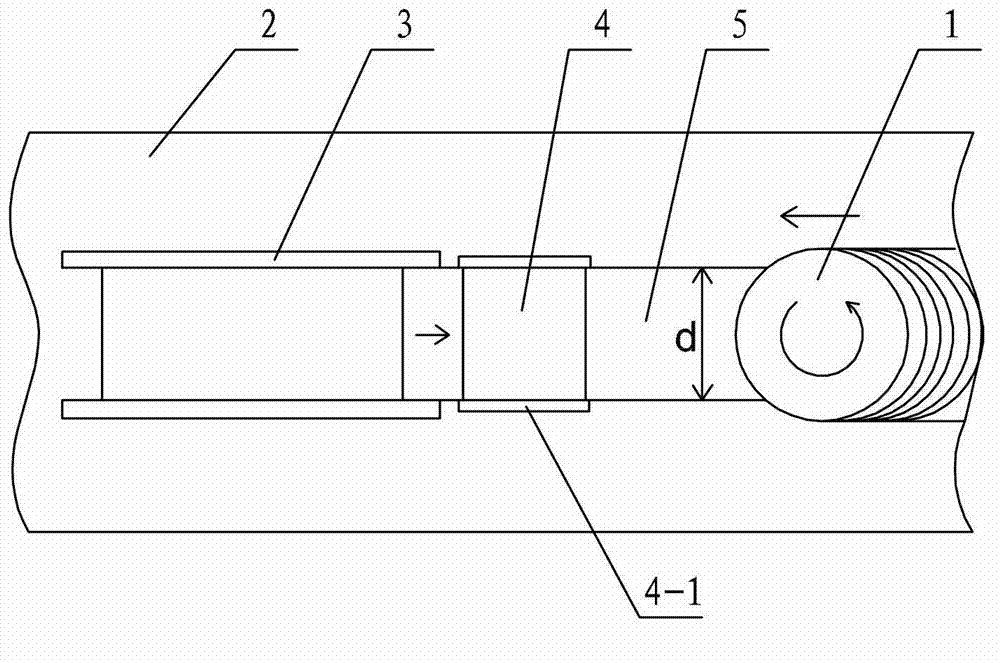

Strap-shaped welding wire filling-in type stirring friction treatment method

InactiveCN103170726ALow dilution rateChange surface propertiesNon-electric welding apparatusBand shapeEngineering

The invention relates to a strap-shaped welding wire filling-in type stirring friction treatment method, relates to a filling-in type stirring friction treatment method, and aims at solving the problem that generally high-energy beam powder bead welding can only be conducted under gas protection or even under vacuum condition. The method comprises the following steps of: firstly, pretreatment preparation, namely, a wire feeding wheel and a positioning guide wheel are fixed on a main shaft of a welding machine, a material to be treated is clamped, a strap-shaped welding wire is put under the positioning guide wheel, the positioning guide wheel is tightly adhered to the surface of the material to be treated, the strap-shaped welding wire is fixed on the surface of the material to be treated, and the end part of the strap-shaped welding wire is put just below a needleless welding tool; secondly, stirring friction treatment, namely, the welding machine is started, the needleless welding tool starts to vertically feed downwards, the shaft shoulder of the needleless welding tool is contacted with the end part of the strap-shaped welding wire and is gradually compressed into the upper surface of the material to be treated, and the strap-shaped welding wire is subjected to bead welding on the surface of the material to be treated by using the stirring and fogging and pressing functions of the shaft shoulder; and thirdly, after-welding settlement, namely, the welding wire is cut off by using a pair of cutting nippers, the residual welding material and overlap are removed by using a steel wire brush. The method is applied to stirring friction treatment.

Owner:HARBIN INST OF TECH

Double-layer composite glass magnesium board with high fireproof grade and preparation method of double-layer composite glass magnesium board

The invention discloses a double-layer composite glass magnesium board with a high fireproof grade. The double-layer composite glass magnesium board is characterized by being prepared from the following raw materials in parts by weight: 42-45 parts of light calcined magnesia, 39-41 parts of magnesium chloride hexahydrate, 7-9 parts of forsterite powder, 5-7 parts of tourmaline powder, 4-6 parts of expanded graphite, 1-2 parts of ammonium polyphosphate, 4.5-5 parts of metakaolin, 2.5-3 parts of aluminum dihydrogen phosphate, 1.5-2.5 parts of aluminum silicate fibers, 0.2-0.25 part of a silane coupling agent kh 550, 1.5-2 parts of waterborne polyurethane, 6-8 parts of a 5% polyvinyl alcohol solution, 15-18 parts of thermoplastic phenolic resin, 5-6 parts of 25% urotropine aqueous solution and a proper amount of pure water. According to the double-layer composite glass magnesium board, the forming time is shortened through a modifying process, the process is convenient for industrial control, the components are simple and easily available, and the production efficiency is improved; the prepared glass magnesium board has double-layer effect, is smooth and attractive in surface, high in fireproof grade, safe and non-toxic, and a moisture absorption and deformation problems are solved.

Owner:ANHUI XINRUN NEW MATERIALS

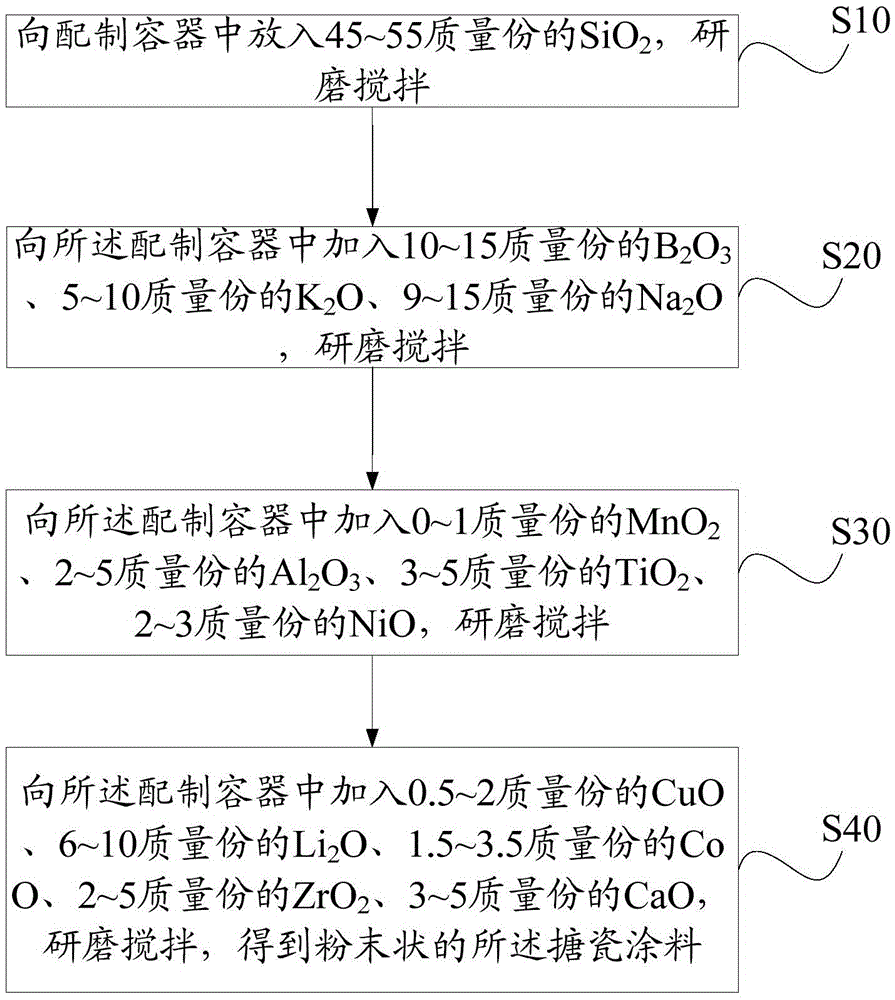

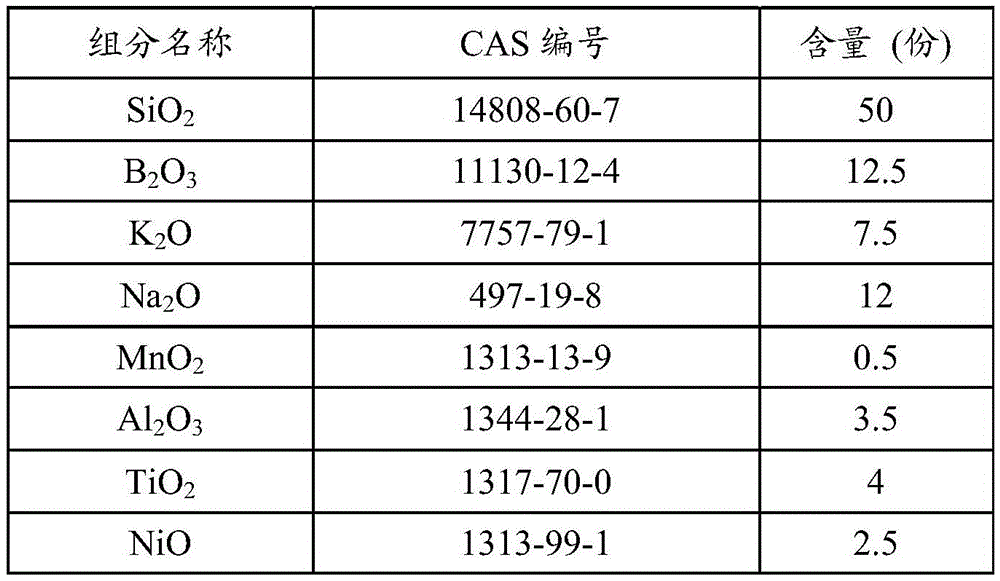

Enamel paint, preparation method thereof, and enamel product

The invention provides an enamel paint, a preparation method thereof, and an enamel product. The enamel paint comprises the following components in parts by weight: 45 to 55 parts of SiO2, 10 to 15 parts of B2O3, 5 to 10 parts of K2O, 9 to 15 parts of Na2O, 0 to 1 part of MnO2, 2 to 5 parts of Al2O3, 3 to 5 parts of TiO2, 2 to 3 parts of NiO, 0.5 to 2 parts of CuO, 6 to 10 parts of Li2O, 1.5 to 3.5 parts of CoO, 2 to 5 parts of ZrO2, and 3 to 5 parts of CaO. By optimizing the components and component contents of enamel paint, the adhesive force and adherence of the enamel paint are effectively improved; the bonding strength between enamel layer and product matrix is enhanced; the possibility of cracking and bursting of enamel is prominently reduced, the yield of enamel products is increased; moreover, during the preparation and application process, the coating performance is improved without using any other adhesive, auxiliary material, or other chemical component, thus the preparation technology and construction technology are simple, at the same time, the development period is not prolonged, and the cost is not increased.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Abrasion-resisting closed drop wire

Owner:霍中南

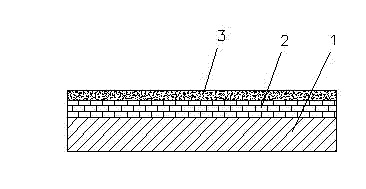

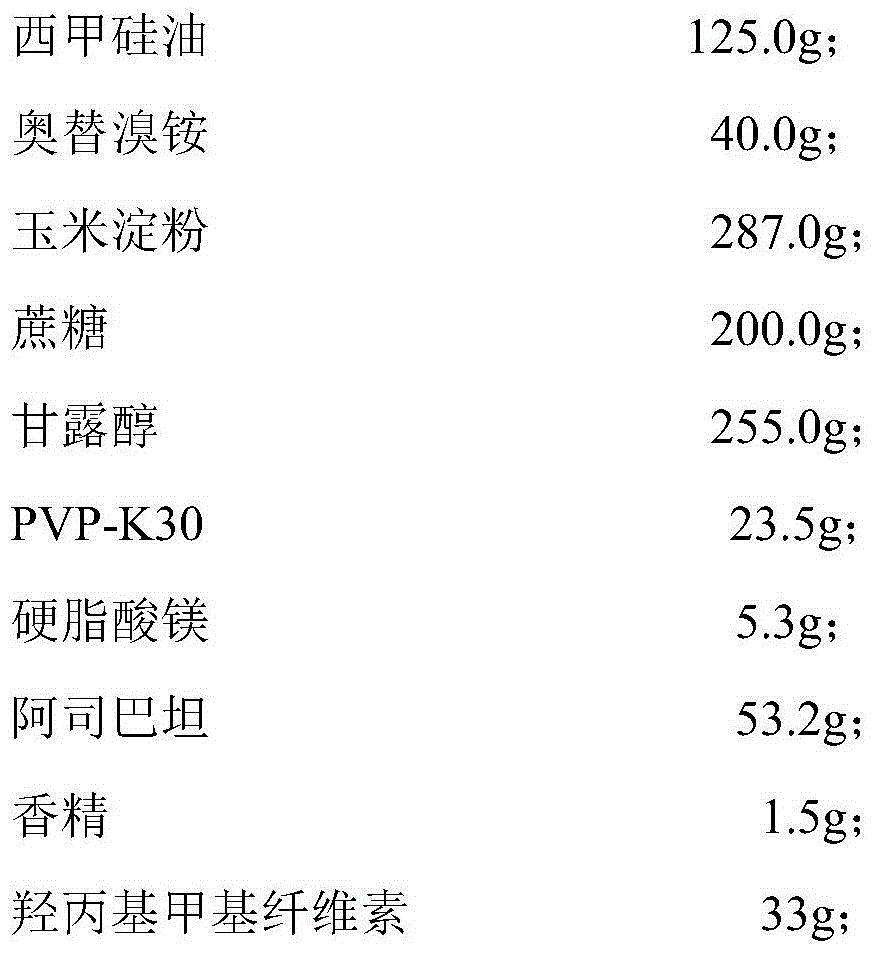

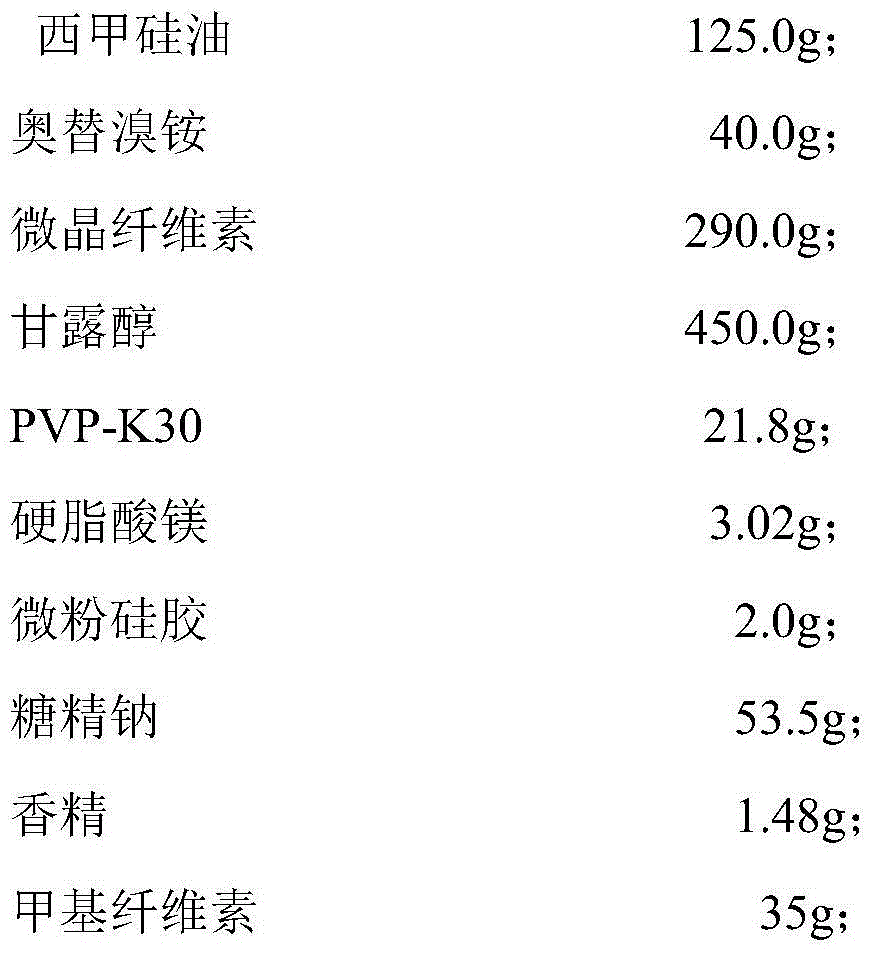

Simethicone otilonium bromide chewable tablets and preparing method thereof

InactiveCN104523717AStable and controllable qualityGreat tasteAntipyreticAnalgesicsOtilonium bromideAdhesive

The invention discloses simethicone otilonium bromide chewable tablets and a preparing method of the simethicone otilonium bromide chewable tablets. The simethicone otilonium bromide chewable tablets comprise, by mass, 12.5 parts of simethicone, 4 parts of otilonium bromide, 10-40 parts of adsorbent, 25-75 parts of filler, 0.2-10 parts of adhesive, 0.2-5.0 parts of lubricant, 0.5-10 parts of corrigent, 0.05-0.5 part of aromatic and 1.5-7.5 parts of moisture sealer coating materials. According to the simethicone otilonium bromide chewable tablets, the formula is reasonable, the cost is low, and the preparing method is simple and suitable for industrial production. The prepared tablets are good in taste, the surfaces of the tablets are smooth and attractive, the tablets are even in color, appropriate in hardness, stable in quality, convenient to take and carry, and particularly suitable for the elderly, children and patients who cannot swallow solid preparations, the compliance of the patients is improved, and the simethicone otilonium bromide chewable tablets have good application prospects to treatment of the irritable bowel syndrome due to various reasons, especially the irritable bowel syndrome accompanied with abdominal distension and stomachache.

Owner:SOUTHWEST UNIVERSITY

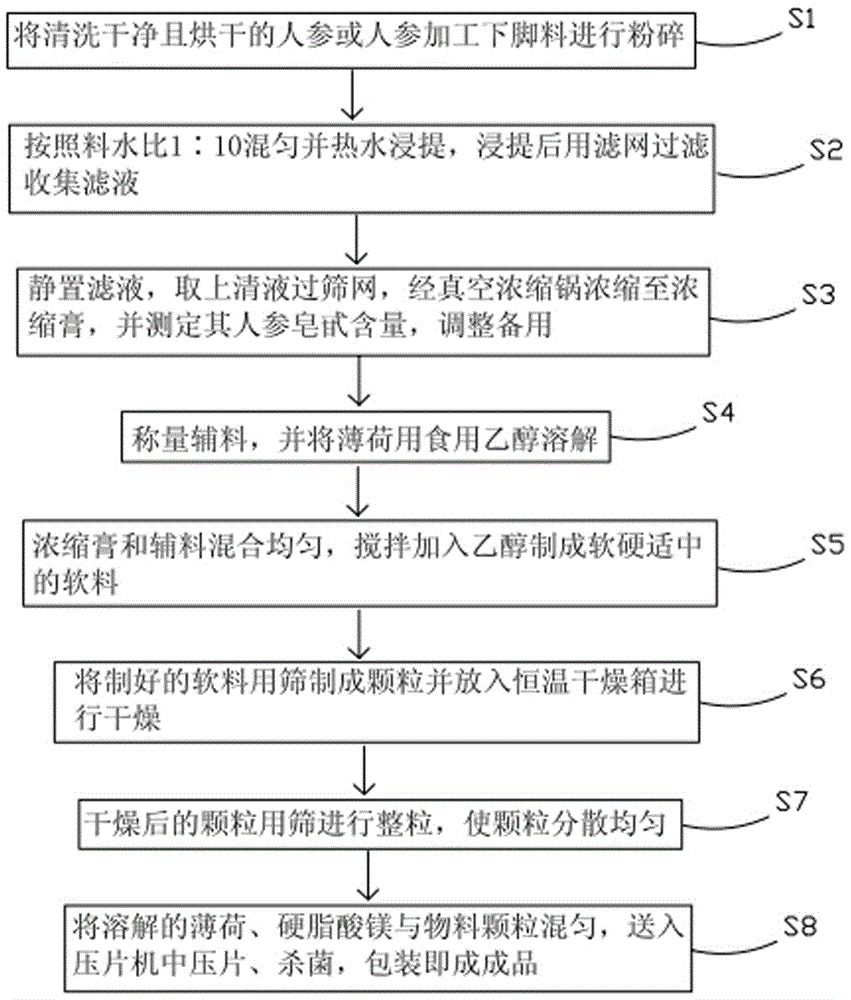

Preparation method of ginseng buccal tablets

InactiveCN106072635AUnique tasteConsistent colorSugar food ingredientsNervous disorderFlavorAdditive ingredient

The invention discloses a preparation method of ginseng buccal tablets. The preparation method comprises the steps that ginseng or ginseng processing leftovers which are washed clean and dried are crushed; the crushed materials are mixed to be uniform according to the material-water ratio of 1:10 and then extracted with hot water, the extracted materials are filtered with a filter screen, and then filtrate is collected; standing is conducted on the filtrate, supernatant liquid is taken to be screened with a screen and then concentrated into concentrated paste through a vacuum concentration pot, and the panaxoside content is measured and adjusted for standby application; auxiliary materials are weighed, and herba menthae is dissolved by edible ethanol; the concentrated paste and the auxiliary materials are mixed to be uniform, ethanol is added under the stirring condition, and a soft material with the moderate hardness is prepared; the prepared soft material is prepared into granules with the screen, and the granules are put into a constant-temperature drying oven to be dried; size stabilizing is conducted on the dried granules through the screen, so that the granules are uniformly dispersed; dissolved herba menthae, magnesium stearate and the granules are mixed to be uniform and then delivered into a tablet press to be tableted and sterilized, and packaging is conducted to obtain the finished product. The ginseng buccal tablets are unique in mouthfeel, uniform in color and luster, good in hardness and disintegrative property, smooth and attractive in surface and convenient to eat and have the specific flavor of ginseng, and the content of the functional ingredient ginseng total saponin is guaranteed.

Owner:YUNCHENG UNIVERISTY

Construction method and device for architectural decorative gray line

ActiveCN106088533AEffective crack resistanceThe transition is naturalBuilding material handlingRough surfaceBuilding design

The invention discloses a construction method and device for an architectural decorative gray line and belongs to the technical field of architecture construction. The method comprises the following steps that a protruding part on the surface of a concrete lintel, a protruding part on the surface of a ring beam, a protruding part on the surface of a frame column, a protruding part on the surface of a beam and the like are subjected to scraping flattening treatment, a gray line base layer is subjected to rough surface scraping, square setting, suspension straightening and ash cake making, gray line angle detail drawings are drawn in the positions, needing edge or corner gray line angle construction, of a wall face according to the requirements of architecture design and the decorative scheme, an ash cushion layer is smeared, line ash is smeared, covering ash is smeared, a gray line connector is repaired, and a maintenance procedure is conducted immediately after construction of the decorative gray line is completed. The construction method obtained by adopting the technology effectively simplifies the procedures, shortens the construction period, reduces work force and eliminates the common quality defects of unstraight line angles, cracks, obvious joint parts and the like, and rework due to quality problems is reduced; and in addition, the whole formed gray line angle is firm, good in durability, smooth and attractive in surface and uniform in color and luster, a line groove is straight and clear, and the appearance quality is high.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com