2MW wind turbine notch potting process

A wind turbine and slot technology, which is applied in the field of 2MW wind turbine slot potting and sealing technology, can solve the problems of 2MW wind turbine slot potting and leaking glue, etc., to prevent leakage of potting glue and achieve a smooth and beautiful surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

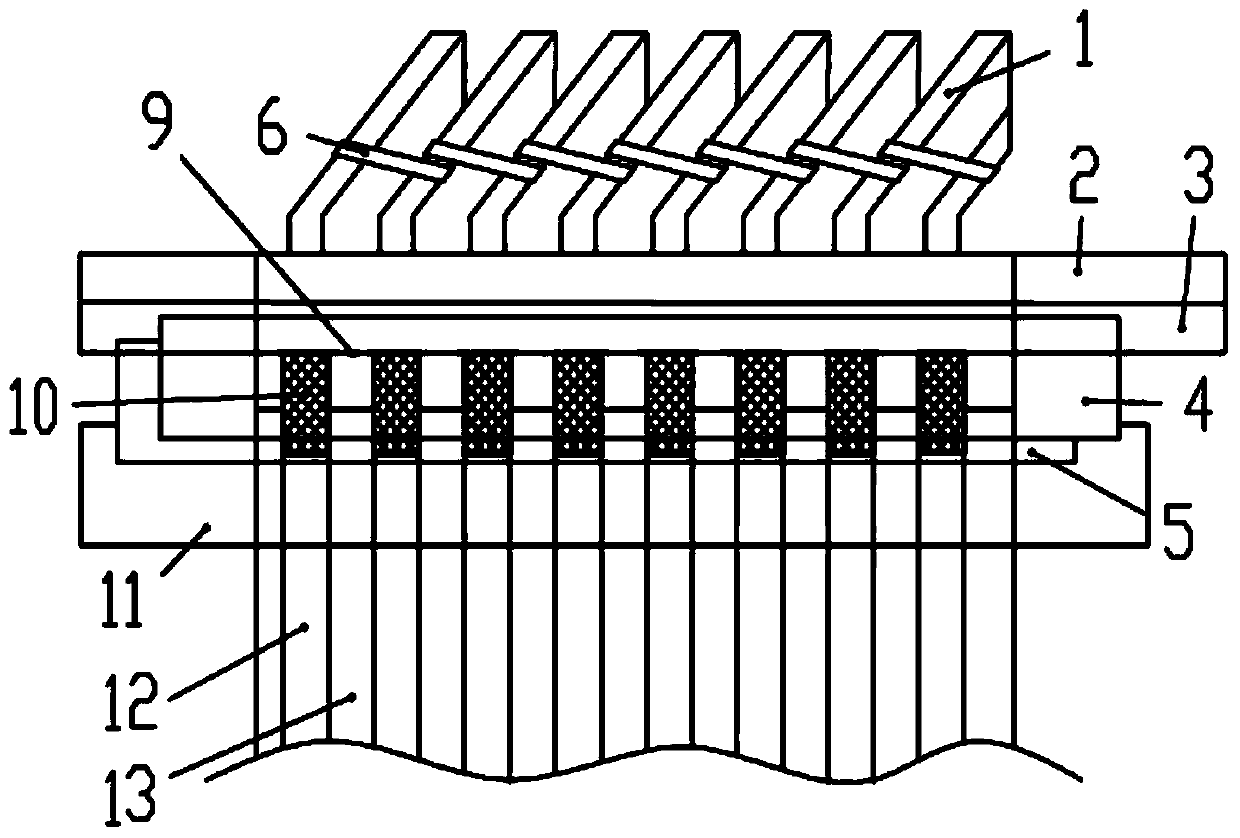

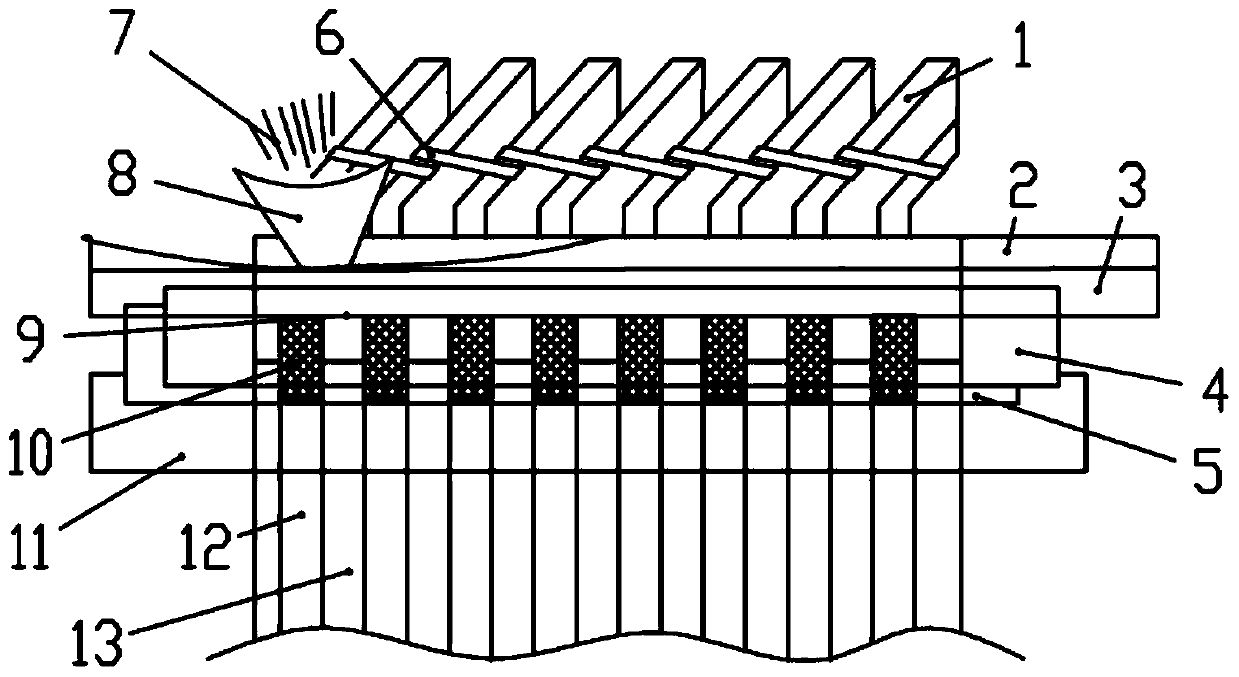

[0026] see figure 1 and figure 2 , figure 1 It is a schematic diagram before the notch potting of a 2MW wind-powered generator in a kind of 2MW wind-driven generator notch potting process of the present invention; figure 2 It is a schematic diagram of a 2MW wind power generator notch potting process in a 2MW wind power generator notch potting process of the present invention. Such as figure 1 and figure 2 As shown, the present invention provides a kind of 2MW wind-driven generator notch potting technique, and the method comprises the steps:

[0027] (1) Paste the foam double-sided adhesive 3 and the lower edge of the outer surface of the transparent composite foil 2 flush together, then wrap it around the outer circle of the stator close to the edge 9 of the notch, and tighten it;

[0028] (2) Cut the glass fiber mat 10 into rectangular blocks and fill it on the surface of the slot wedge 12. The upper end of the glass fiber mat 10 is close to the lower end of the foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com