Production method of multi-layer composite adhesive fabric

A multi-layer compounding and production method technology, applied in the direction of layered products, rubber derived rubber, rubber layered products, etc., can solve the problems of loose, rough surface and poor protective performance of the tape, and achieve uniform dispersion of tissue, ingenious conception, The effect of excellent protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

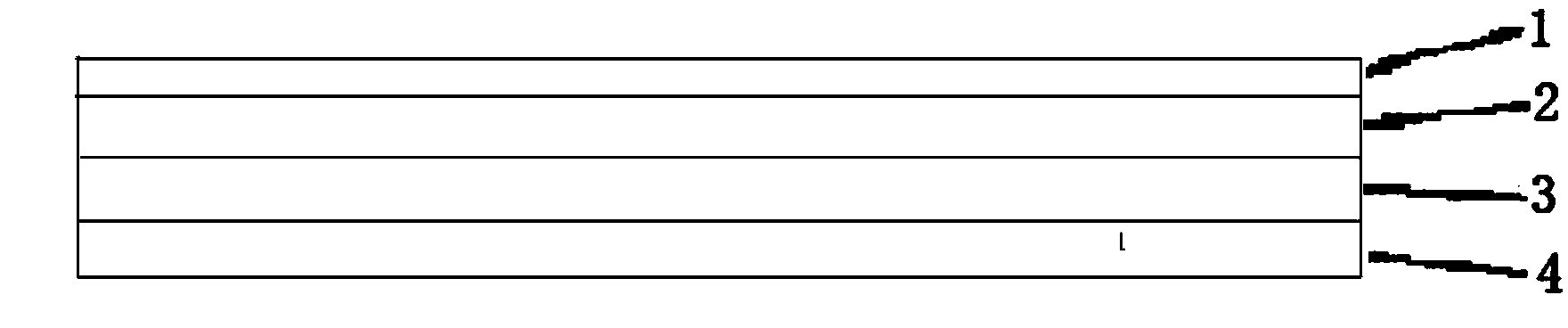

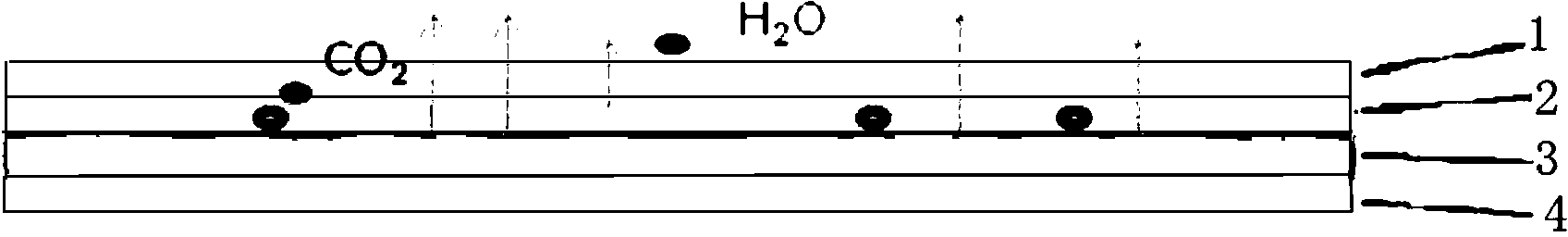

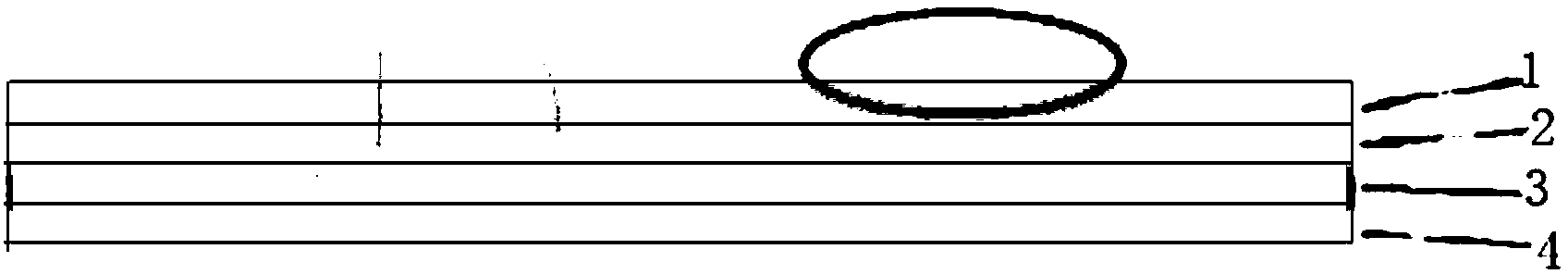

Image

Examples

Embodiment 1

[0047] Embodiment 1 A kind of production method of multi-layer composite adhesive tape, comprises the following steps, the first step, batching; Prepare two kinds of adhesive components;

[0048] The raw material composition and mass ratio of the first rubber: chlorobutyl rubber: 100 parts; zinc oxide: 4.8 parts; sulfur: 1.5 parts; stearic acid: 2.0 parts; accelerator DM——dibenzothiazole disulfide: 1.1 parts; accelerator CZ——N-cyclohexyl-2-benzothiazolyl sulfenamide: 1.5 parts, accelerator TT—tetramethylthiuram disulfide: 0.7 parts;

[0049] The raw material composition and mass ratio of the second rubber: fluorine rubber: 100 parts; bisphenol AF——2,2-bis-4-hydroxyphenylhexafluoropropane: 2.4 parts; accelerator BPP——benzyl triphenyl chloride Phosphorus: 0.75 parts; Calcium hydroxide: 7 parts; Calcium oxide: 5.5 parts;

[0050] The second step, mixing;

[0051] Mix the first rubber, put the chlorinated butyl rubber into the open mill and masticate for 10 minutes; add stearic ...

Embodiment 2

[0065] Embodiment 2 A kind of production method of multi-layer composite adhesive tape, comprises the following steps, the first step, batching; Prepare two kinds of adhesive components;

[0066] The raw material composition and mass ratio of the first rubber: chlorobutyl rubber: 100 parts; zinc oxide: 5.2 parts; sulfur: 1.4 parts; stearic acid: 2.1 parts; accelerator DM——dibenzothiazole disulfide: 1.2 parts; accelerator CZ——N-cyclohexyl-2-benzothiazolyl sulfenamide: 1.6 parts, accelerator TT—tetramethylthiuram disulfide: 0.8 parts;

[0067] The raw material composition and mass ratio of the second rubber: fluorine rubber: 100 parts; bisphenol AF——2,2-bis-4-hydroxyphenylhexafluoropropane: 2.6 parts; accelerator BPP——benzyl triphenyl chloride Phosphorus: 0.8 parts; Calcium hydroxide: 8 parts; Calcium oxide: 6 parts;

[0068] The second step, mixing;

[0069] Mix the first rubber, put the chlorinated butyl rubber into the open mixer and masticate for 12 minutes; add stearic ac...

Embodiment 3

[0083] Embodiment 3 A kind of production method of multi-layer composite adhesive tape, comprises the following steps, the first step, batching, prepares the components of two kinds of adhesives;

[0084] The raw material composition and mass ratio of the first rubber: chlorobutyl rubber: 100 parts; zinc oxide: 5.0 parts; sulfur: 1.6 parts; stearic acid: 2.2 parts; accelerator DM——dibenzothiazole disulfide: 1.1 parts; accelerator CZ——N-cyclohexyl-2-benzothiazolyl sulfenamide: 1.4 parts, accelerator TT—tetramethylthiuram disulfide: 0.8 parts;

[0085] The raw material composition and mass ratio of the second rubber: fluorine rubber: 100 parts; bisphenol AF——2,2-bis-4-hydroxyphenylhexafluoropropane: 2.5 parts; accelerator BPP——benzyl triphenyl chloride Phosphorus: 0.7 parts; Calcium hydroxide: 7 parts; Calcium oxide: 5 parts;

[0086] The second step, mixing;

[0087] Mix the first rubber, put the chlorinated butyl rubber into the open mixer and masticate for 15 minutes; add s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com