Patents

Literature

46results about How to "Nature of influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

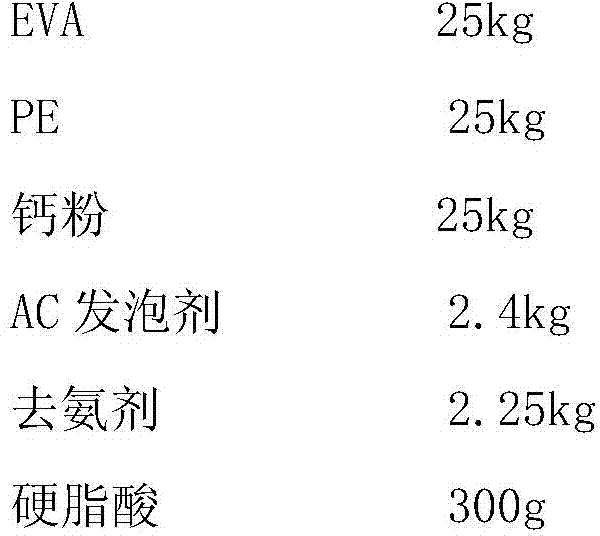

EVA foam material and preparation method thereof

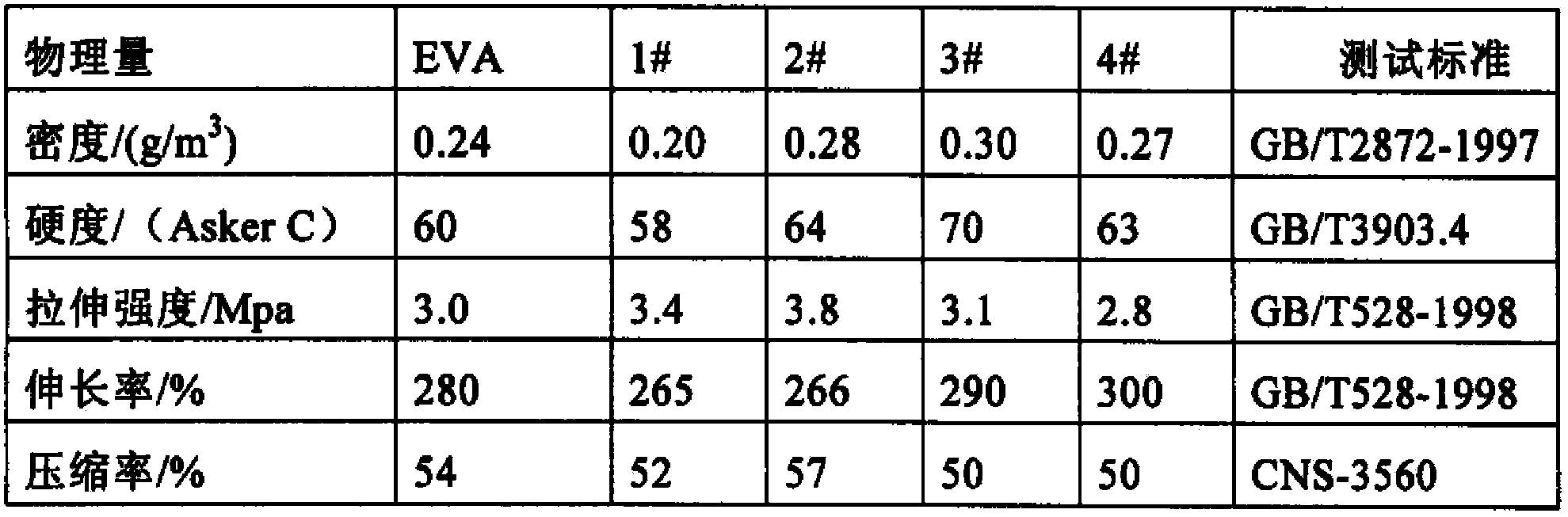

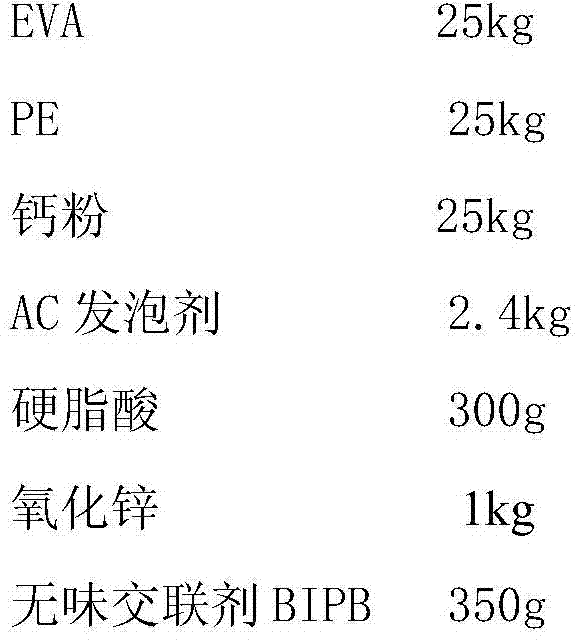

The invention relates to an EVA (ethylene / vinyl acetate) foam material and a preparation method thereof. The foaming material comprises the following components in parts by weight: 100 of EVA, 2-10 of a foaming agent, 0.5-5 of a foaming promoter, 0.05-1 of a bridging agent, 5-30 of a filler, 0.5-5 of a deodorant, and 0.5-5 of a lubricant. The preparation method includes: mixing the raw materials uniformly, then drying the mixture in an oven at 60-80DEG C for 6-12h to obtain a dried mixture, subjecting the dried mixture to mixing injection molding to obtain an EVA sheet, cutting the EVA sheet, then putting the cut EVA sheet into a flat vulcanizing machine to undergo die-filling hot pressing, then performing automatic pressure release, and cooling the die, thus obtaining the EVA foam material. Compared with the prior art, the deodorant integrating absorption and reaction is adopted by the invention and added to EVA and various additives. With very good dispersibility, the deodorant reacts with an ammonia radical through a chelating mechanism and strongly adsorbs ammonia so as to effectively remove the ammonia radical and ammonia, and can destroy the formation conditions of formamide before its formation and has no influence to the properties of production products. Thus, the EVA foam material has wide application.

Owner:HEFEI GENIUS NEW MATERIALS

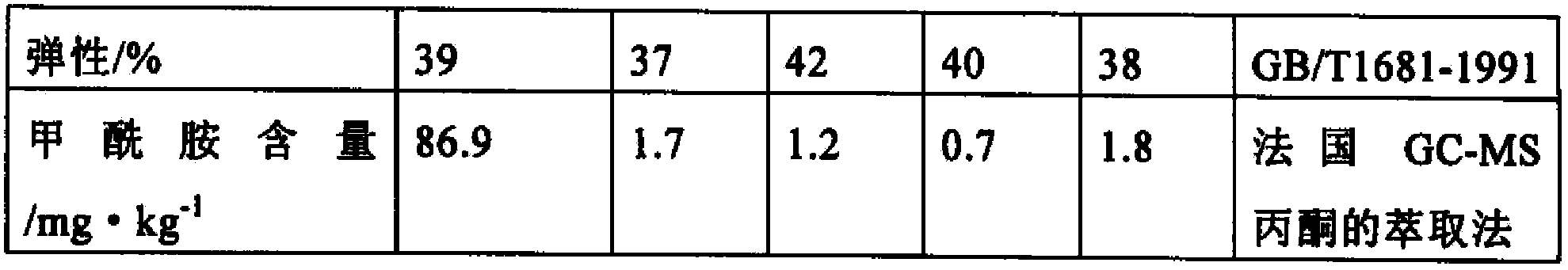

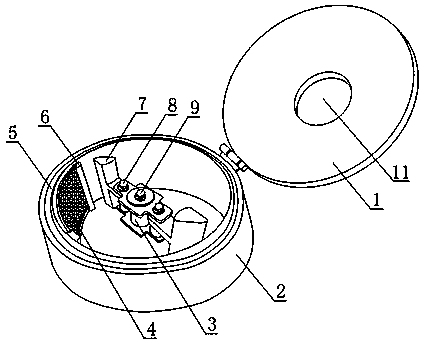

Asphalt laying device for municipal road

The invention discloses an asphalt laying device for a municipal road. The asphalt laying device comprises a frame, wherein wheels are arranged at the bottom of the frame; a processing box body is arranged at the top of the frame; a feeding box is arranged inside the processing box body; a stirring tank is arranged on one side of the feeding box; the top of the feeding box is provided with a feeding opening; a pair of grinding rollers is arranged below the feeding opening; the feeding box is internally provided with a sieve plate; one end of the sieve plate is hinged to the inner wall of one side of the feeding box; the other end of the sieve plate penetrates through the other side wall of the feeding box and is connected with a top plate; a first belt pulley is arranged on one side of thefeeding box; a second belt pulley is arranged below the first belt pulley; a first cam is fixedly arranged on the back side of the second belt pulley; the top of the first cam is contacted with the bottom end of the top plate; and the bottom of the feeding box is communicated with a discharging auger. The asphalt laying device disclosed by the invention is convenient and quick to use and uniformin heating, has the effect of maintaining the asphalt performance and can avoid the condition that the properties of asphalt are affected due to long-time contact of asphalt and air; and by use of anequalization plate, the asphalt can be uniformly laid on the ground.

Owner:王秀兰

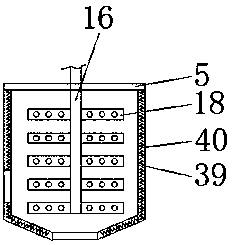

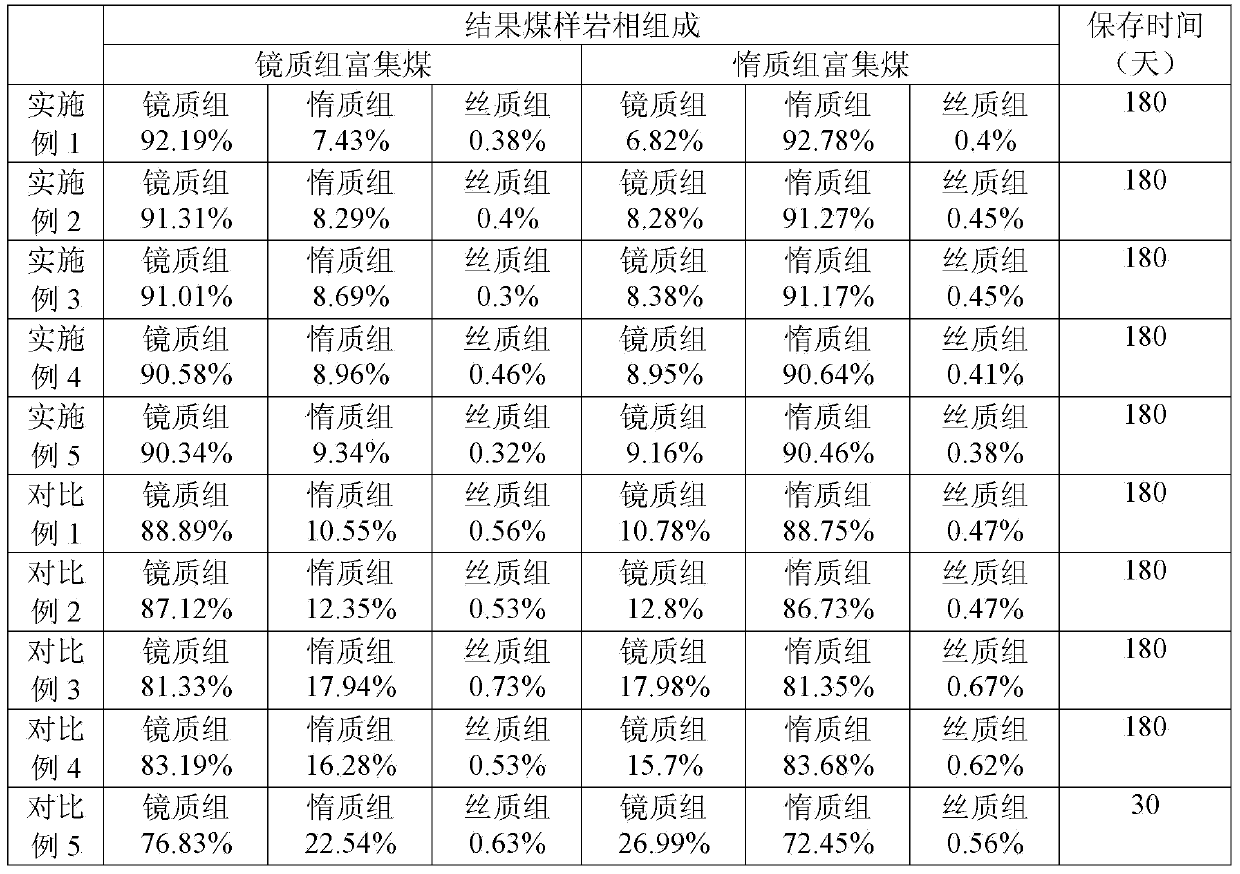

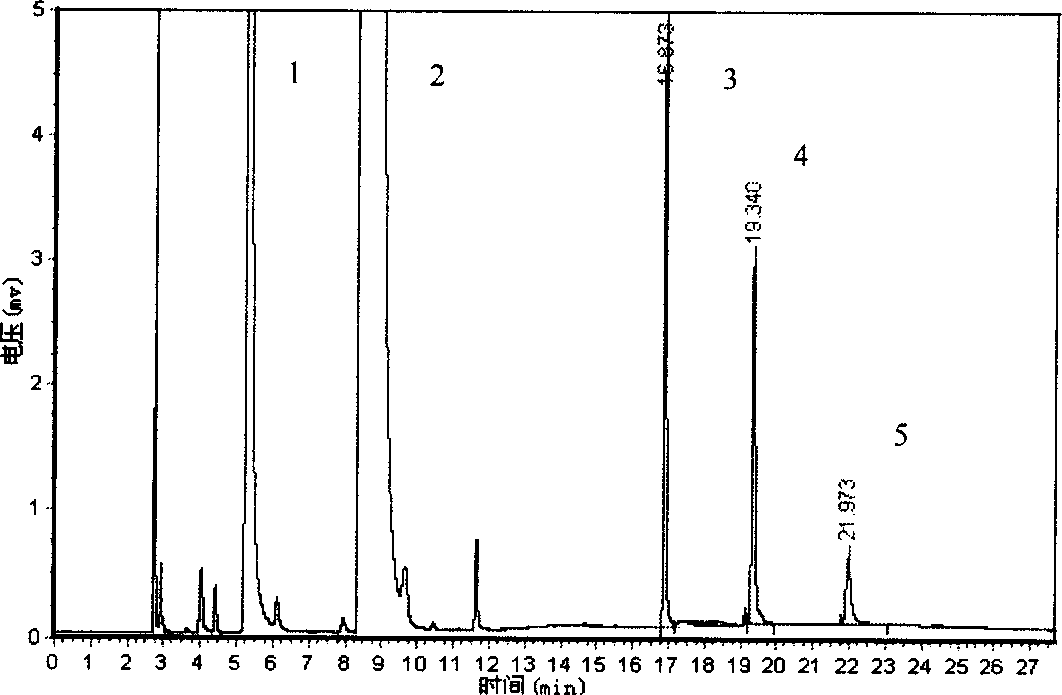

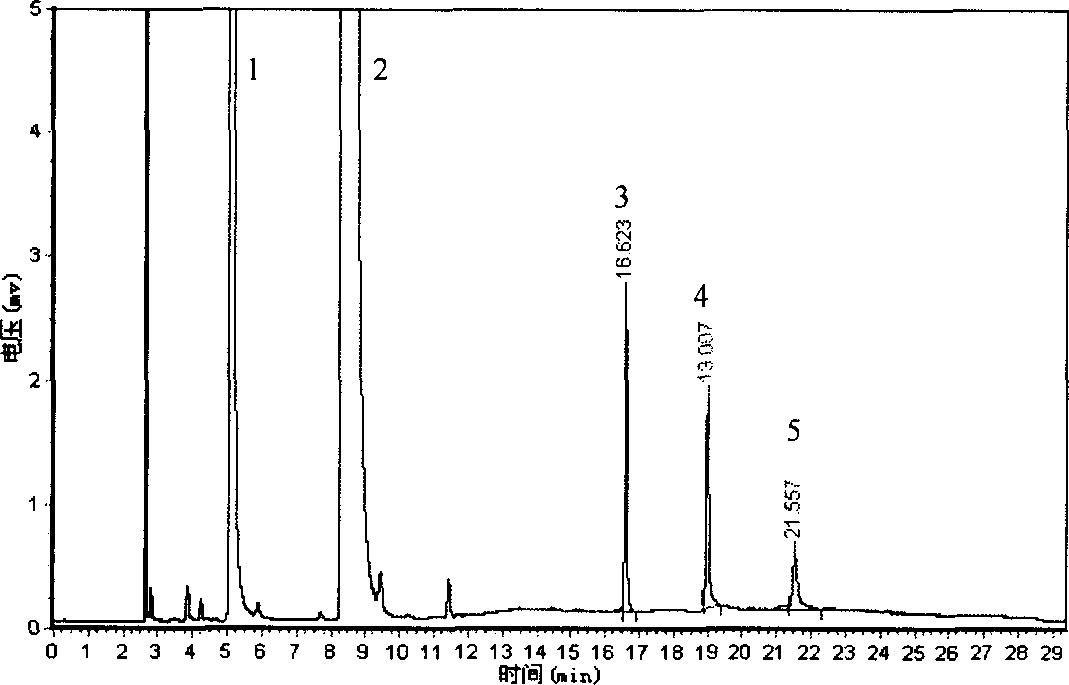

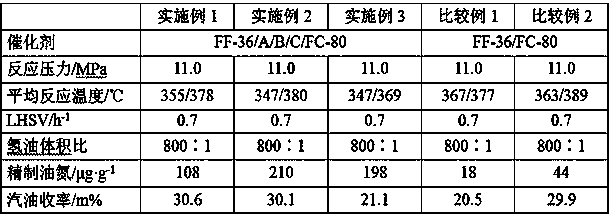

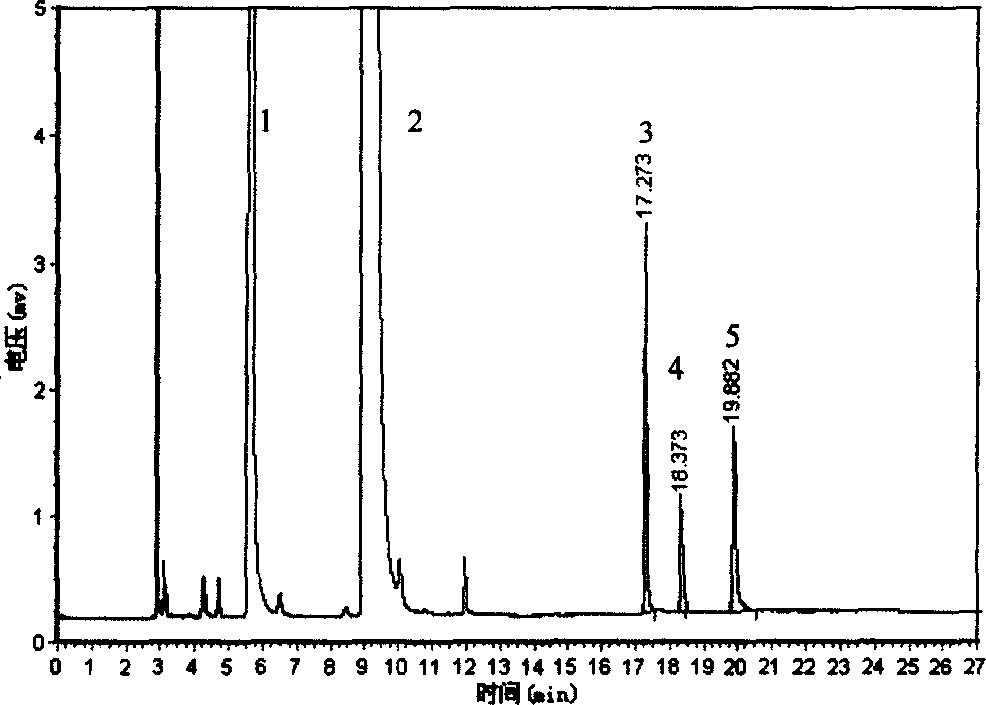

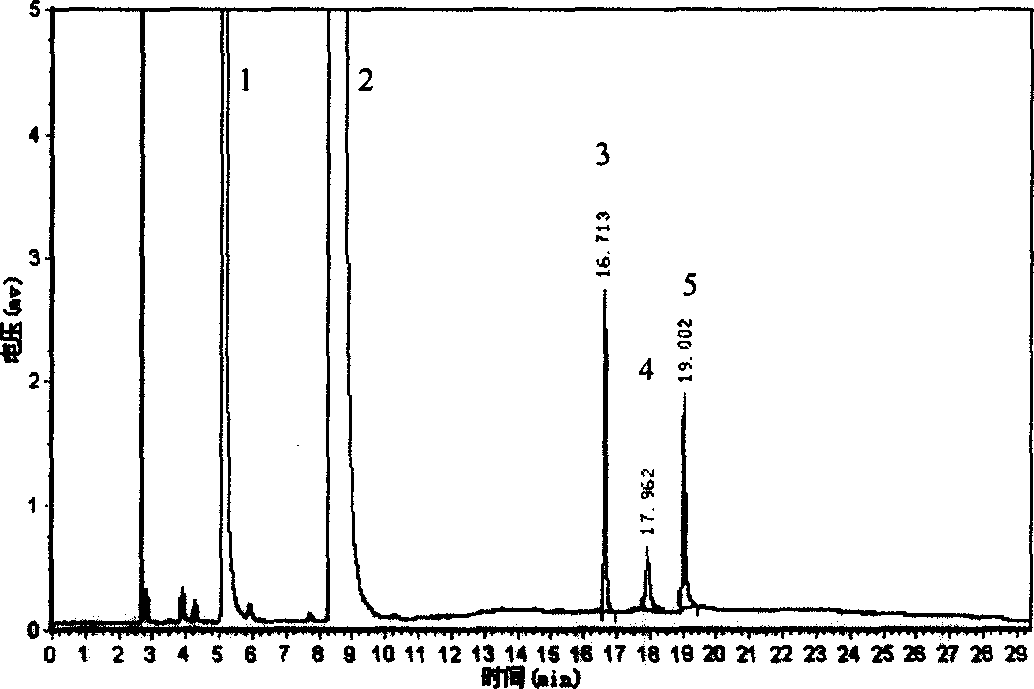

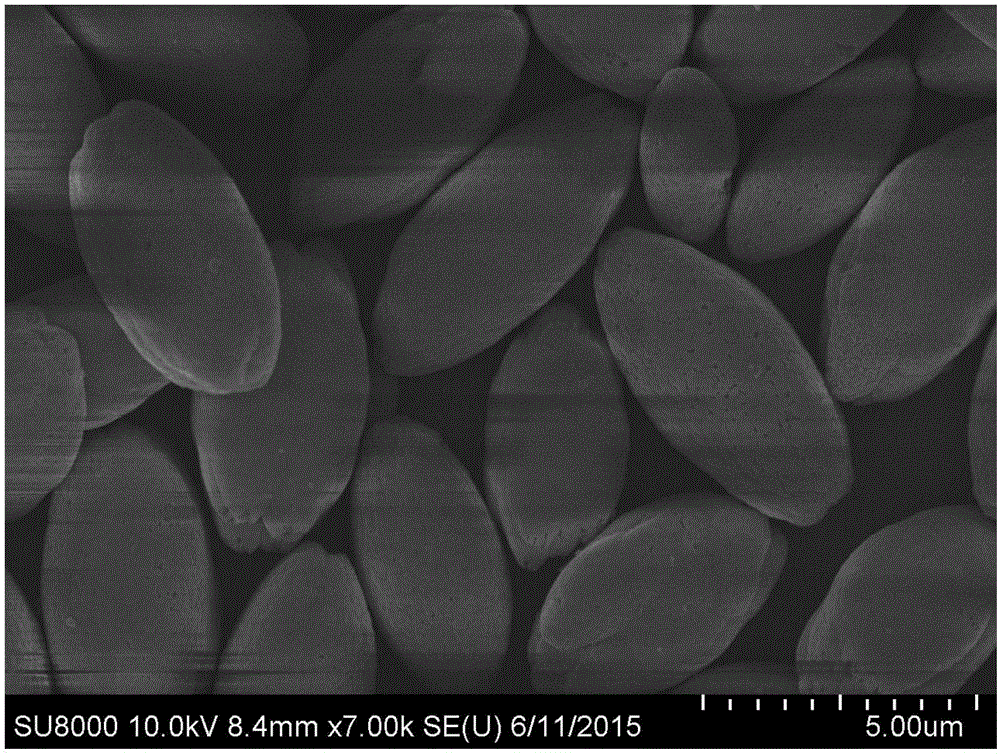

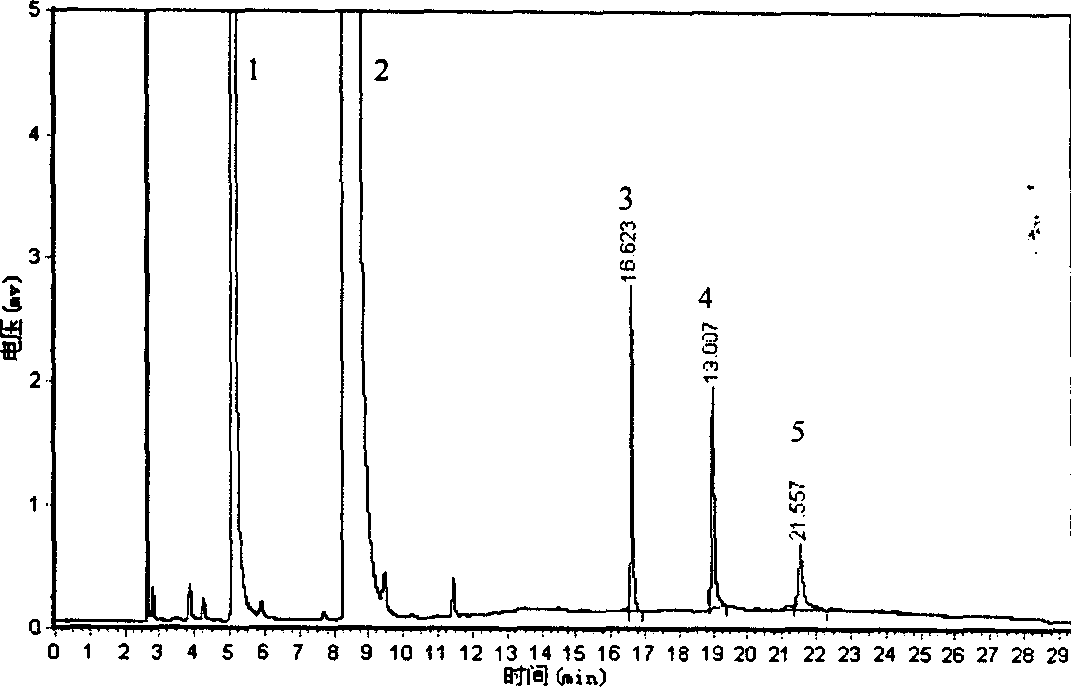

Enrichment method of coal micromaceral

ActiveCN103551238AInfluence composition structureNature of influenceGrain treatmentsEnrichment methodsSolvent

The invention discloses an enrichment method of coal micromaceral. The enrichment method comprises the following steps: a step of crushing and separating, namely, executing crushing and separating treatment for at least two times, crushing a coal sample in the first-time crushing and separating treatment process, and separating out an inert enrichment component of small particle diameter and a vitrinite enrichment component of large particle diameter according to the predetermined particle diameter, wherein the subsequent crushing and separating treatment process for each time is that the vitrinite enrichment component obtained through crushing and separating treatment for the previous time is crushed, and the inert enrichment component of small particle diameter and the vitrinite enrichment component of large particle diameter are separated out according to the predetermined particle diameter corresponding to the subsequent crushing and separating steps; and a step of enriching, namely, collecting the inert enrichment components obtained through crushing and separating treatment for each time to obtain inert enrichment coal, and collecting the vitrinite enrichment component obtained in the last-time crushing and separating treatment process to obtain vitrinite enrichment coal. According to the enrichment method disclosed by the invention, a heavy-medium solvent is not used, so that damage is avoided; the obtained enrichment coal is easy to store; in addition, even through the enrichment coal is ground to be below 200 meshes, the composition structures and the properties of the coal cannot be influenced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

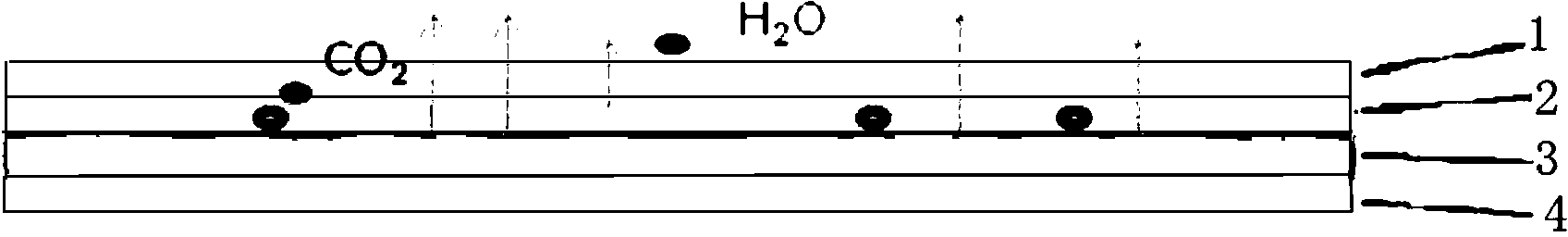

Production method of multi-layer composite adhesive fabric

ActiveCN103360982AGuaranteed compactnessImprove the protective effectNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementChemistry

The invention relates to a production process of an adhesive fabric, particularly relates to a production method of a multi-layer composite adhesive fabric, and solves the technical problem that the adhesive fabric is loose and coarse in surface and extremely poor in protection property due to the fact that bubble, pinhole and sponge phenomena often exist on the surface of the adhesive fabric as a result of identical curing points of each adhesive layer in the multi-layer adhesive fabric production process in the prior art. The production method of a multi-layer composite adhesive fabric comprises the following steps: 1, component preparation: preparing components of two adhesives; 2, compounding: respectively compounding the two adhesives; 3, adhesive cement preparation: preparing adhesive cements of the two adhesives; 4, adhesive coating: coating the adhesive cement of a second adhesive on two faces of a nylon fabric, and then coating the adhesive cement of a first adhesive on one face of the nylon fabric; and 5, curing to obtain the multi-layer composite adhesive fabric. According to the formula of the process provided by the invention, the quality of the product is greatly improved; and the product is smooth and beautiful in surface, and has very good protection property against various corrosive substances.

Owner:SHANXI XINHUA CHEM

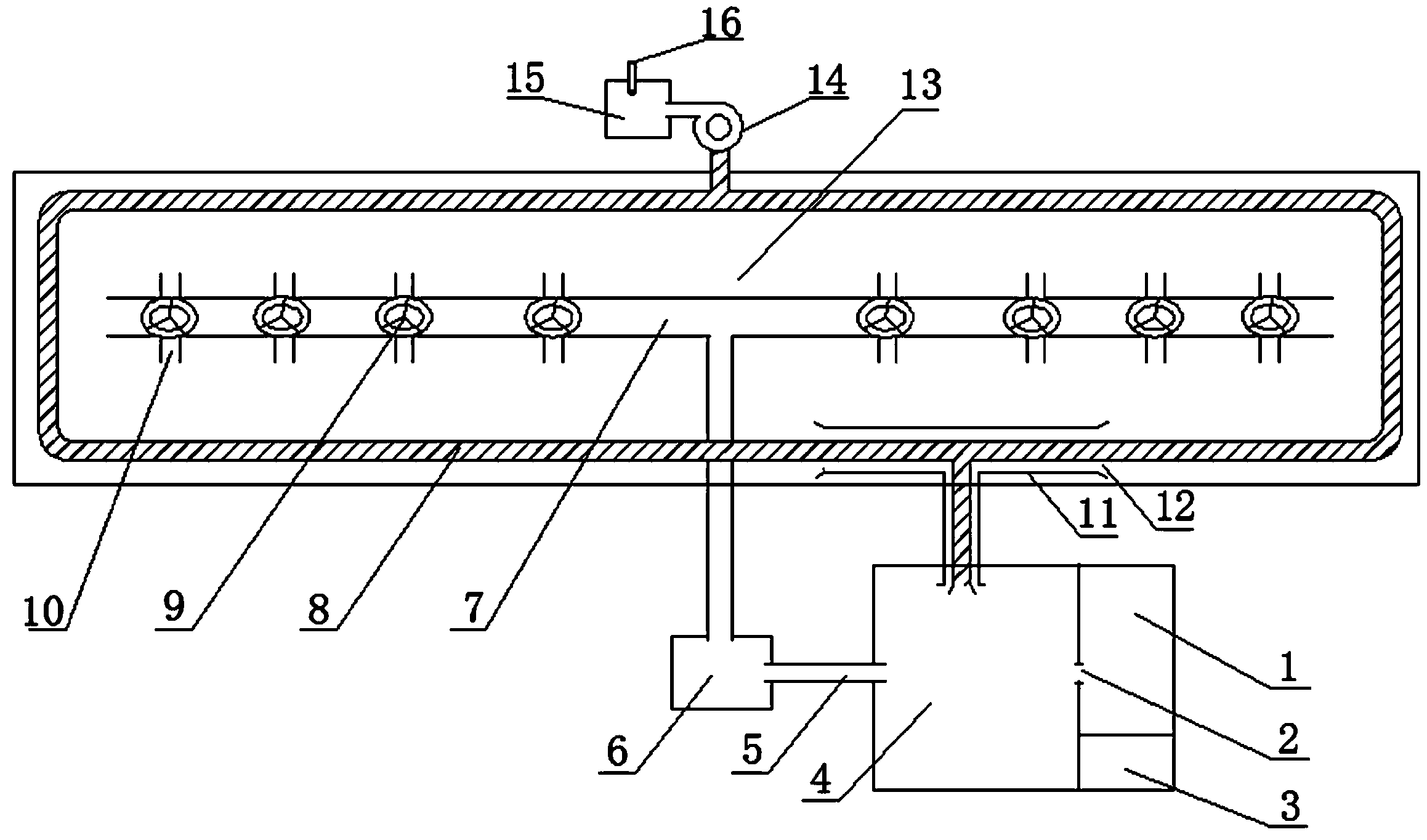

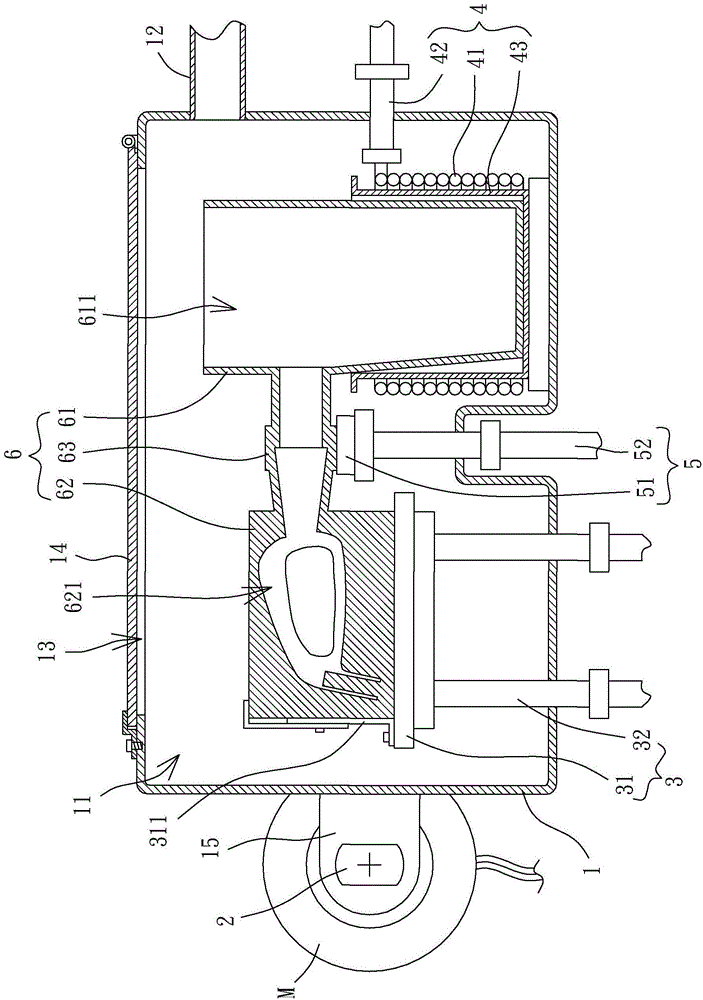

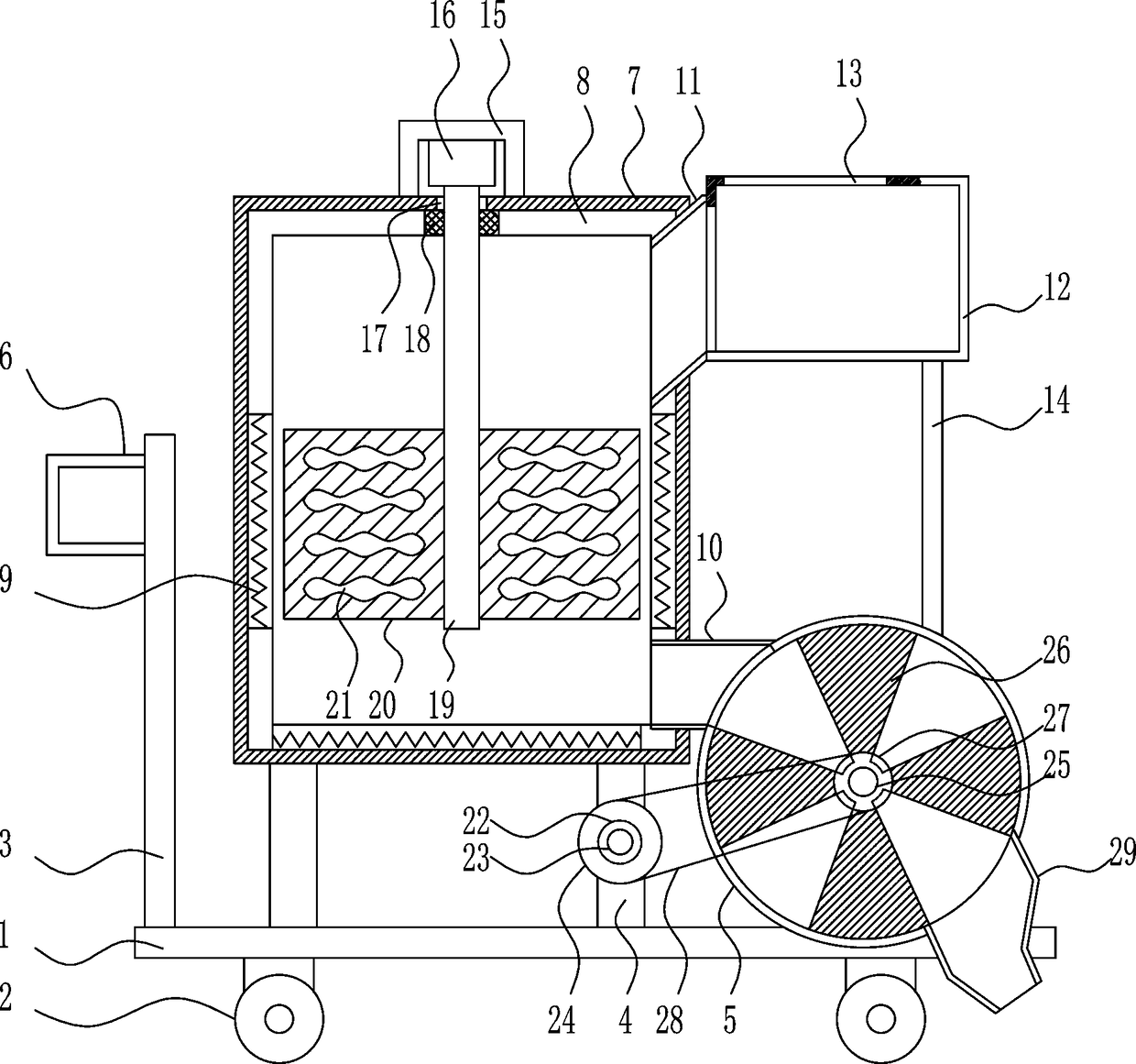

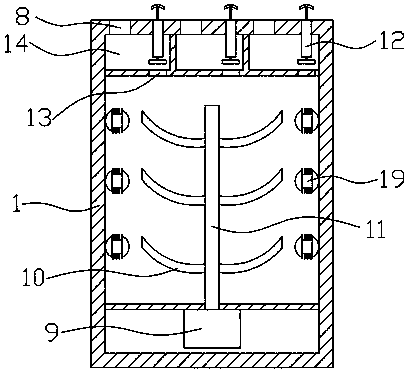

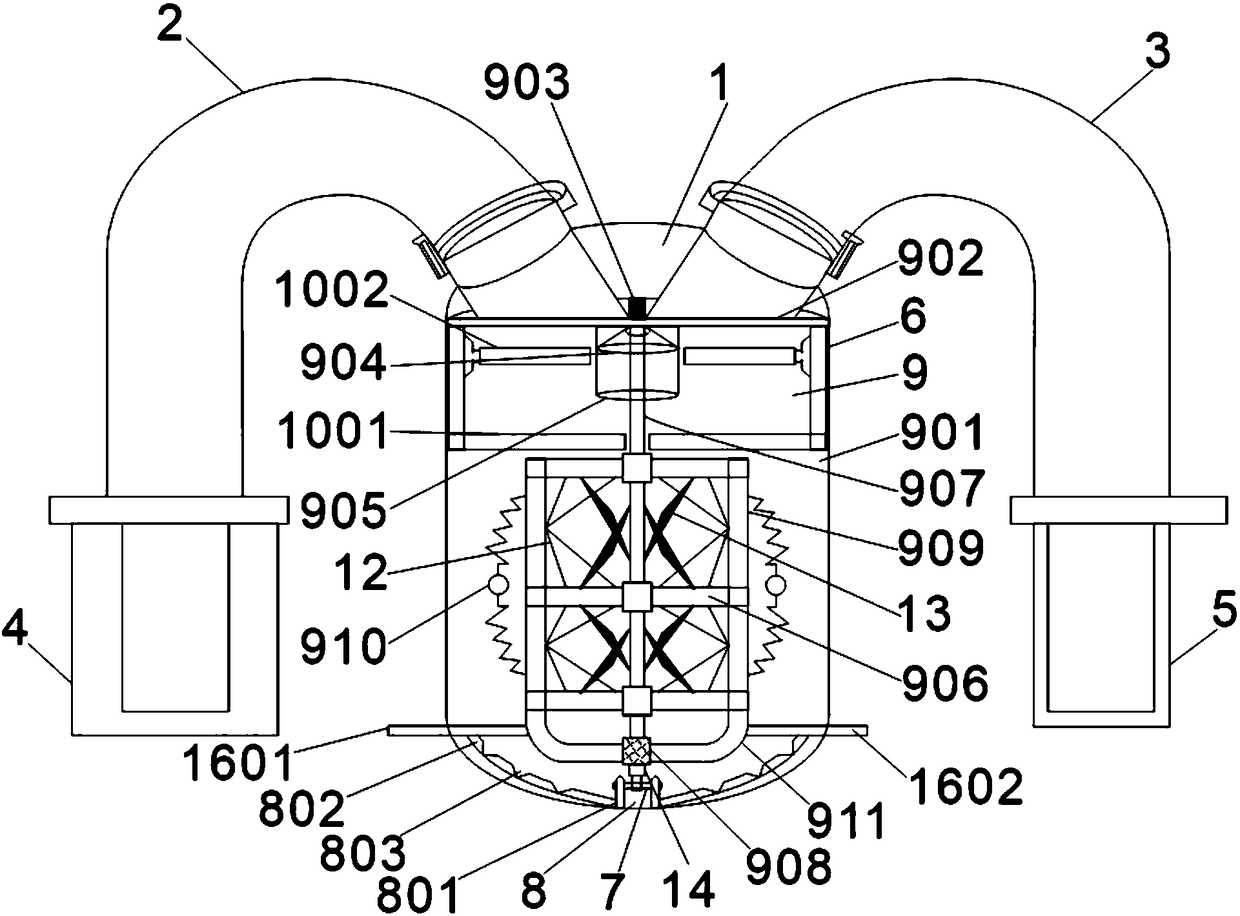

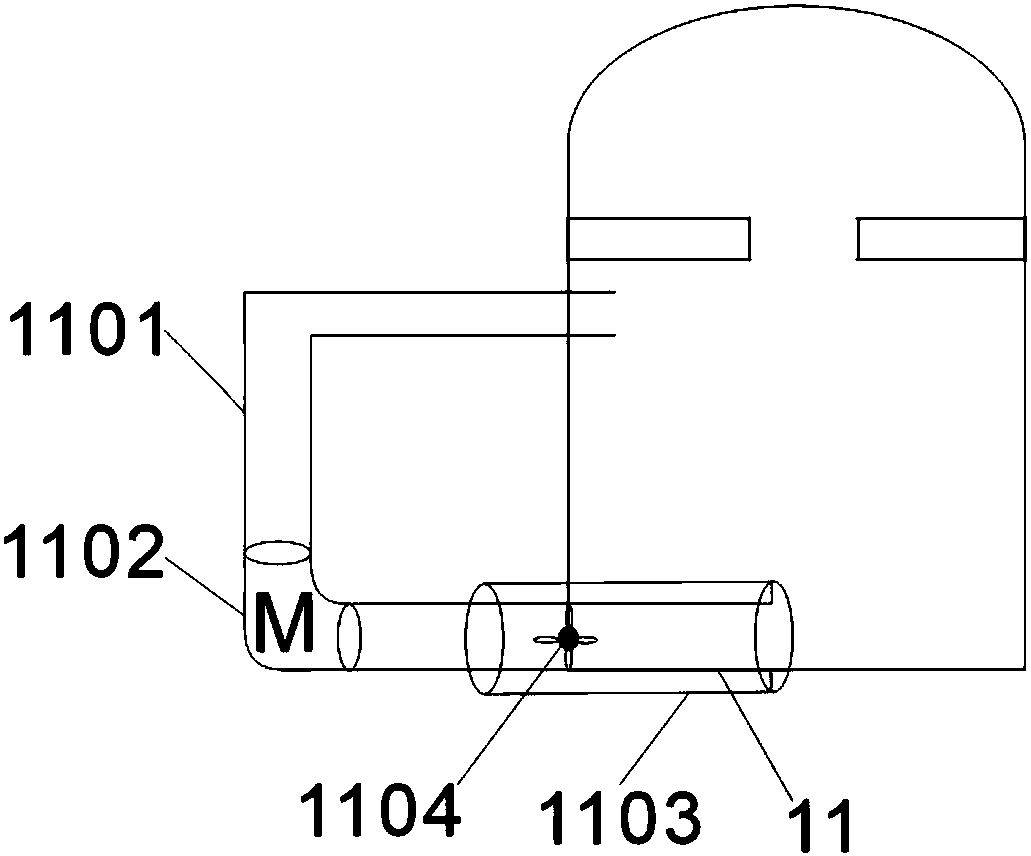

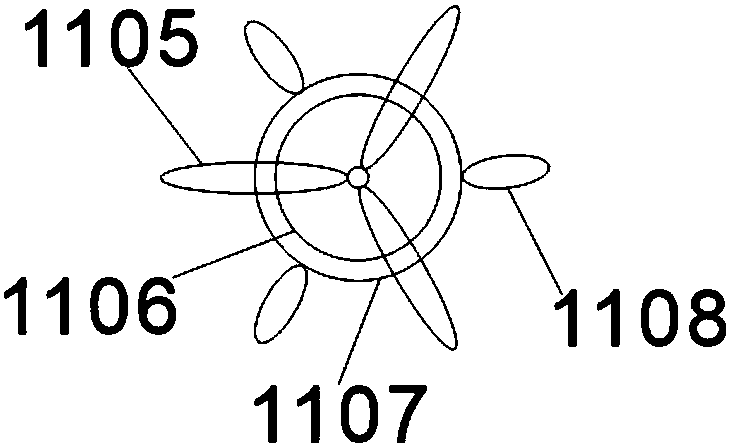

Medicinal material and food drying equipment

InactiveCN103776243ANature of influenceStable temperatureDrying gas arrangementsDrying solid materialsMedicinal herbsCombustion chamber

The invention discloses medicinal material and food drying equipment, which comprises a hot-air system, a circulating system, a drying chamber and an electric control box, wherein the hot-air system comprises a fuel chamber and a combustion chamber, and a feeding opening is arranged between the fuel chamber and the combustion chamber; the circulating system comprises a hot-gas circulating system and a waste-gas circulating system, wherein the hot-gas circulating system comprises a circulating fan, hot-air pipes, a heat-discharging pipe and a gas-returning pipe; the combustion chamber is connected with one end of the circulating fan through the hot-air pipe, and the other end of the circulating fan is connected with the heat-discharging pipe in the drying chamber through the hot-air pipe; the waste-gas circulating system comprises a waste-gas hot-air pipe and an exhaust fan. Temperature in the drying chamber of the medicinal material and food drying equipment disclosed by the invention can be kept constant for a long time, so that influences on the properties of medicinal materials and food due to excessive temperature fluctuation are avoided; waste heat generated in the combustion chamber is fully utilized for circularly heating the drying chamber, so that energy sources are greatly saved.

Owner:玉林市玉州区聚兴农副产品加工厂

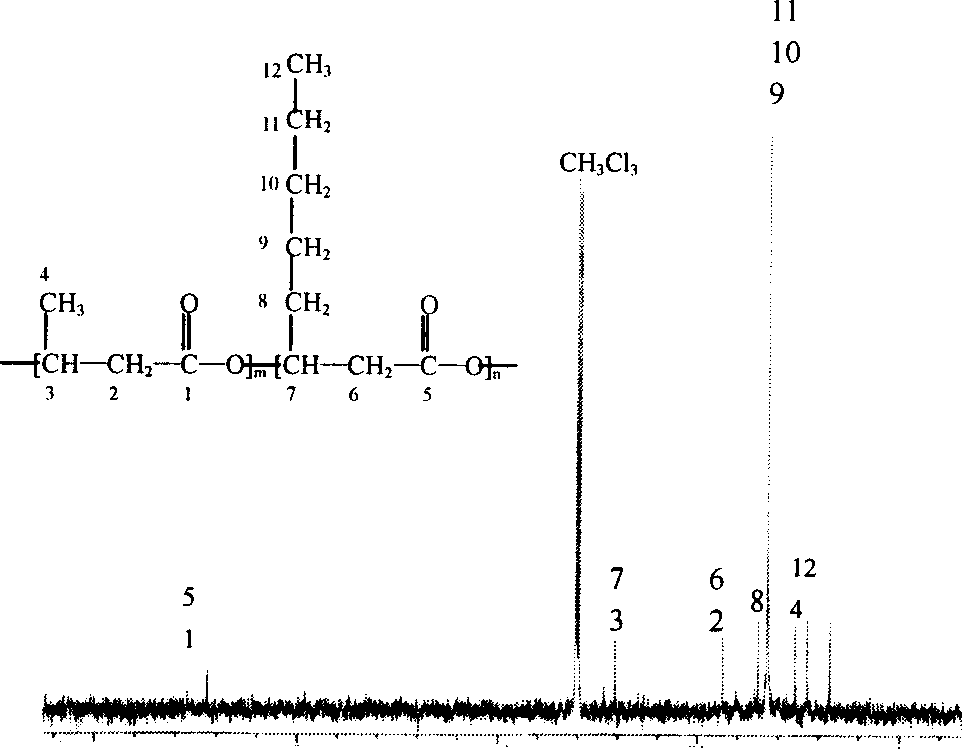

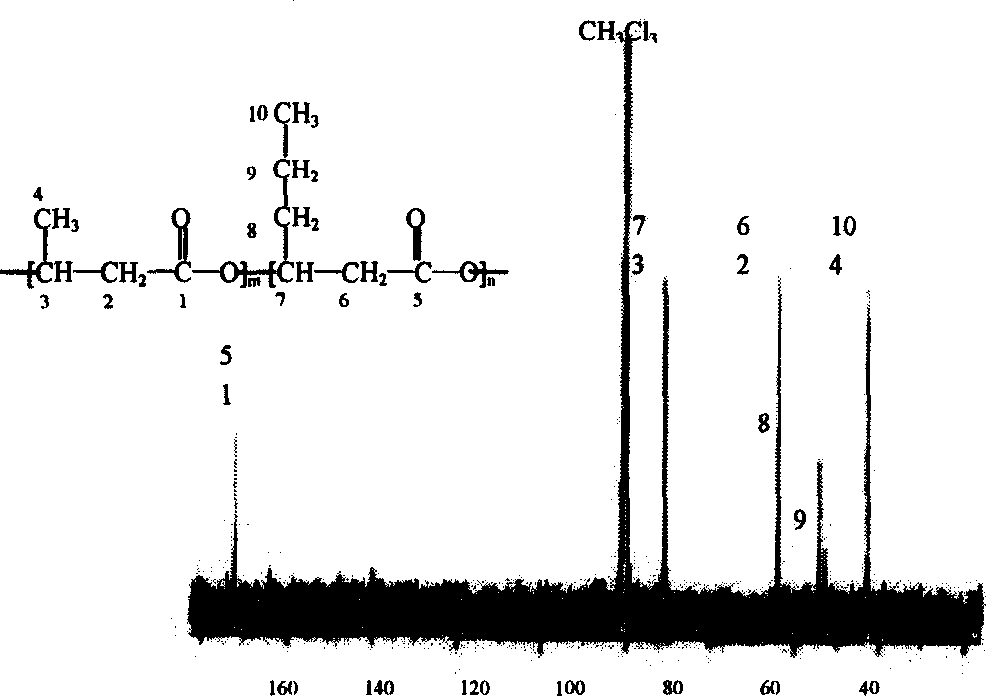

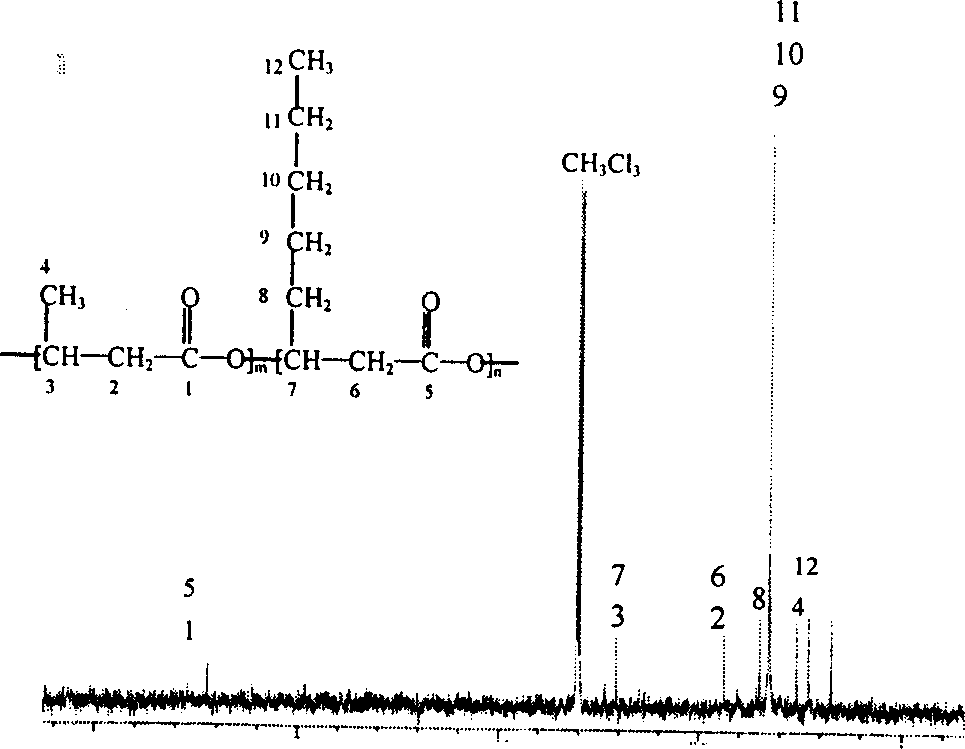

Hydroxy alkanoic acid polymer and its producing method

InactiveCN1648149ANature of influenceReduce contentBacteriaFermentationHydroxybutyric acidPurification methods

The present invention discloses one kind of hydroxy alkanoic acid polymer, that is, 3-hydroxy butyric acid-3-hydroxy caprylic acid polymer (PHBHO). The 3-hydroxy butyric acid-3-hydroxy caprylic acid polymer (PHBHO) is prepared with Sinorhizobium fredii as production strain, carbohydrate as carbon source and ammonium salt as nitrogen source, and through high density fermentation and metabolism regulation with lauric acid in optimal culture medium and under optimal culture condition. Corresponding fermentation management method, separation and purification method and quality detection method are established. The present invention can obtain PHBHO product up to 14.4-22.1 g / L, of molecular weight of 112000-185000 Da, and endotoxin content 4-6 EU / g, and the novel nanometer level material may be used in biomedicine and medical tissue engineering.

Owner:SHANXI UNIV

Method for molding iron rod head of gold through vacuum weight casting

ActiveCN104827013AImprove liquidityImprove molding yield and qualityMolten metal conveying equipmentsVacuum furnaceMetal

The invention discloses a method for molding an iron rod head of gold through vacuum weight casting, and the method is used for solving various problems of an atmosphere gravity casting method. The method comprises the steps: enabling a housing die to be positioned and placed in a vacuum furnace, wherein the housing die is provided with a crucible part and a casting part which are communicated with each other, and the vacuum furnace is provided with a rotating shaft; enabling a metal ingot to be placed at the crucible part, and enabling the metal ingot to be melted into metal liquid in a vacuum environment; driving the rotating shaft to enable the vacuum furnace to be inclined towards a side, and enabling the metal liquid to flow into a molded die hole in the casting part under the action of gravity; damaging the housing die so as to obtain a cast part which comprises a cast portion; enabling the cast portion to be separated from the cast part, so as to obtain a plurality of cast parts of the iron rod head of golf.

Owner:FUSHENG IND CO LTD

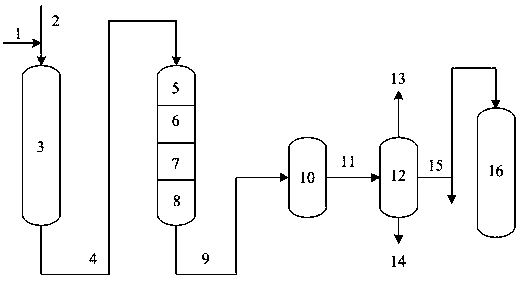

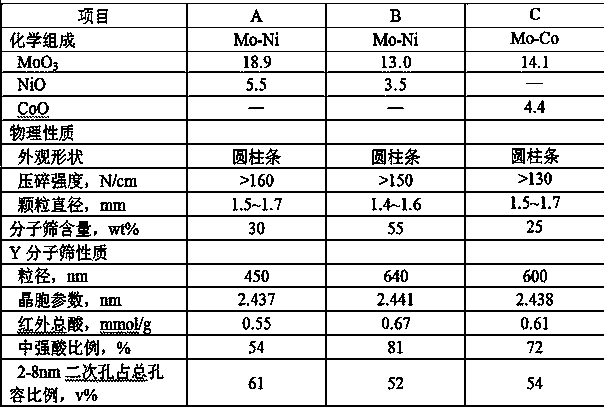

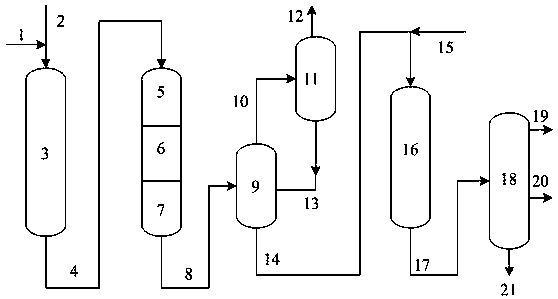

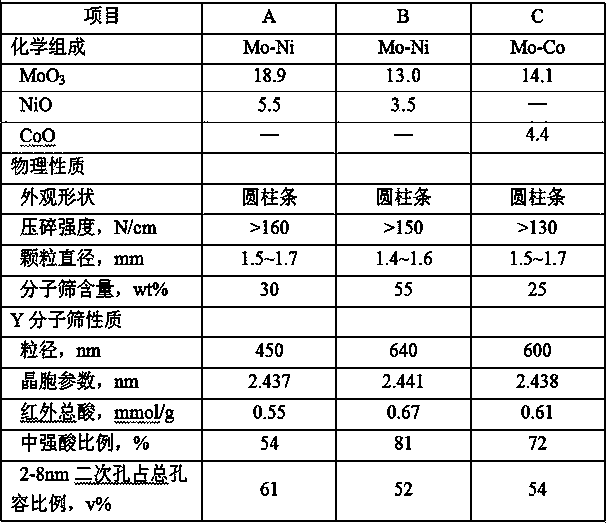

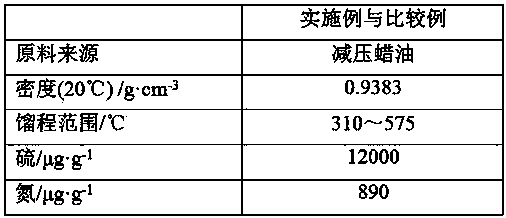

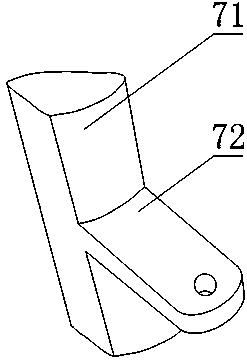

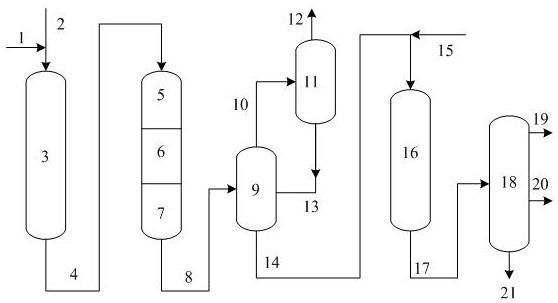

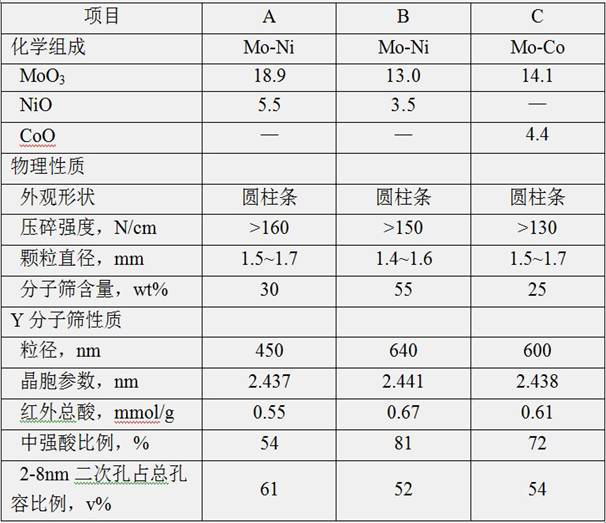

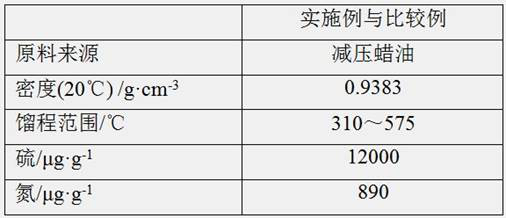

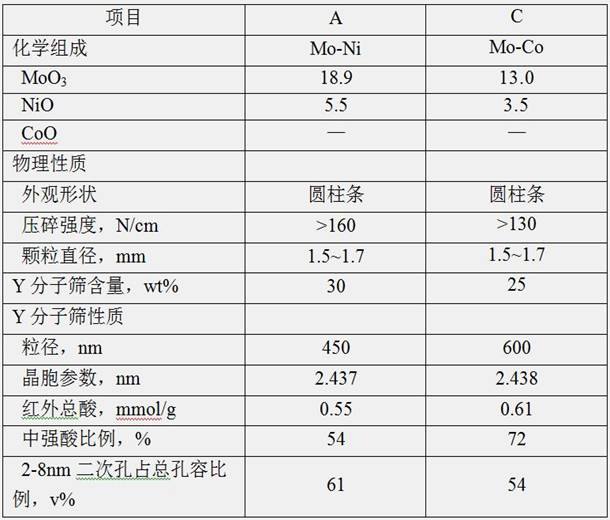

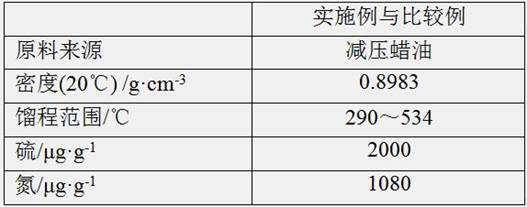

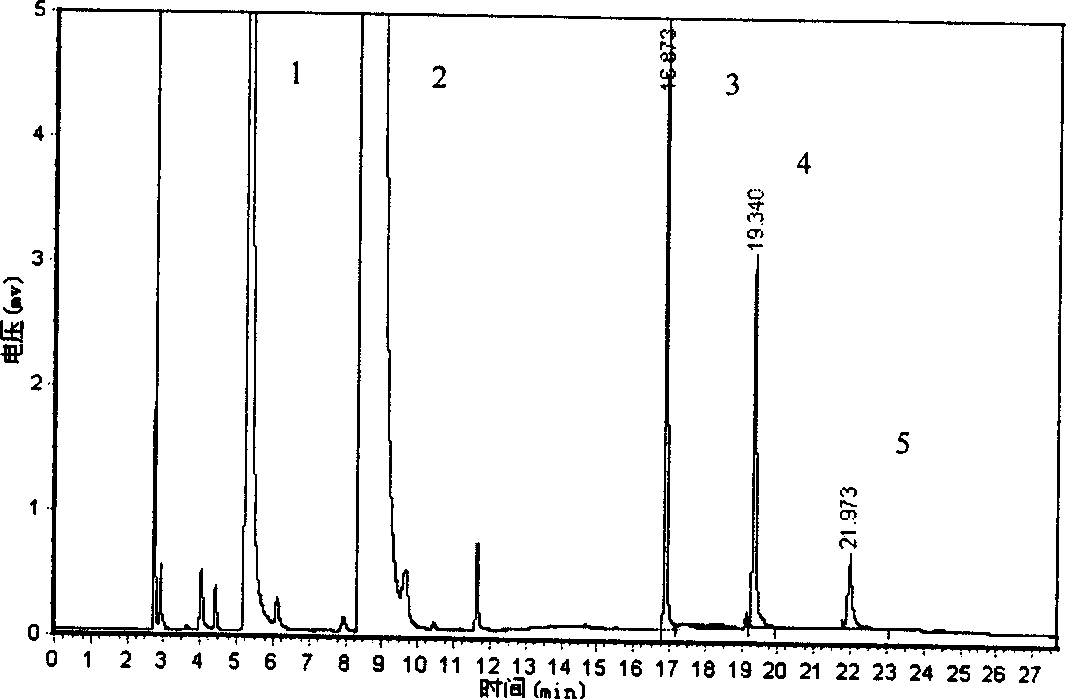

Method for producing gasoline and base oil by a catalyst grading technology

ActiveCN109988631AReduce sulfur contentBoost octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxHydrogen

The invention discloses a method for producing gasoline and base oil by a catalyst grading technology. The method comprises the following steps: a) under a hydrofining condition, mixing a heavy oil raw material with hydrogen, and allowing the mixture to flow through a reaction zone containing a hydrofining catalyst bed layer to perform a restrictive hydrofining reaction; b) allowing the reaction effluent obtained in the step a) to flow through a reaction zone containing a graded wax oil hydro-conversion catalyst bed layer to perform a hydro-conversion reaction under hydro-conversion process conditions; and allowing the reaction effluent to flow through a reaction zone containing a wax oil hydrocracking catalyst bed layer to perform a hydrocracking reaction under hydrocracking process conditions; and c) carrying out gas-liquid separation, fractionation and other processes on the reaction effluent obtained in the step b) to obtain converted gasoline, converted diesel oil and unconvertedoil. The method provided by the invention can convert heavy distillate oil into gasoline and base oil, and provides an economically feasible route for processing of inferior raw materials and production of gasoline and base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

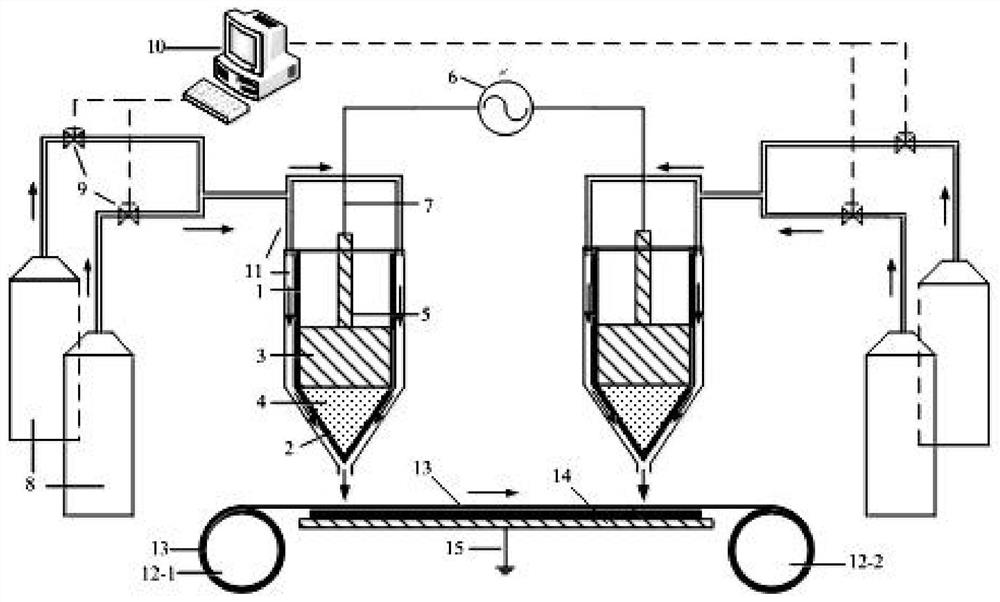

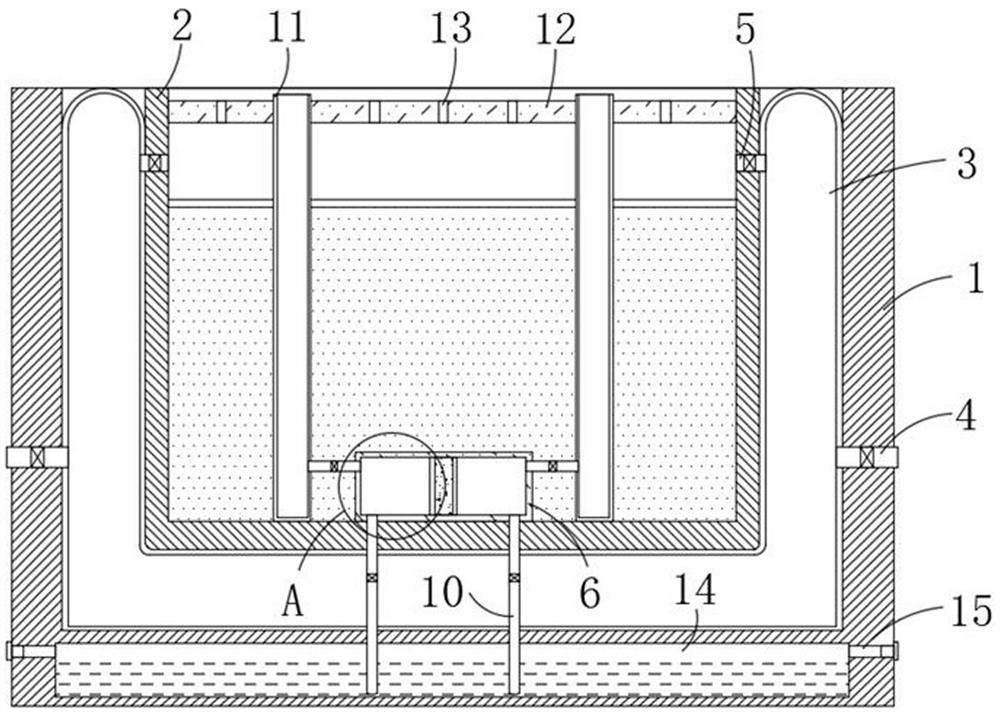

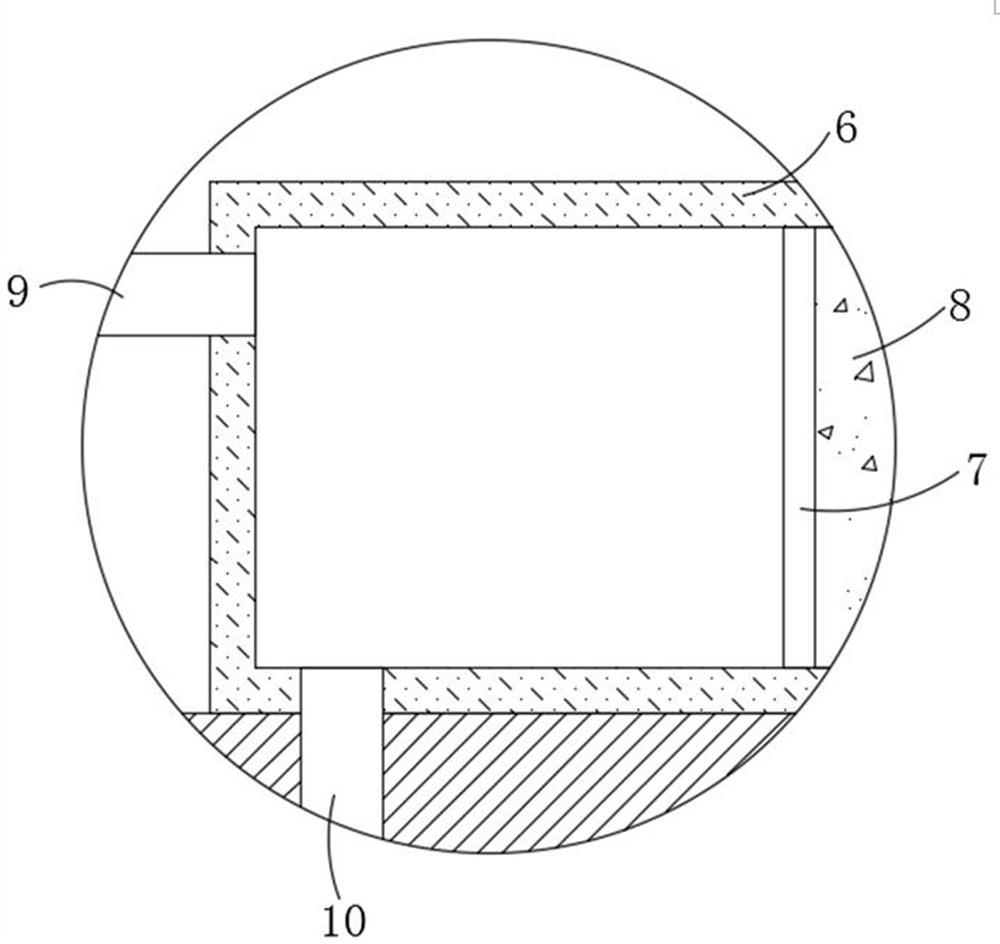

Material modification device, system and method based on dielectric barrier discharge plasma

The disclosure discloses a material modification device based on dielectric barrier discharge plasma, comprising: an upper part of a device main body, a lower part of a device main body, a copper plate, a copper screw and nano-iron powder. The present disclosure also discloses a material modification system based on dielectric barrier discharge plasma. The disclosure also discloses a material modification method based on dielectric barrier discharge plasma. The disclosure can generate a uniform one-dimensional discharge, reduce the randomness and dispersion of the discharge distribution in space, and ensure the uniformity of the large-area material treatment effect; the disclosure can match the discharge gas according to the modification requirements of the thin film material, purposefully Introducing a specific group; this disclosure sets up a film material transmission mechanism, which can use low-temperature plasma to perform large-area, uniform, and continuous treatment of materials, and can be applied to research, teaching, and industrial production promotion of material surface modification.

Owner:XI AN JIAOTONG UNIV

Method for producing hydroxy alkanoic acid polymer

InactiveCN1648150ANature of influenceReduce contentTissue cultureFermentationHydroxybutyric acidPurification methods

The present invention discloses the production process of hydroxy alkanoic acid polymer. The hydroxy alkanoic acid polymer is prepared with Sinorhizobium fredii as production strain, carbohydrate as carbon source and ammonium salt as nitrogen source, and through high density fermentation and metabolism regulation with caprate in optimal culture medium and under optimal culture condition to obtain 3-hydroxy butyric acid-3-hydroxy caprylic acid polymer. Corresponding fermentation management method, separation and purification method and quality detection method are established. The present invention can obtain 3-hydroxy butyric acid-3-hydroxy caprylic acid polymer product up to 10.7-16.4 g / L, of molecular weight of 127000-137000 Da, and endotoxin content 4-6 EU / g, and the novel nanometer level material may be used in biomedicine and medical tissue engineering.

Owner:SHANXI UNIV

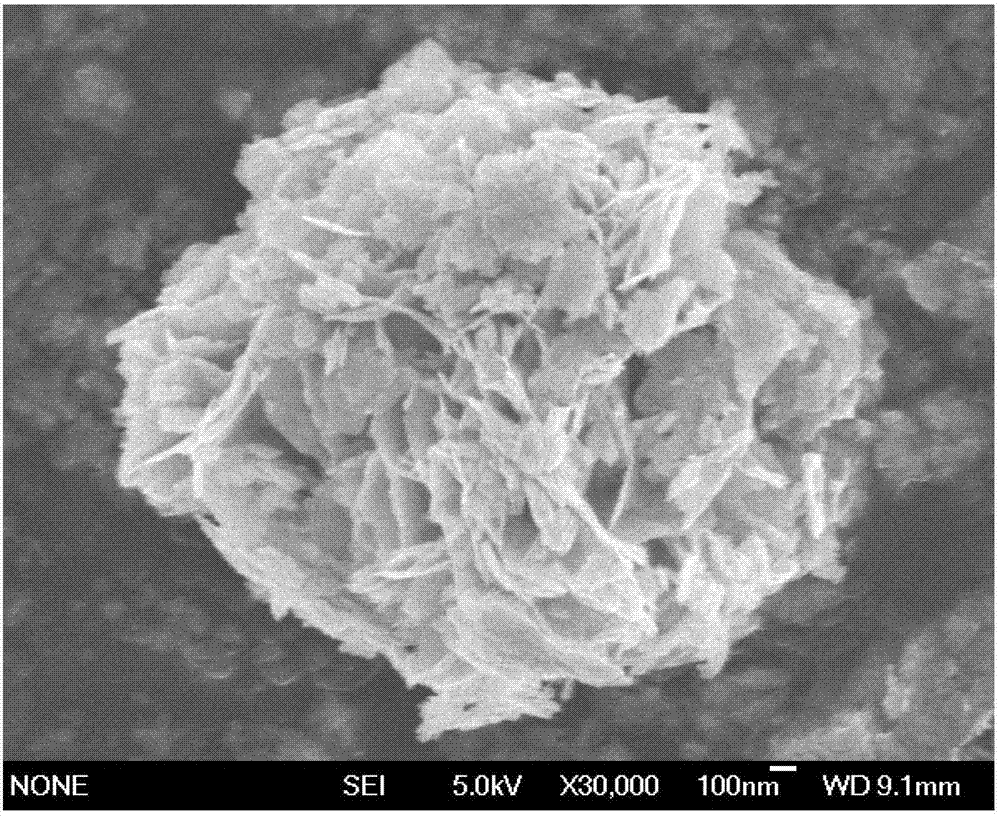

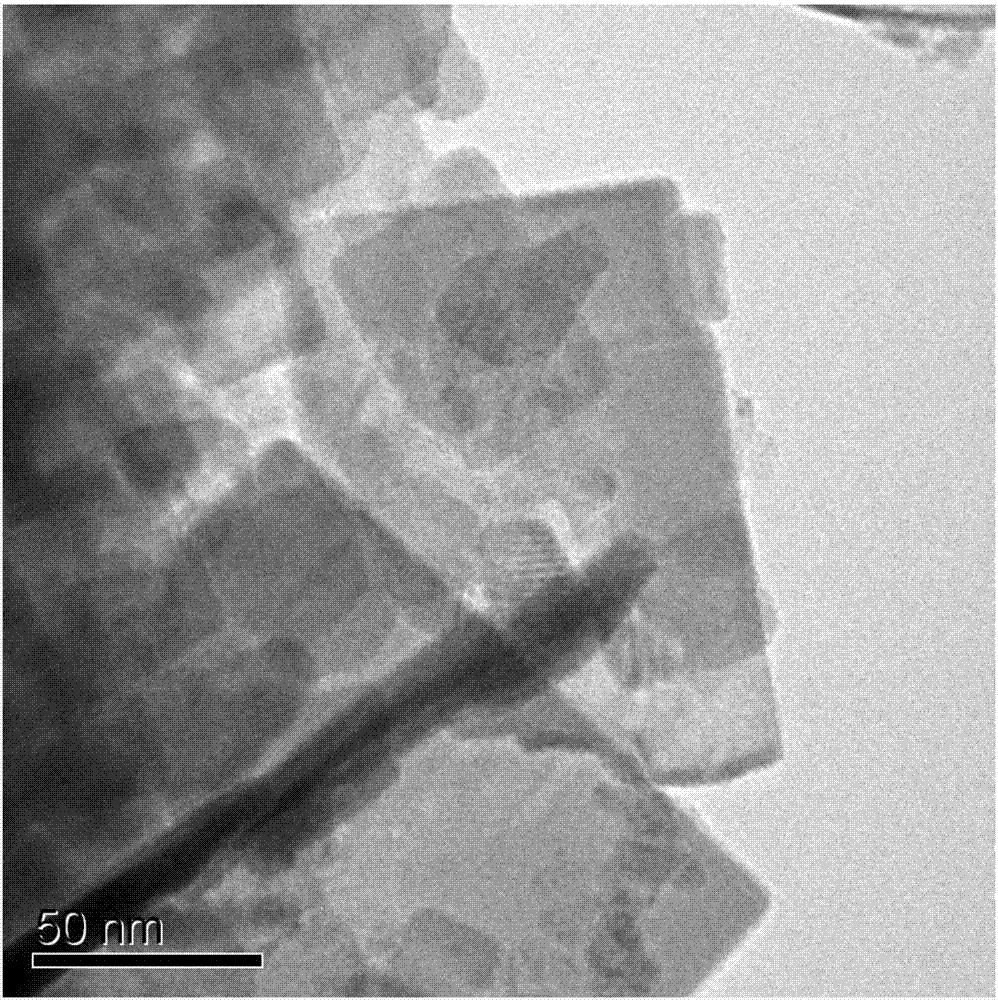

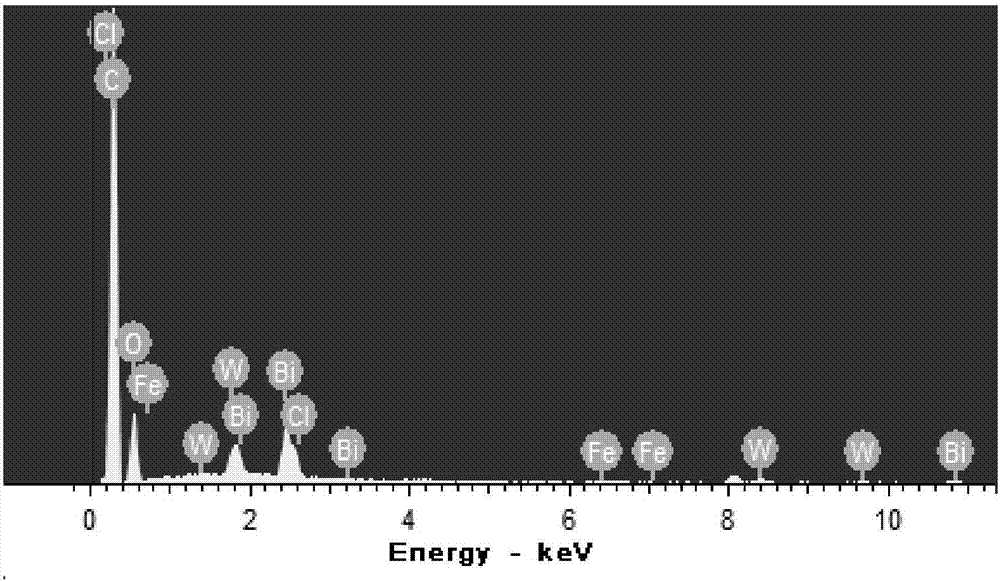

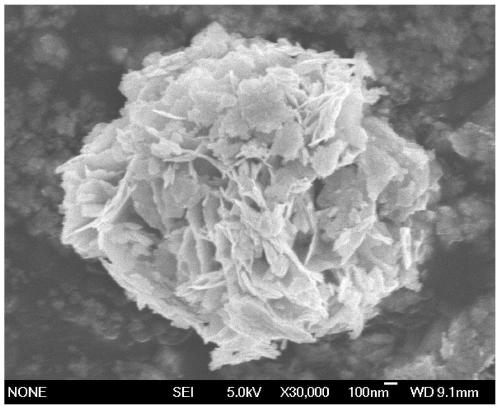

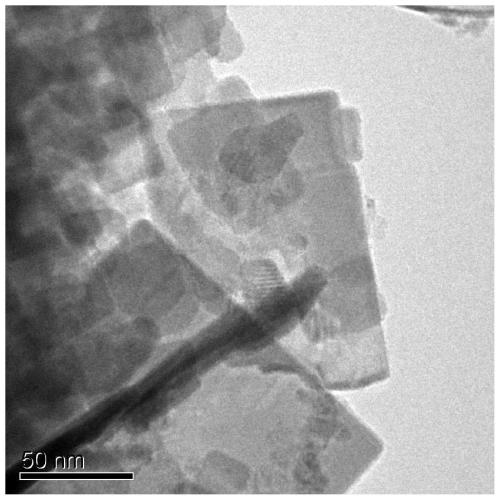

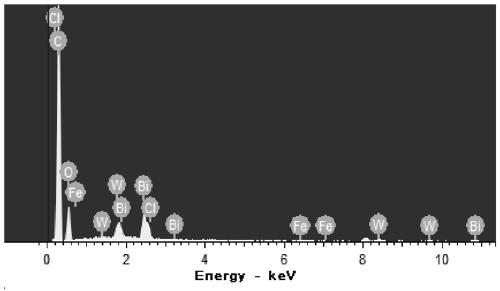

Ferriporphyrin/bismuth tungstate composite photocatalytic material and preparation method thereof

ActiveCN107159312AGood electronic conductivityImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsChemistryTungstate

The invention discloses a ferriporphyrin / bismuth tungstate composite photocatalytic material and a preparation method thereof. The composite photocatalytic material includes ferriporphyrin and bismuth tungstate, wherein the ferriporphyrin is supported on the bismuth tungstate. The preparation method includes the steps of: dissolving the ferriporphyrin in a mixture solution of acetonitrile and dimethylsulfoxide to obtain a ferriporphyrin solution; dissolving the bismuth tungstate in the ferriporphyrin solution to obtain a mixed solution of bismuth tungstate and ferriporphyrin; regulating the pH value of the mixed solution and allowing the mixed solution to stand to produce the ferriporphyrin / bismuth tungstate composite photocatalytic material. The composite photocatalytic material has good dispersibility, is strong in stability and is easy to recycle and reutilize. The photocatalytic material can be widely applied, has excellent photocatalytic performance and is environment-friendly. The preparation method has mild reaction conditions and simple process and is environment-friendly, and can be used in large-scale production.

Owner:HUNAN UNIV

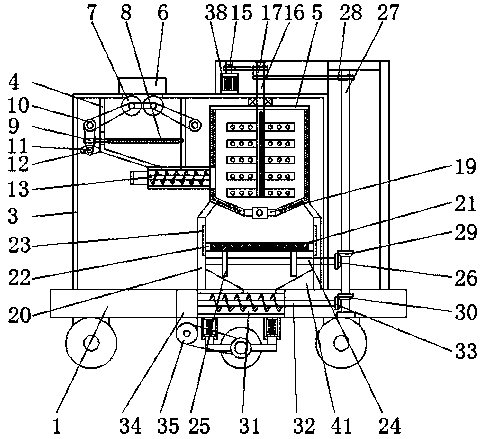

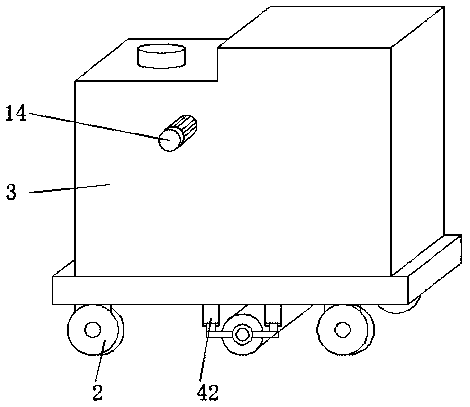

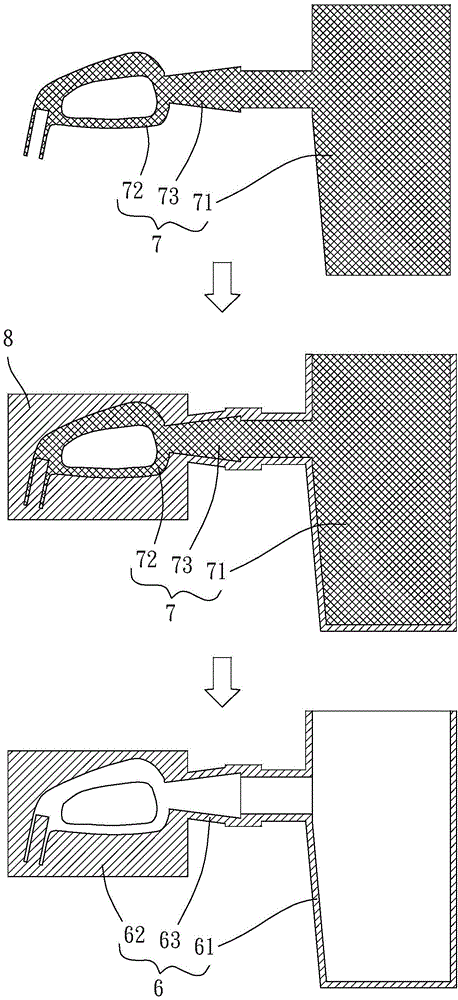

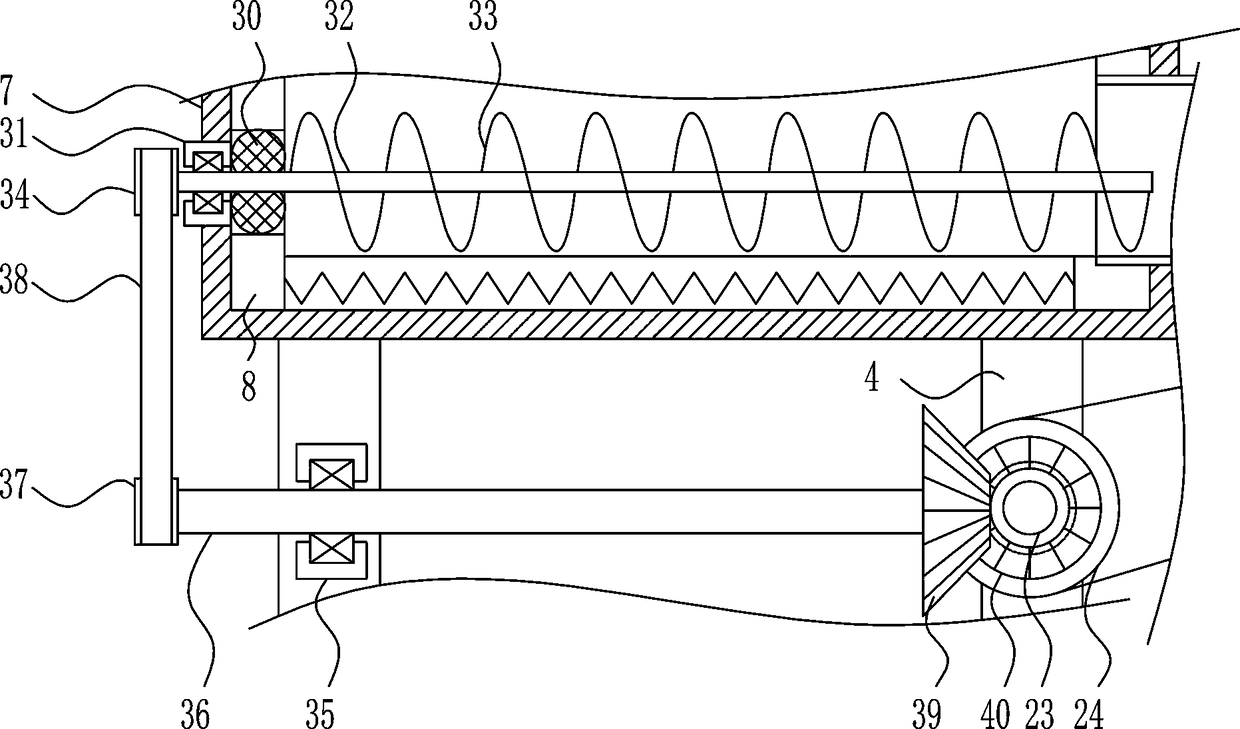

Municipal road asphalt spreading pulling trolley

InactiveCN108252183ANature of influenceWon't block accessRoads maintainenceInsulation layerEngineering

The invention relates to a municipal road asphalt spreading pulling trolley and in particular relates to a spreading pulling trolley. Aiming at solving the technical problems, the invention provides the municipal road asphalt spreading pulling trolley capable of uniformly spreading asphalt and uniformly heating, and ensuring the performance of the asphalt. The municipal road asphalt spreading pulling trolley provided by the invention comprises a bottom plate, wheels, a first bracket, a second bracket, a cylinder, a pull handle, a heat insulation layer, a discharging pipe, a feeding pipe, a feeding box and the like; the wheels are arranged on the bottom plate; the first bracket, the second bracket and the cylinder are arranged at the top of the bottom plate in sequence from left to right; the pull handle is arranged at the upper part of the left side of the first bracket; a first shell is arranged at the top of the second bracket. The municipal road asphalt spreading pulling trolley provided by the invention has the effects of uniformly spreading asphalt and uniformly heating, and ensuring the performance of the asphalt; the feeding pipe is covered with a piston so that a conditionthat the asphalt is in contact with the air for long time and the property of the asphalt is influenced can be avoided; a sector-shaped rotary plate can be used for uniformly spreading the asphalt onthe ground and a heat insulation layer can be used for preventing temperature from being lost.

Owner:江苏世丰企业管理咨询有限公司

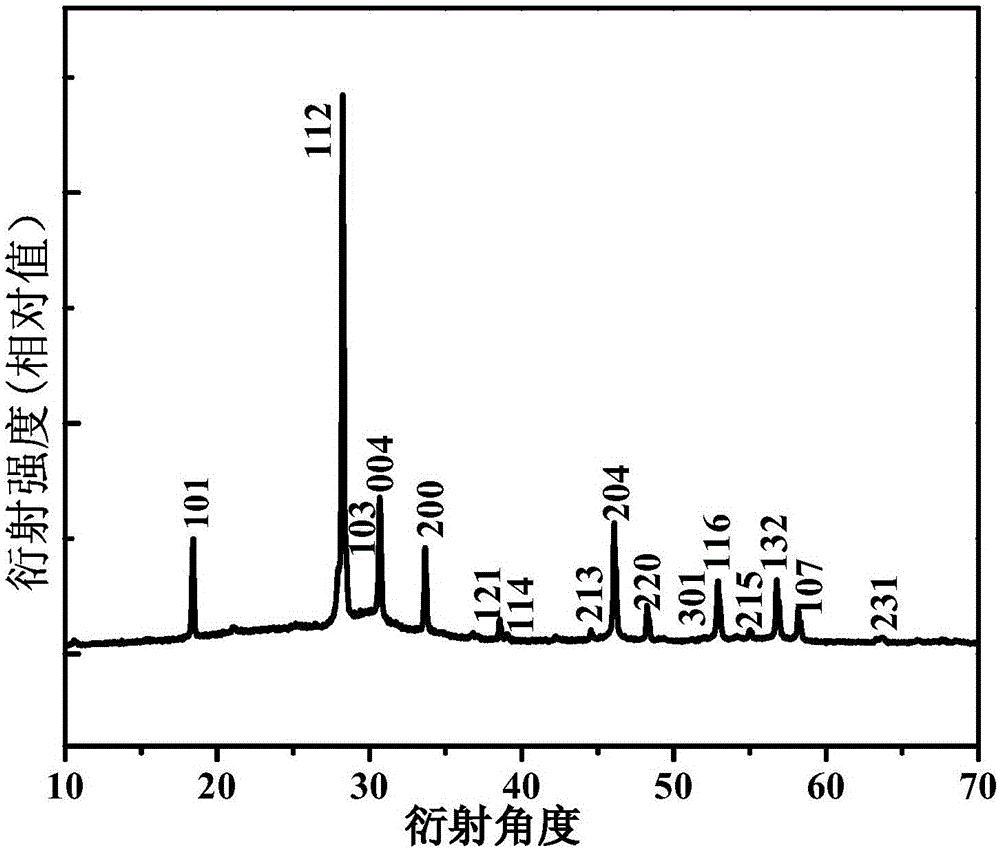

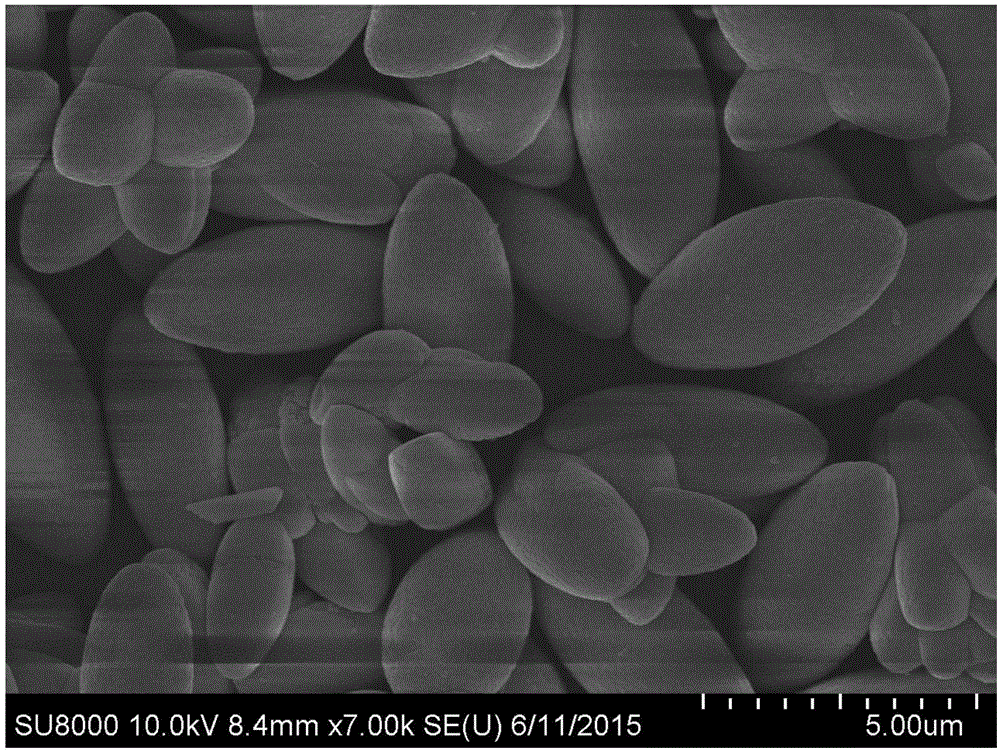

Method for fast preparation of olive-shaped lanthanum sodium tungstate

ActiveCN105110376AAvoid it happening againReduce usageMaterial nanotechnologyTungsten compoundsMaterials processingCrystallinity

The invention relates to a method for fast preparation of olive-shaped lanthanum sodium tungstate and belongs to the field of the inorganic material and functional material processing preparation technology. The method utilizes a simple hydro-thermal technology, sodium tungstate and lanthanum nitrate as raw materials and sodium nitrate as an additive to prepare a lot of products in short time. The prepared lanthanum sodium tungstate with a thin sheet structure is self-assembled to form the olive-shaped structure with the average length of 4.5-5.5 microns and waist average width of 2.5-3.5 microns. The olive-shaped lanthanum sodium tungstate has the characteristics of high degree of crystallization, uniform sizes and good dispersibility. The method has simple processes and a low cost. The product can be cleaned easily, is suitable for automatic large-scale production and has a wide application prospect.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

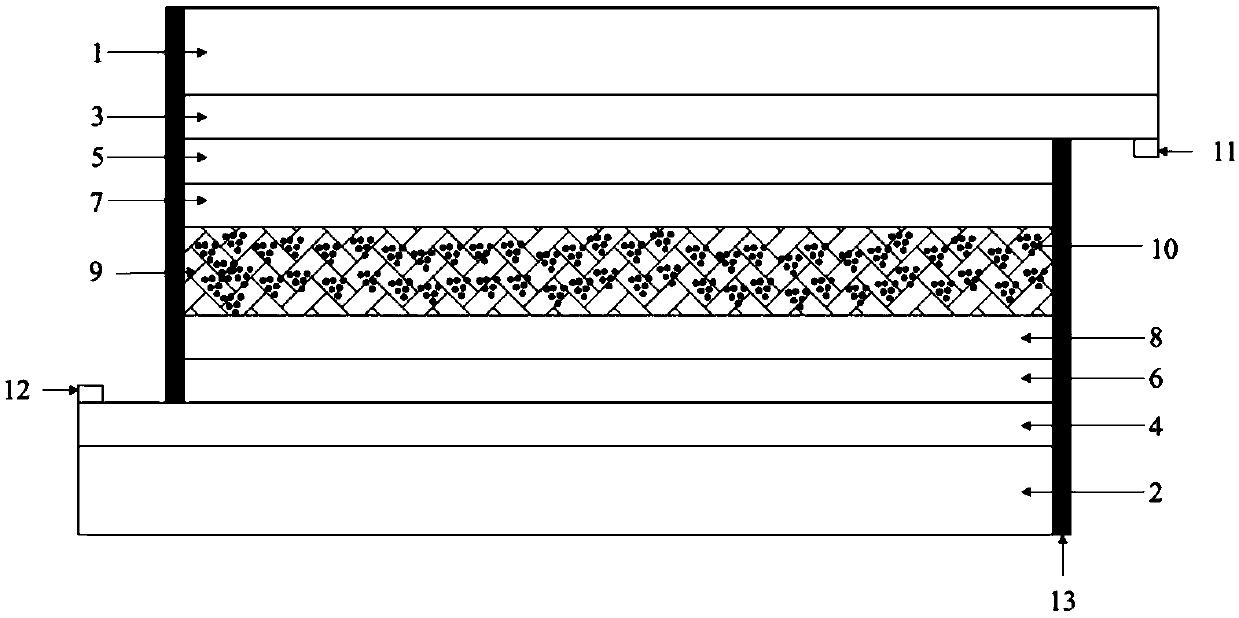

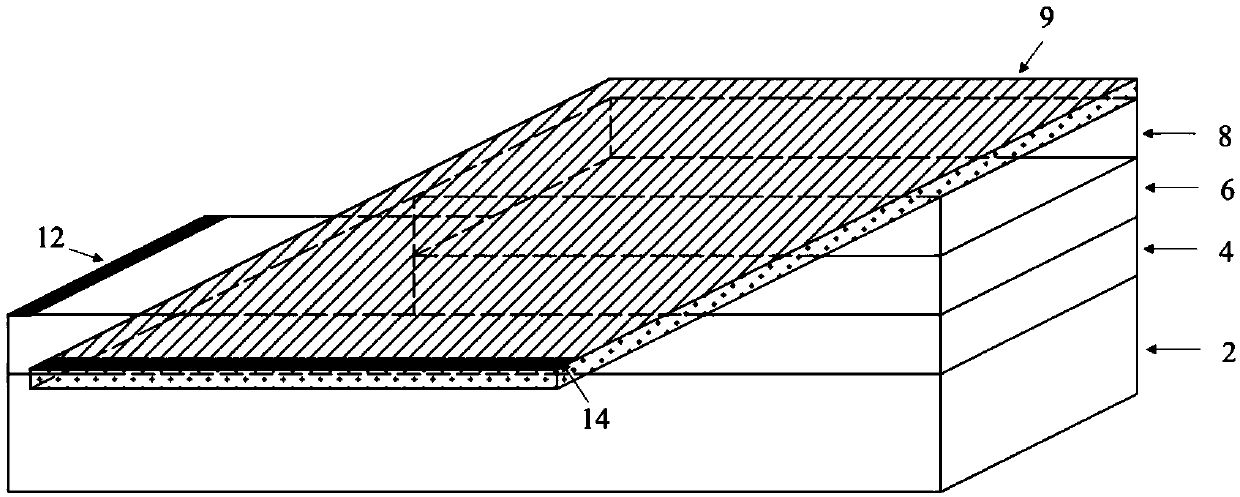

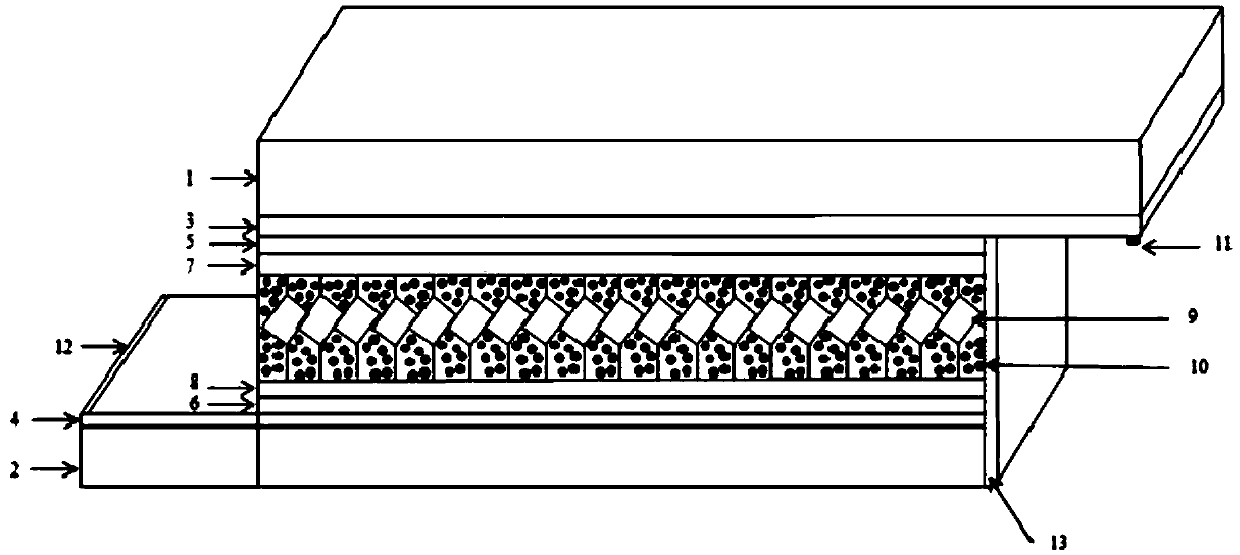

Perovskite solar cell module

ActiveCN109585657ALarge specific surface areaIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerPerovskite solar cell

The invention discloses a perovskite solar cell module. The structure is a sandwich structure of 'conductive glass / electronic transmission body / multifunctional nickel net / / electronic transmission body / conductive glass', and specifically comprises upper-layer conductive glass, lower-layer conductive glass, a multifunctional nickel net, an upper-layer electronic transmission body, a lower-layer electronic transmission body, an electrode and a glass adhesive. According to the structure, the perovskite absorption layer can be in full contact with the electron transmission body, electrons can be rapidly guided out from the two pieces of conductive glass, and the electron transmission efficiency is greatly improved; The interface contact of the perovskite absorption layer / hole transport layer can be increased through the net structure, and the hole transport efficiency is promoted. In addition, the whole perovskite absorption layer is completely in a closed state by tightly packaging the battery assembly, so that the environmental stability of the whole battery assembly is improved. The perovskite solar cell module has the advantages of being simple in structure, reasonable in design, high in practical value, low in cost, convenient and fast to assemble and the like, and is particularly suitable for being used as a perovskite solar cell module.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

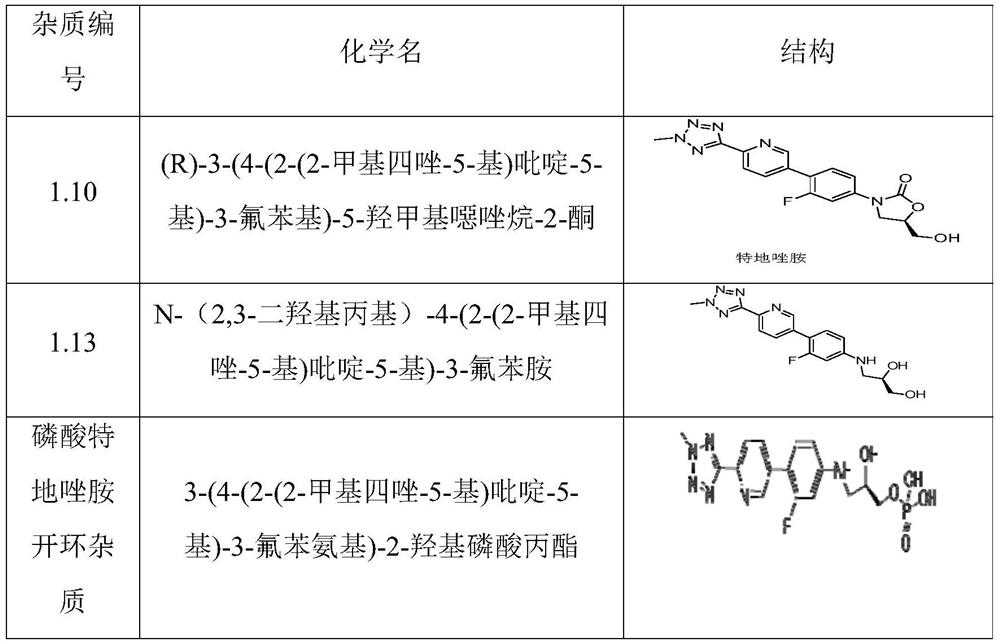

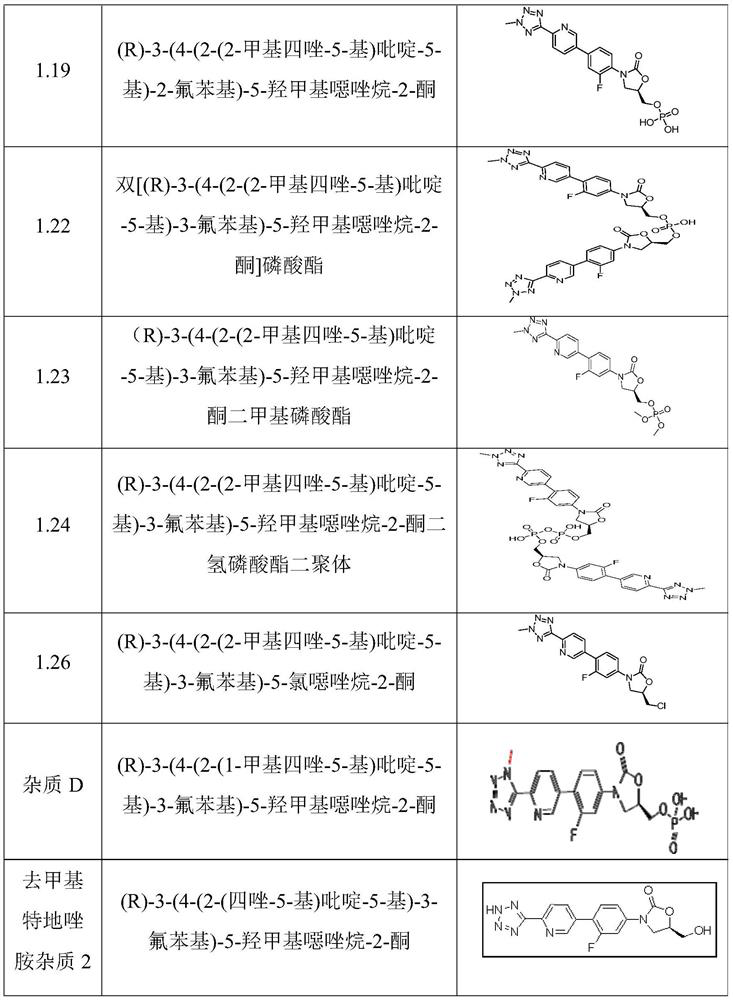

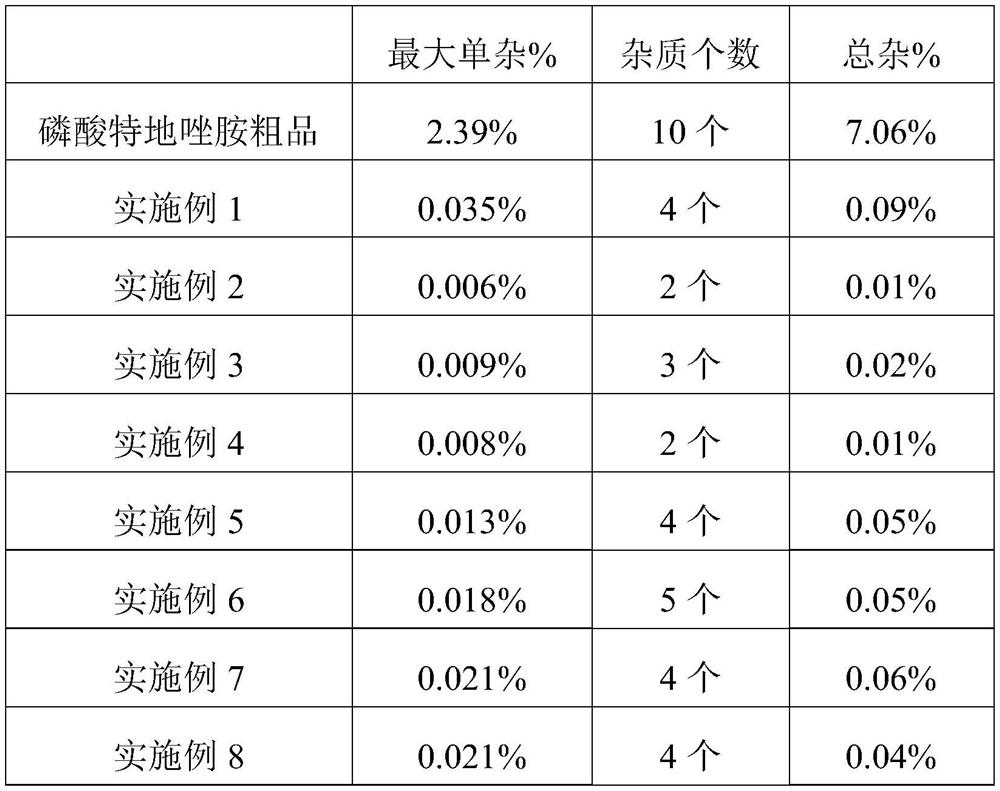

Purification method of tedizolid phosphate

InactiveCN112961186AHigh purityEase of industrial productionGroup 5/15 element organic compoundsAlcoholPhosphate

The invention relates to the technical field of medicinal chemistry, in particular to a purification method of tedizolid phosphate. The method comprises the following steps: firstly, crude tedizolid phosphate is creatively mixed with absolute ethyl alcohol, impurities with lower polarity than tedizolid phosphate in the crude tedizolid phosphate are dissolved in the absolute ethyl alcohol, then the impurities are removed by filtering, and tedizolid phosphate is left in a filtered solid; and other impurities can be removed by combining the subsequent steps of converting tedizolid phosphate solid into tedizolid phosphate disodium salt, acidifying, crystallizing and the like. The tedizolid phosphate obtained through purification is high in purity, the sodium hydroxide solution is clear, and a high-boiling-point solvent which is difficult to remove does not need to be used in the purification process of the purification method. The method is simple, convenient and beneficial to industrial production.

Owner:HAINAN GENERAL & KANGLI PHARMA

High toughness composite for 3D (three dimensional) printing and preparation method of composite

InactiveCN108659335AImprove crack resistanceGood dimensional stabilityAdditive manufacturing apparatusCrack resistancePolymer science

The invention discloses a high toughness composite for 3D (three dimensional) printing and a preparation method of the composite, and relates to the field of 3D printing materials. The composite comprises the following raw materials in parts by weight: 40-50 parts of polypropylene, 30-40 parts of polyethylene glycol terephthalate, 18-26 parts of lignin, 8-15 parts of polypropylene fiber, 5-9 partsof nano silica gel, 6-10 parts of fumed silica, 5-9 parts of a barite powder, 5-9 parts of silicon carbide, 4-8 parts of tung oil, 2-4 parts of 2-methylimidazole, 1.8-3.5 parts of a coupling agent and 3-7 parts of a plasticizer. Through a synergic matching effect of raw material ingredients, the composite is good in toughness, excellent in crack resistance, high in dimensional stability and material processability and wide in application scope, and the preparation method is simple.

Owner:肥西县碧涛建材有限公司

Efficient environment-friendly plant fertilization apparatus

InactiveCN108371901AImprove mixing uniformityImprove self-cleaning abilityManure treatmentTransportation and packagingFertilizerEngineering

The invention discloses an efficient environment-friendly plant fertilization apparatus and belongs to the technical field of fertilization equipment. The efficient environment-friendly plant fertilization apparatus comprises a box body, a nozzle connected to the left of the box body, a handle connected to the right of the box body and a stirring component arranged in the box body. A fixed ball isconnected to the surface of the inner wall of the box body and includes small half-balls arranged in symmetry; a center post is connected between the small half-balls in rolling manner; bristles areconnected to the top and bottom of the center post. The efficient environment-friendly plant fertilization apparatus is convenient to use, has a self-cleaning function, allows fertilizer to be sprayedconveniently in fractional manner so that fertilizer properties are ensured, has high stirring uniformity so that plant yield can be increased.

Owner:金华市时酷农业科技有限公司

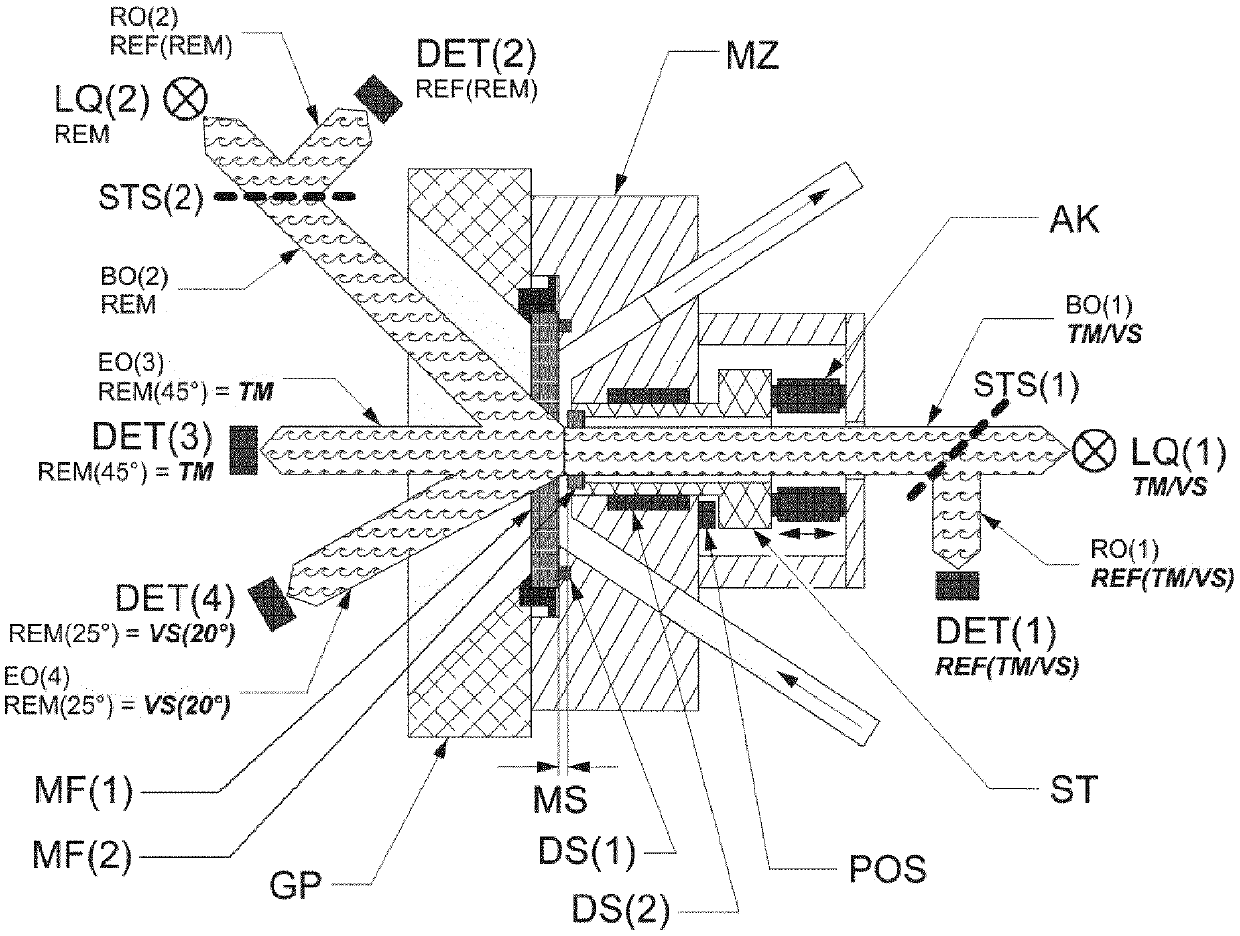

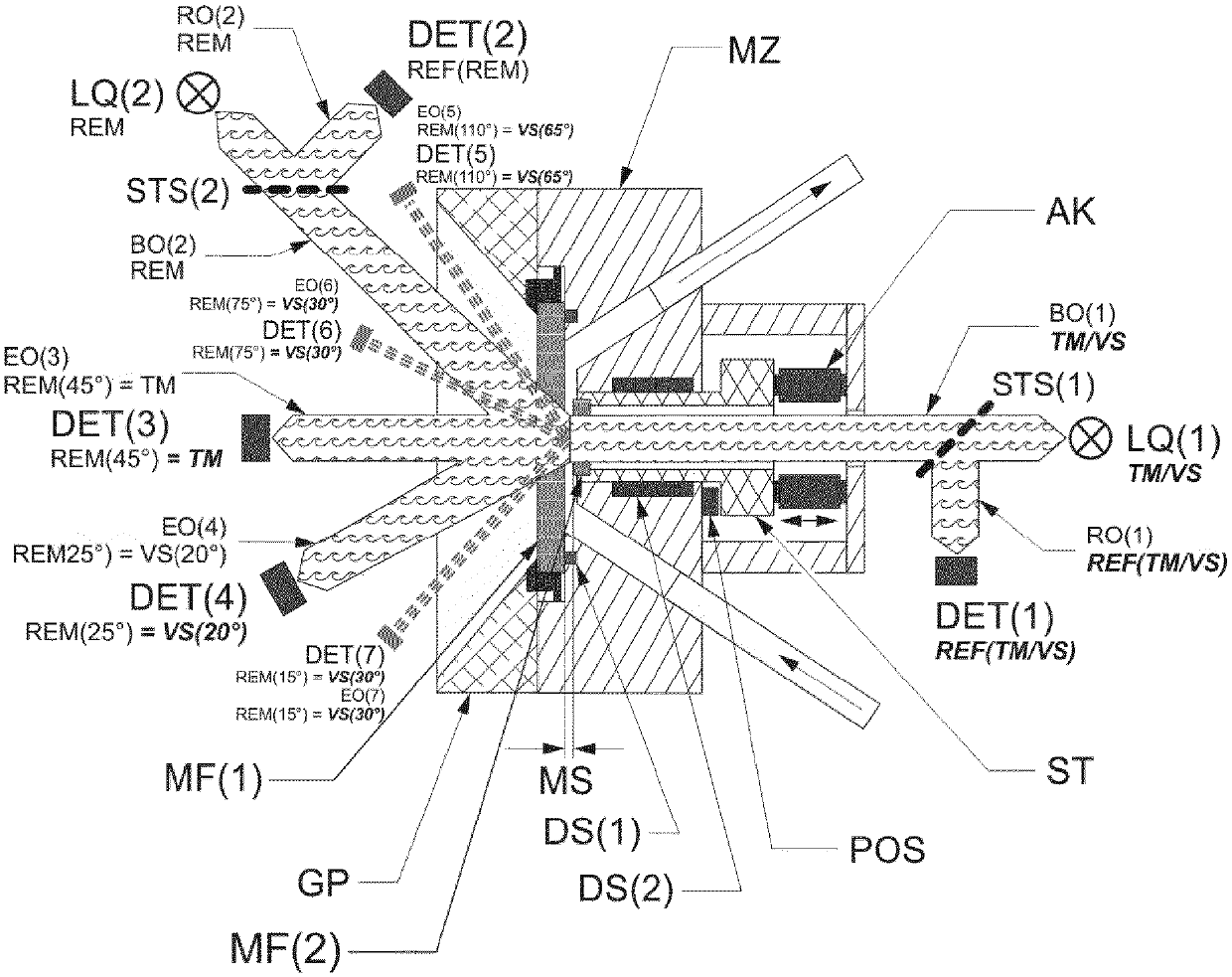

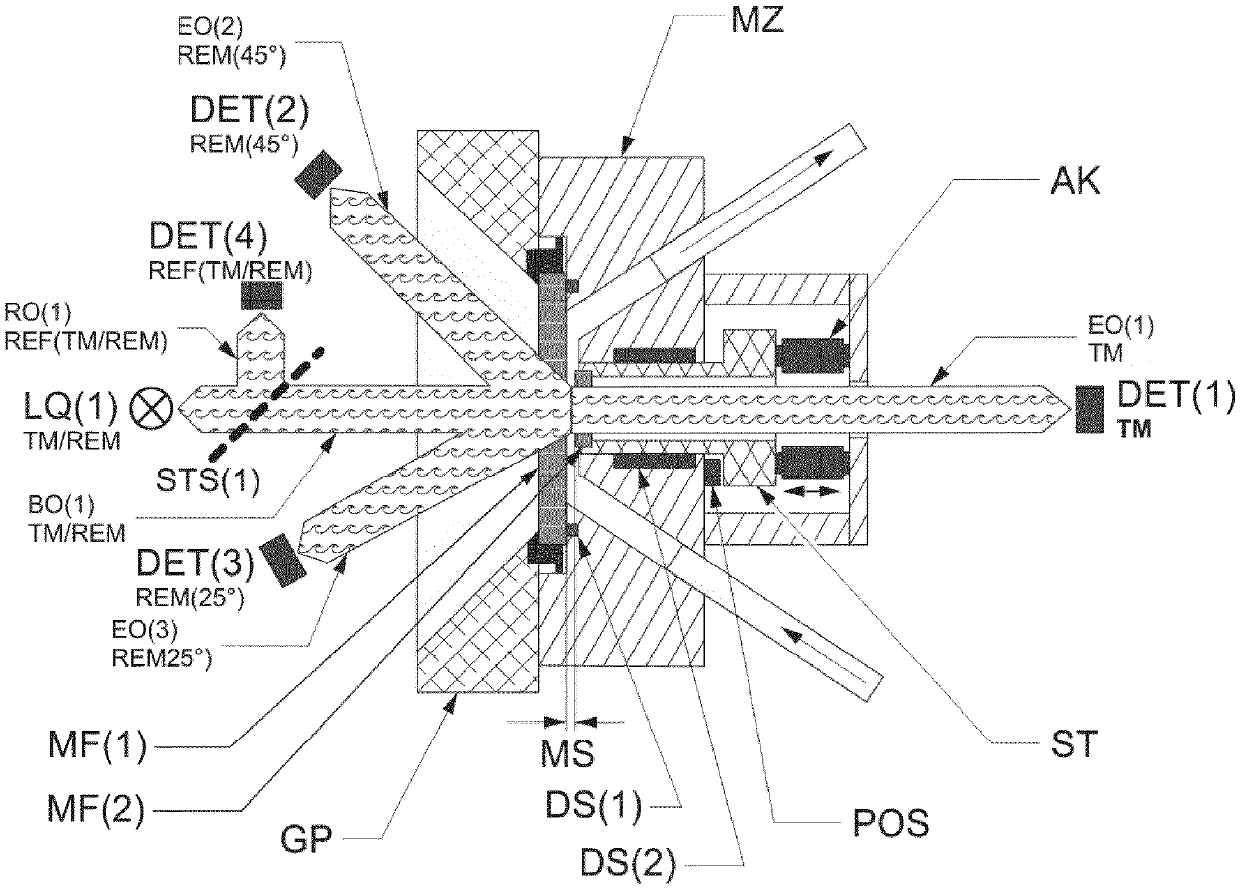

Sensor for a virtually simultaneous measurement of a transmission and/or forward scattering and/or remission and for a simultaneous measurement of the transmission and forward scattering or transmission and remission of a liquid sample

InactiveCN109690288ADetermine transmissionDetermine and/or forward scatterColor measuring devicesWithdrawing sample devicesForward scatterLacquer

Owner:BASF COATINGS GMBH

Iron porphyrin/bismuth tungstate composite photocatalytic material and preparation method thereof

ActiveCN107159312BImprove electronic conductivityImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsTungstatePorphyrin

The invention discloses an iron porphyrin / bismuth tungstate composite photocatalytic material and a preparation method thereof. The composite photocatalytic material includes iron porphyrin and bismuth tungstate, wherein the iron porphyrin is loaded on the bismuth tungstate. The preparation method includes dissolving iron porphyrin in a mixed solution of acetonitrile and dimethyl sulfoxide to obtain an iron porphyrin solution, and dissolving bismuth tungstate into the iron porphyrin solution to obtain a mixed solution of bismuth tungstate and iron porphyrin. , adjust the pH value of the mixed solution of bismuth tungstate and iron porphyrin, let it stand, and prepare an iron porphyrin / bismuth tungstate composite photocatalytic material. The composite photocatalytic material of the present invention has the advantages of good dispersion, strong stability, and easy recycling and reuse. It is an environmentally friendly composite photocatalytic material with excellent photocatalytic performance that can be widely used. Its preparation method has reaction conditions. It has the advantages of mildness, simple process, and environmental protection, and can be used for large-scale preparation.

Owner:HUNAN UNIV

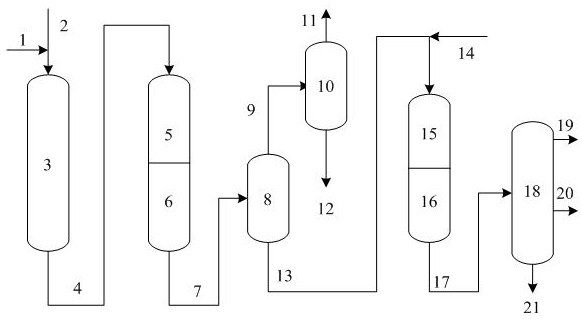

A method for producing gasoline and oil with a low condensation point by a catalyst grading technology

ActiveCN109988644ADoes not affect octane ratingIncrease contentMolecular sieve catalystsTreatment with hydrotreatment processesGas phaseFractionation

The invention discloses a method for producing gasoline and diesel oil with a low condensation point by a catalyst grading technology. The method comprises the following steps: a) mixing a heavy oil raw material with hydrogen, and allowing the mixture to pass through a reaction zone containing a hydrorefining catalyst bed layer to perform a restrictive hydrorefining reaction; b) allowing a reaction effluent obtained in the step a) to pass through a reaction zone containing a graded wax oil hydro-conversion catalyst bed layer under hydro-conversion process conditions, and allowing a reaction effluent to enter a flash tank for separation so as to obtain a gas phase and a liquid phase; c) performing subsequent separation, steam stripping and fractionation on the gas phase in the step b) to obtain converted gasoline; and d) allowing the liquid phase in the step b) to pass through a reaction zone containing a wax oil hydrocracking catalyst bed layer to perform a hydrocracking / isomerizationreaction under a hydrocracking condition, and separating and fractionating the reaction effluent to obtain heavy naphtha, low-condensation-point diesel oil and unconverted oil. According to the method, high-quality gasoline blending components and low-condensation-point diesel oil can be obtained, and good economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ammonia removal agent for rubber and plastic foam products and preparation method thereof

The invention discloses an ammonia removal agent used for a rubber and plastic foaming product and a preparation method thereof. The ammonia removal agent comprises, by weight, 60-65 parts of anhydrous aluminum sulfate, 2-3 parts of surface modification agents and 32-37 parts of solvent. The method includes the steps that the surface modification agents and the solvent are added into a container according to the proportion and then stirred; in the stirring process, the anhydrous aluminum sulfate is added to be dissolved into even paste, so that the ammonia removal agent is obtained. The ammonia removal agent is added into EVA and can rapidly disperse and react with ammonia radicals, in this way, the ammonia radicals and ammonia are effectively removed, and conditions for forming formamide can be broken before the formamide is formed.

Owner:东莞豪峻橡塑有限公司

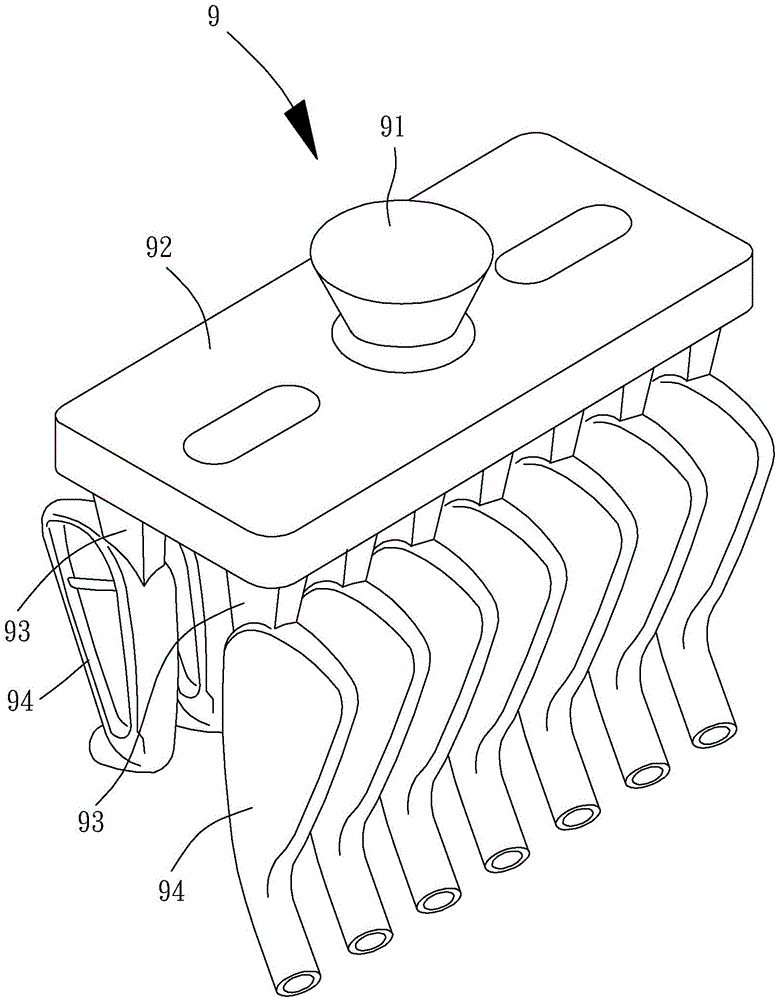

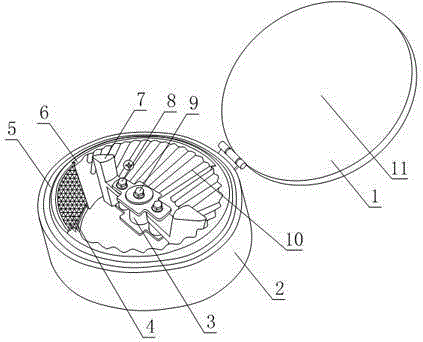

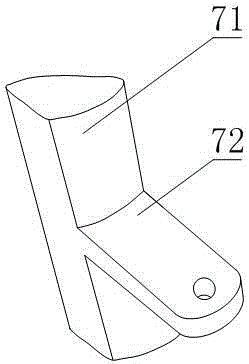

Medicine crushing mechanism

The invention discloses a medicine crushing mechanism. The medicine crushing mechanism comprises a barrel-shaped cylinder, wherein a rotating shaft connected with a driving motor is additionally arranged in the cylinder, and is positioned in the center of the cylinder; the medicine crushing mechanism further comprises a pin base, a pin and a crushing head; the pin base is fixedly connected with the rotating shaft; pin holes are formed in the pin base and the crushing head; the pin is in clearance fit with the two pin holes, or is in interference fit with one of the pin holes and in clearance fit with the other one of the pin holes; the length direction of the pin is parallel to the axial direction of the rotating shaft; and the distance from the free end of the crushing head to the axis of the rotating shaft is not greater than the radius of the cylinder. The medicine crushing mechanism is in favor of preventing the conditions of blockage of the crushing head in the operation process, influence on material properties due to acute heating of materials in a short time caused by excessive instant material output power and increment of power consumption of idle work of equipment or even equipment damage, and satisfies the crushing requirements of superfine materials.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

Inferior raw oil lightening treatment process and system

ActiveCN113122328AFlexible handlingAchieve separationTreatment with hydrotreatment processesBulk chemical productionFuel oilHydrogen treatment

The invention provides an inferior raw oil lightening treatment process and system. The treatment process comprises the following steps: firstly, treating inferior raw oil in a solvent deasphalting unit to obtain deasphalted oil and deoiled asphalt; feeding the deasphalted oil into a degumming unit to be treated to obtain a first light fraction and a first heavy fraction; mixing and feeding the deoiled asphalt, optional catalytic diesel oil and hydrogen into a fluidized bed hydrogenation reaction zone for reaction, and separating a reaction effluent to obtain a second light fraction and unconverted tail oil; mixng the first heavy fraction and the second light fraction with hydrogen, and then feeding an obtained mixture into a hydrotreating reaction zone for reaction; mixing and feeding the first light fraction and the hydrogenation reaction effluent into a catalytic cracking reaction zone for reaction, and separating the reaction effluent to obtain dry gas, liquefied gas, catalytic gasoline, catalytic diesel oil and catalytic heavy oil. According to the process, organic combination of a decarburization process and a hydrogenation process in lightening of the inferior raw oil is realized, lightening of the inferior raw oil is realized to the greatest extent, and meanwhile, the running period of a device is greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing gasoline and low pour point oil by catalyst grading technology

ActiveCN109988644BLowering the freezing pointReduce sulfur contentMolecular sieve catalystsTreatment with hydrotreatment processesNaphthaPtru catalyst

The invention discloses a method for producing gasoline and diesel oil with a low condensation point by a catalyst grading technology. The method comprises the following steps: a) mixing a heavy oil raw material with hydrogen, and allowing the mixture to pass through a reaction zone containing a hydrorefining catalyst bed layer to perform a restrictive hydrorefining reaction; b) allowing a reaction effluent obtained in the step a) to pass through a reaction zone containing a graded wax oil hydro-conversion catalyst bed layer under hydro-conversion process conditions, and allowing a reaction effluent to enter a flash tank for separation so as to obtain a gas phase and a liquid phase; c) performing subsequent separation, steam stripping and fractionation on the gas phase in the step b) to obtain converted gasoline; and d) allowing the liquid phase in the step b) to pass through a reaction zone containing a wax oil hydrocracking catalyst bed layer to perform a hydrocracking / isomerizationreaction under a hydrocracking condition, and separating and fractionating the reaction effluent to obtain heavy naphtha, low-condensation-point diesel oil and unconverted oil. According to the method, high-quality gasoline blending components and low-condensation-point diesel oil can be obtained, and good economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst grading technology to produce gasoline and a method for producing more low pour point oil

ActiveCN109988649BReduce sulfur contentBoost octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroxy alkanoic acid polymer and its producing method

InactiveCN1283688CNature of influenceReduce contentBacteriaFermentationHydroxybutyric acidPurification methods

Owner:SHANXI UNIV

Humic acid carbon source topdressing formula and preparation method thereof

InactiveCN111978133AImprove fertilizer use efficiencyAddressing Decreased FertilityMagnesium fertilisersAlkali orthophosphate fertiliserAgricultural cropsPotassium oxide

The invention relates to the technical field of agricultural fertilizers, and particularly relates to a humic acid carbon source topdressing formula and a preparation method thereof. The formula comprises the following components: weathered coal, humic acid, fulvic acid, nitrogen, ammonium bicarbonate, potassium hydroxide, monopotassium phosphate, potassium sulfate, boric acid and magnesium sulfate. The formula is characterized in that the dosage of each material is as follows: 70% of weathered coal, 40-50% of humic acid, 20-30% of fulvic acid, 15% of nitrogen, 10% of ammonium bicarbonate, 10%of potassium hydroxide, 6-8% of monopotassium phosphate, 10% of potassium sulfate, 5% of boric acid and 3% of magnesium sulfate. The formula structure improves the fertilizer utilization rate, effectively solves the problems of fertility reduction and fertilizer removal in middle and later periods of crops, makes the fertilizer efficiency more durable, and improves and enhances the stress resistance of plants.

Owner:刘江涛

Integrated canning system of emulsified liquid detergent preparation device

InactiveCN108516509AEnhance stirringUniform compositionChemical/physical/physico-chemical stationary reactorsLiquid bottlingSurface mountingActive component

The invention discloses an integrated canning system of an emulsified liquid detergent preparation device. The integrated canning system comprises a primary reaction chamber, wherein a feeding deviceand a canning device are connected with two sides of the primary reaction chamber respectively through a primary feeding pipe and a primary discharging pipe; the primary reaction chamber comprises a tank body; a turbulent flow pump is mounted at the bottom of the tank body through a square bracket; an emulsification dispersion device is fixedly mounted at the top of the square bracket; the canningdevice comprises a reversed U-shaped bracket; a reversed T-shaped bracket is fixedly mounted on a side face of the reversed U-shaped bracket; a canning conveyor belt is mounted on the upper surface of the reversed U-shaped bracket; a sliding rail is arranged on the front surface of the reversed T-shaped bracket; a canning liquid storage bucket is mounted on the sliding rail through a sliding block; a rack, which is engaged with a gear on a rotary shaft of a hoisting motor, is arranged at the inner side of a retractable rod, and emulsification and stirring of a liquid detergent are improved; main components are vibrated and activated and surface active components are kept at maximum; the components of the liquid detergent are relatively uniform; the liquid detergent can be rapidly canned after being prepared, the activity is kept and the washing capability of the liquid detergent is improved.

Owner:北京乾淳知识产权运营有限公司

Placing rack for transporting thermosetting powder coating

InactiveCN112918914AReduce vibrationGuaranteed stabilityShock-sensitive articlesContainers to prevent mechanical damageWater storageEngineering

The invention discloses a placing rack for transporting a thermosetting powder coating. The placing rack comprises a placing box, wherein a container box is arranged in the placing box; an air bag is arranged between the placing box and the container box; a plurality of air inlet pipes communicated with the interior of the container box are arranged on the air bag at equal intervals; a plurality of exhaust pipes communicated with the outside are further evenly arranged on the air bag; a first one-way valve and a second one-way valve are arranged in each exhaust pipe and each air inlet pipe correspondingly; a sealed cover is in threaded connection with an opening in the upper end of the container box; and a plurality of water storage barrels are evenly and vertically arranged on the inner bottom wall of the container box. By arranging the air bag, vibration borne by the container box can be buffered, circulation of air in the container box can be kept, the interior of the container box can be cooled for a long time by means of evaporation of clean water through cooperation of a linkage mechanism and the water storage barrels, and the situation that the property of the thermosetting powder coating is affected by the too high temperature of the container box is avoided.

Owner:张家界福安家木业有限公司

A crushing mechanism that is beneficial to the crushing efficiency of medicinal materials

The invention discloses a smashing mechanism beneficial to medicine material smashing efficiency. The smashing mechanism comprises a cylinder body, a rotating shaft connected with a driving motor is further arranged in the cylinder body, the rotating shaft is arranged in the center of the cylinder body, and the smashing mechanism further comprises a dowel bushing, dowels, a liner plate and a smashing head. The liner plate is an arc-shaped plate, the outer side of the liner plate is fixedly connected with the inner wall of the cylinder body, raised grains or grooves are formed in the inner side of the liner plate, the dowel bushing is fixedly connected with the rotating shaft, dowel holes are formed in the dowel bushing and the smashing head, one dowel is in clearance fit with the two dowel holes, or is in interference fit with one dowel hole and in clearance fit with the other dowel hole. The smashing efficiency is high in working efficiency, the conditions that in the working process, the smashing head is clamped and blocked, the instantaneous output power on the materials is too large, as the result, the materials are sharply heated up in a short time, material properties are affected, useless power consumption of the mechanism is increased, and even the mechanism is damaged are completely eradicated, and the smashing mechanism meets the processing requirements for superfine material smashing.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com