EVA foam material and preparation method thereof

A foaming material, EVA100 technology, applied in the field of EVA foaming material and its preparation, can solve the problems of expensive OBSH foaming agent, inability to compare foamed products, formamide residue, etc., and achieve a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

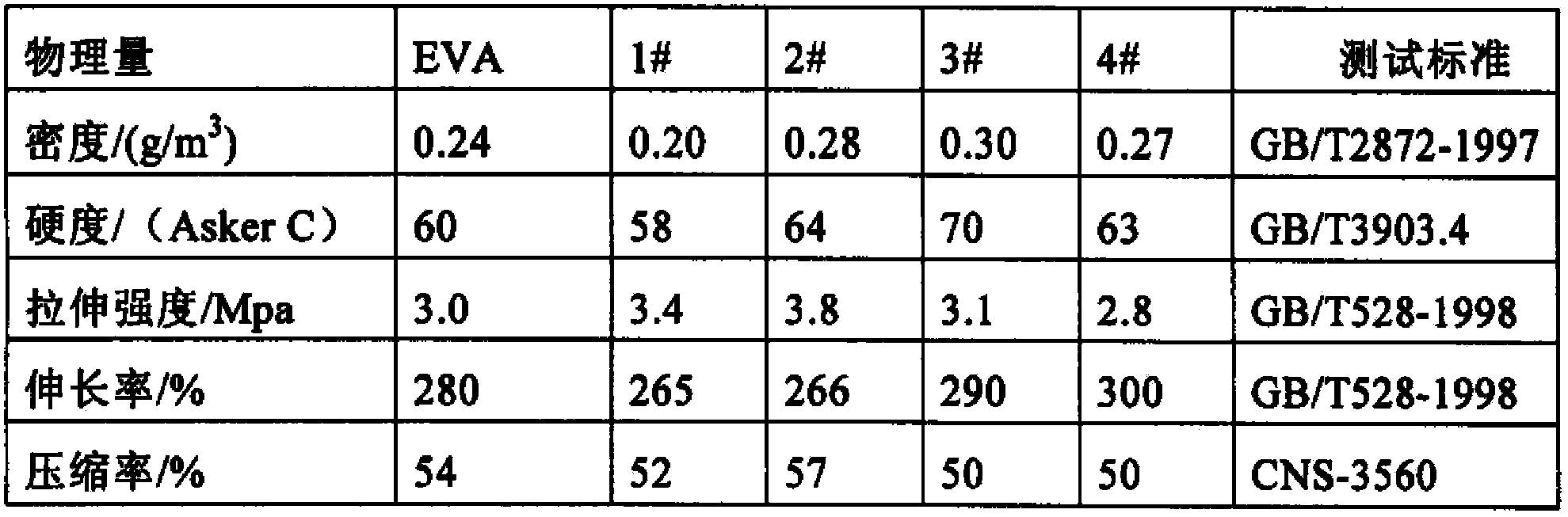

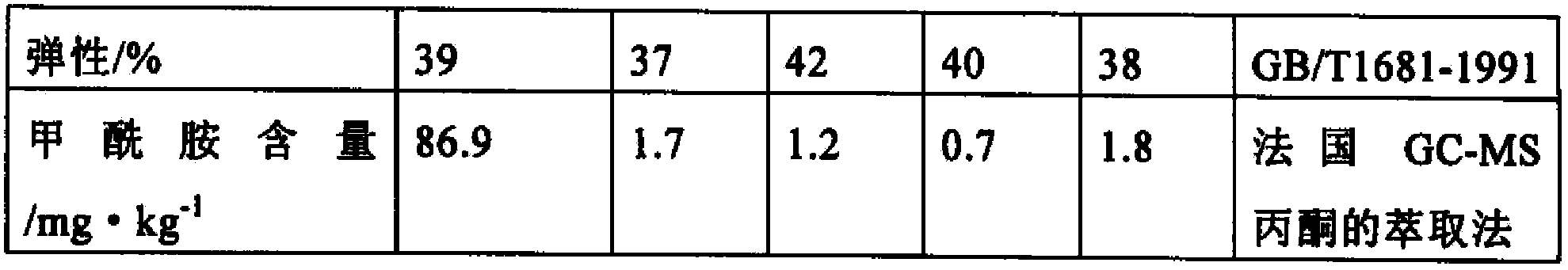

Embodiment 1

[0034] Mix 100 parts of EVA260 (VA content is 28wt%), 2 parts of AC3000-H, 1 part of zinc oxide, 0.05 parts of BIBP, 5 parts of calcium carbonate, 0.5 parts of SW100, 0.5 parts of stearic acid and bake in an oven at 60 °C 6h, then carry out mixing injection molding, the temperature is controlled at 100°C, at this time is the temperature at which the crosslinking agent works, and the blowing agent has not yet taken effect. Continue to cut the EVA sheet obtained by injection molding and put it into a flat vulcanizing machine for hot pressing. Control the molding temperature at 160°C, the pressure at 1Mpa, and the time for 1min. After that, the pressure will be automatically released, and then the mold will be cooled, and the EVA foam material 1# will be taken out. For testing.

Embodiment 2

[0036] Mix 100 parts of EVA7350 (VA content is 18wt%), 4 parts of AC3000-H, 0.5 parts of zinc stearate, 0.1 part of DCP, 10 parts of talcum powder, 1 part of SW120, and 2 parts of stearic acid, and then put them in an oven at 70 ° C Internally bake for 10 hours, then carry out mixing and injection molding, the temperature is controlled at 110°C, at this time is the temperature at which the crosslinking agent works, and the foaming agent has not yet taken effect. Continue to cut the EVA sheet obtained by injection molding, put it into a flat vulcanizing machine, install it into a mold and press it, control the molding temperature at 170°C, the pressure at 5Mpa, and the time for 5min, then automatically release the pressure, then cool the mold, and take out the EVA foam material 2#, For testing.

Embodiment 3

[0038] Mix 100 parts of EVA8038 (VA content is 14wt%), 8 parts of AC3000-H, 3 parts of zinc oxide, 0.5 parts of PL400, 20 parts of calcium carbonate, 3 parts of SW5510, and 5 parts of stearic acid, and then bake in an oven at 80°C 12h, then carry out mixing injection molding, the temperature is controlled at 120 ℃, at this time is the temperature at which the crosslinking agent works, and the blowing agent has not yet taken effect. Continue to cut the EVA sheet obtained by injection molding, put it into a flat vulcanizing machine, load it into a mold and press it, control the molding temperature at 180°C, the pressure at 10Mpa, and the time for 10min, then automatically release the pressure, then cool the mold, and take out the EVA foam material 3#, For testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com