Method for producing gasoline and low pour point oil by catalyst grading technology

A catalyst and gradation technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of good quality of hydrocracking products, improvement of catalyst process, single selection of raw materials, etc., to improve quality , the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

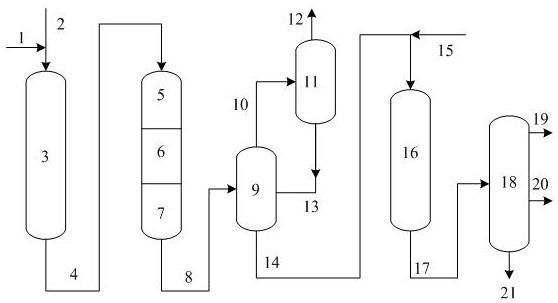

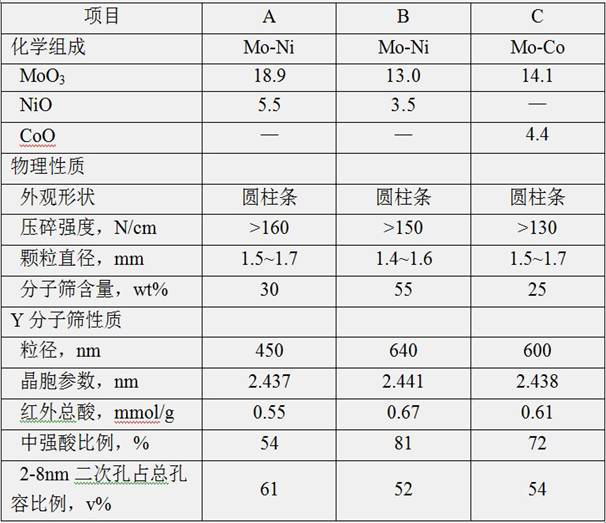

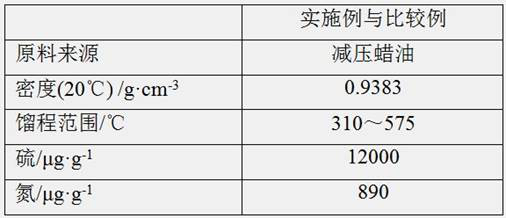

[0042] use figure 1 In the combined process flow shown, straight-run wax oil is selected as the conversion / cracking / isomerization raw material for hydrogenation to produce gasoline, and certain refining (nitrogen content 100ppm) and conversion depth (gasoline yield 30%) are controlled. The catalysts used in the examples are the commercial catalyst FF-36 hydrotreating catalyst, the special hydroconversion catalysts A, B and C single-ring aromatics retained hydroconversion catalysts, and the commercial catalyst FC-14 hydrocracking catalyst.

[0043] The properties of catalysts A, B and C are shown in Table 1, the properties of feed oil are shown in Table 2, and the operating conditions are shown in Table 3.

Embodiment 2

[0045] use figure 1 In the combined process flow shown, straight-run wax oil is selected as the conversion / cracking / isomerization raw material for hydrogenation to produce gasoline, and certain refining (nitrogen content 200ppm) and conversion depth (gasoline yield 30%) are controlled. The catalysts used in the examples are the commercial catalyst FF-36 hydrotreating catalyst, the special hydroconversion catalysts A, B and C single-ring aromatics retained hydroconversion catalysts, and the commercial catalyst FC-14 hydrocracking catalyst.

[0046] The properties of catalysts A, B and C are shown in Table 1, the properties of feed oil are shown in Table 2, and the operating conditions are shown in Table 3.

Embodiment 3

[0048] use figure 1 In the combined process shown, straight-run wax oil is selected as the conversion / cracking / isomerization raw material for hydrogenation to produce gasoline, and certain refining (nitrogen content 200ppm) and conversion depth (gasoline yield 20%) are controlled. The catalysts used in the examples are the commercial catalyst FF-36 hydrotreating catalyst, the special hydroconversion catalysts A, B and C single-ring aromatics retained hydroconversion catalysts, and the commercial catalyst FC-14 hydrocracking catalyst.

[0049] The properties of catalysts A, B and C are shown in Table 1, the properties of feed oil are shown in Table 2, and the operating conditions are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com