Method for producing diesel oil and chemical materials by f-t synthetic wax

A production method and technology of chemical raw materials, applied in the field of clean diesel oil and chemical raw materials, can solve the problems of not being an ideal source of raw materials for lubricating oil base oils and high content of straight-chain hydrocarbons, so as to reduce gas production, increase diesel yield, and reduce secondary The effect of secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

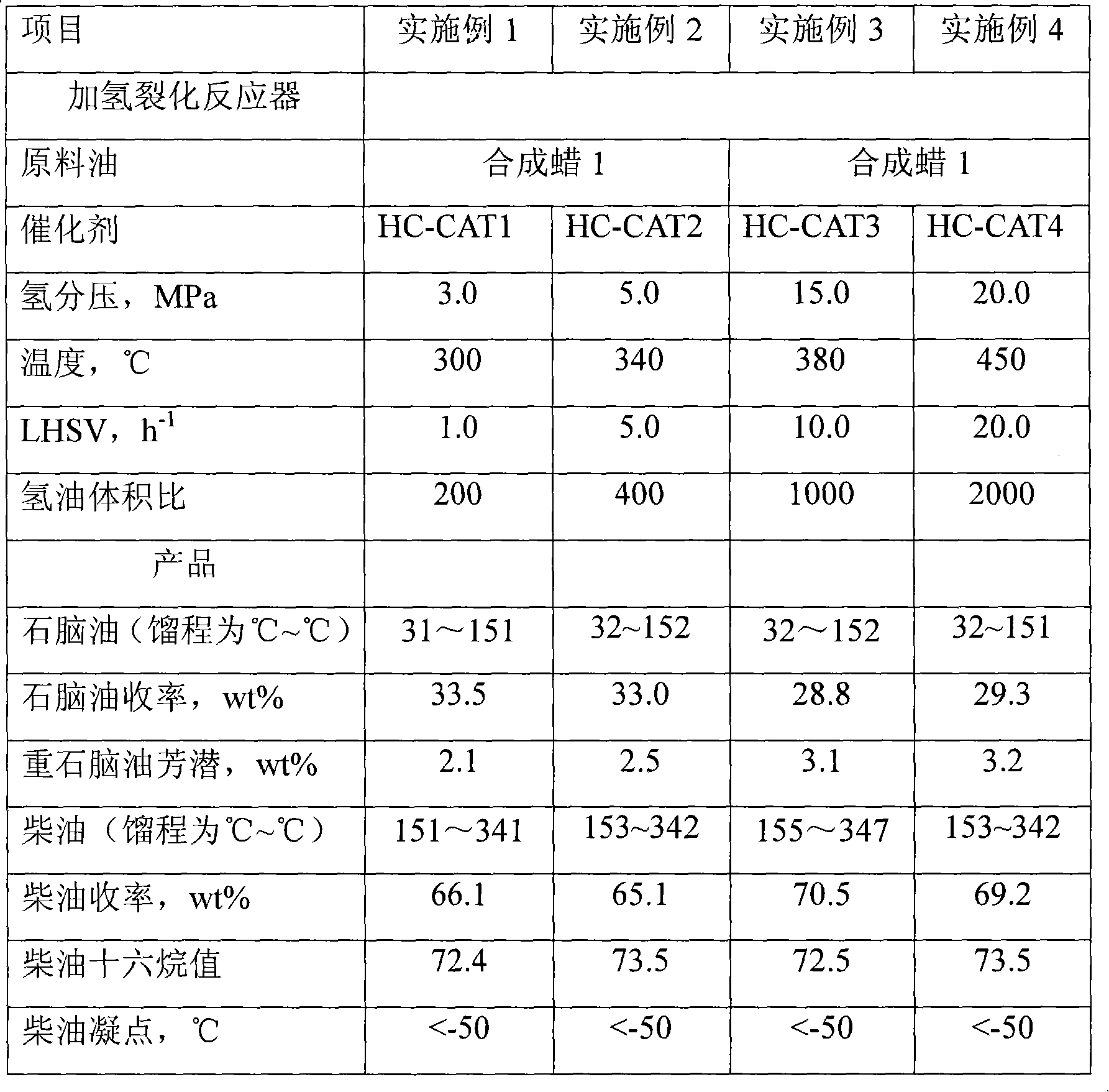

[0041] Embodiment 1-4 Catalytic Hydrocracking of Fischer-Tropsch Waxes

[0042] The properties of the raw materials used are listed in Table 1. The properties of the hydrocracking catalysts used are shown in Table 2. See Table 3 for hydrocracking operating conditions and product distribution and properties. The recycling of tail oil back to hydrocracking refers to full or partial recycling, and the operation mode of full recycling is adopted in the examples. Before carrying out the hydrocracking reaction, the hydrocracking catalyst is presulfided to change the active metal therein from an oxidized state to a sulfided state. The specific operation is to use hydrogen containing 0.8% (V) of hydrogen sulfide in the reactor to keep the temperature at 200° C. for 5 hours, and at 320° C. for 10 hours. The volume space velocity of hydrogen is 1000h -1 , the pressure is 5MPa.

[0043] Table 1 Raw Oil Properties

[0044] Raw oil

Synthetic Wax 1

Synthetic Wax 2

...

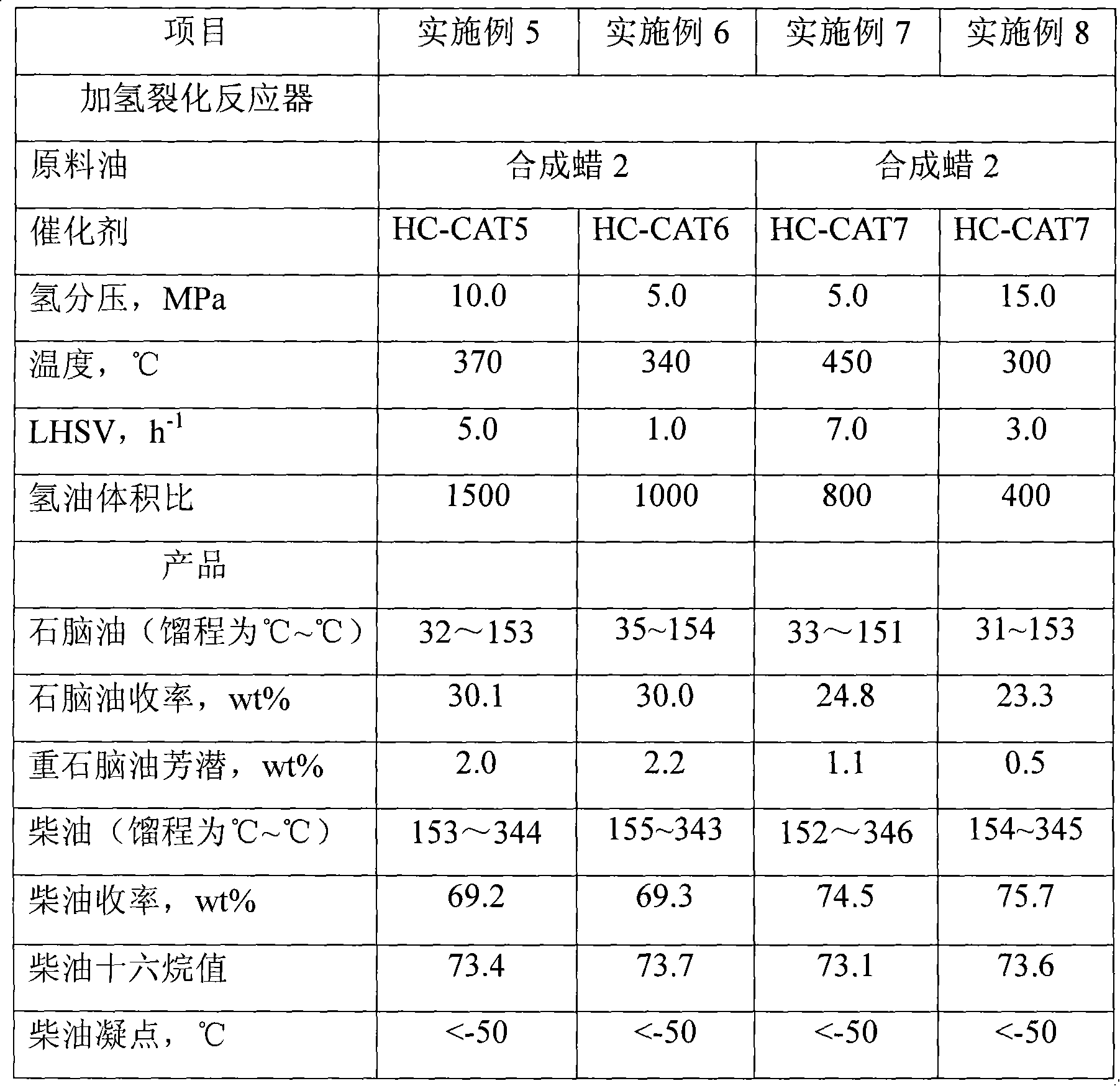

Embodiment 5~8

[0049] Embodiment 5-8 Preparation of Hydrocracking Catalyst and Catalytic Hydrocracking of Fischer-Tropsch Waxes

[0050] Beta zeolite is prepared according to the following method, and the beta zeolite is used to prepare the hydrocracking catalyst of the method of the present invention, and then the prepared catalyst is used to carry out catalytic hydrocracking reaction of Fischer-Tropsch synthetic wax.

[0051] 1. Preparation of modified β zeolite

[0052] (1) Preparation of Modified Beta Zeolite B-1

[0053] With 78g sodium aluminate (laboratory preparation contains Al 2 o 3 19.9m%, containing Na 2O 21.44m%), 435g tetraethylammonium hydroxide aqueous solution (the product of industrial production, concentration 1.4N), 288g of coarse porous silica gel particle (Qingdao ocean chemical plant production, containing SiO 2 95%) and 120g of purified water are mixed evenly, and reacted in a 2-liter stainless steel reactor at 100°C for 20 hours under sufficient continuous st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com