Patents

Literature

66results about How to "Ideal comprehensive processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation combined method for diesel oil

ActiveCN101724457ADeep modificationReduce cokingTreatment with hydrotreatment processesHydrogenCombined method

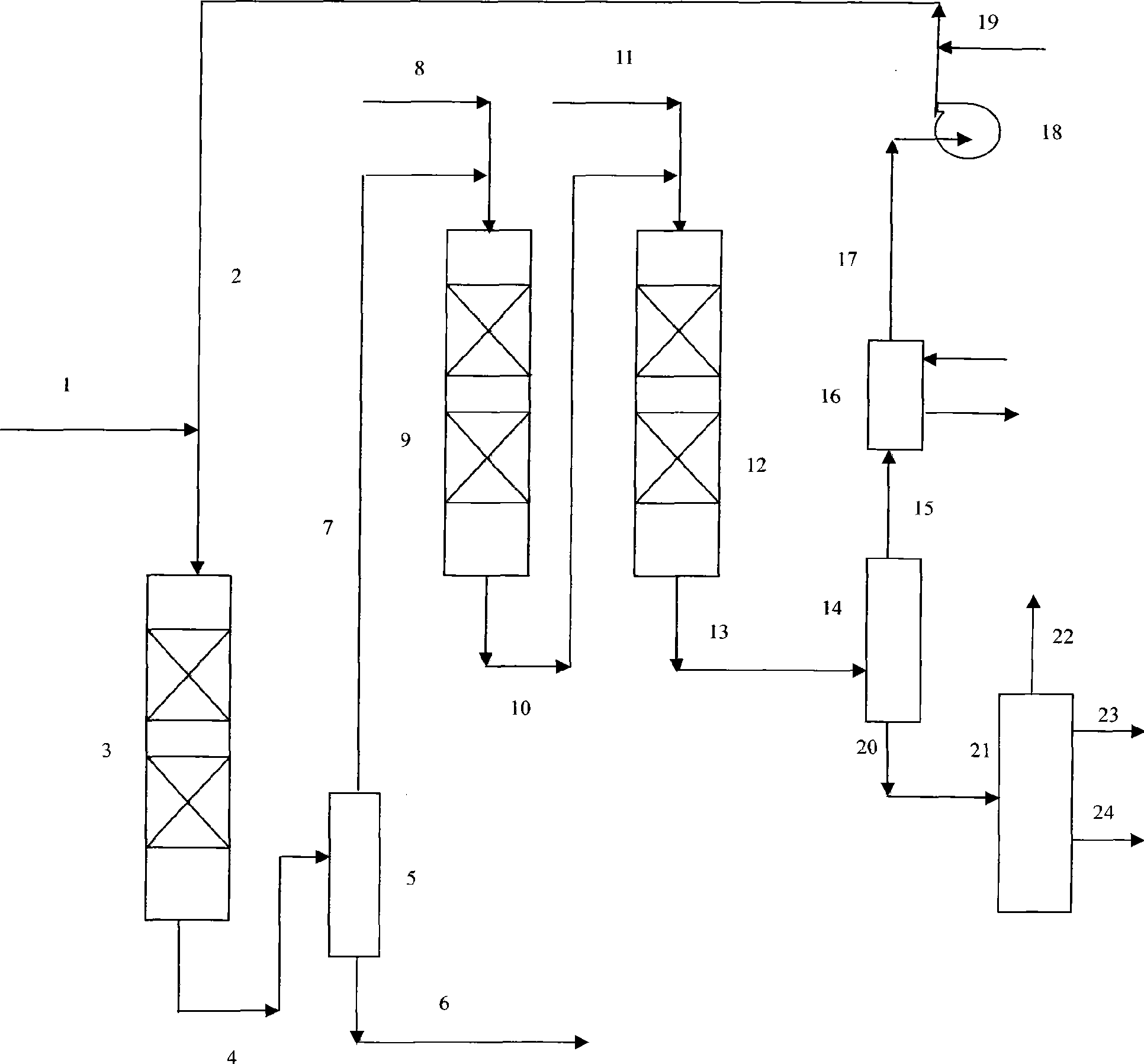

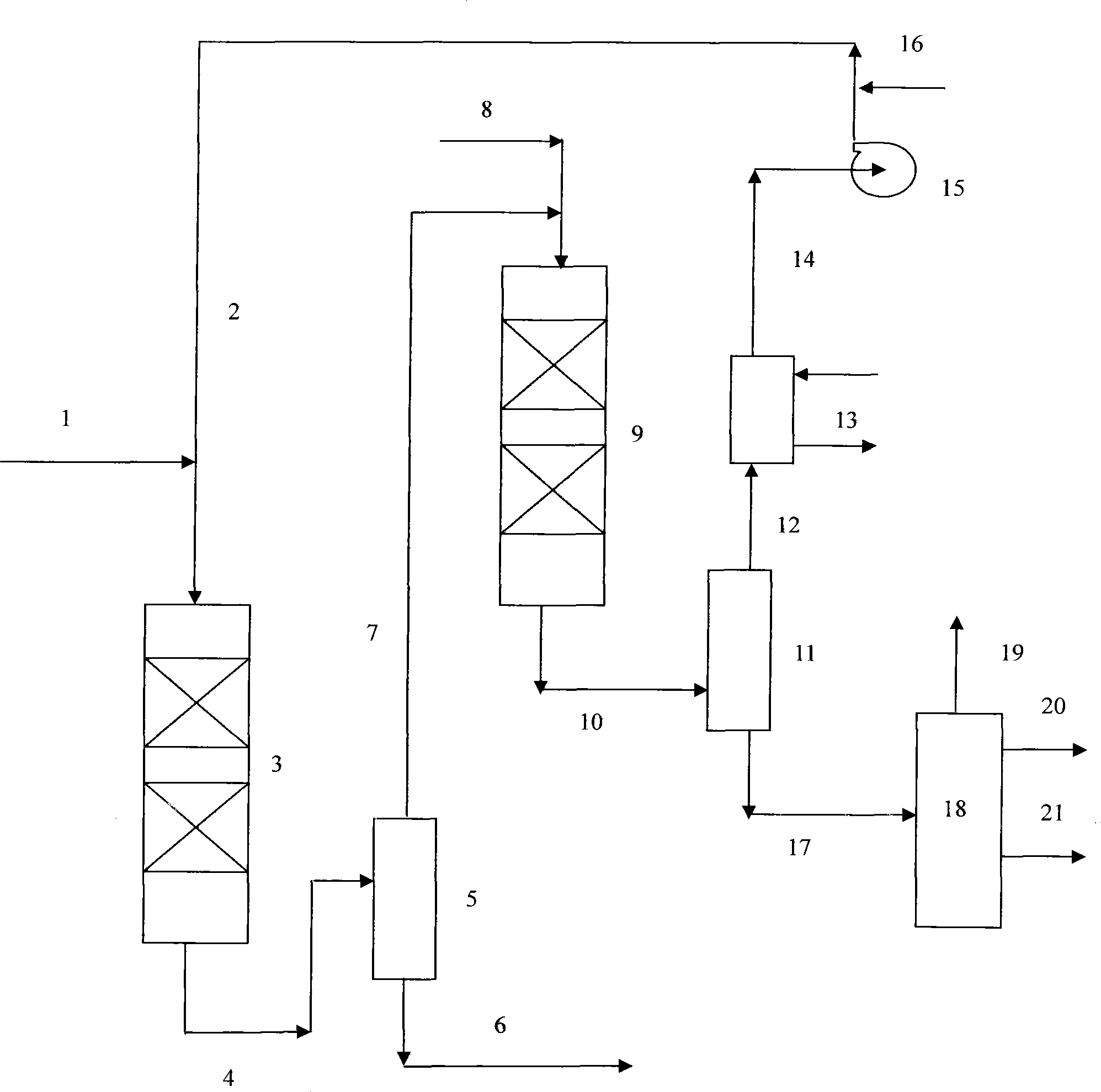

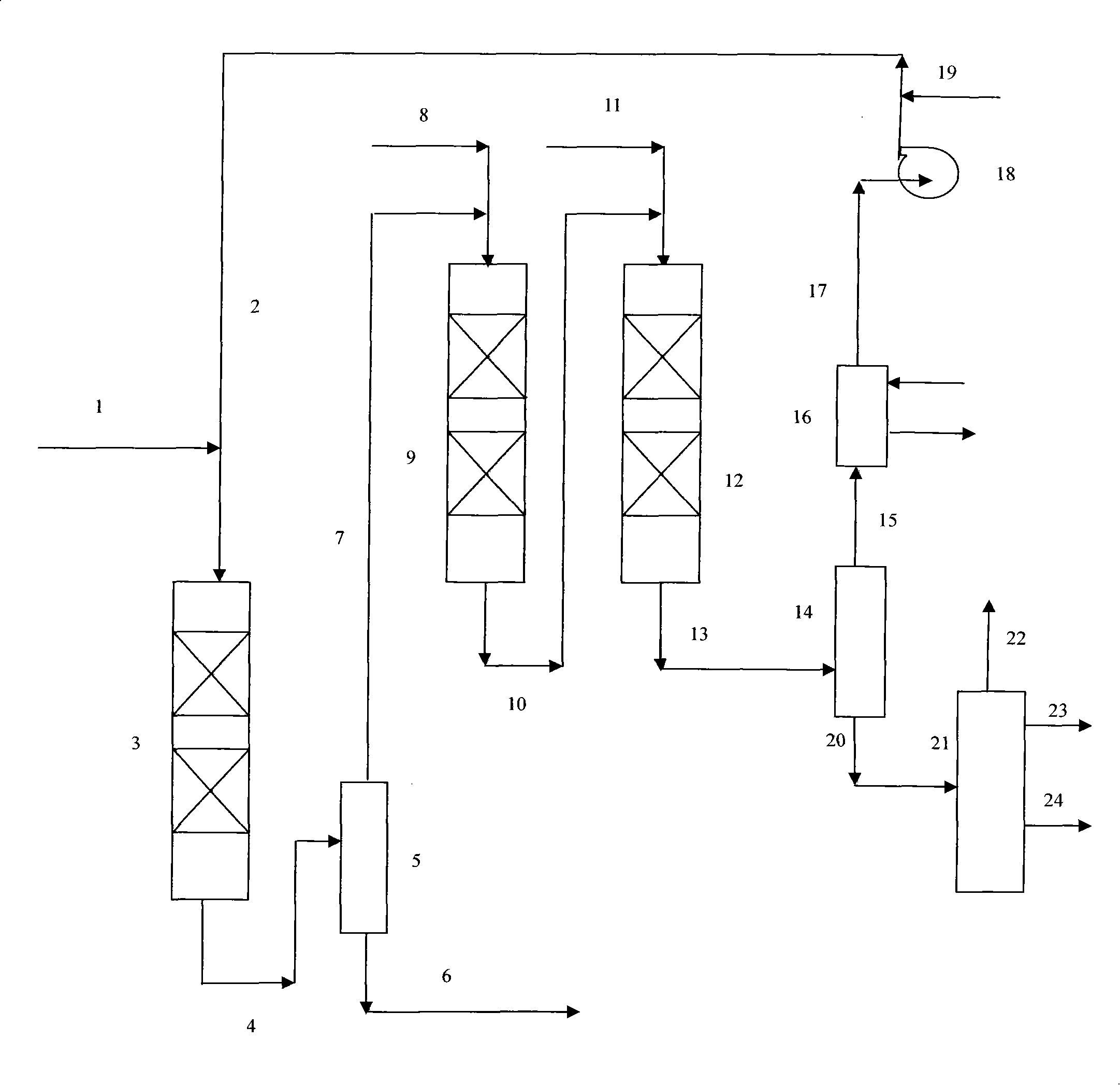

The invention discloses a hydrogenation combined method for diesel oil, which comprises the following steps: dividing a straight-run diesel oil raw material and / or a coking diesel oil raw material into two parts of materials, performing hydro-upgrading reaction on one part of the material after being mixed with a catalytically cracked diesel oil raw material, and performing hydro-refining reaction on the other part of the material. The hydro-refining reaction and the hydro-upgrading reaction share a set of hydrogen recycling system. The combined method of the invention meets the requirement of products with different amounts and quality by flexibly adjusting raw oil ratio of two reaction zones, reduces operating severity of a hydro-upgrading reaction zone and prolongs the operation cycle at the same time. In addition, the method of the invention simplifies the process flow, can decrease equipment and reduces investment and operation cost. The method is suitable for hydro-processes of various inferior-quality distillate raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

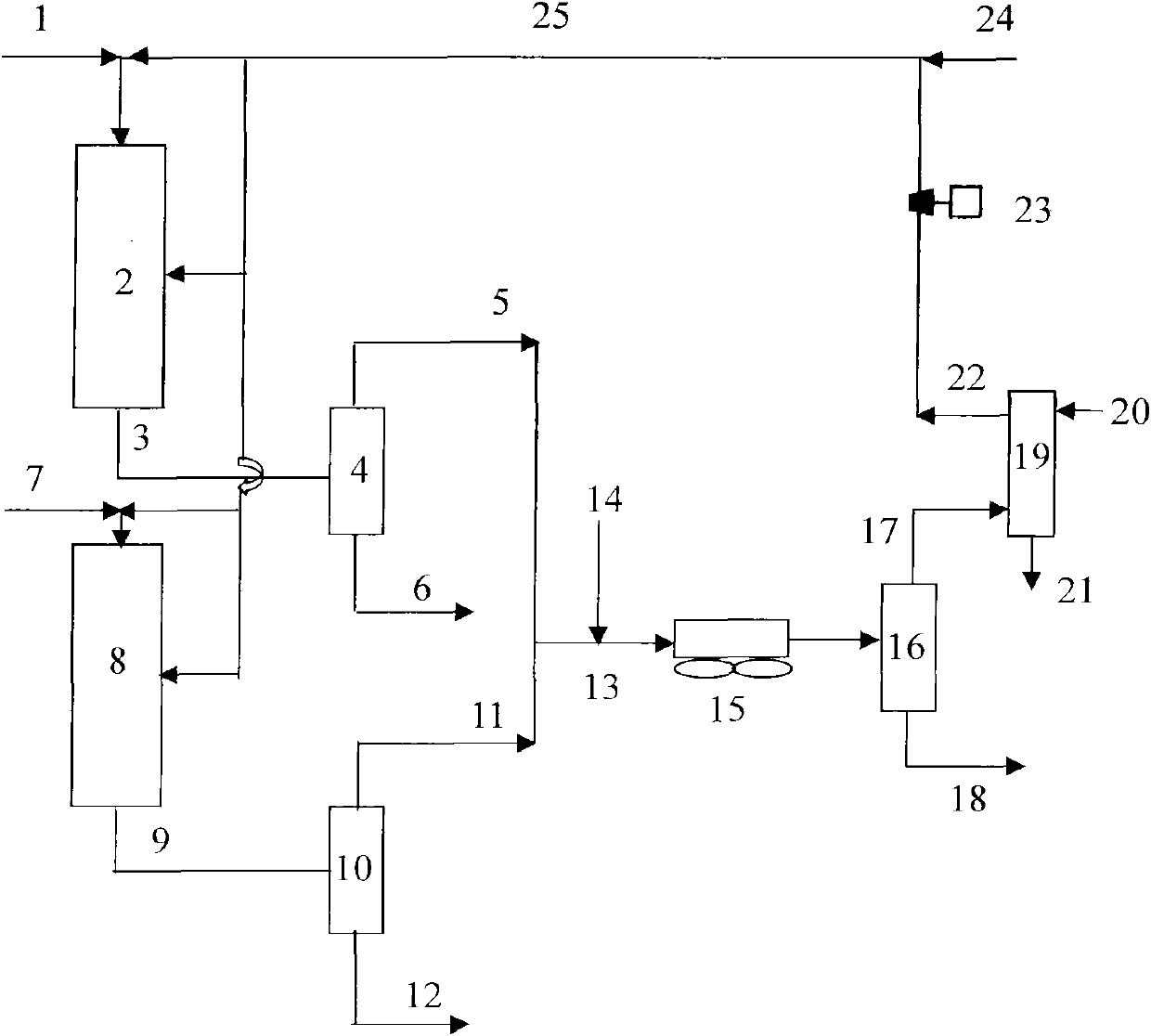

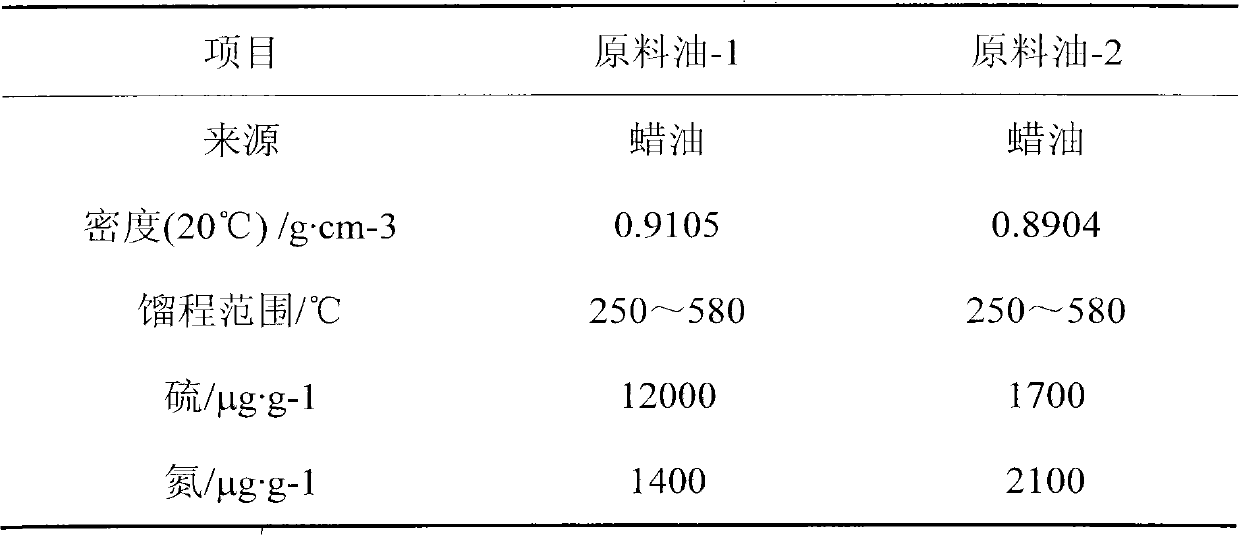

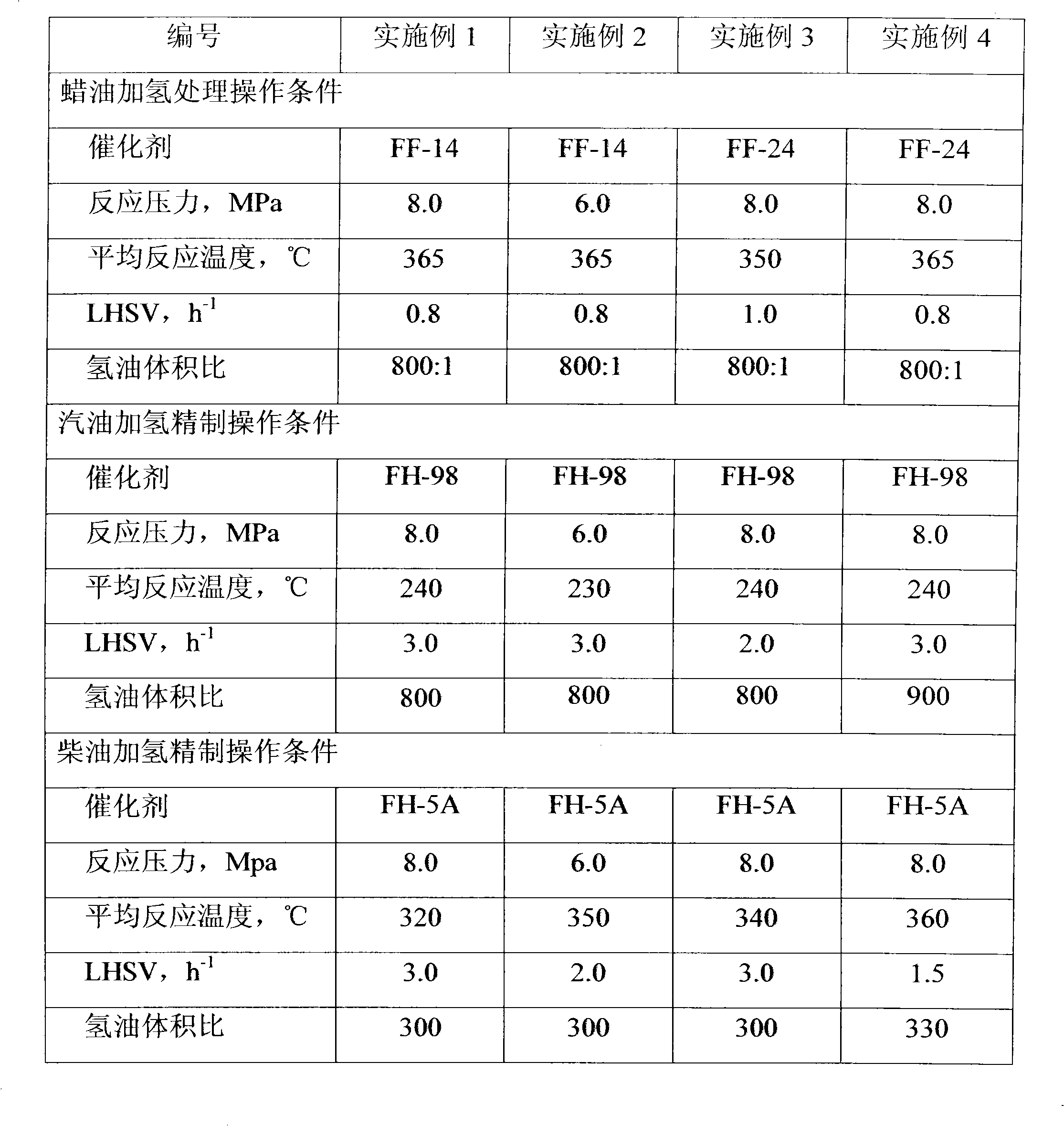

Hydro-desulphurizing combined method

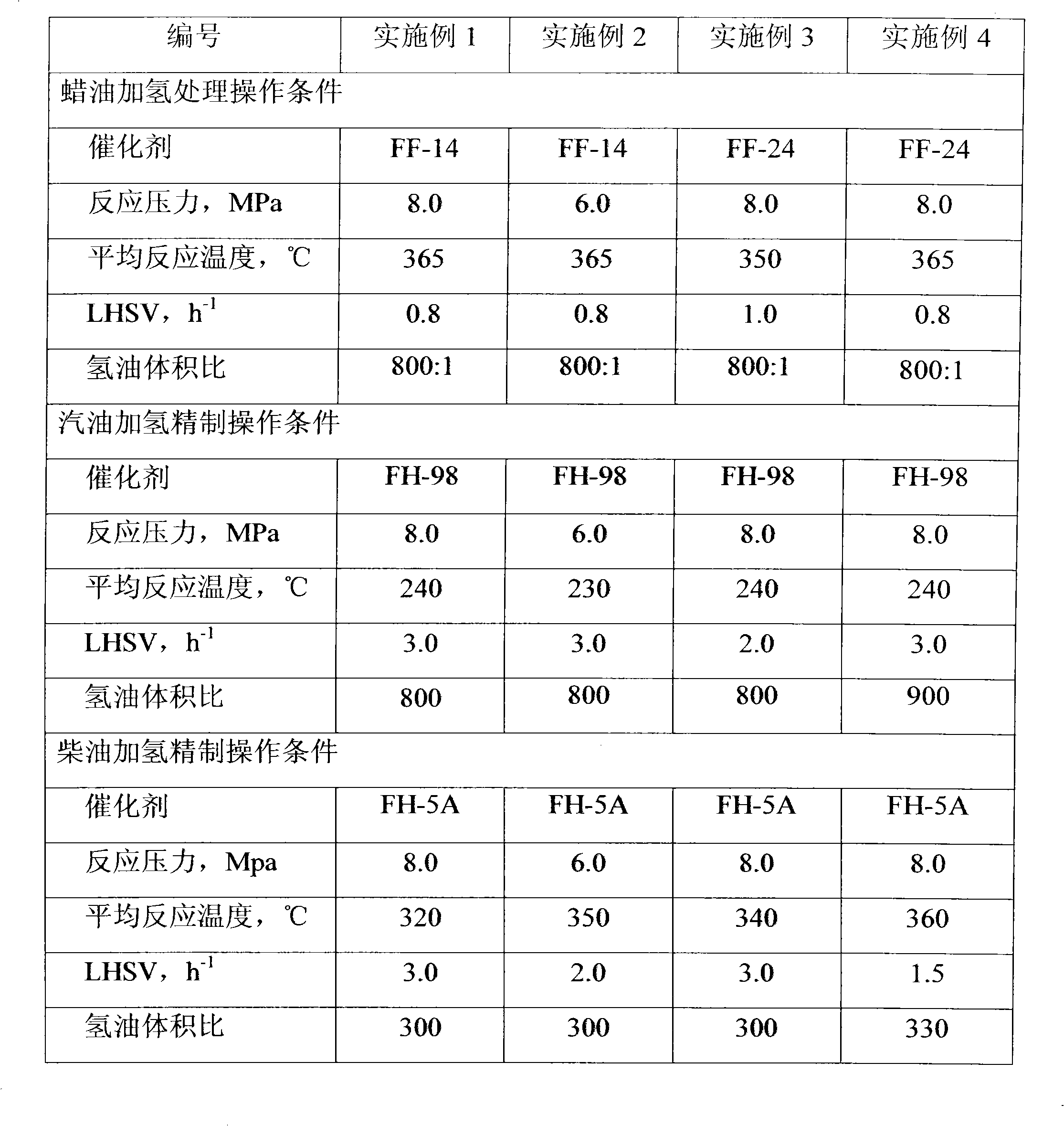

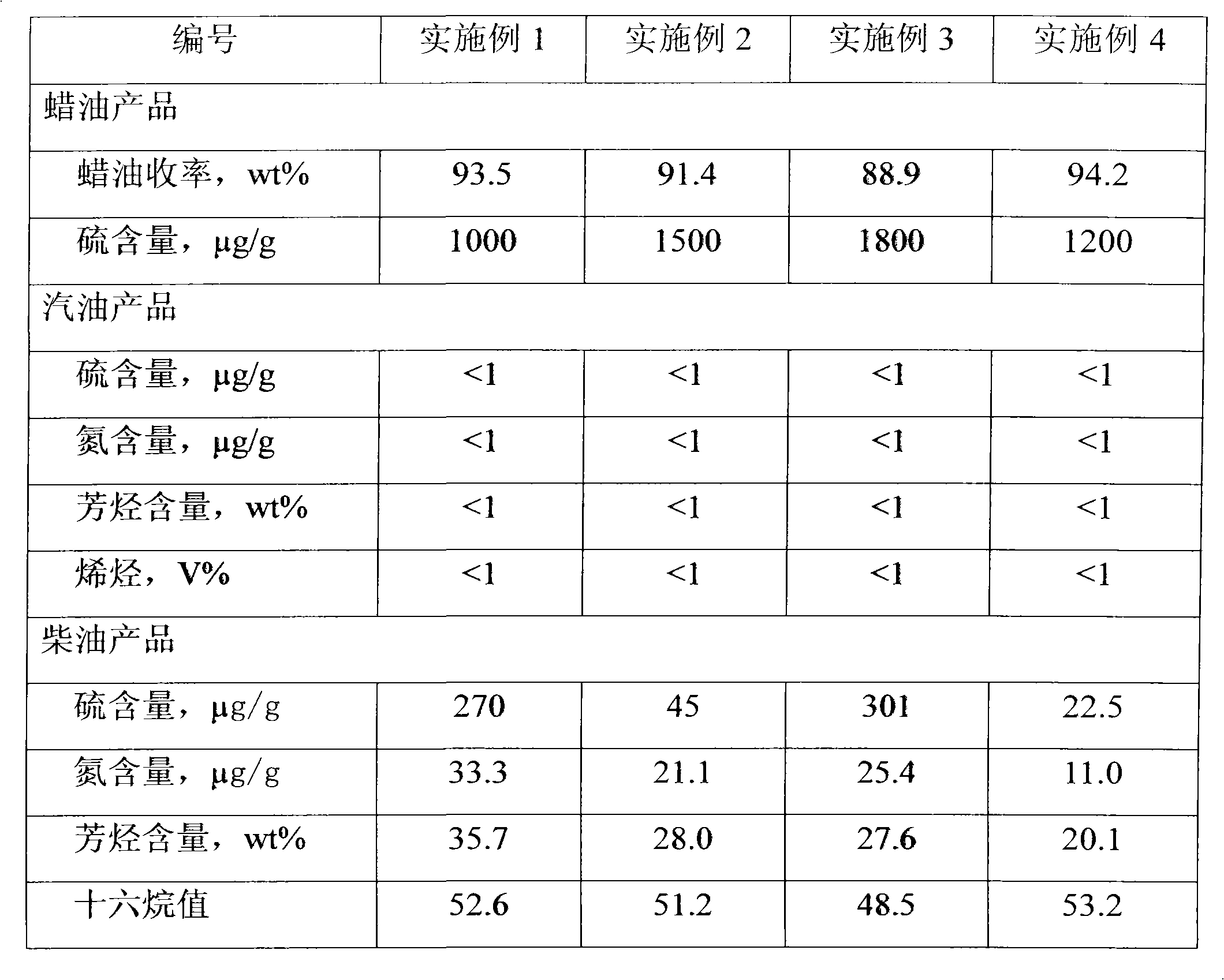

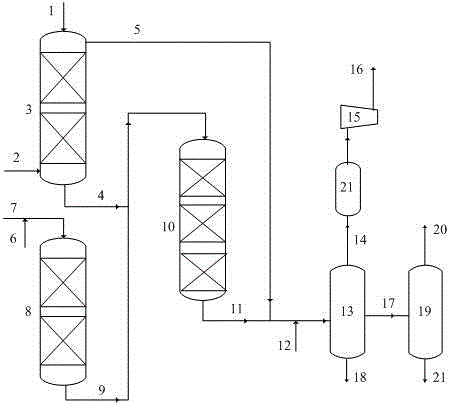

ActiveCN101412928AImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesWaxChemistry

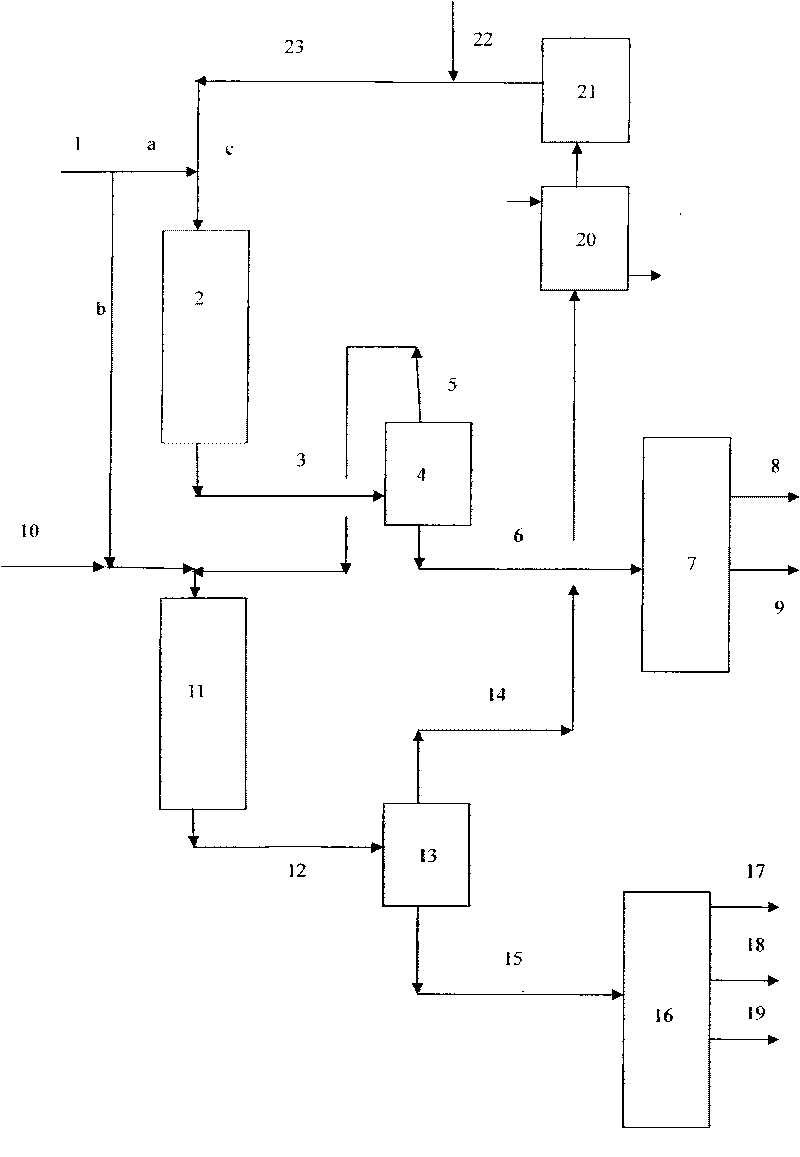

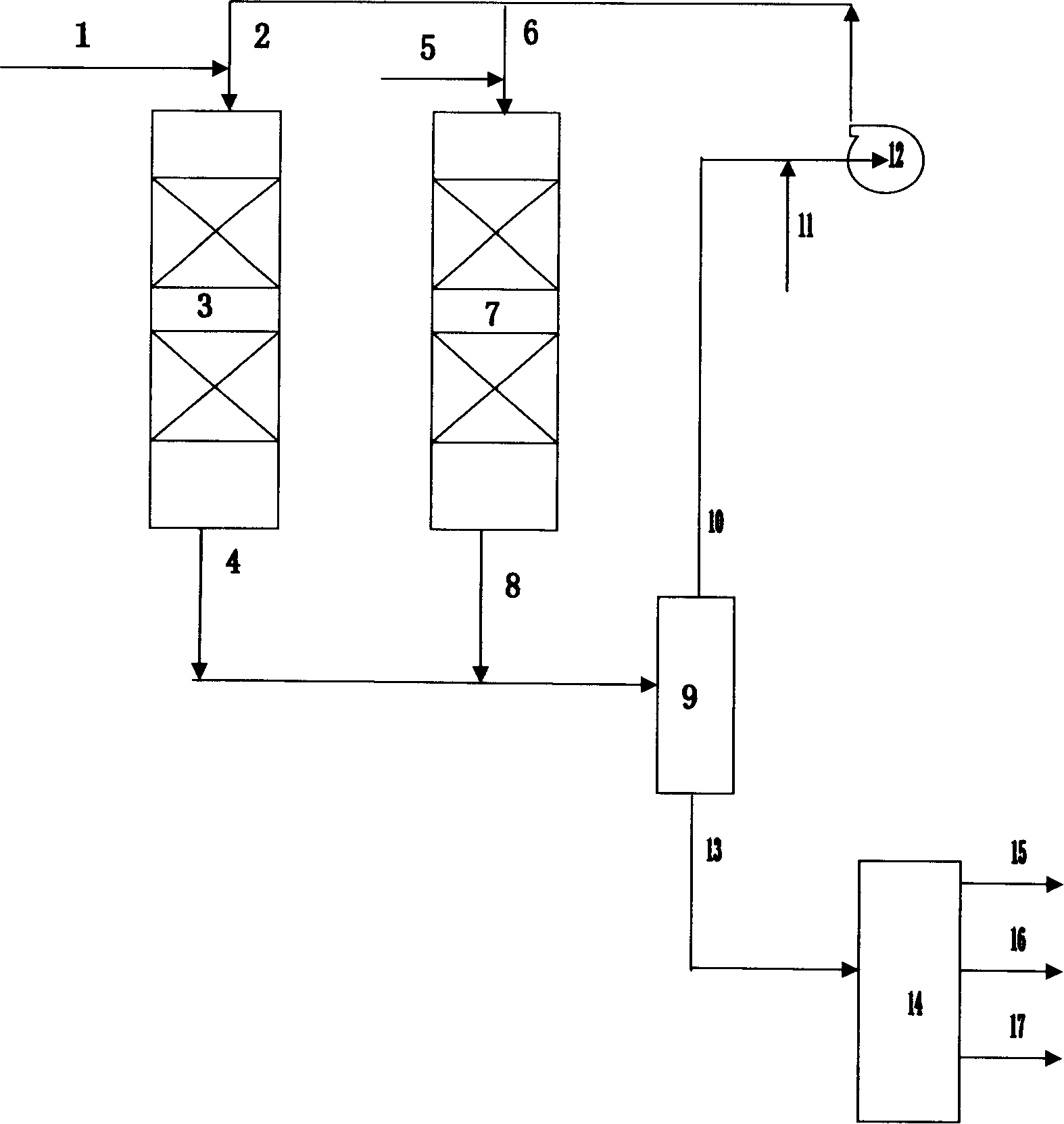

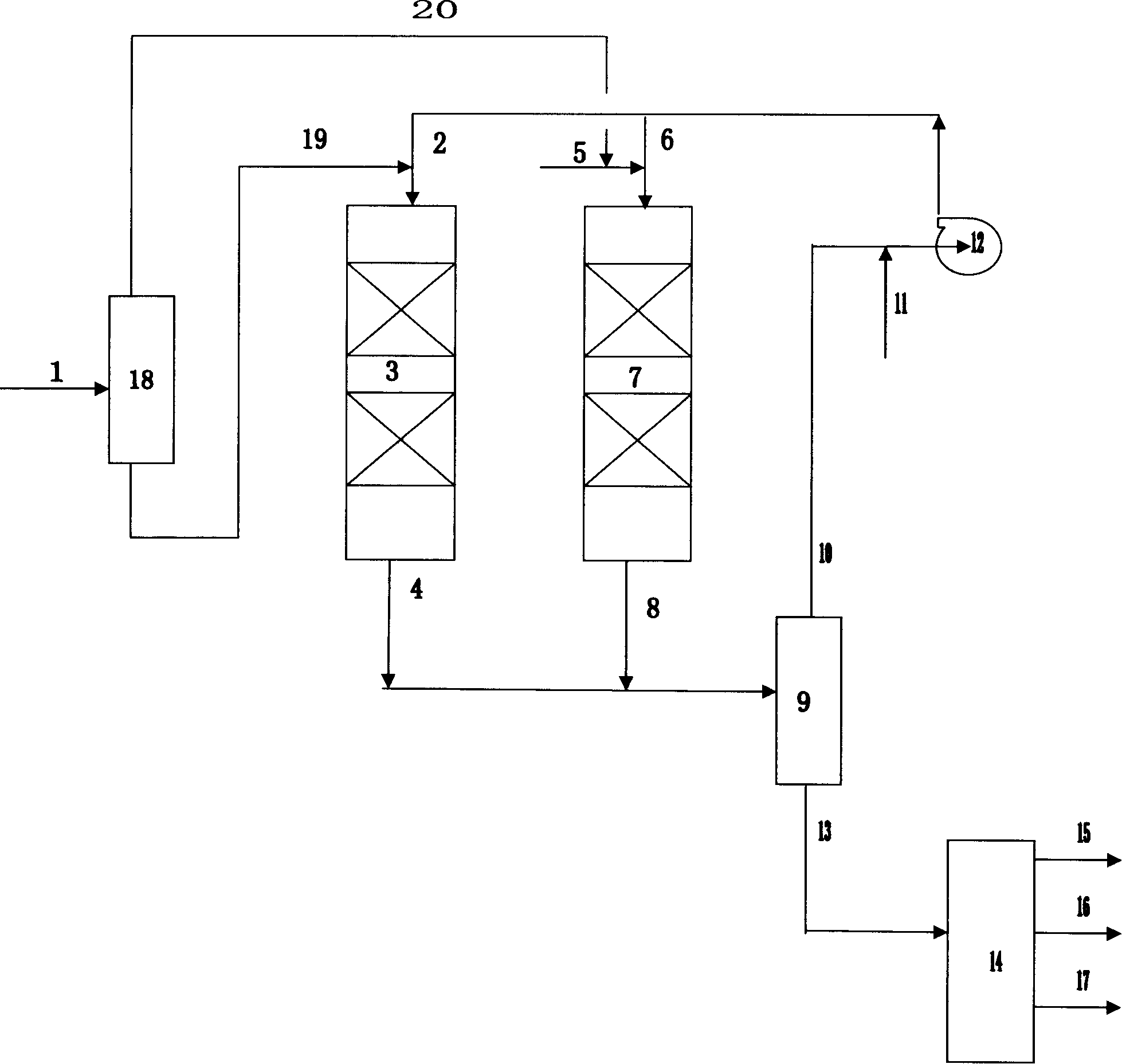

The invention discloses a hydroprocessing and desulfurizing integration method, in particular a wax oil hydroprocessing and diesel hydrorefining integration process method. The method comprises the following steps: raw wax oil passes through a first reaction zone in the presence of hydrogen first, liquid obtained after separation of products is taken as catalytic cracking raw materia; hydrogen-containing gas and gas phase of light liquid obtained after separation are mixed with diesel raw material to enter a second reaction zone; and gas after separation of products in the second reaction zone is recycled after desulfurization, and liquid obtained after separation is subjected to fractionation to obtain hydrogenant naphtha and hydrogenant diesel. The method aims at technical characteristics of wax oil hydroprocessing and hydrorefining, integrates the two technologies for application, simplifies process flow, simplifies the process flow at the same time of meeting the same product requirements, and reduces equipment, investment and operating cost. The method is applied to newly built equipment to reduce equipment investment and applied to expanding reformation of the prior devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Unionfining technological process

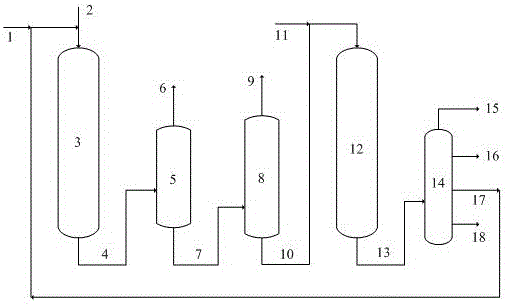

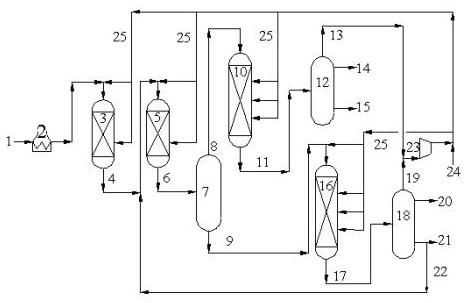

ActiveCN101412924AImprove product qualityQuality improvementTreatment with hydrotreatment processesWaxNaphtha

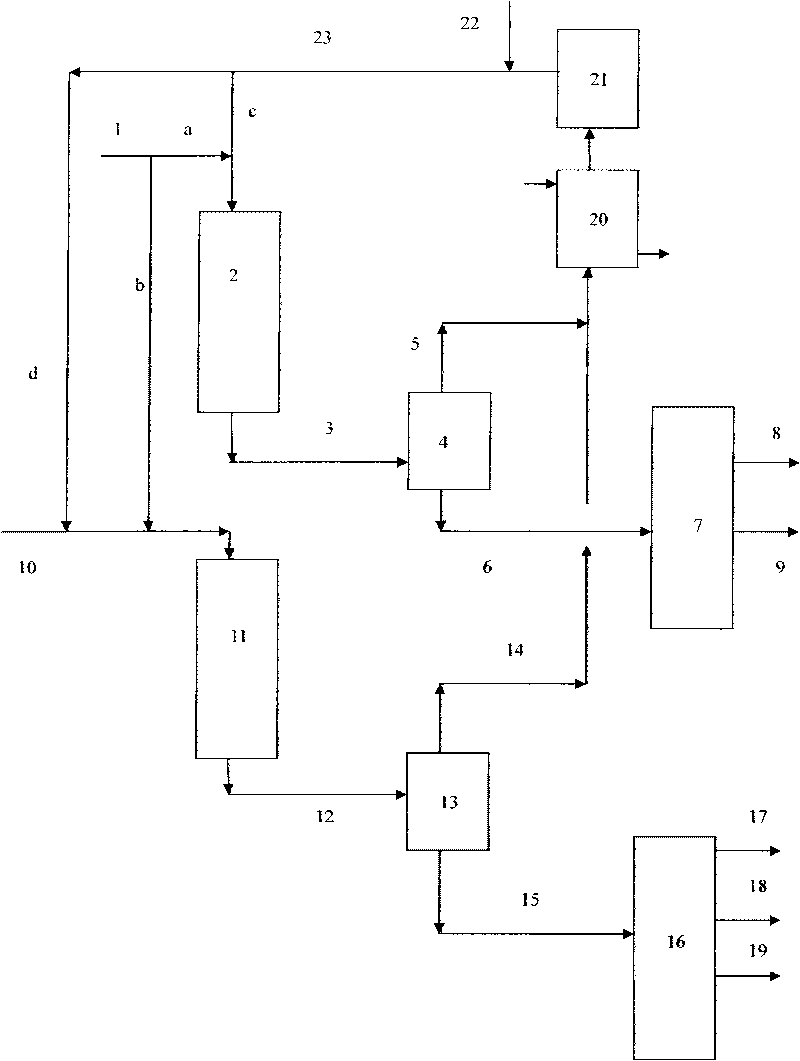

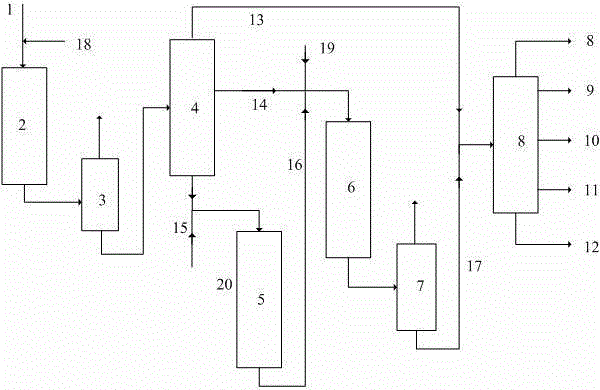

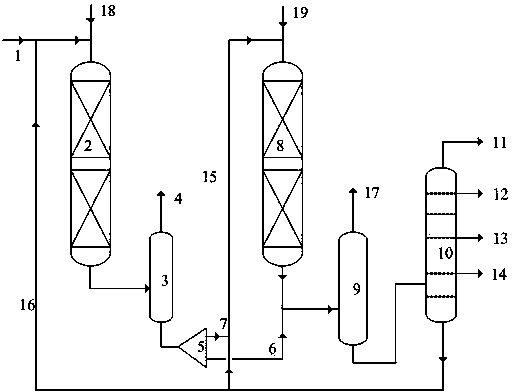

The invention discloses a combined hydrogenation process method, in particular a combined hydrogenation process method for wax oil hydroprocessing, poor ignition quality fuel hydroupgrading and diesel hydrorefining. The method comprises the following steps: raw wax oil passes through a first reaction zone in the presence of hydrogen first, liquid after separation of products is taken as catalyticcracking raw material; the gas phase obtained through separation is mixed with poor ignition quality fuel raw material to enter a second reaction zone for hydroupgrading reaction; products in the second reaction zone are mixed with other diesel raw materials to enter a third reaction zone for hydrorefining reaction; and gas after separation of products in the third reaction zone is recycled afterdesulfurization, and liquid obtained after separation is subjected to steam stripping to obtain hydrogenant naphtha and hydrogenant diesel. The method aims at technical characteristics of wax oil hydroprocessing, poor ignition quality fuel hydroupgrading and diesel hydrorefining, integrates the three technologies organically, simplifies process flow at the same time of meeting the same product requirements, and reduces equipment, investment and operating cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior distillate oil combination hydrogenation modified method

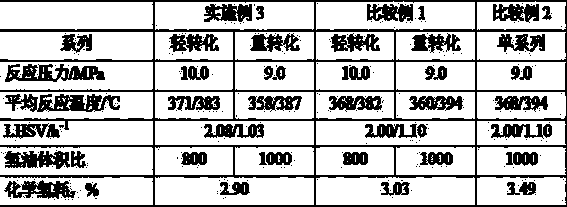

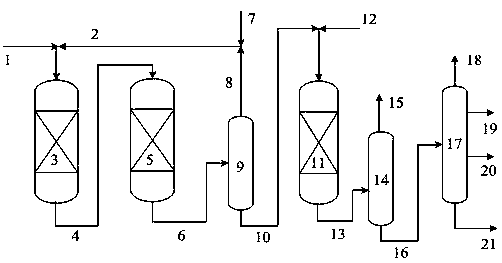

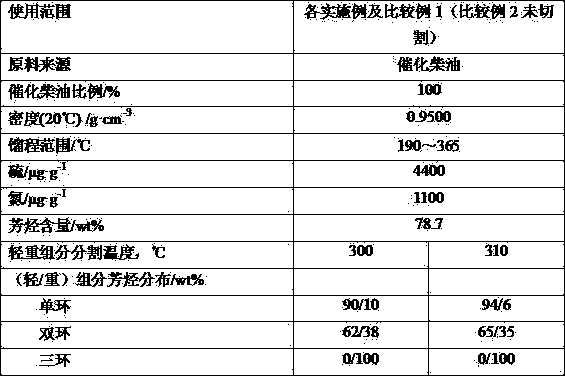

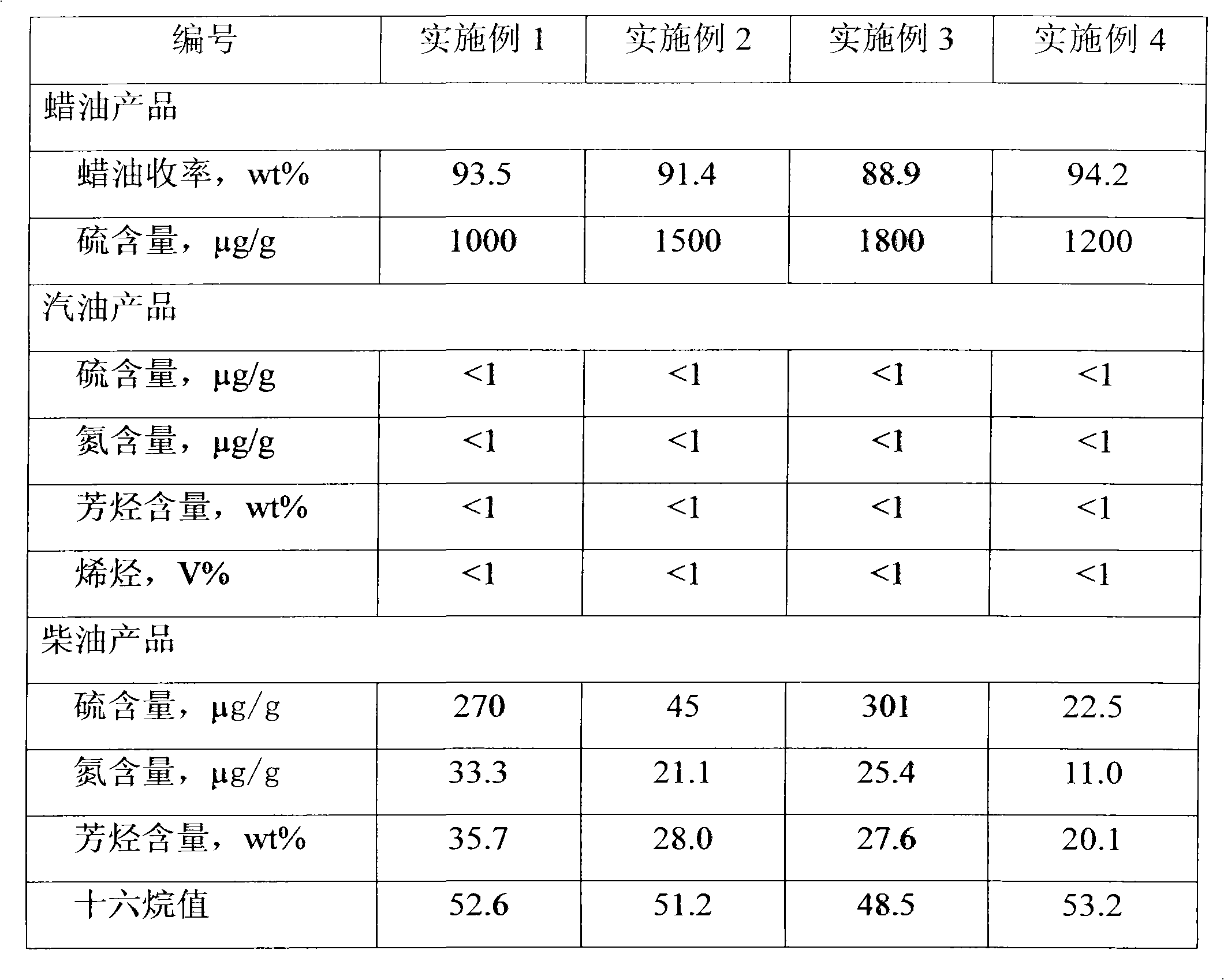

ActiveCN101165142AWide distillation rangeLow yieldTreatment with hydrotreatment processesGasoline stabilisationSulfurNitrogen

The combined inferior distillate oil hydrogenating modification process includes hydrogenation modifying catalytically cracked diesel oil fraction material, hydrogenation refining pyrolytic distillate oil material, and separating the reaction effluent from both hydrogenation modifying and hydrogenation refining in a common separating system. The hydrogenating process of the present invention has high diesel oil yield, and is simple and low in cost, and the hydrogenated product has low content of S, P and other impurities and greatly raised cetane number. The process is suitable for hydrogenating of different types of inferior distillate oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

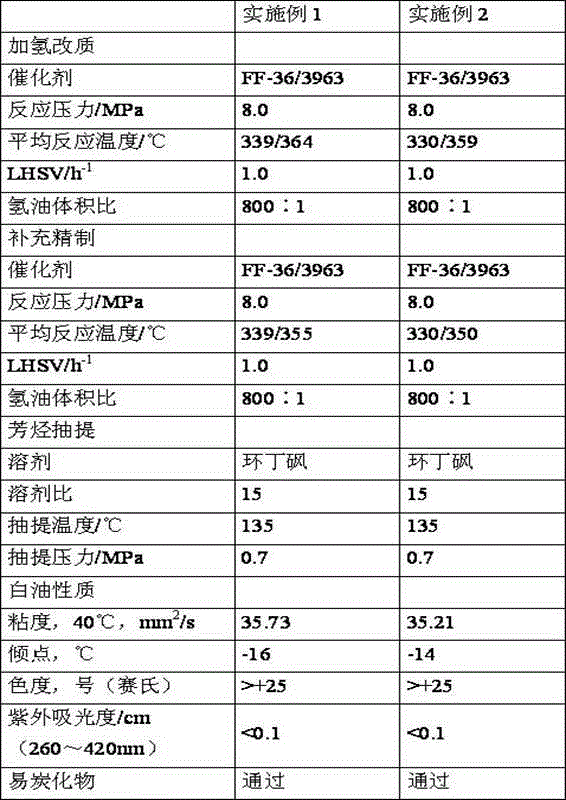

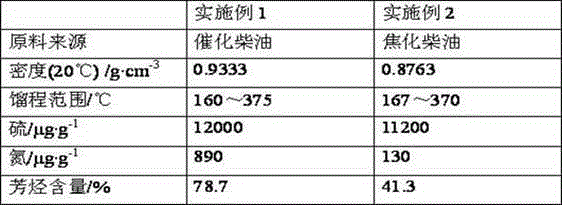

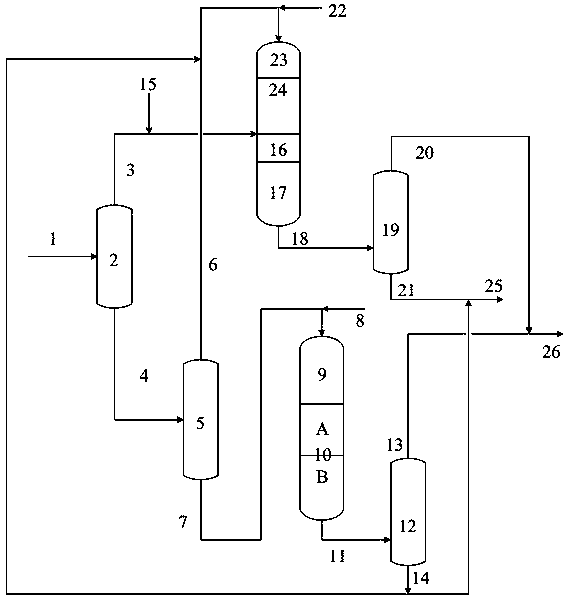

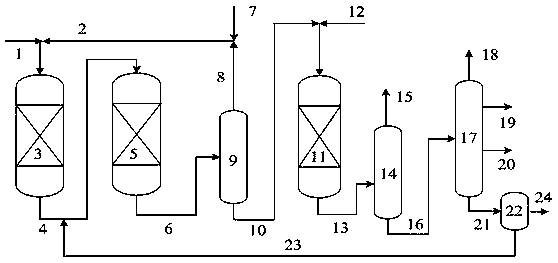

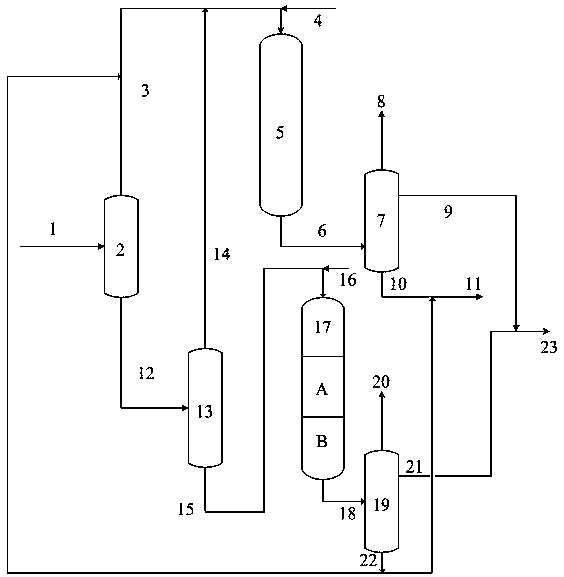

Hydrogenation combination process for producing high-quality white oil

ActiveCN104560179ALow aromatic contentLess equipmentTreatment with hydrotreatment processesHydrocarbon oils treatment productsWhite oilDiesel fuel

The invention discloses a hydrogenation combination process for producing high-quality white oil. The process comprises the following steps: (1) mixing a poor diesel raw material with hydrogen under the hydro-upgrading process condition, and enabling a mixture to pass through a hydro-upgrading reaction region with a hydro-upgrading catalyst bed layer; (2) feeding a reaction effluent obtained in the step (1) into a hydro-refining reaction region for hydro-refining; (3) performing gas-liquid separation on a reaction effluent obtained in the step (2), and feeding an obtained liquid product into an aromatic extraction device for aromatic separation to obtain an aromatic component and a non-aromatic raffinate oil component, wherein the aromatic component can enter a catalytic cracking unit or a BTX aromatic unit, and the non-aromatic raffinate oil component is the high-quality white oil. The non-aromatic raffinate oil obtained by the process is the high-quality white oil which is sulfur-free and aromatic-free and has the pour point of lower than 0 DEG C and the Saybolt color value of more than +20; due to the adoption of the process, the poor diesel can be converted into a high-added-value white oil product to the maximum extent, the application range of the poor diesel is extended, and the economic benefit of the processed poor diesel is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

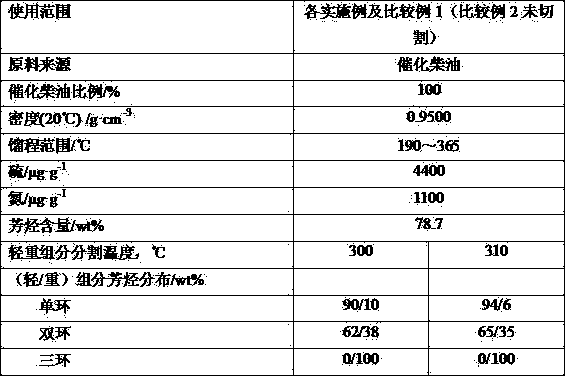

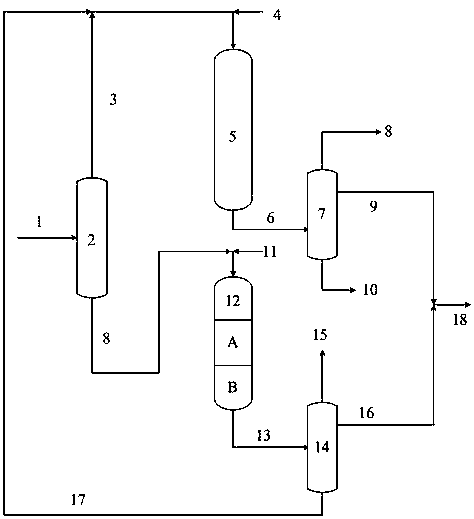

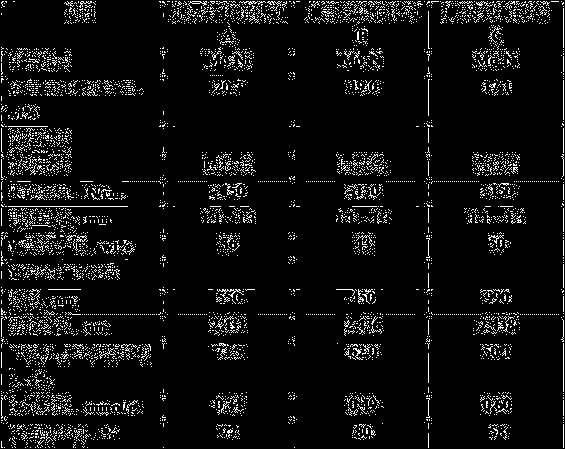

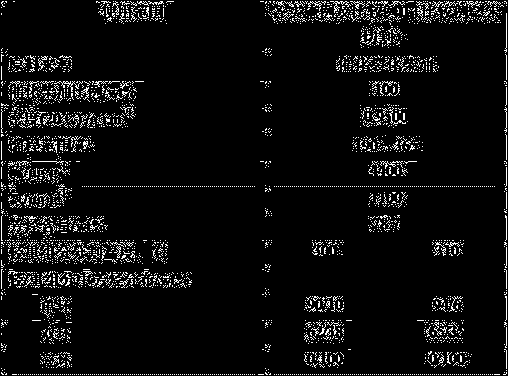

Processing treatment method of catalytic diesel

ActiveCN108102709AEasy to handleImprove targetingHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjectedto hydrofining and hydro-conversion reactions, and gasoline and diesel components are obtained; the heavy components are separated, and a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained; the non-triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, the triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, and gasoline components and diesel components are obtained; a gasoline product is obtained after gasoline from all parts is mixed, and a diesel product is obtained after diesel components from all parts are mixed. Through the reasonable separation and processing process, different types of raw materials can be selectively and independently processed, so that qualified gasoline and dieselproducts can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-upgrading combined method

ActiveCN101412926AImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesWaxHydrogen

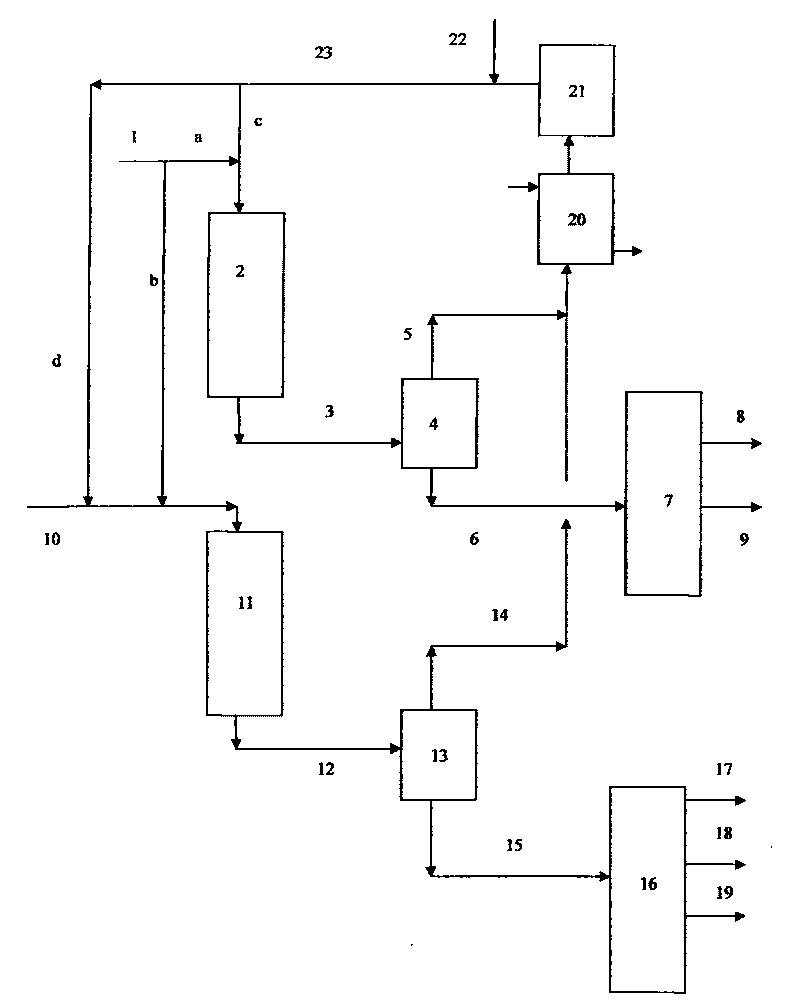

The invention discloses a hydroprocessing and upgrading integration method, in particular a wax oil hydroprocessing and diesel hydroupgrading integration process. The method comprises the following steps: raw wax oil passes through a first reaction zone in the presence of hydrogen first, liquid obtained after separation of products is taken as catalytic cracking raw materia; the gas phase obtained through separation is mixed with diesel raw material to enter a second reaction zone; and gas after separation of products in the second reaction zone is recycled after desulfurization, and liquid obtained after separation is subjected to fractionation to obtain hydrogenant naphtha and hydrogenant diesel. The method aims at technical characteristics of wax oil hydroprocessing and hydroupgrading,integrates the two technologies for application, simplifies process flow, and reduces equipment, investment and operating cost at the same time of reaching high product quality. The method is appliedto newly built equipment to reduce equipment investment and applied to expanding reformation of the prior devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

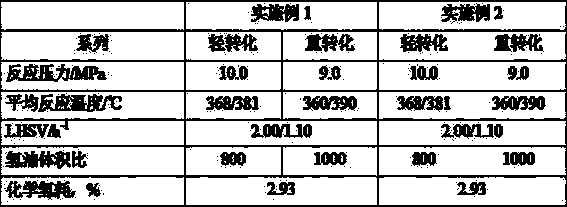

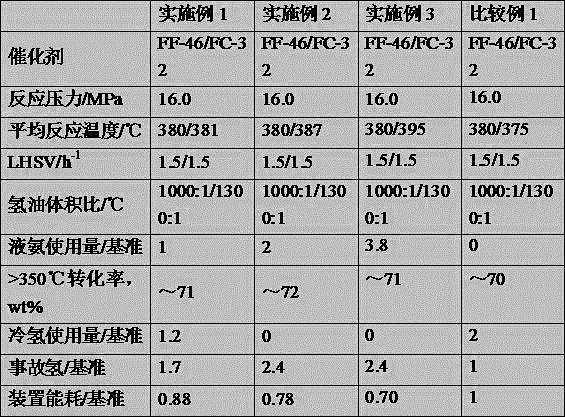

Hydrocracking technological method for processing inferior raw material

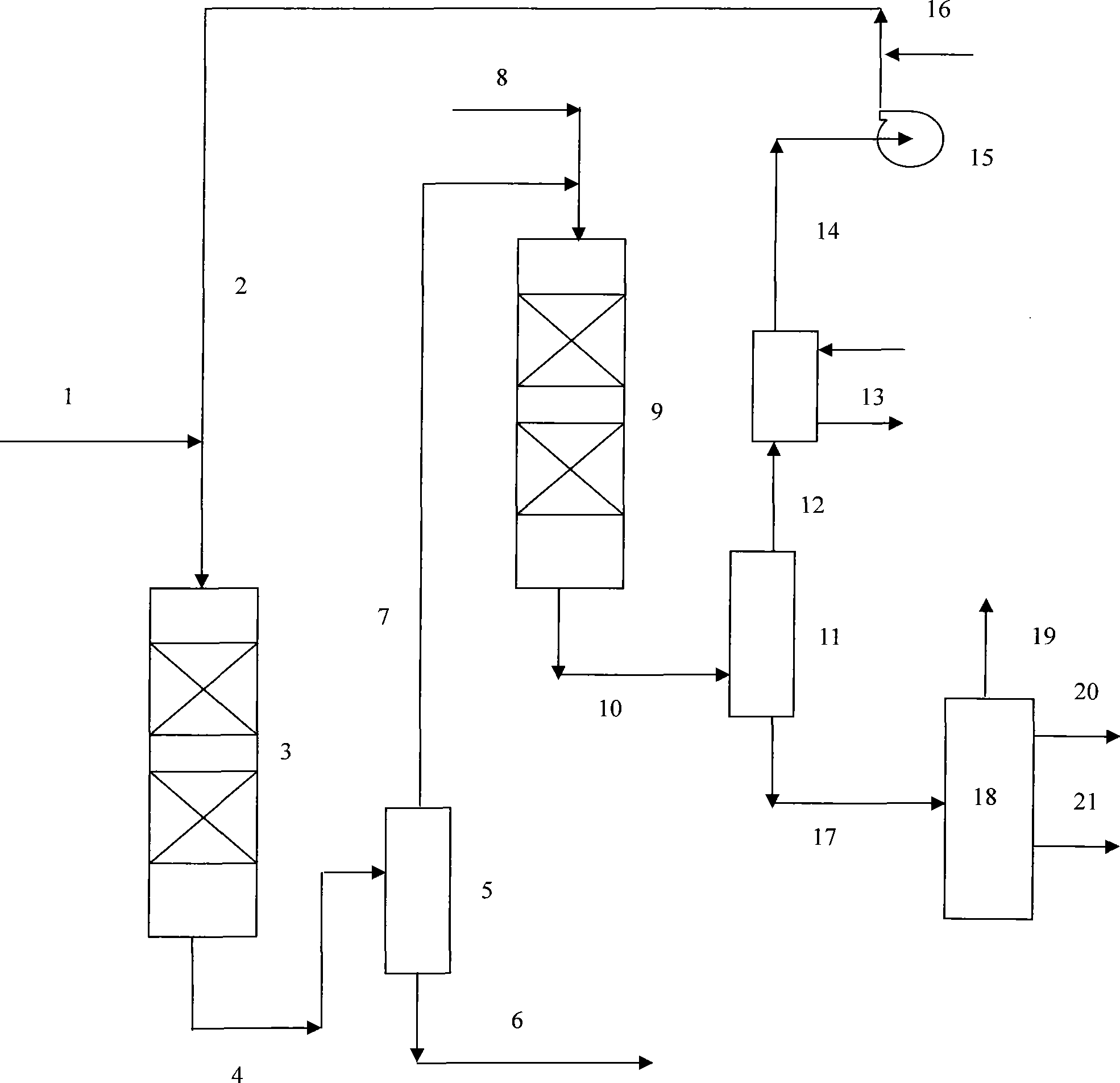

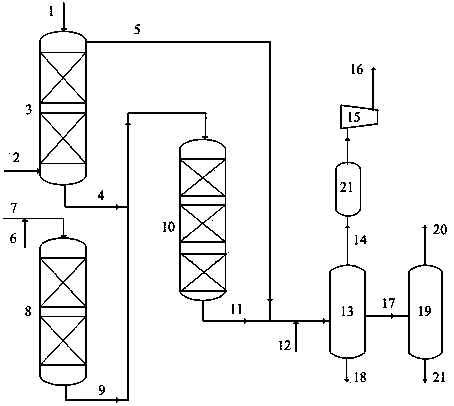

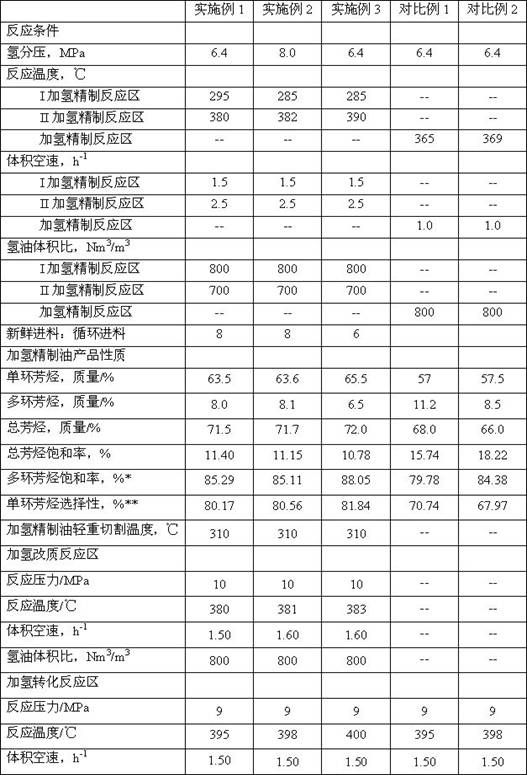

ActiveCN103059944AReduced volumetric space velocityHigh volumetric space velocityTreatment with hydrotreatment processesLiquid productLow nitrogen

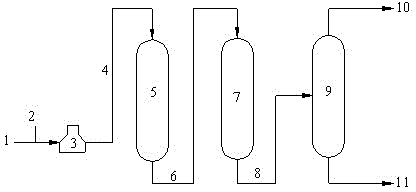

The invention relates to a hydrocracking method for processing an inferior raw material. The method comprises: passing the inferior raw material through a first hydrotreating area, and subjecting the liquid product to fractionation in a first fractionating tower; passing the obtained heavy distillate oil through a second hydrotreating area, and passing the obtained effluent and intermediate distillate generated by the fractionation to a hydrocracking area together; and leaving the cracking liquid product and light distillate generated in the fractionation to enter a second fractionating tower, thus obtaining the product. Compared with the prior art, the invention makes use of fractionation to separate out the light and intermediate distillate with a low nitrogen content from the hydrotreating product, thus reducing the space velocity of feed entering the second hydrotreating area, and also being able to properly mitigating the operation severity of the first hydrotreating area. Therefore, while meeting the demand for long-period operation treatment of the inferior raw material, the method provided in the invention also enhances the device processing capacity to the utmost. On the basis of improving the product quality, the method can achieve an ideal comprehensive processing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

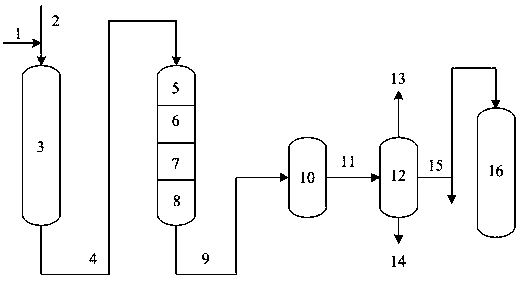

Combined hydrocracking method used for processing inferior raw materials

ActiveCN103773481AExtended operating cycleImprove product qualityTreatment with hydrotreatment processesLiquid productProcess engineering

The invention discloses a combined hydrocracking method used for processing inferior raw materials. According to the combined hydrocracking method, counter current hydrogenation technology is adopted for pre-treatment of high-nitrogen raw oil, and parallel hydrogenation technology is adopted for pre-treatment of common raw oil; a liquid obtained via counter current hydrogenation and an effluent of parallel hydrogenation are delivered into a hydrocracking reactor for reaction; an effluent of hydrocracking is mixed with gas obtained via counter current hydrogenation; and gas-liquid separation is carried, and an obtained liquid product is subjected to fractionation so as to obtain a hydrocracking product. The liquid obtained via the pre-treatment of high-nitrogen raw oil contains almost no ammonia, so that the liquid is mixed with the effluent obtained via hydrogenation of common raw oil, and a mixture is subjected to hydrocracking, influences of ammonia partial pressure on hydrocracking are reduced, and apparatus running period is prolonged; and at the same time, an ammonium salt is obtained via combination of NH3 in an ammonia-containing gas with hydrogen sulfide, is washed via water injection, so that amine liquid consumption of a recycle hydrogen desulfurization tower is reduced greatly, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

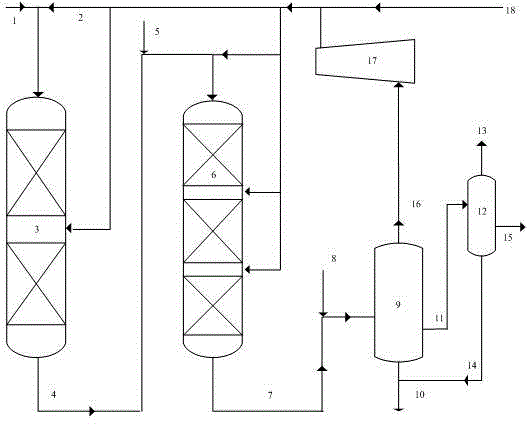

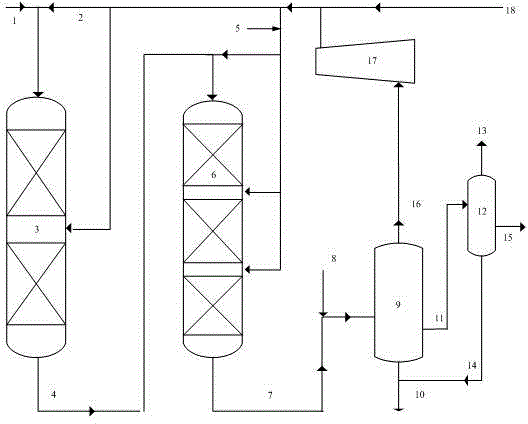

A method of improving running safety of a hydrocracking device

ActiveCN105754649AGood temperature matchingRaise the reaction temperatureTreatment with hydrotreatment processesReaction temperatureProcess engineering

A method of hydrocracking is disclosed. The method does not need any transformation on a hydrocracking device and only utilizes present procedures of the device. Passivation gas containing ammonia gas is injected into a catalyst bed layer through an inlet of a hydrocracking reactor to reduce reaction activity, the reaction temperature of a cracking catalyst is increased under the premise of not greatly changing product distribution, and the temperature of an outlet of a refining reactor and the temperature of an inlet of the cracking reactor are matched reasonably to the utmost. The method improves operation safety, flexibility and emergency incident responding capability of the device, avoids overtemperature, and reduces energy consumption of the device to a certain degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing gasoline and base oil by a catalyst grading technology

ActiveCN109988631AReduce sulfur contentBoost octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxHydrogen

The invention discloses a method for producing gasoline and base oil by a catalyst grading technology. The method comprises the following steps: a) under a hydrofining condition, mixing a heavy oil raw material with hydrogen, and allowing the mixture to flow through a reaction zone containing a hydrofining catalyst bed layer to perform a restrictive hydrofining reaction; b) allowing the reaction effluent obtained in the step a) to flow through a reaction zone containing a graded wax oil hydro-conversion catalyst bed layer to perform a hydro-conversion reaction under hydro-conversion process conditions; and allowing the reaction effluent to flow through a reaction zone containing a wax oil hydrocracking catalyst bed layer to perform a hydrocracking reaction under hydrocracking process conditions; and c) carrying out gas-liquid separation, fractionation and other processes on the reaction effluent obtained in the step b) to obtain converted gasoline, converted diesel oil and unconvertedoil. The method provided by the invention can convert heavy distillate oil into gasoline and base oil, and provides an economically feasible route for processing of inferior raw materials and production of gasoline and base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel

ActiveCN108102702AHigh Yield High OctaneReduced activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsContact reactionGasoline

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel oil

ActiveCN108102713AGreat suitability and pertinenceImprove product qualityTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryGasoline

The invention discloses a processing method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected to hydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is subjected to hydrofining and hydroconversion, and a gasoline component and a dieseloil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that qualified gasoline and diesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil .

Owner:CHINA PETROLEUM & CHEM CORP +1

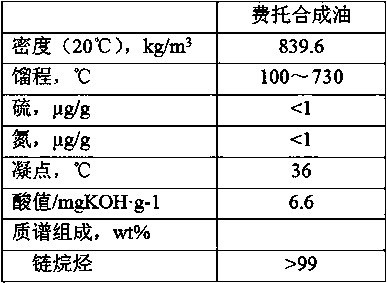

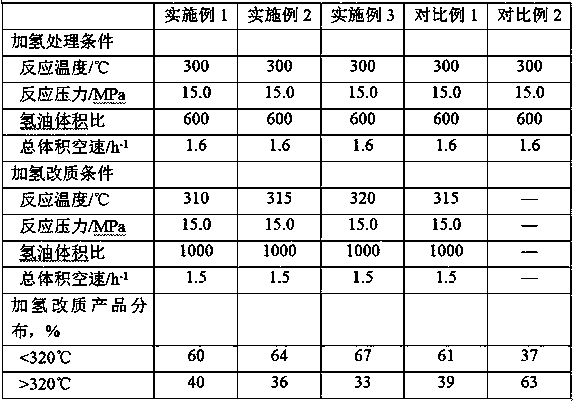

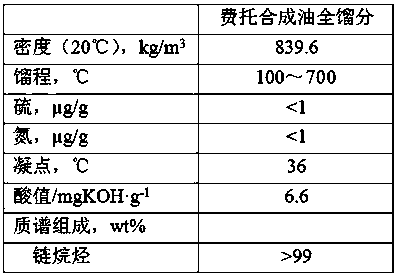

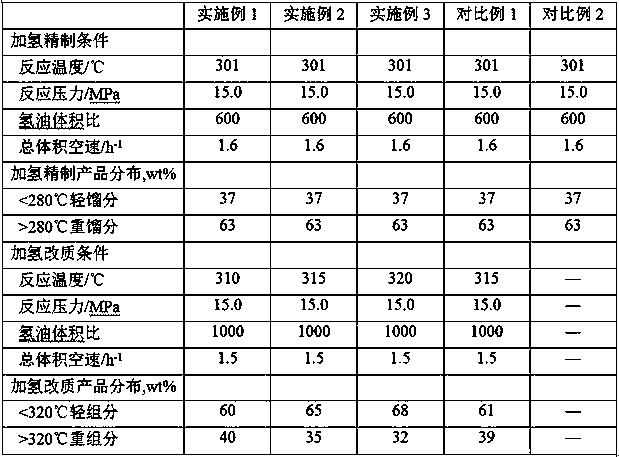

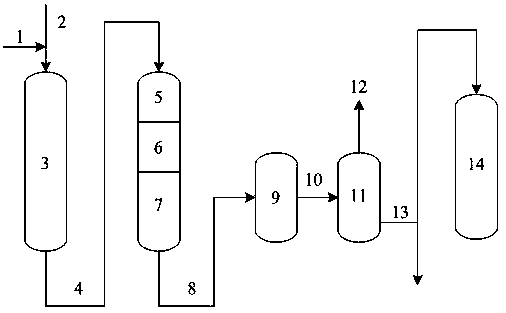

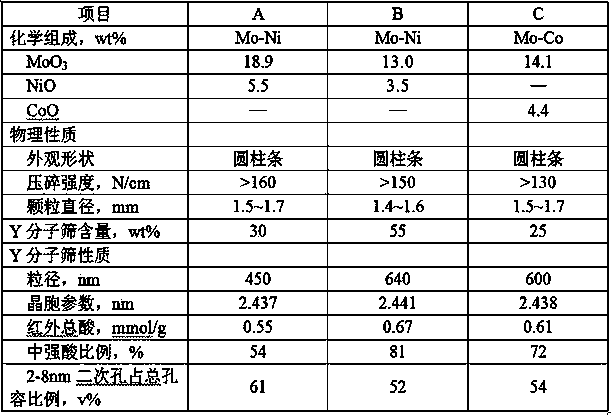

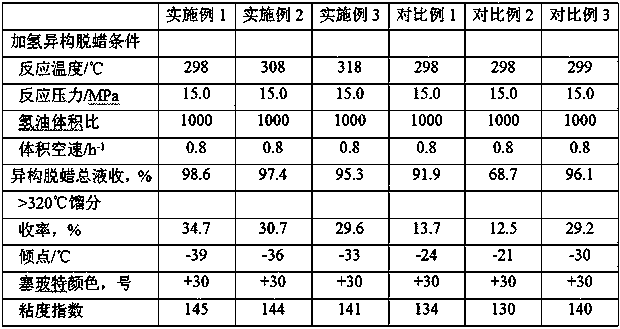

Hydrogenation method for producing API III <+> base oil from Fischer-Tropsch synthetic oil

ActiveCN111378495ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Generated oil obtained through separation of a hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reactionzone, and different types of API III <+> lubricating oil base oil products are obtained through separation and fractionation of an isodewaxing reaction effluent. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of Fischer-Tropsch synthetic oil

ActiveCN111378494ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Heavy distillate oil generated oil obtained through hydrofining-hydro-upgrading reaction effluent separation enters an isodewaxing reaction zone, and an isodewaxing reaction effluent is subjected to separation and fractionation to obtain different types of API III <+> lubricating oil base oil products. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fractionhydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing gasoline by a catalyst grading technology

ActiveCN109988651AReduce sulfur contentBoost octaneTreatment with hydrotreatment processesRefining by aromatic hydrocarbon hydrogenationGasolineFuel oil

The invention discloses a method for producing gasoline by a catalyst grading technology. The method comprises the following steps: carrying out restricted hydrogenation saturation on a conventional heavy raw material; then performing hydro-conversion to produce high-quality gasoline or blend components under certain limited process conditions and a specific catalyst grading condition; and subjecting a byproduct liquid phase component to a cracking reaction to produce other fuel oil products with high quality or high-quality ethylene cracking raw materials. The method disclosed by the invention can be used for producing a target product to the maximum extent on the basis of selective processing of the heavy fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing gasoline and oil with a low condensation point by a catalyst grading technology

ActiveCN109988644ADoes not affect octane ratingIncrease contentMolecular sieve catalystsTreatment with hydrotreatment processesGas phaseFractionation

The invention discloses a method for producing gasoline and diesel oil with a low condensation point by a catalyst grading technology. The method comprises the following steps: a) mixing a heavy oil raw material with hydrogen, and allowing the mixture to pass through a reaction zone containing a hydrorefining catalyst bed layer to perform a restrictive hydrorefining reaction; b) allowing a reaction effluent obtained in the step a) to pass through a reaction zone containing a graded wax oil hydro-conversion catalyst bed layer under hydro-conversion process conditions, and allowing a reaction effluent to enter a flash tank for separation so as to obtain a gas phase and a liquid phase; c) performing subsequent separation, steam stripping and fractionation on the gas phase in the step b) to obtain converted gasoline; and d) allowing the liquid phase in the step b) to pass through a reaction zone containing a wax oil hydrocracking catalyst bed layer to perform a hydrocracking / isomerizationreaction under a hydrocracking condition, and separating and fractionating the reaction effluent to obtain heavy naphtha, low-condensation-point diesel oil and unconverted oil. According to the method, high-quality gasoline blending components and low-condensation-point diesel oil can be obtained, and good economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation process combination method

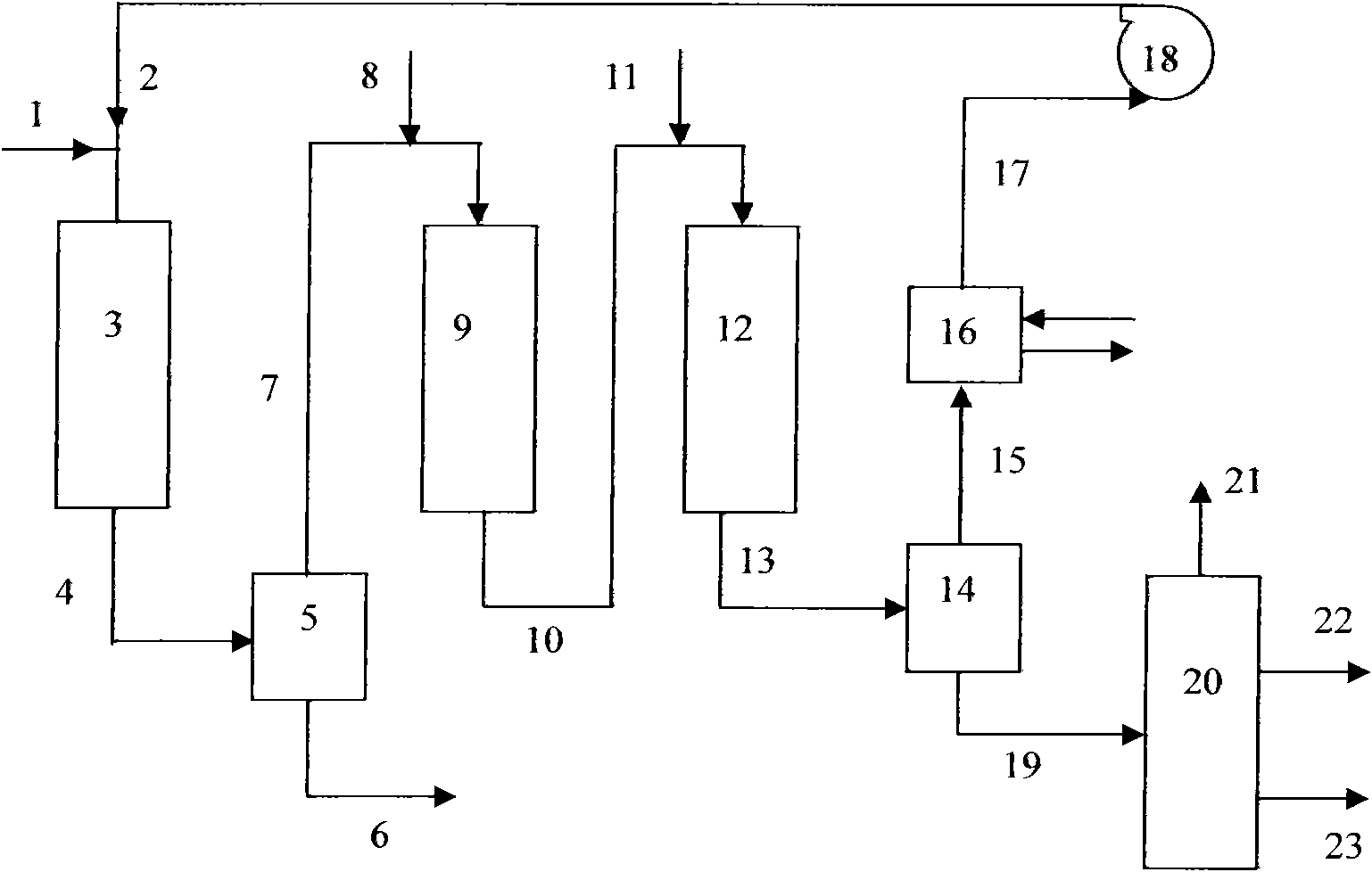

ActiveCN102465030AIncrease temperatureAvoid cokingTreatment with hydrotreatment processesWaxGas phase

The invention discloses a hydrogenation process combination method. The method comprises the following steps: 1, mixing a wax oil raw material with hydrogen, allowing them to go through a first hydrogenation reaction zone, and separating the obtained hydrogenation reaction effluent by allowing it to enter a hot high-pressure separator; 2, mixing the gas phase and coked gasoline obtained in step 1, and allowing them to go through a second hydrogenation reaction zone under gasoline hydrofinishing conditions; and 3, directly mixing the reaction effluent obtained in step 2 with a diesel oil raw material, allowing them to go through a third hydrogenation reaction zone under diesel oil hydrofinishing conditions, and separating and fractionating the obtained reaction effluent to obtain lightweight products. According to the invention, the wax oil hydrogenation high-pressure separation gas is directly mixed with the coked gasoline fraction to generate heat, so the temperature of the material entering the coked gasoline hydrogenation reaction zone is elevated, thereby reaction demands are satisfied; and a coked gasoline heating furnace an be canceled, so a work stopping problem caused by furnace tube coking generated during heating the coked gasoline in the heating furnace is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

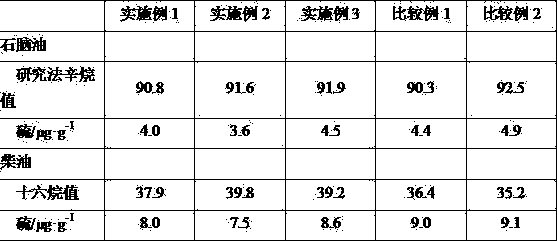

A combined process method for processing low-quality diesel oil

ActiveCN103805247BReduce sulfur contentOctane RatingTreatment with hydrotreatment processesOil processingFractionation

The invention discloses a combination method used for processing inferior diesel oil. According to the combination method used for processing inferior diesel oil, secondary processing of inferior diesel fractions comprises following steps: hydro-upgrading reaction is carried out firstly, and aromatic hydrocarbon selective ring-opening reaction is carried out; a reaction effluent is separated so as to obtain a liquid material, and the liquid material is extracted; aromatic hydrocarbon components are taken as catalytic cracking raw materials and are subjected to catalytic cracking reaction, and a gas material, catalytic gasoline and catalytic diesel oil are obtained via separation and fractionation; and catalytic diesel oil can be recycled back to a hydro-upgrading reactor. The combination method is capable of converting inferior diesel oil into catalytic gasoline products with high octane value as much as possible, increasing gasoline yield and octane value of a catalytic unit as far as possible, and providing an economical feasible technical route for inferior diesel oil processing.

Owner:CHINA PETROLEUM & CHEM CORP +1

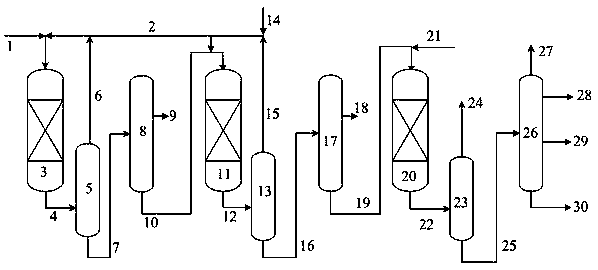

Hydrogenation process for producing API III < + > base oil from Fischer-Tropsch synthetic oil

ActiveCN111378493ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a hydrogenation process for producing API III < + > lubricating oil base oil from Fischer-Tropsch synthetic oil. The Fischer-Tropsch synthetic oil is used as a raw material, and a hydrofining-hydro-upgrading-isodewaxing two-stage hydrogenation process is adopted to produce API III + lubricating oil base oil. The generated oil obtained by separation of hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reaction zone; and the process further includes separating and fractionating the isodewaxing reaction effluent to obtain different types of API III + lubricating oil base oil products, cooling fractionated vacuum bottom oil to obtain an incompletely converted wax component, and returning the incompletely converted wax component to the hydro-upgrading reactor to continue the upgrading reaction. The invention has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthesis oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing treatment method of catalytic diesel oil

ActiveCN108102703AIdeal comprehensive processing effectLow operating costTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected tohydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is separated, a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained, the obtained triaromatic hydrocarbon component is subjected to hydrofining and hydroconversion, and a gasoline component and a diesel oil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that inferior catalytic cracking diesel oil can be reasonably used to produce qualified gasoline anddiesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Unionfining technological process

ActiveCN101412924BImprove product qualityQuality improvementTreatment with hydrotreatment processesWaxNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible hydrocracking method

ActiveCN103059960BImprove adaptabilityFlexible productionTreatment with hydrotreatment processesWaxHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

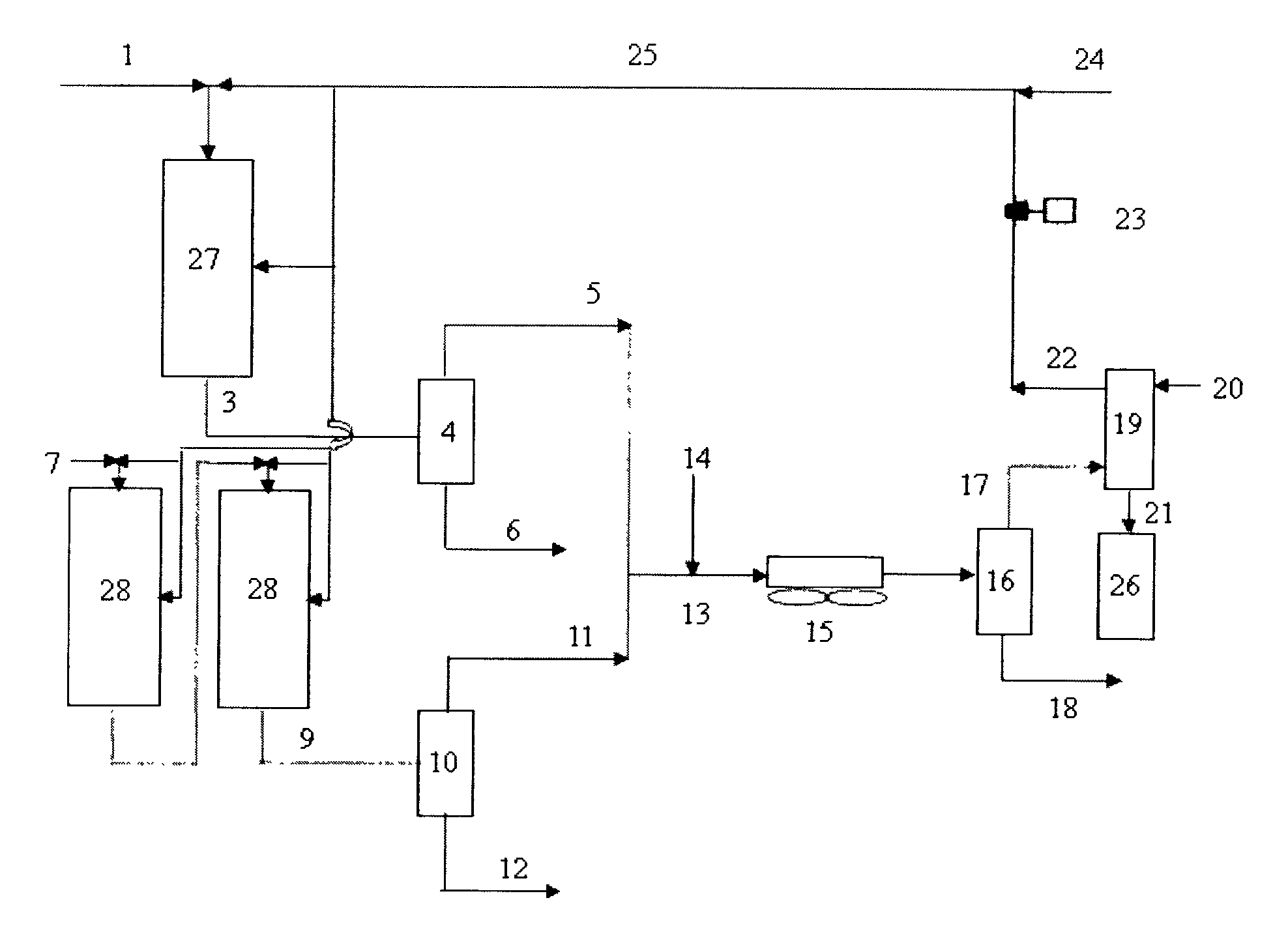

Integrated hydroprocessing method

ActiveCN102329639BExtended replenishment periodReduce consumptionTreatment with hydrotreatment processesHydrogenSulfur

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated hydrocracking method

ActiveCN102329640BReduce injection volumeImprove product qualityTreatment with hydrotreatment processesHydrogenSulfur

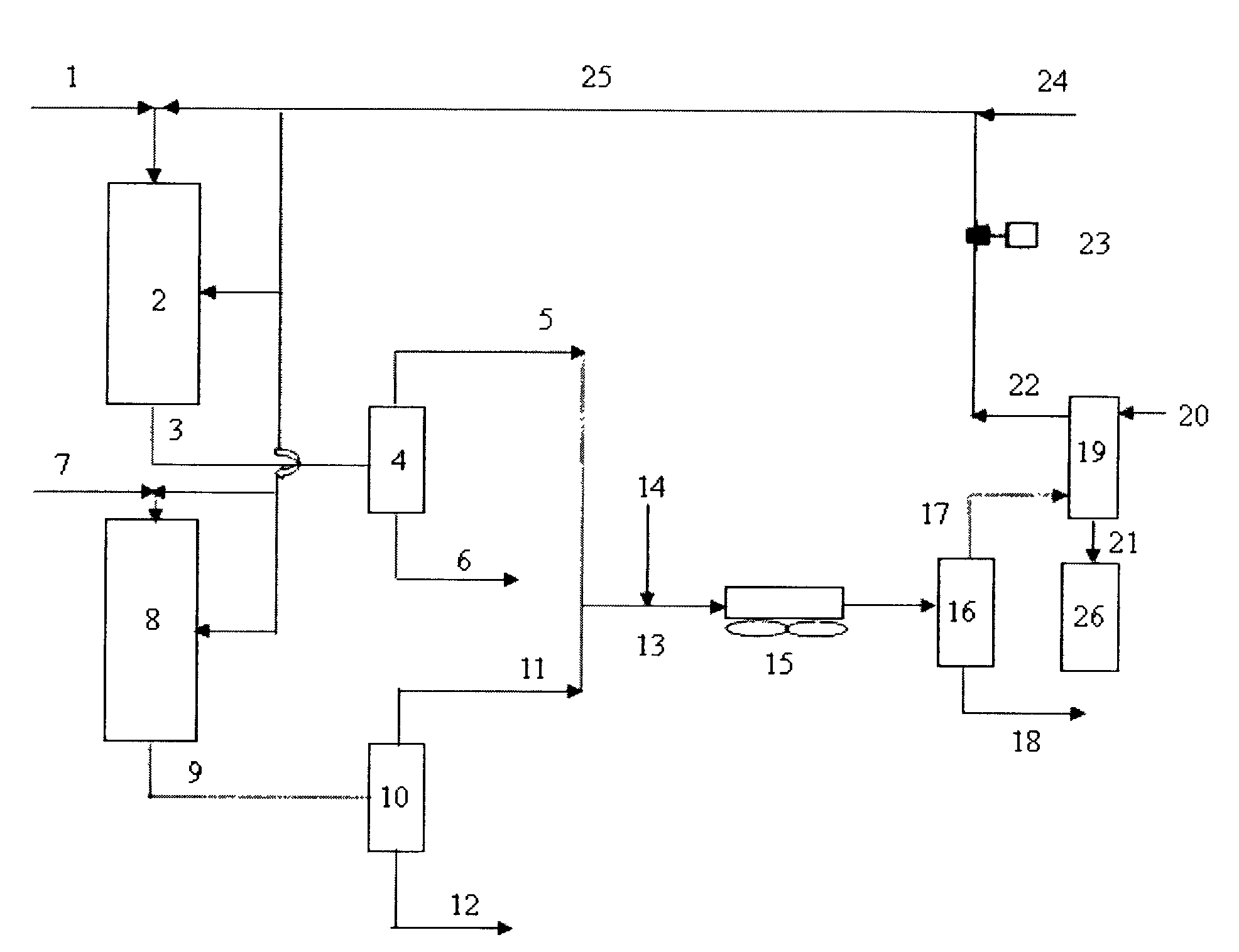

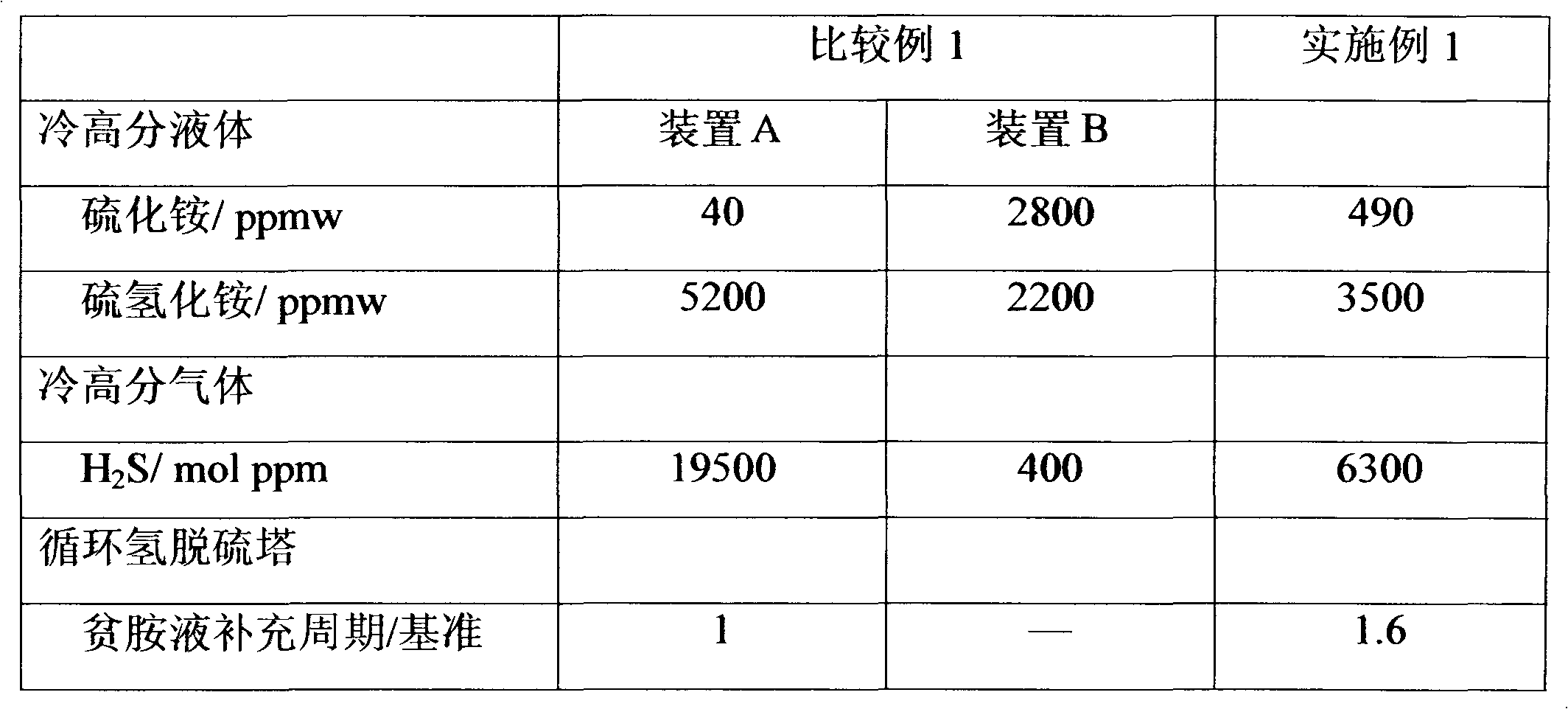

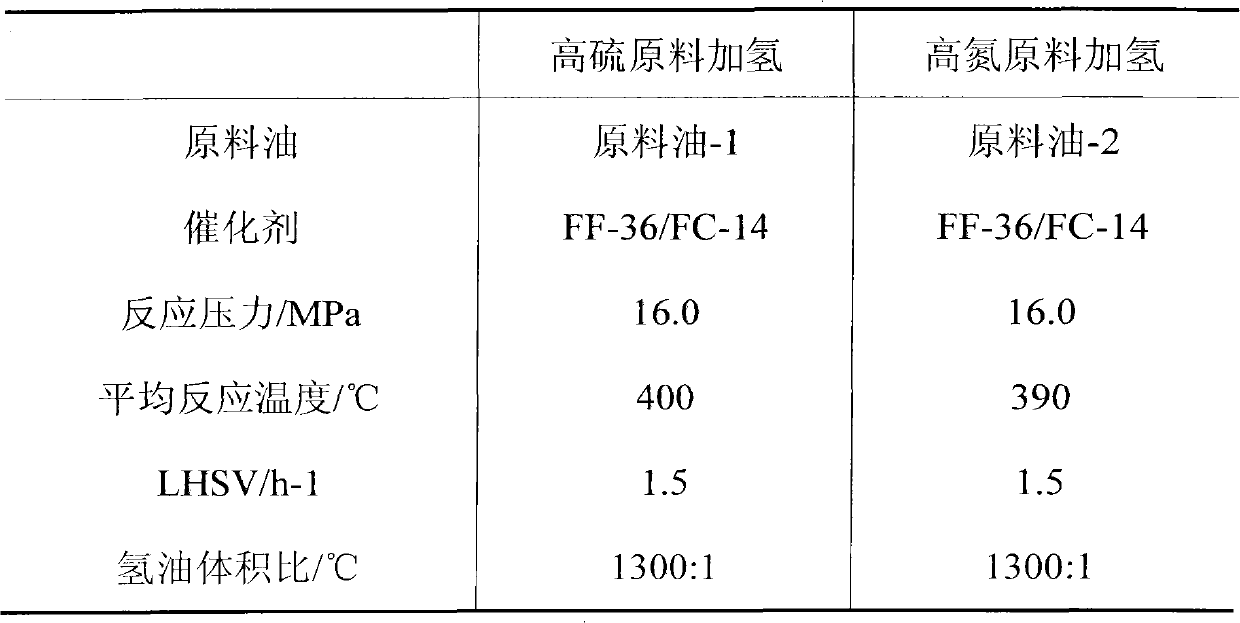

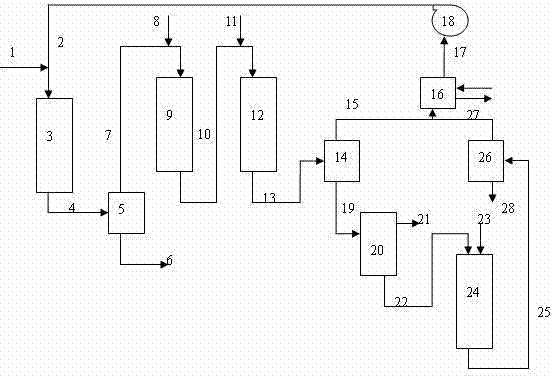

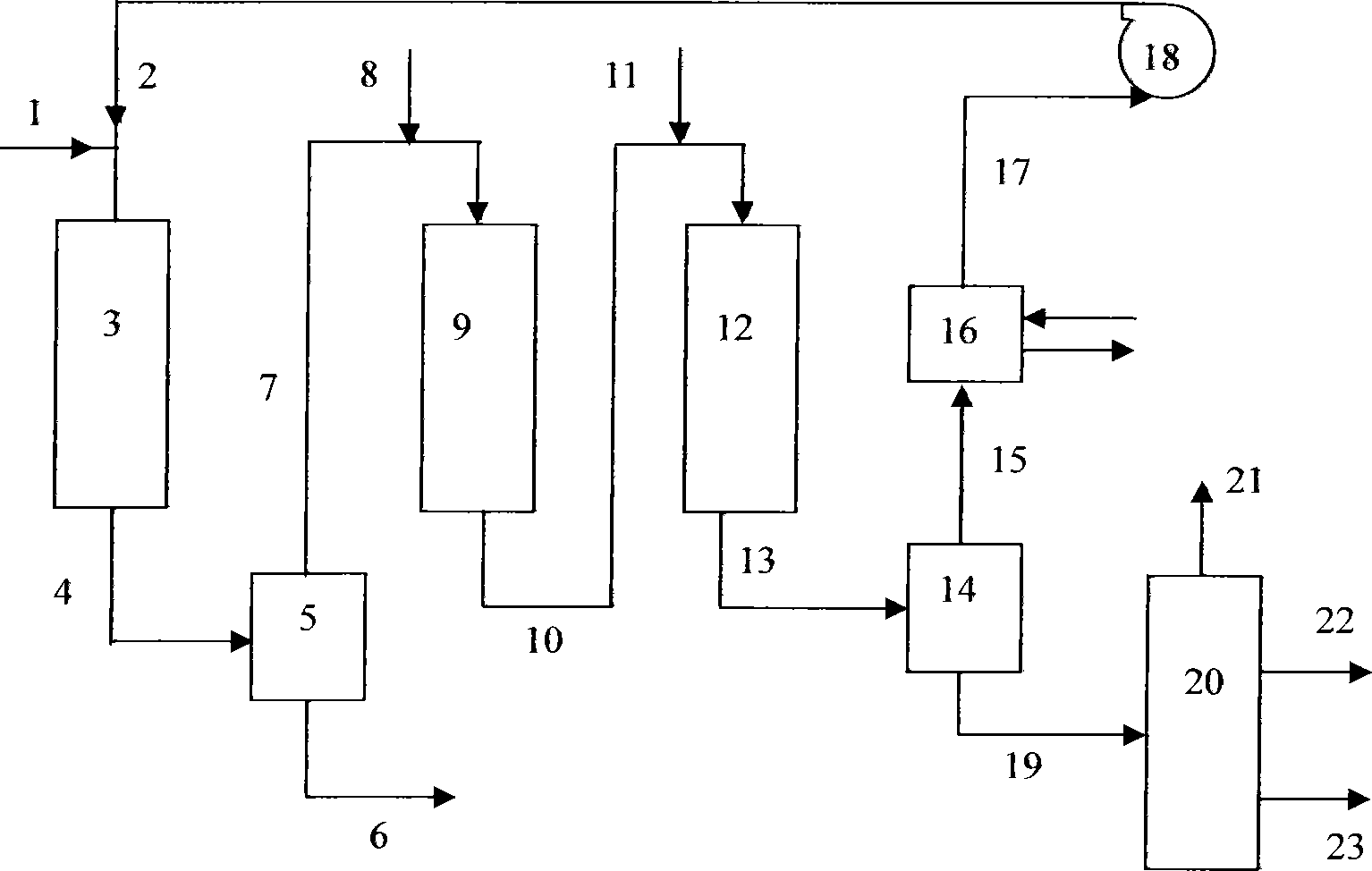

The invention discloses an integrated hydrocracking method. The method includes the following steps: under hydrocracking conditions, high-sulfur raw oil and hydrogen are mixed and then pass through a hydrocracking catalyst bed, high-nitrogen raw oil and hydrogen are mixed and then pass through a hydrocracking catalyst bed, reaction effluents respectively enter hot high-pressure separators and are separated, two routes of produced gas are mixed and injected into washing water and then enter a cold high-pressure separator via a high-pressure air cooler, and the produced hydrogen-rich gas is recycled after passing through a circulating hydrogen desulfurization tower. The integrated hydrocracking method organically combines hydrocracking processes for processing different natures of materials, consequently, on the basis of the normal processing of different natures of poor-quality materials, the respective characteristics of the materials can be sufficiently utilized, and thereby an ideal comprehensive processing effect can be achieved. The method integrates two gas routes together, and has the advantages of little equipment investment, lower operation cost, simplified process flow and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of combined hydrotreating method

ActiveCN102876366BIncrease temperatureAvoid cokingTreatment with hydrotreatment processesWaxHydrogenation reaction

The invention discloses a combined hydrotreatment method, comprising the following steps of: allowing a wax oil raw material and hydrogen to pass through a first hydrogenation reaction zone and separating a reaction effluent; mixing an obtained gas phase and coker gasoline and allowing the mixture to pass through a second hydrogenation reaction zone; directly mixing the reaction effluent and a diesel oil raw material and letting them pass through a third hydrogenation reaction zone, and carrying out separation and fractionation on the obtained reaction effluent so as to obtain refined gasoline and diesel oil; mixing the diesel oil and supplemented hydrogen and letting them pass through a fourth hydrogenation reaction zone, and dropping pour point. By the adoption of the method, heat brought from a gas generated from wax oil hydrotreatment at a higher temperature and reaction heat of coker gasoline can be reasonably utilized; and on the basis of minimizing construction investment to the maximum, refined gasoline, diesel oil with low condensation point and high-quality catalytic cracking raw oil can be produced, thus reaching an ideal comprehensive processing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation process combination method

ActiveCN102465030BIncrease temperatureAvoid cokingTreatment with hydrotreatment processesWaxGas phase

The invention discloses a hydrogenation process combination method. The method comprises the following steps: 1, mixing a wax oil raw material with hydrogen, allowing them to go through a first hydrogenation reaction zone, and separating the obtained hydrogenation reaction effluent by allowing it to enter a hot high-pressure separator; 2, mixing the gas phase and coked gasoline obtained in step 1, and allowing them to go through a second hydrogenation reaction zone under gasoline hydrofinishing conditions; and 3, directly mixing the reaction effluent obtained in step 2 with a diesel oil raw material, allowing them to go through a third hydrogenation reaction zone under diesel oil hydrofinishing conditions, and separating and fractionating the obtained reaction effluent to obtain lightweight products. According to the invention, the wax oil hydrogenation high-pressure separation gas is directly mixed with the coked gasoline fraction to generate heat, so the temperature of the material entering the coked gasoline hydrogenation reaction zone is elevated, thereby reaction demands are satisfied; and a coked gasoline heating furnace an be canceled, so a work stopping problem caused by furnace tube coking generated during heating the coked gasoline in the heating furnace is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined hydrocracking method for processing inferior raw materials

ActiveCN103773481BExtended operating cycleImprove product qualityTreatment with hydrotreatment processesLiquid productFractionation

The invention discloses a combined hydrocracking method used for processing inferior raw materials. According to the combined hydrocracking method, counter current hydrogenation technology is adopted for pre-treatment of high-nitrogen raw oil, and parallel hydrogenation technology is adopted for pre-treatment of common raw oil; a liquid obtained via counter current hydrogenation and an effluent of parallel hydrogenation are delivered into a hydrocracking reactor for reaction; an effluent of hydrocracking is mixed with gas obtained via counter current hydrogenation; and gas-liquid separation is carried, and an obtained liquid product is subjected to fractionation so as to obtain a hydrocracking product. The liquid obtained via the pre-treatment of high-nitrogen raw oil contains almost no ammonia, so that the liquid is mixed with the effluent obtained via hydrogenation of common raw oil, and a mixture is subjected to hydrocracking, influences of ammonia partial pressure on hydrocracking are reduced, and apparatus running period is prolonged; and at the same time, an ammonium salt is obtained via combination of NH3 in an ammonia-containing gas with hydrogen sulfide, is washed via water injection, so that amine liquid consumption of a recycle hydrogen desulfurization tower is reduced greatly, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-quality gasoline and diesel oil by catalyzing diesel oil

ActiveCN109777494BIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesReaction temperatureEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for processing low-sulfur raw material

ActiveCN102465014BImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesHydrogenTotal investment

The invention discloses a hydrocracking method for processing a low-sulfur raw material. The method comprises the steps of: hydroprocessing a high-sulfur raw material, and performing gas-liquid separation on a reaction effluent to obtain sulfur-containing hydrogen-enriched gas; hydrocracking low-sulfur raw oil, and performing gas-liquid separation on a reaction effluent to obtain a low-sulfur hydrogen-enriched gas; and mixing the sulfur-containing hydrogen-enriched gas and the low-sulfur hydrogen-enriched gas, selectively performing hydrogen sulfide removal treatment on the gas mixture, and circulating the treated gas mixture to a reactor inlet. According to the invention, two paths of hydrogen-enriched gas of the hydroprocessing process and the hydrocracking process are effectively combined, and the sulfur-containing hydrogen-enriched gas subjected to hydroprocessing is fully utilized to replenish sulfur for a low-sulfur raw material hydrocracking device, so that the problem of sulfur loss of the catalyst during long-term operation of the low-sulfur hydrocracking device is effectively solved. The hydrocracking method disclosed by the invention has the advantages of simplified process flow, low operation cost, low total investment and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com