Hydro-desulphurizing combined method

A combined method, hydrodesulfurization technology, applied in the fields of hydroprocessing process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of high operating cost and high total investment cost, achieve low operating cost, save new hydrogen compressors, The effect of saving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

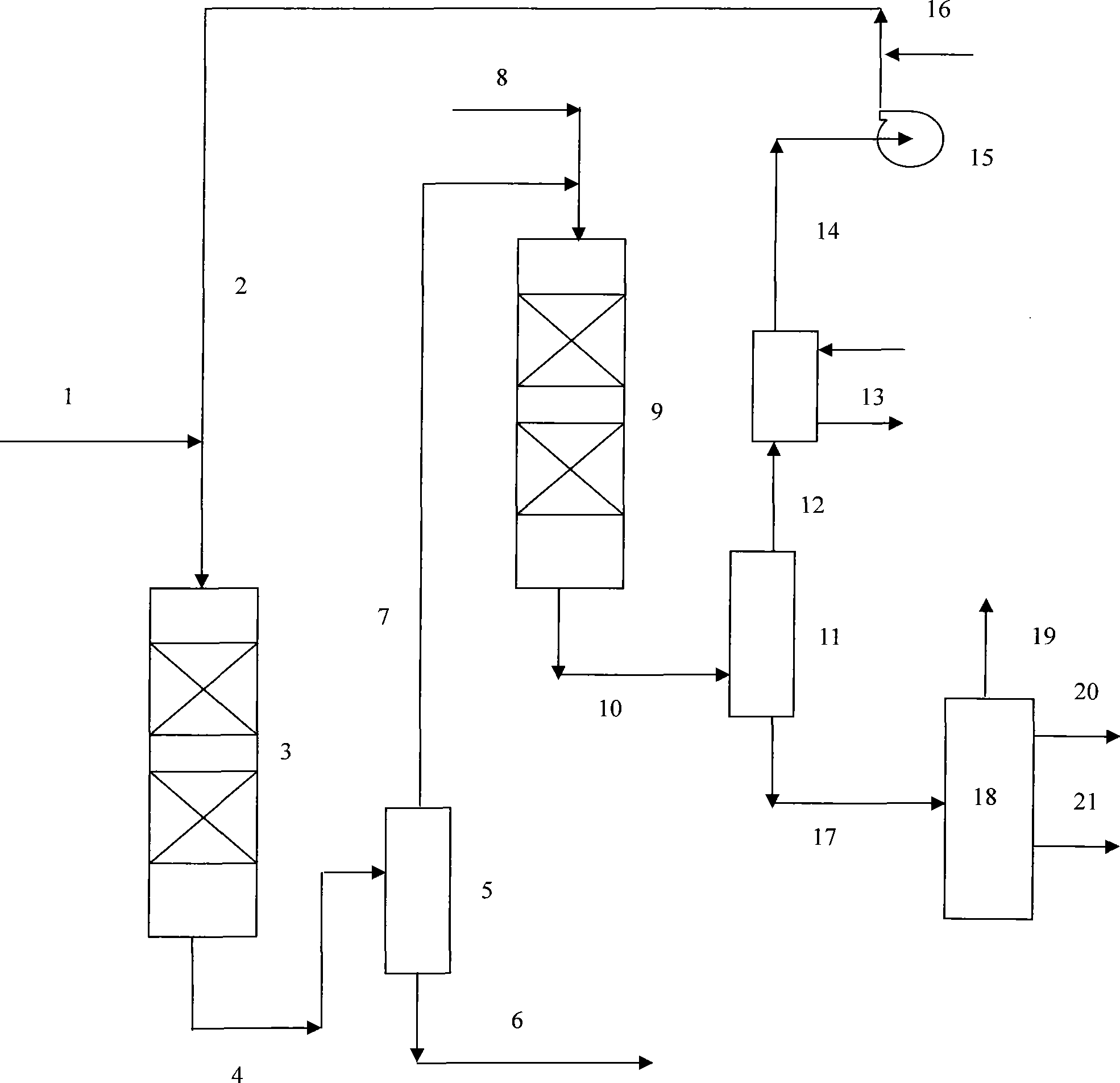

[0019] First, wax oil hydrotreating feed oil 1 and hydrogen gas 2 are mixed into hydrotreating reactor 3 to obtain hydrotreating product 4 containing low impurities such as sulfur and nitrogen. 4 is separated in hot high-pressure separator 5 to obtain liquid hydrogenation The wax oil directly enters the catalytic cracking unit, and the separated gas phase (including hydrogen and light distillate oil) 7 is mixed with the hydrorefined diesel feedstock 8 and enters the hydrorefining reactor 9 . After a series of reactions, the hydrorefining product 10 is obtained. Hydrofining product 10 is separated in high-pressure separator 11 to obtain hydrogen sulfide-containing gas 12 into dehydrogen sulfide tower 13, and recycle gas 14 obtained after dehydrogen sulfide is pressurized by recycle hydrogen compressor 15 and mixed with new hydrogen 16 recycle. The liquid 17 separated in the high-pressure separator 11 enters the stripper 18 (if there are more gasoline fractions in 8, it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com