A method of improving running safety of a hydrocracking device

A hydrocracking and safety technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., to achieve the effect of improving safety, increasing reaction temperature and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

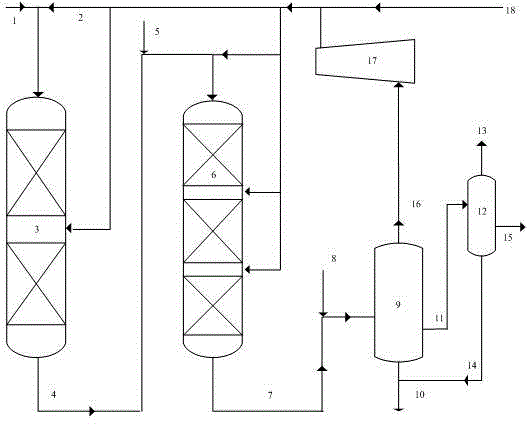

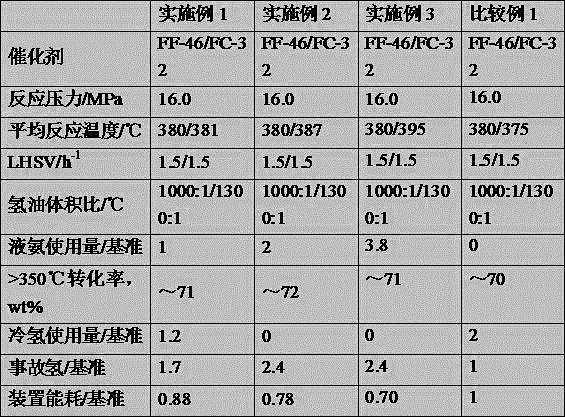

[0041] use figure 1 In the process flow shown, a hydrocracking reaction is carried out, a certain amount of ammonia gas is injected (anhydrous liquid ammonia is injected through a passivation system), and the concentration of ammonia in the circulating hydrogen at the inlet of the cracking reactor is controlled to be 2000 μL / L. The inlet of the device is assisted to inject cold hydrogen to reduce the temperature to a certain extent. The combination of the two can improve the safety of the device operation. The operating conditions and results are listed in Table 3.

Embodiment 2

[0043] use figure 1 In the process flow shown, the hydrocracking reaction is carried out, the gas containing ammonia is injected (anhydrous liquid ammonia is injected through the passivation system), the ammonia concentration in the circulating hydrogen at the inlet of the cracking reactor is controlled to be 5000 μL / L, and the cooling of the cracking reactor is stopped at the same time. The injection of hydrogen only depends on the partial pressure of ammonia to improve the safety of device operation. The operating conditions and results are listed in Table 3.

Embodiment 3

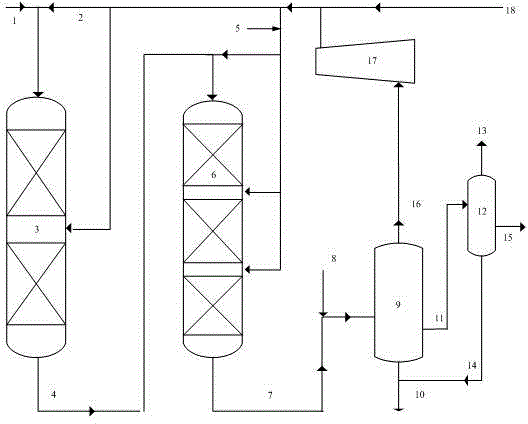

[0045] use figure 2 In the process flow shown, the hydrocracking reaction is carried out; the passivation system and the cooling hydrogen system are used to simultaneously inject anhydrous liquid ammonia between the cracking reactor inlet and each cracking catalyst bed. Separately control the ammonia concentration in the cracking reactor inlet and the mixed circulation hydrogen at the inlet of each bed layer to 2000μL / L; at the same time, stop the injection of cold hydrogen in the cracking reactor, and only rely on the partial pressure of ammonia to improve the safety, operating conditions and operation of the unit. The results are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com