ORC system and method for cascade recovery and utilization of low-grade heat

A low-grade heat and cascaded recovery technology, applied in the field of energy saving, can solve the problems of large heat transfer temperature difference, limited improvement of thermal efficiency, and low slip temperature in the heat recovery process of variable temperature heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

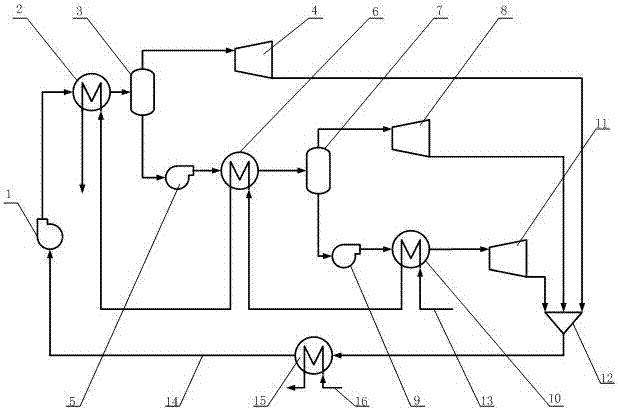

[0026] Refer to the attached figure 1 Explain the operation process of the ORC system for cascade recovery and utilization of low-grade heat in this system.

[0027] The working medium 14 enters the cold side of the first heat exchanger 2 to absorb heat from the heat source 13 on the hot side, and the heat-absorbed working medium 14 enters the inlet of the first gas-liquid separator 3 .

[0028] The gaseous working medium 14 at the gas phase outlet of the first gas-liquid separator 3 enters the inlet of the first expander 4 to perform expansion work, and the product at the outlet of the first expander 4 enters the inlet of the mixer 12 .

[0029] The liquid working medium 14 at the liquid phase outlet of the first gas-liquid separator 3 enters the cold side of the second heat exchange 6 after being pressurized by the second pump 5 to absorb the heat of the heat source 13 on the hot side, and the liquid at the outlet of the cold side of the second heat exchanger 6 The working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com