Work and coldness co-production system and method of recovering working medium effective ingredient refrigeration

A technology of co-production of power and cooling, active ingredients, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of heat recovery and utilization, no recycling of active ingredients, achieve good temperature matching, reduce irreversible losses, reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

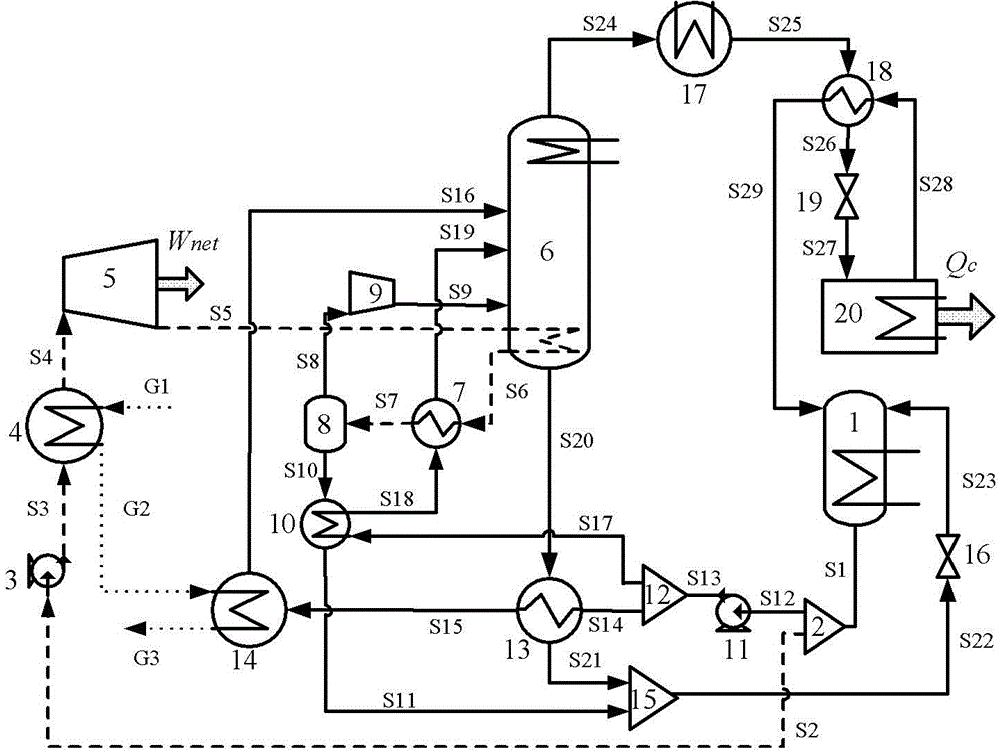

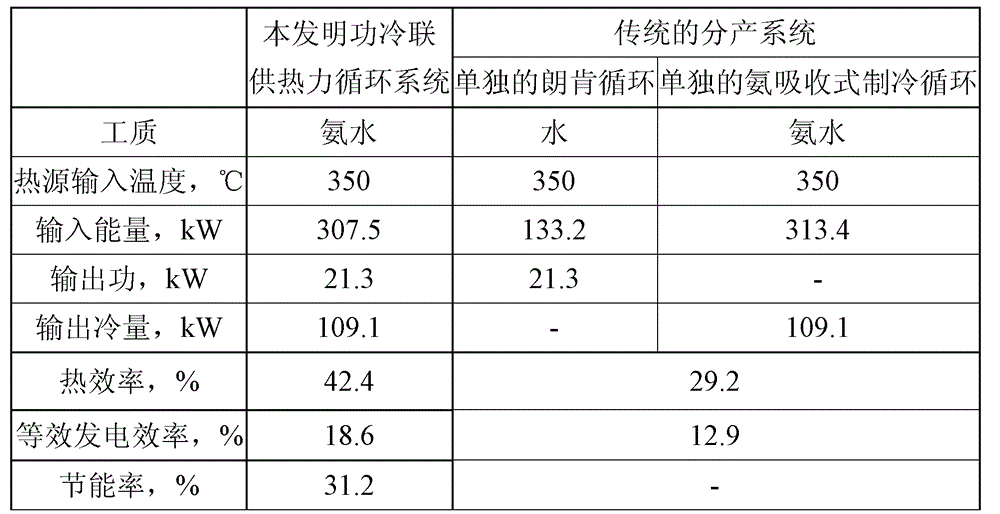

[0027] The present invention provides a system and method for recovering active components of working medium for refrigeration. By organically integrating the working sub-cycle and the absorption refrigeration sub-cycle using the same mixed working medium, the heat of the external heat source is utilized in stages, so that the external The high-temperature part of the heat source is used to heat the working medium, and the low-temperature part is used to heat the absorption refrigeration medium. At the same time, the exhaust heat of the work sub-cycle is also recycled by the absorption refrigeration sub-cycle. The exhaust gas of the working sub-cycle expander undergoes gas-liquid separation after partial heat recovery, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com