Jet booster two-stage super-cooling trans-critical CO2 dual-temperature system and application

A transcritical, CO2 technology, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of gas-phase working medium not participating in evaporation and heat absorption, deterioration of heat exchange effect of heat exchangers, and no contribution to the refrigeration process, etc. The effect of eliminating throttling process, improving space utilization, and reducing irreversible loss of throttling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0034] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

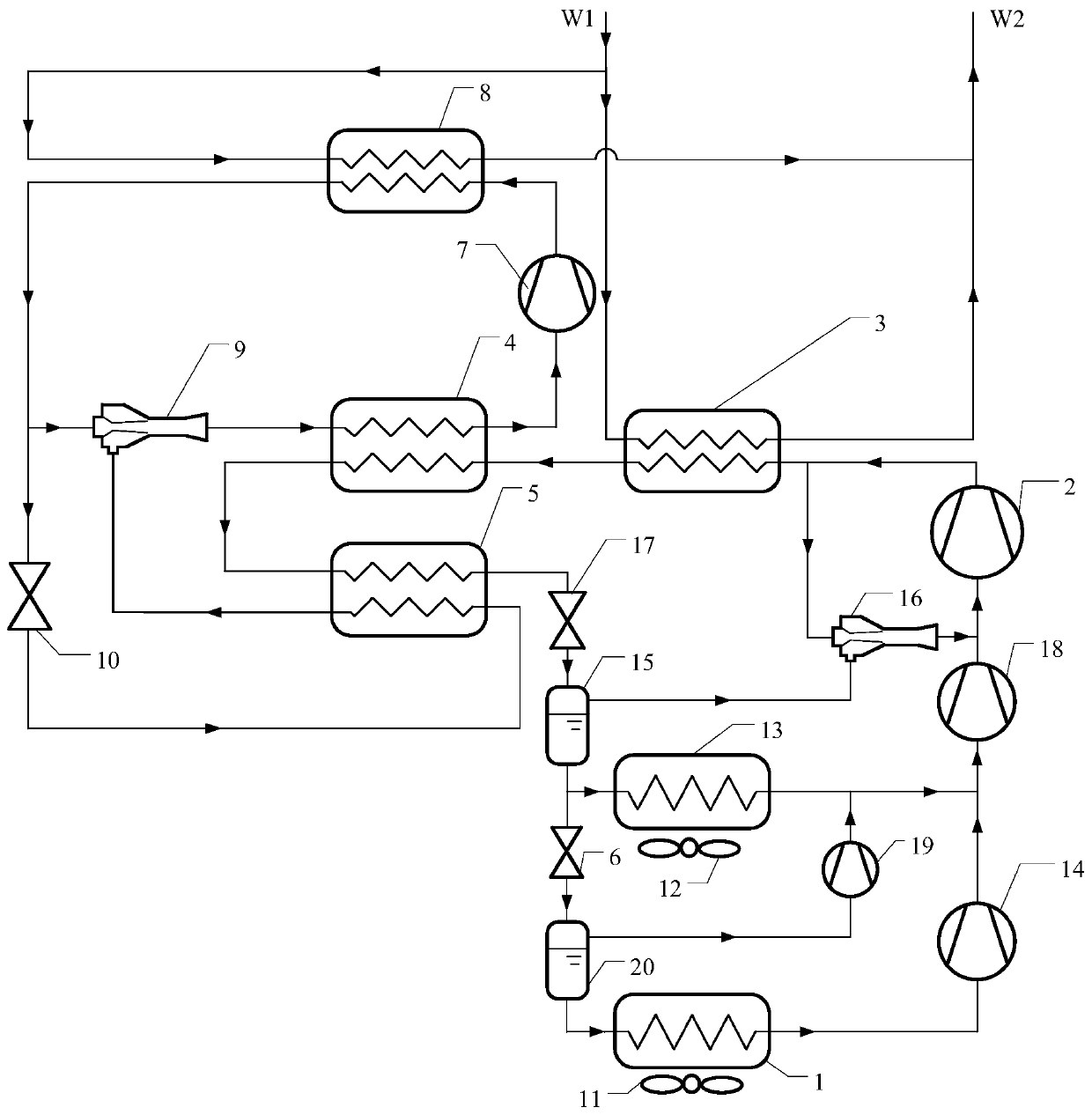

[0035] Such as figure 1 As shown, an ejector supercooled two-stage supercooled transcritical CO 2 Dual temperature system, including ejector pressurized double subcooler series mechanical subcooling cycle and transcritical CO 2 Dual temperature zone cycle. Of which: transcritical CO 2 Dual zone cycle including CO 2 Low temperature stage evaporator 1, CO 2 Medium temperature evaporator 13, CO 2 Low pressure stage compressor 14, CO 2 Low pressure stage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com