Processing method of Fischer-Tropsch synthetic oil

A Fischer-Tropsch synthetic oil and processing method technology, which is applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems that Fischer-Tropsch synthetic oil cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

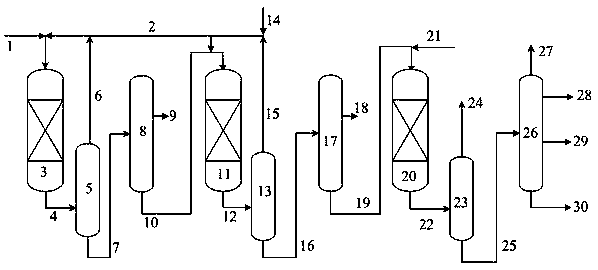

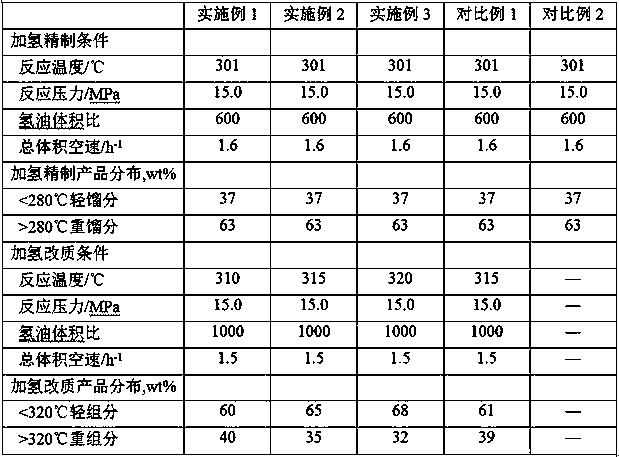

[0042] Such as figure 1 As shown in the process, the existing commercial catalyst is selected, the hydrotreating reaction zone uses the hydrofinishing catalyst FF-26, the hydrogenation upgrading reaction zone uses the hydrogenation upgrading catalyst FC-14, and the isomerization dewaxing reaction zone uses the iso Constructed dewaxing catalyst FIW-12. In the oil produced by hydrofining, the cut point of the light fraction and the heavy fraction is 280 °C. The cutting point of hydrogenated light components and heavy components is 320 ℃. See 2-3 for process conditions and results.

Embodiment 2

[0044] process such as figure 1 shown. Adjust the upgrading conversion rate, see 2-3 for the process conditions and results.

Embodiment 3

[0046] process such as figure 1 shown. Adjust the upgrading conversion rate, see 2-3 for the process conditions and results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com