Patents

Literature

38results about How to "Suitable for lysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Directly-prepared ultrahigh-purity carbon nanotube and preparation method thereof

The invention discloses a directly-prepared ultrahigh-purity carbon nanotube and a preparation method thereof, belonging to the technical field of carbon nanotubes. Under the condition that purification is not required, the purity of the carbon nanotube is greater than 99.7 weight percent, the tube diameter is between 0.8 nanometer and 30 nanometers, the specific surface area is between 200 m<2> / g and 500 m<2> / g, the agglomeration density is between 30 kg / m<3> and 150 kg / m<3> and the agglomeration particle size is between 20 microns and 150 microns. A method for directly preparing the ultrahigh-purity carbon nanotube by adopting a chemical vapor deposition method comprises the following steps of: dispersing catalyst crystal grains generated with a liquid phase method onto the surface of an inert carrier, drying and baking; cracking hydrocarbon with 1-6 carbon atoms in a fluidized bed reactor to generate a carbon nanotube; and separating the inert carrier from the generated carbon nanotube at a higher air speed. The carbon nanotube obtained with the method has the purity between 99.7 percent and 99.9 percent, and has the advantages of high carbon nanotube quality, no need of removing impurities by acid treatment, low cost and easiness for amplification and preparation.

Owner:TSINGHUA UNIV

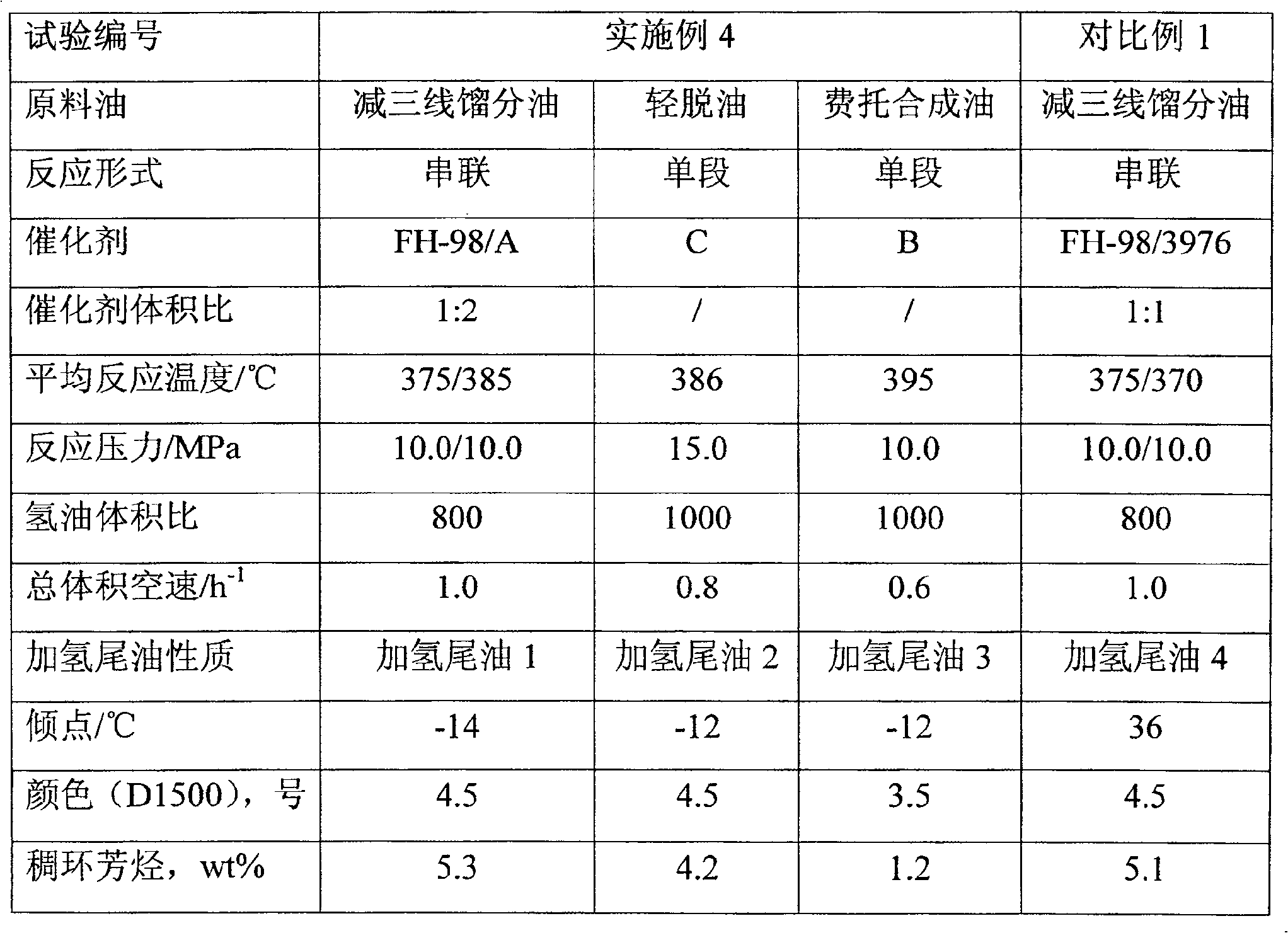

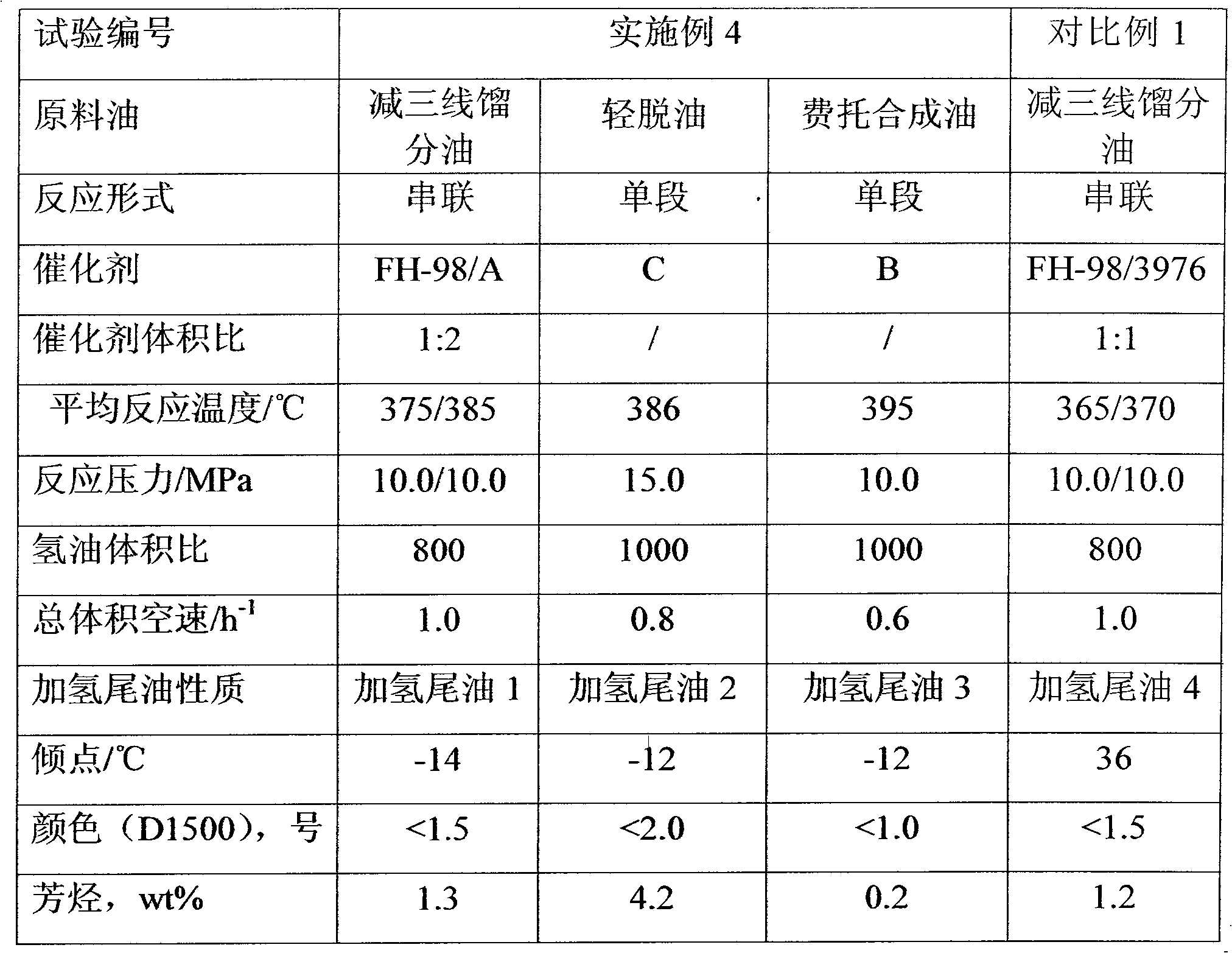

Method for producing food grade white oil by hydrogenating tail oil

ActiveCN1944587ASimple processLess investmentTreatment with hydrotreatment processesEdible oils/fatsSolvent refiningChemistry

The present invention provides method of producing food grade white oil with hydrogenated tail oil. Hydrogenated tail oil as material is treated through one high pressure hydrogenating and refining process under proper condition to obtain the food grade white oil product. The hydrogenated tail oil is produced with vacuum gas oil, refined solvent oil or Fischer-Tropsch synthesized oil as material and through hydrocracking or hydrotreating process under the action of hydrogenating catalyst, and has pour point lower than -10deg.c.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing ethene and propene by catalysis cracking

ActiveCN101190864ASuitable for lysisStrong acidMolecular sieve catalystsBulk chemical productionCracking reactionEthylene

The invention relates to a catalyst used for producing ethylene and propylene by catalytic cracking, and mainly solves the problem that temperature required by the catalyst is high while selectivity to the ethylene and the propylene is low in the existing catalytic cracking reaction. The invention adopts the technical proposal of sieving ZSM-5 / beta zeolite accrete molecular as catalyst, and SiO2 / Al2O3 mole ratio of which is more than 100 to 500, thereby properly solving the problem. The invention is used for industrial production of the ethylene and the propylene by the catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

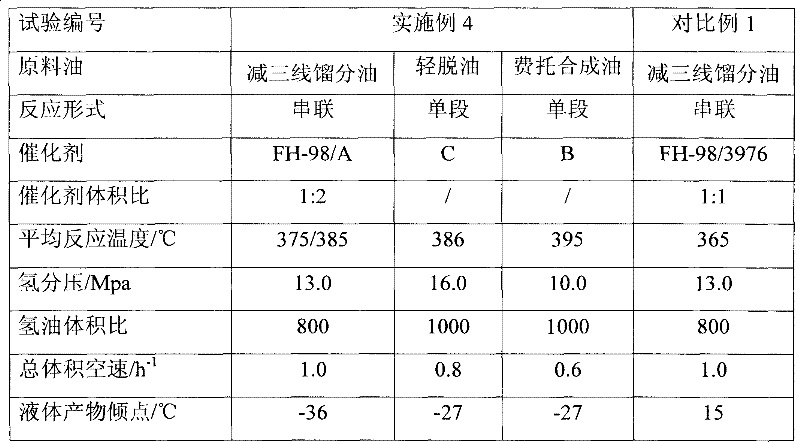

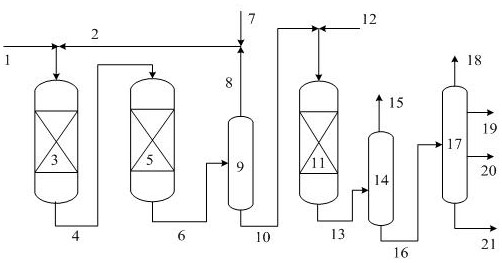

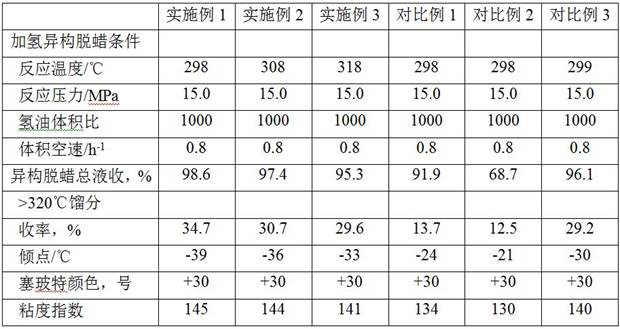

One-stage hydrogenation method for producing food-level white oil

ActiveCN101148606AHigh activityHigh selectivityTreatment with hydrotreatment processesEdible oils/fatsLiquid productMolecular sieve

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking or hydrogenating, hot high pressure separating out gas and light distillate to obtain liquid product, mixing with newly formed hydrogen, and high pressure hydro-finishing in a reactor with loaded reduction type hydrogenating catalyst, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lignin hydro-cracking catalyst and preparation method thereof

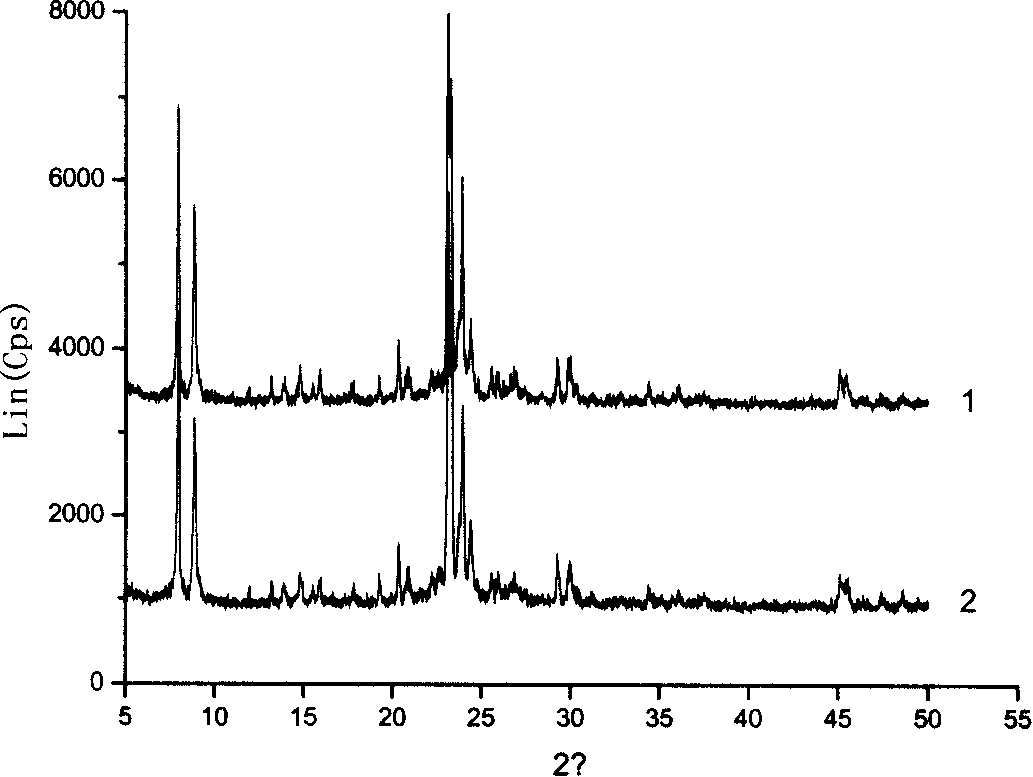

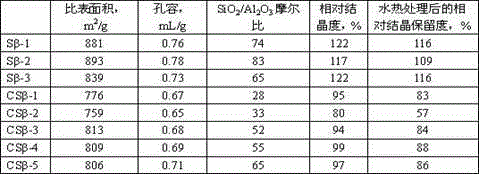

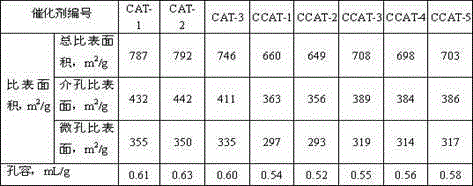

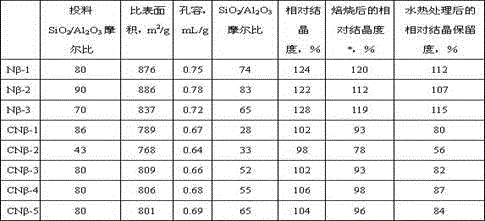

ActiveCN106140278AGood crystal orientationReduce usageMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveCrystallinity

The invention discloses a lignin hydro-cracking catalyst which comprises an H beta molecular sieve and a hydrogenating active metal component, wherein the hydrogenating active metal component belongs to a group VIB and / or a group VIII; the pore volume of the catalyst is 0.5-0.8 mL / g, the total specific surface area is 600-800 m<2> / g, the mesoporous specific surface area is 400-450 m<2> / g, and the micropore specific surface area is 300-370 m<2> / g; the H beta molecular sieve has the following properties that the molar ratio of SiO2 to Al2O3 is 60:100, the specific surface area is 700-900 m<2> / g, the pore volume is 0.6-0.9 mL / g, and the relative crystallinity is 100-148 percent. The catalyst is prepared by adopting an impregnation method. The catalyst adopts a beta-type molecular sieve with high silica-alumina ratio, high crystallinity, large specific surface area and a special channel structure as an acidic component and has higher reaction activity and higher liquid yield for lignin hydro-cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

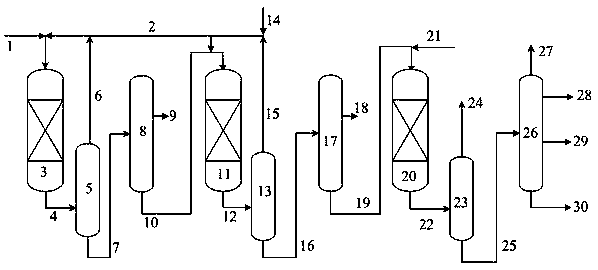

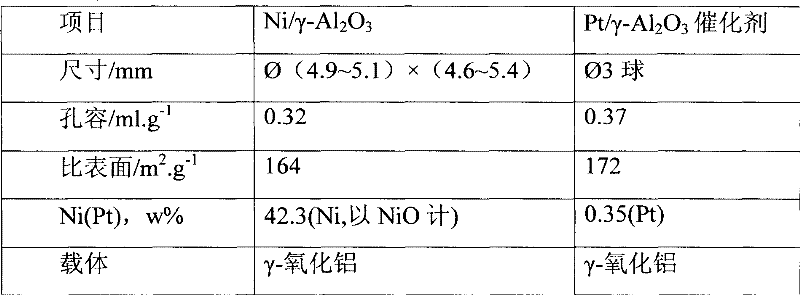

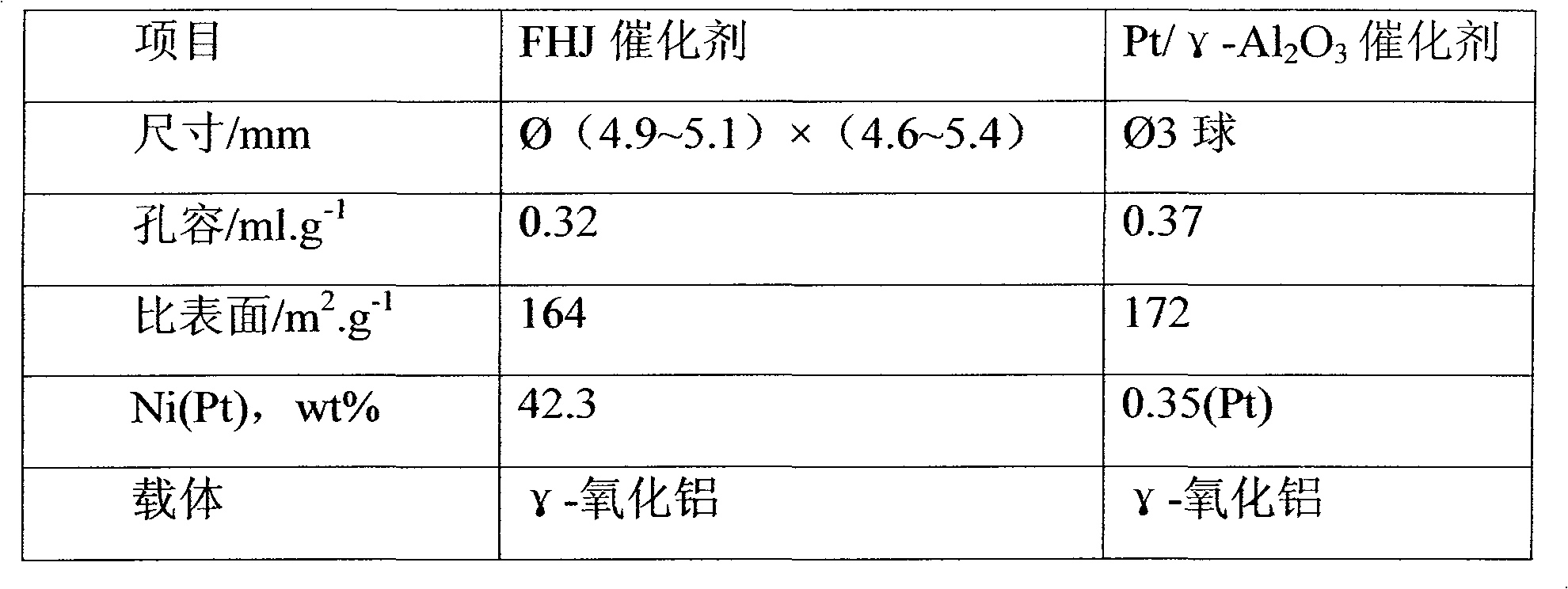

Method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil

ActiveCN102311785BImprove comprehensive hydroprocessing capacityImprove stabilityTreatment with hydrotreatment processesLubricant compositionHydrogenation processBase oil

The invention relates to a method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil. The naphthenic distillate is used as raw material and a one-stage in series hydrogenation process of hydrotreating-hydrodewaxing-hydrofinishing is adopted to produce the lubricating oil basic oil. Ordinary hydrotreating catalysts are filled in the upper part of a hydrotreating reaction area, and hydrotreating catalysts containing modified zeolites are filled in the lower part of the hydrotreating reaction area. The hydrodewaxing and hydrofinishing reaction areas are the same as those of the prior art, and are filled with hydrodewaxing catalysts and hydrofinishing catalysts. Compared with the prior art, the method disclosed by the invention has the advantages that system energy consumption is reduced, the pour point of a product is properly reduced, and the stability of the product is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Naphtha catalytic pyrolysis catalyst for preparing ethylene propylene

ActiveCN101279286ASuitable for lysisStrong acidMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisNaphtha

The present invention relates to a catalyst used for manufacturing ethylene and propylene by naphtha catalytic pyrolysis which mainly solves the problems of high reaction temperature and low yield of catalyst to ethylene and propylene in the existing catalytic pyrolysis reaction. The present invention better solves the problems by adopting the technical proposal of taking a ZSM-5 / Y zeolite symbiosis molecular sieve as the catalyst. The present invention can be used for the industrial production of ethylene and propylene by naphtha catalytic pyrolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

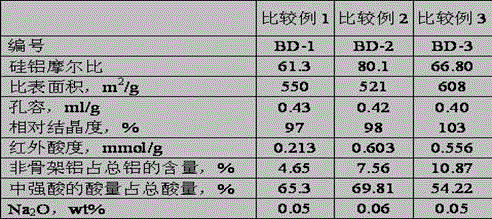

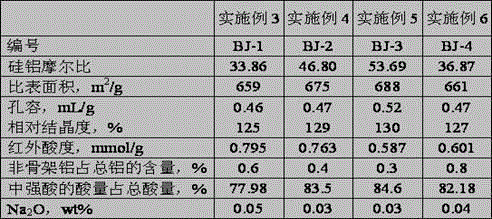

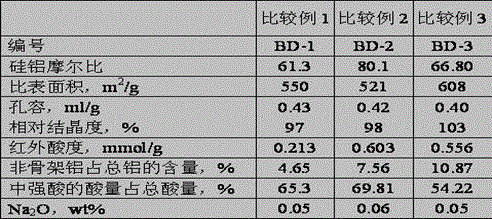

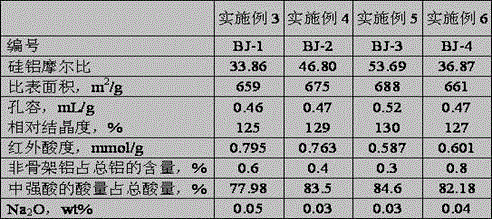

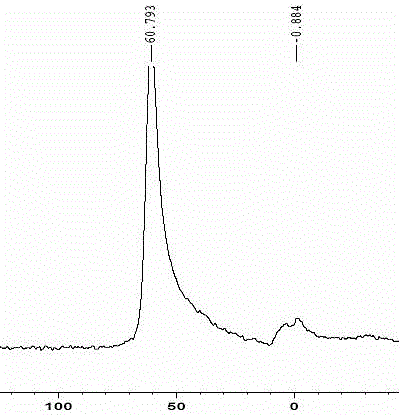

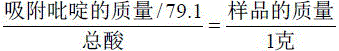

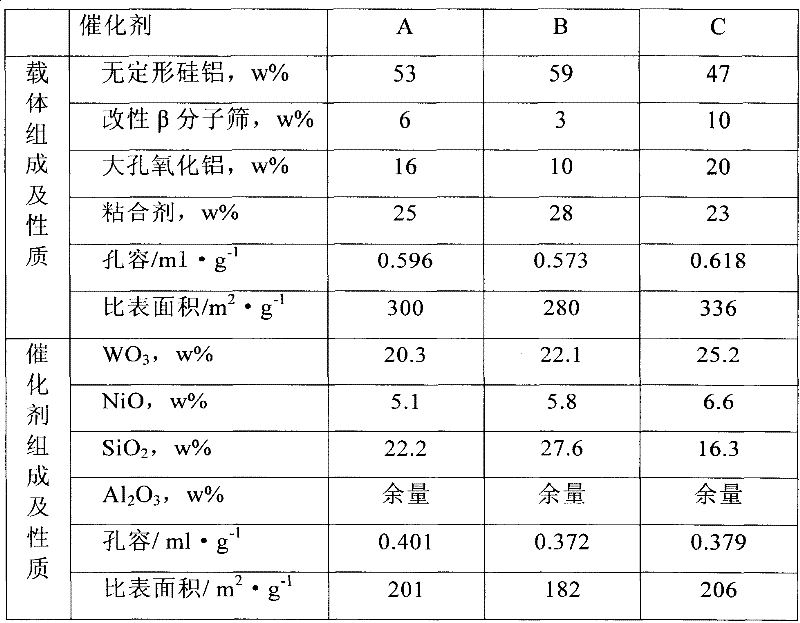

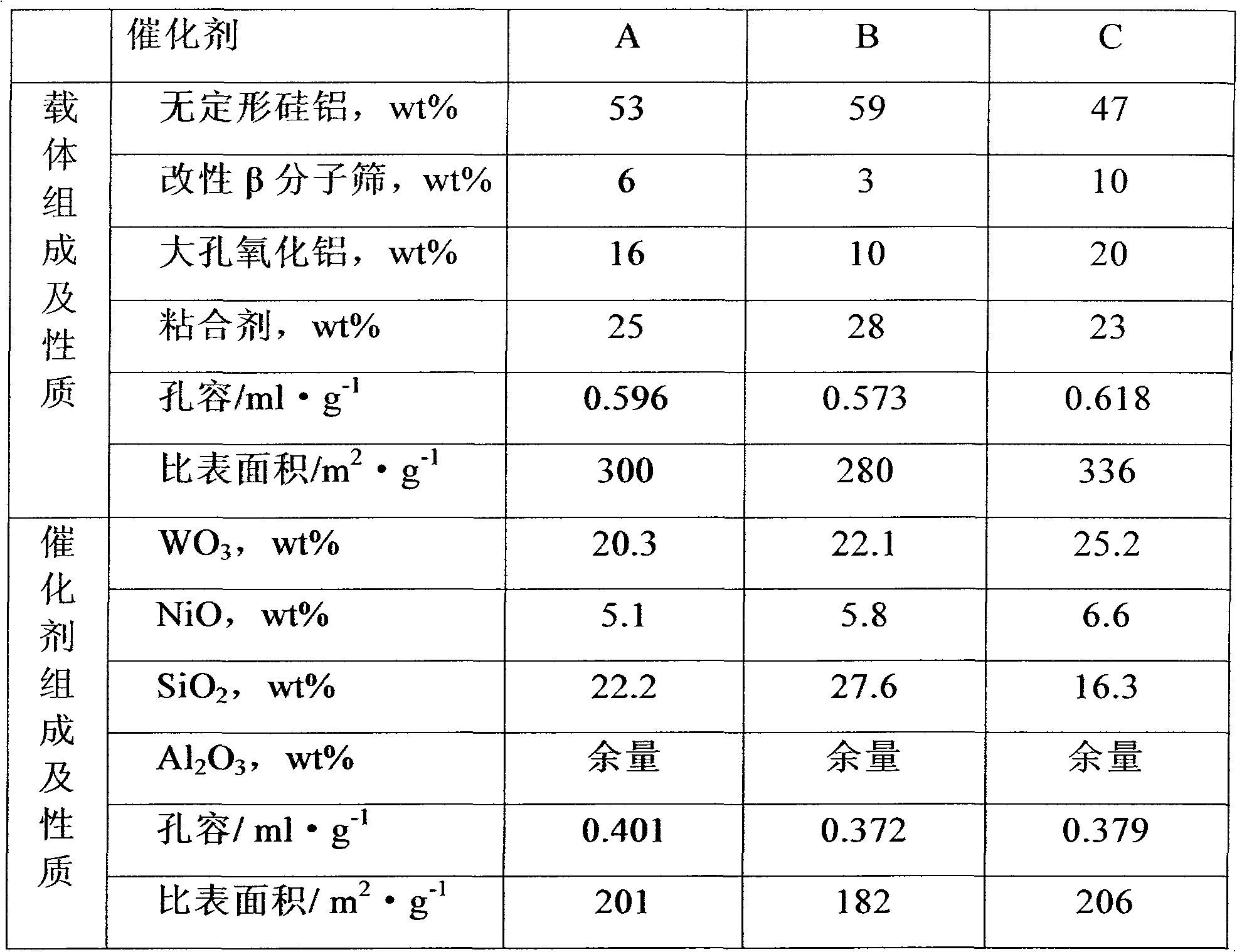

A hydrocracking catalyst and a preparing method thereof

ActiveCN104667958ALarge specific surface areaHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

A hydrocracking catalyst and a preparing method thereof are disclosed. The catalyst comprises metal components with hydrogenation activity and a carrier comprising a beta molecular sieve, amorphous silicon aluminum and aluminum oxide, wherein properties of the beta molecular sieve are as follows: the specific surface area is 400-800 m2 / g, the total pore volume is 0.4-0.55 mL / g, the SiO2 / Al2O3 mole ratio is 30-60, the relative crystallinity is 120-140%, the infrared acid content is 0.55-1.0 mmol / g, the non-framework aluminum accounts for less than 1% of the total aluminum, the amount of medium-strong acids which is measured by a NH3-TPD method accounts for 70-85% of the total acid amount, and the percent of Na2O is not more than 0.15 wt%. The preparing method includes mixing the beta molecular sieve, the amorphous silicon aluminum and the aluminum oxide, kneading and forming to prepare the carrier; and loading the metal components with hydrogenation activity by a conventional method. The beta molecular sieve which is proper in silicon aluminum ratio, large in specific surface area, proper in acidity, reasonable in pore structure and low in content of non-framework aluminum, and the amorphous silicon aluminum are adopted as cracking components of the catalyst. The prepared catalyst is characterized by producing a clean diesel oil product with a low condensation point with the highest yield, improving properties of hydrogenation tail oil, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

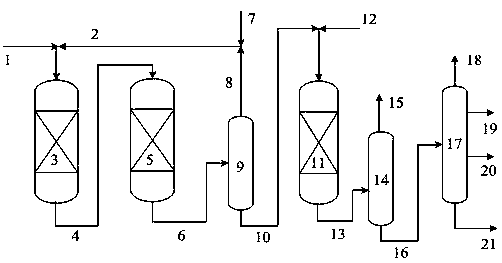

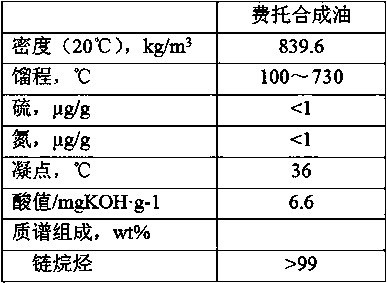

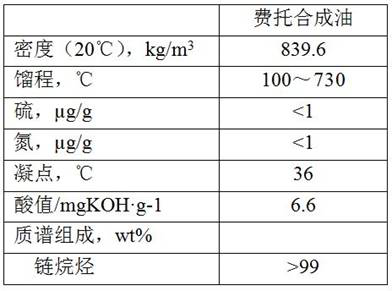

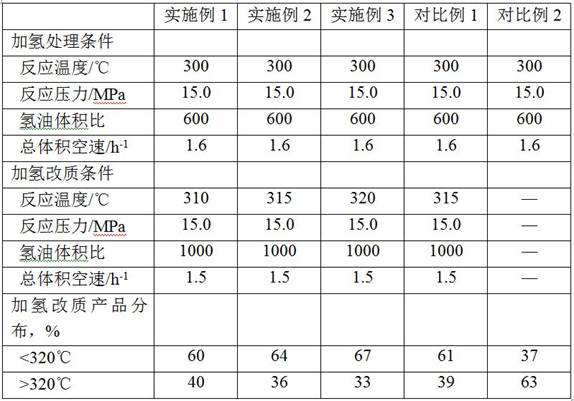

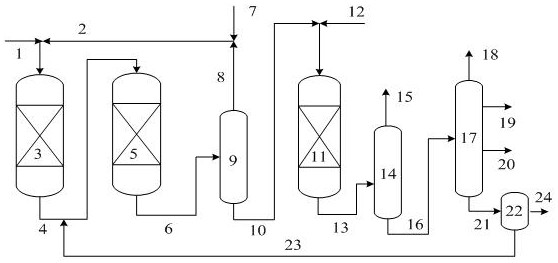

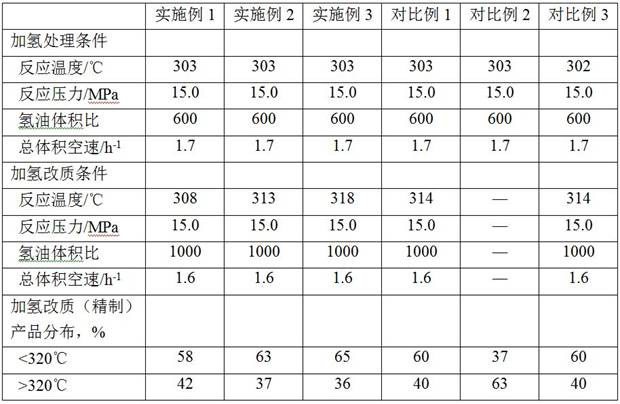

Hydrogenation method for producing API III <+> base oil from Fischer-Tropsch synthetic oil

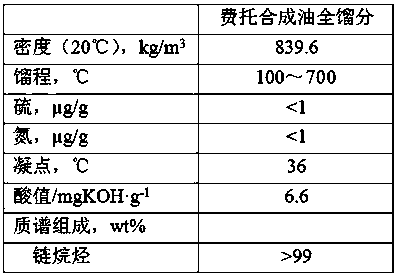

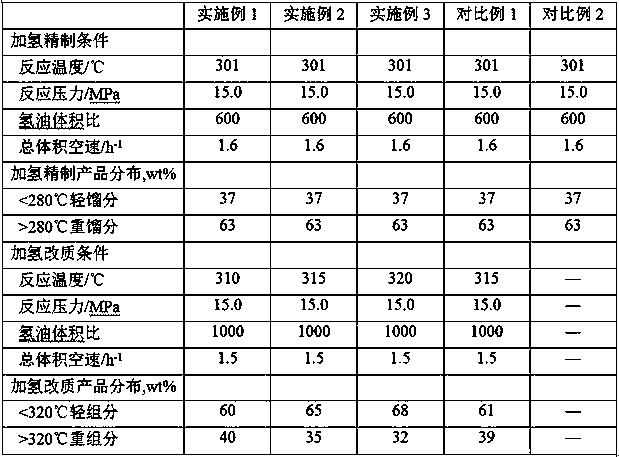

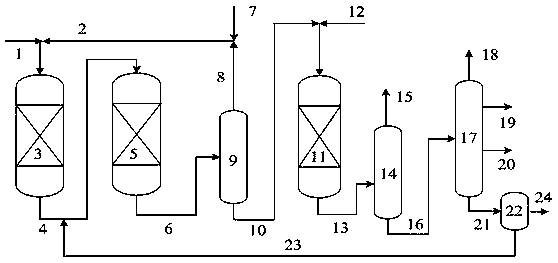

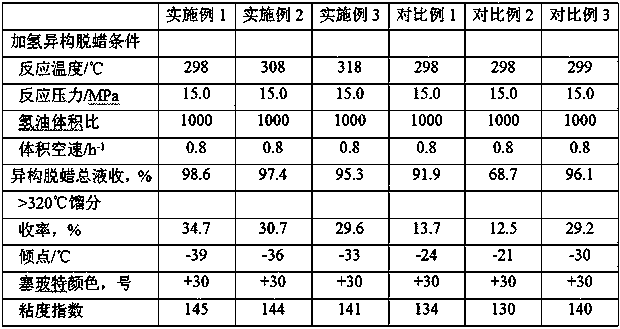

ActiveCN111378495ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

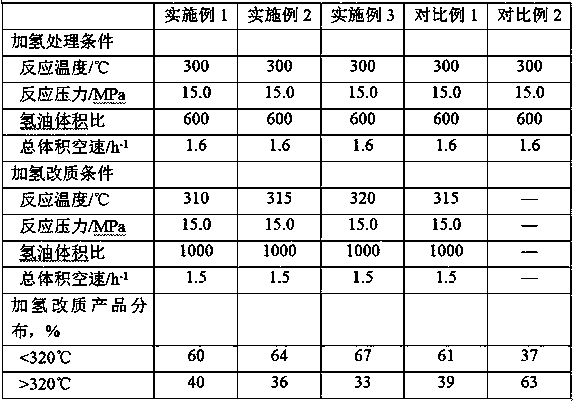

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Generated oil obtained through separation of a hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reactionzone, and different types of API III <+> lubricating oil base oil products are obtained through separation and fractionation of an isodewaxing reaction effluent. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and its preparation method

ActiveCN104667958BLarge specific surface areaHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sieveStrong acids

A hydrocracking catalyst and a preparing method thereof are disclosed. The catalyst comprises metal components with hydrogenation activity and a carrier comprising a beta molecular sieve, amorphous silicon aluminum and aluminum oxide, wherein properties of the beta molecular sieve are as follows: the specific surface area is 400-800 m2 / g, the total pore volume is 0.4-0.55 mL / g, the SiO2 / Al2O3 mole ratio is 30-60, the relative crystallinity is 120-140%, the infrared acid content is 0.55-1.0 mmol / g, the non-framework aluminum accounts for less than 1% of the total aluminum, the amount of medium-strong acids which is measured by a NH3-TPD method accounts for 70-85% of the total acid amount, and the percent of Na2O is not more than 0.15 wt%. The preparing method includes mixing the beta molecular sieve, the amorphous silicon aluminum and the aluminum oxide, kneading and forming to prepare the carrier; and loading the metal components with hydrogenation activity by a conventional method. The beta molecular sieve which is proper in silicon aluminum ratio, large in specific surface area, proper in acidity, reasonable in pore structure and low in content of non-framework aluminum, and the amorphous silicon aluminum are adopted as cracking components of the catalyst. The prepared catalyst is characterized by producing a clean diesel oil product with a low condensation point with the highest yield, improving properties of hydrogenation tail oil, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of Fischer-Tropsch synthetic oil

ActiveCN111378494ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Heavy distillate oil generated oil obtained through hydrofining-hydro-upgrading reaction effluent separation enters an isodewaxing reaction zone, and an isodewaxing reaction effluent is subjected to separation and fractionation to obtain different types of API III <+> lubricating oil base oil products. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fractionhydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing food-level white oil by hydrogenation technique

ActiveCN101148610AHigh activityHigh selectivityTreatment with hydrotreatment processesHydrocarbon oils refiningMolecular sieveDistillation

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking inside a hydrocracking co-current reactor to obtain reaction product, hydrorefining in a countercurrent hydrorefining reactor with flash region to exhaust gas and liquid hydrocarbon, the reverse contact reaction between the downward flowing liquid hydrocarbon and the bottom entering newly formed hydrogen in the bed layer with reduction type hydrogenating catalyst, and final gas-liquid separation and product distillation, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst, and preparation method thereof

ActiveCN106140285AHigh crystallinityImprove stabilityCatalyst carriersMolecular sieve catalystsMolecular sieveAdhesive

The invention discloses a preparation method for a hydrocracking catalyst and a preparation method thereof. The catalyst comprises a carrier and a hydrogenation active metal component. The carrier comprises a beta molecular sieve, amorphous silicon aluminum and an adhesive. The beta molecular sieve has the properties that a mol ratio of SiO2 to Al2O3 is 60 to 100; a specific surface area is 505 to 850 m<2> / g; a pore volume is 0.35 to 0.60 mL / g; and relative crystallinity is 100 to 148%. After hydro-thermal treatment by water vapor, the relative crystallinity of the beta molecular sieve is 95% or above. According to the invention, the beta molecular sieve with high crystallinity, a high silica-alumina ratio and good stability is used as an acidic component of the carrier and matched with amorphous silicon aluminum; and the hydrocracking catalyst prepared from the carrier is especially applicable to one-stage tandem hydrocracking process and has the characteristics of high activity, good medium oil selectivity and good product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior-diesel hydro-upgrading catalyst carrier and preparation method thereof

ActiveCN107233913AHigh yieldIncrease cetane numberCatalyst carriersMolecular sieve catalystsAlkaneMolecular sieve

The invention discloses an inferior-diesel hydro-upgrading catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified beta molecular sieve, amorphous silica-alumina, macroporous alumina and SB powder. When the catalyst carrier is used for preparing a catalyst, metals for hydrogenation comprise non-noble metals of group VIB and group VIII. The modified beta molecular sieve and the amorphous silica-alumina are taken as cracking components, so that nitrogen resistance of the catalyst is improved, and long-period operation of the catalyst is ensured when high-nitrogen materials are being processed. The modified beta molecular sieve has good cycloalkane ring opening selectivity and a good alkane isomerism performance, and exhibits the advantages of high diesel productivity, large reduction amplitude of diesel solidifying point and obvious improvement of cetane number while the carrier is used for catalytically processing inferior diesel.

Owner:PETROCHINA CO LTD

Hydrogenation process for producing API III < + > base oil from Fischer-Tropsch synthetic oil

ActiveCN111378493ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a hydrogenation process for producing API III < + > lubricating oil base oil from Fischer-Tropsch synthetic oil. The Fischer-Tropsch synthetic oil is used as a raw material, and a hydrofining-hydro-upgrading-isodewaxing two-stage hydrogenation process is adopted to produce API III + lubricating oil base oil. The generated oil obtained by separation of hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reaction zone; and the process further includes separating and fractionating the isodewaxing reaction effluent to obtain different types of API III + lubricating oil base oil products, cooling fractionated vacuum bottom oil to obtain an incompletely converted wax component, and returning the incompletely converted wax component to the hydro-upgrading reactor to continue the upgrading reaction. The invention has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthesis oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing lubricating oil basic oil from hydrogenated tail oil

ActiveCN100549142CHigh activityHigh selectivityHydrocarbon oil crackingTreatment with hydrotreatment processesMolecular sieveDistillation

The invention relates to a method for producing lubricating oil base oil from hydrogenated tail oil. Using hydrocracking tail oil as raw material, it can directly carry out vacuum distillation, and under suitable conditions, lubricating oil base oil products can be obtained. The hydrocracking tail oil is made of vacuum distillate oil, solvent refined deasphalted oil and Fischer-Tropsch synthetic oil as raw materials, and uses a hydrocracking catalyst containing modified β molecular sieves. Modified β-molecular sieve with high silicon-aluminum ratio, high crystallinity, and certain secondary pores, through hydrocracking or hydrocracking process, the tail oil with pour point less than -10°C can be obtained. The invention can produce lubricating oil base oil products with excellent performance by selecting the hydrogenated tail oil processed by suitable hydrocracking catalysts without going through pour point depressing and refining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

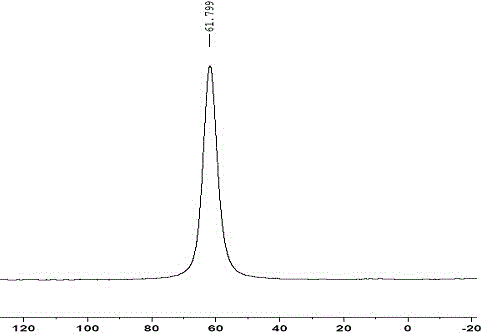

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN106140251BHigh crystallinityImprove stabilityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrogenation cracking catalyst carrier and a preparation method thereof. The carrier comprises a beta molecular sieve, amorphous silica-alumina and a binder; the beta molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 60-100, the specific surface area is 505-850 m<2> / g, the pore volume is 0.35-0.60 mL / g, and the relative crystallinity degree is 100%-148%; the relative crystallinity degree of the beta molecular sieve subjected to water steam hydrothermal treatment is more than or equal to 95%. The beta molecular sieve with high crystallinity degree, high silica / alumina ratio and good stability is used as an acid component of the carrier and cooperates with the amorphous silica-alumina, so a hydrogenation cracking catalyst prepared by the obtained carrier has the characteristics of high activity, good medium oil selection, and good product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of diesel oil hydrogenation upgrading catalyst carrier and preparation method thereof

ActiveCN104667995BSuitable for lysisImprove heterogeneous performanceCatalyst carriersMolecular sieve catalystsMolecular sieveSilicon

The invention discloses a hydroupgrading catalyst carrier and a preparation method thereof. The carrier contains a beta molecular sieve and aluminum oxide, wherein the natures of the beta molecular sieve are as follows: the molar ratio of SiO2 / Al2O3 is 30-150, non-framework aluminum accounts for below 2% of total aluminum, and silicon atoms coordinated by a Si(OAl) structure account for above 95% of the silicon atoms in a framework structure. The preparation method comprises the following steps: mixing the beta molecular sieve and aluminum oxide and forming for preparation. The carrier disclosed by the invention takes the beta molecular sieve with a uniform framework silica-alumina structure as a cracking component, and a catalyst prepared by using the carrier disclosed by the invention has the characteristics of high yield of a diesel product, good product quality and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation cracking catalyst and preparation method of same

ActiveCN106140280AHigh crystallinityImprove stabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The invention discloses a hydrogenation cracking catalyst and a preparation method of same. The hydrogenation cracking catalyst comprises a carrier and a hydrogenation active metal component, wherein the carrier includes [beta] molecular sieve, amorphous silica-alumina, and an adhesive. On the basis of the weight of the carrier, the carrier includes, by weight, 2-15% of the [beta] molecular sieve, 45-85% of the amorphous silica-alumina, and 13-40% of the adhesive. In the carrier, the [beta] molecular sieve, which is high in crystallization degree, high in Si / Al ratio and good in stability, is used as an acidic component and is matched with the amorphous silica-alumina, so that the hydrogenation cracking catalyst prepared with the carrier is especially suitable for a single-stage hydrogenation cracking process with high activity, good medium oil selectivity and high product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing food-level white oil by hydrogenation technique

ActiveCN101148610BHigh activityHigh selectivityTreatment with hydrotreatment processesHydrocarbon oils refiningMolecular sieveDistillation

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking inside a hydrocracking co-current reactor to obtain reaction product, hydrorefining in a countercurrent hydrorefining reactor with flash region to exhaust gas and liquid hydrocarbon, the reverse contact reaction between the downward flowing liquid hydrocarbon and the bottom entering newly formed hydrogen in the bed layer with reduction type hydrogenating catalyst, and final gas-liquid separation and product distillation, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of naβ type molecular sieve and preparation method thereof

ActiveCN106145140BHigh crystallinityHigh purityCrystalline aluminosilicate zeolitesMolecular sieveCrystallinity

The invention discloses a Naβ molecular sieve and a preparation method thereof. The properties of the Naβ-type molecular sieve are as follows: the SiO2 / Al2O3 molar ratio is 40-100, the specific surface area is 500-800m2 / g, the pore volume is 0.35-0.60mL / g, and the relative crystallinity is 101%-150%. The relative crystallinity of the molecular sieve after air roasting is above 100%; the relative crystallinity of the Naβ molecular sieve after steam hydrothermal treatment is above 95%. The preparation method of the invention can not only reduce the usage amount of the organic template, but also can synthesize the Naβ molecular sieve with high crystallinity and high silicon-aluminum ratio, and has better thermal stability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior diesel oil hydrogenation upgrading catalyst carrier and preparation method thereof

ActiveCN107233913BSuitable for lysisImprove heterogeneous performanceCatalyst carriersMolecular sieve catalystsAlkaneMolecular sieve

The invention discloses an inferior-diesel hydro-upgrading catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified beta molecular sieve, amorphous silica-alumina, macroporous alumina and SB powder. When the catalyst carrier is used for preparing a catalyst, metals for hydrogenation comprise non-noble metals of group VIB and group VIII. The modified beta molecular sieve and the amorphous silica-alumina are taken as cracking components, so that nitrogen resistance of the catalyst is improved, and long-period operation of the catalyst is ensured when high-nitrogen materials are being processed. The modified beta molecular sieve has good cycloalkane ring opening selectivity and a good alkane isomerism performance, and exhibits the advantages of high diesel productivity, large reduction amplitude of diesel solidifying point and obvious improvement of cetane number while the carrier is used for catalytically processing inferior diesel.

Owner:PETROCHINA CO LTD

A Fischer-Tropsch synthetic oil production api Ⅲ + Hydrogenation method of base oil

ActiveCN111378495BSlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Using Fischer-Tropsch synthetic oil as raw material, the two-stage hydrogenation process of hydrorefining-hydro-upgrading-isomerization dewaxing is used to produce API III + Lubricant base oil. Hydrofining - The resulting oil obtained from the separation of the hydrogenation upgrading reaction effluent enters the isomerization dewaxing reaction zone, and the isomerization dewaxing reaction effluent is separated and fractionated to obtain different types of API III + Lubricant base oil products. The invention has simple technological process and wide adaptability of raw materials, and can be applied to the process of producing special oil products with good stability through hydrogenation of Fischer-Tropsch synthetic oil distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation process for producing API III+ base oil from Fischer-Tropsch synthetic oil

ActiveCN111378493BSlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationHydrogenation process

The invention discloses a method for producing API III from Fischer-Tropsch synthetic oil + Hydrogenation process of lube base oil. Using Fischer-Tropsch synthetic oil as raw material, adopt the two-stage hydrogenation process of hydrofining-hydro-upgrading-isomerization dewaxing to produce API III + Lubricant base oil. Hydrofining - The resulting oil obtained from the separation of the hydrogenation upgrading reaction effluent enters the isomerization dewaxing reaction zone, and the isomerization dewaxing reaction effluent is separated and fractionated to obtain different types of API III + The lubricating oil base oil product, the incompletely converted wax component obtained by cooling the fractionated reduced bottom oil is returned to the hydrogenation reforming reactor to continue the reforming reaction. The invention has simple technological process and wide adaptability of raw materials, and can be applied to the process of producing special oil products with good stability through hydrogenation of Fischer-Tropsch synthetic oil distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing food grade white oil by hydrogenating tail oil

ActiveCN100422295CHigh activityHigh yieldTreatment with hydrotreatment processesEdible oils/fatsHigh pressurePour point

The present invention provides method of producing food grade white oil with hydrogenated tail oil. Hydrogenated tail oil as material is treated through one high pressure hydrogenating and refining process under proper condition to obtain the food grade white oil product. The hydrogenated tail oil is produced with vacuum gas oil, refined solvent oil or Fischer-Tropsch synthesized oil as material and through hydrocracking or hydrotreating process under the action of hydrogenating catalyst, and has pour point lower than -10deg.c.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst and preparation method thereof

ActiveCN106140280BHigh crystallinityImprove stabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The invention discloses a hydrogenation cracking catalyst and a preparation method of same. The hydrogenation cracking catalyst comprises a carrier and a hydrogenation active metal component, wherein the carrier includes [beta] molecular sieve, amorphous silica-alumina, and an adhesive. On the basis of the weight of the carrier, the carrier includes, by weight, 2-15% of the [beta] molecular sieve, 45-85% of the amorphous silica-alumina, and 13-40% of the adhesive. In the carrier, the [beta] molecular sieve, which is high in crystallization degree, high in Si / Al ratio and good in stability, is used as an acidic component and is matched with the amorphous silica-alumina, so that the hydrogenation cracking catalyst prepared with the carrier is especially suitable for a single-stage hydrogenation cracking process with high activity, good medium oil selectivity and high product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN106140285BHigh crystallinityImprove stabilityCatalyst carriersMolecular sieve catalystsMolecular sieveAdhesive

The invention discloses a preparation method for a hydrocracking catalyst and a preparation method thereof. The catalyst comprises a carrier and a hydrogenation active metal component. The carrier comprises a beta molecular sieve, amorphous silicon aluminum and an adhesive. The beta molecular sieve has the properties that a mol ratio of SiO2 to Al2O3 is 60 to 100; a specific surface area is 505 to 850 m<2> / g; a pore volume is 0.35 to 0.60 mL / g; and relative crystallinity is 100 to 148%. After hydro-thermal treatment by water vapor, the relative crystallinity of the beta molecular sieve is 95% or above. According to the invention, the beta molecular sieve with high crystallinity, a high silica-alumina ratio and good stability is used as an acidic component of the carrier and matched with amorphous silicon aluminum; and the hydrocracking catalyst prepared from the carrier is especially applicable to one-stage tandem hydrocracking process and has the characteristics of high activity, good medium oil selectivity and good product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Directly-prepared ultrahigh-purity carbon nanotube and preparation method thereof

The invention discloses a directly-prepared ultrahigh-purity carbon nanotube and a preparation method thereof, belonging to the technical field of carbon nanotubes. Under the condition that purification is not required, the purity of the carbon nanotube is greater than 99.7 weight percent, the tube diameter is between 0.8 nanometer and 30 nanometers, the specific surface area is between 200 m<2> / g and 500 m<2> / g, the agglomeration density is between 30 kg / m<3> and 150 kg / m<3> and the agglomeration particle size is between 20 microns and 150 microns. A method for directly preparing the ultrahigh-purity carbon nanotube by adopting a chemical vapor deposition method comprises the following steps of: dispersing catalyst crystal grains generated with a liquid phase method onto the surface of an inert carrier, drying and baking; cracking hydrocarbon with 1-6 carbon atoms in a fluidized bed reactor to generate a carbon nanotube; and separating the inert carrier from the generated carbon nanotube at a higher air speed. The carbon nanotube obtained with the method has the purity between 99.7 percent and 99.9 percent, and has the advantages of high carbon nanotube quality, no need of removing impurities by acid treatment, low cost and easiness for amplification and preparation.

Owner:TSINGHUA UNIV

A kind of hβ type molecular sieve and preparation method thereof

ActiveCN106145133BHigh crystallinityHigh purityMolecular-sieve and base-exchange compoundsMolecular sieveThermal stability

The invention discloses an Hβ molecular sieve and a preparation method thereof. The properties of the Hβ-type molecular sieve are as follows: the SiO2 / Al2O3 molar ratio is 40-100, the specific surface area is 502-850m2 / g, the pore volume is 0.35-0.60mL / g, and the relative crystallinity is 100%-148%. The relative crystallinity of the molecular sieve after steam hydrothermal treatment is above 95%. The preparation method of the present invention can not only reduce the usage amount of the organic template, but also can synthesize the Hβ molecular sieve with high crystallinity and high silicon-aluminum ratio, and has better thermal stability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Na-[beta]-type molecular sieve and preparation method thereof

ActiveCN106145140AGood crystal orientationReduce usageCrystalline aluminosilicate zeolitesChemistryMolecular sieve

The invention discloses a Na-[beta]-type molecular sieve and a preparation method thereof, wherein the Na-[beta]-type molecular sieve is 40-100 in molar ratio of SiO2 to Al2O3, is 500-800 m<2> / g in specific surface area, is 0.35-0.60 ml / g in pore volume, is 101-150% in relative crystallization degree, is more than 100% in relative crystallization degree when being roasted in air and is more than 95% in relative crystallization degree when being subjected to hydrothermal treatment with water vapor. The preparation method reduces use quantity of an organic template agent and can synthesize the Na-[beta]-type molecular sieve which is high in crystallization degree and silicon / aluminum ratio and has better thermal stability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com