Naphtha catalytic pyrolysis catalyst for preparing ethylene propylene

A catalytic cracking, ethylene propylene technology, applied in physical/chemical process catalysts, molecular sieve catalysts, hydrocarbon cracking to produce hydrocarbons, etc., can solve the problems of high operating temperature, low ethylene propylene yield, low catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

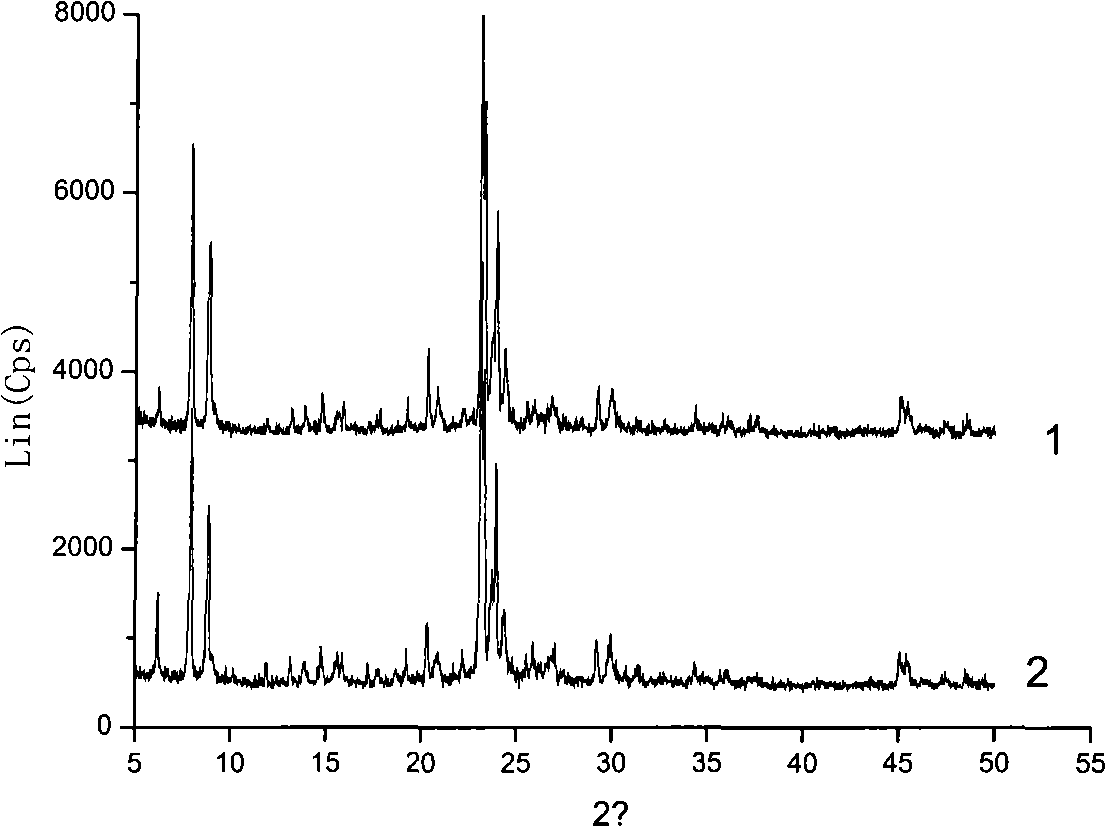

[0018] Take 284 grams of sodium metasilicate and dissolve it into solution A with 300 grams of distilled water. Take 33.3 grams of aluminum sulfate and use 100 grams of distilled water to make solution B. Pour solution B into solution A slowly, stir vigorously, and then add 24.4 grams of ethyl acetate. Diamine, after stirring for a period of time, adjust the pH to 11.5 with dilute sulfuric acid, and control the molar ratio of the sol as: Si:Al:ethylamine:H 2 O=1:0.1:0.4:40, add 2.8 grams of Y zeolite seed crystals, put the mixed solution into the autoclave, keep it at 130°C for 40 hours, then take it out and wash it twice, dry at 120°C for 4 hours, and roast at 550°C After 3 hours, the ZSM-5 / Y zeolite symbiotic molecular sieve was prepared. The XRD pattern is as follows figure 1 As shown in the middle curve 1, it can be quantified by XRD diffraction that the symbiotic molecular sieve contains 94.5% of ZSM-5 and 5.5% of Y zeolite by weight percentage. Exchange twice with 5% ammoniu...

Embodiment 2~4

[0020] According to the method of Example 1, the pH of the solution was controlled to be 10.5, 11, and 12, respectively, and ZSM-5 / Y zeolite symbiotic molecular sieves were synthesized, respectively, denoted as FH-2, FH-3, and FH-4. The ratio of ZSM-5 and Y zeolite is shown in Table 4. According to the method of Example 1, the results are shown in Table 5.

Embodiment 5~12

[0022] According to the method of Example 1, the different molar ratios of the solutions were controlled, and the synthesized ZSM-5 / Y zeolite intergrowth molecular sieve was shown in Table 2, and the ratio of ZSM-5 and Y zeolite was shown in Table 4. According to the method of Example 1, the results are shown in Table 5.

[0023] Table 2

[0024] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com