Patents

Literature

37results about How to "Good crystal orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

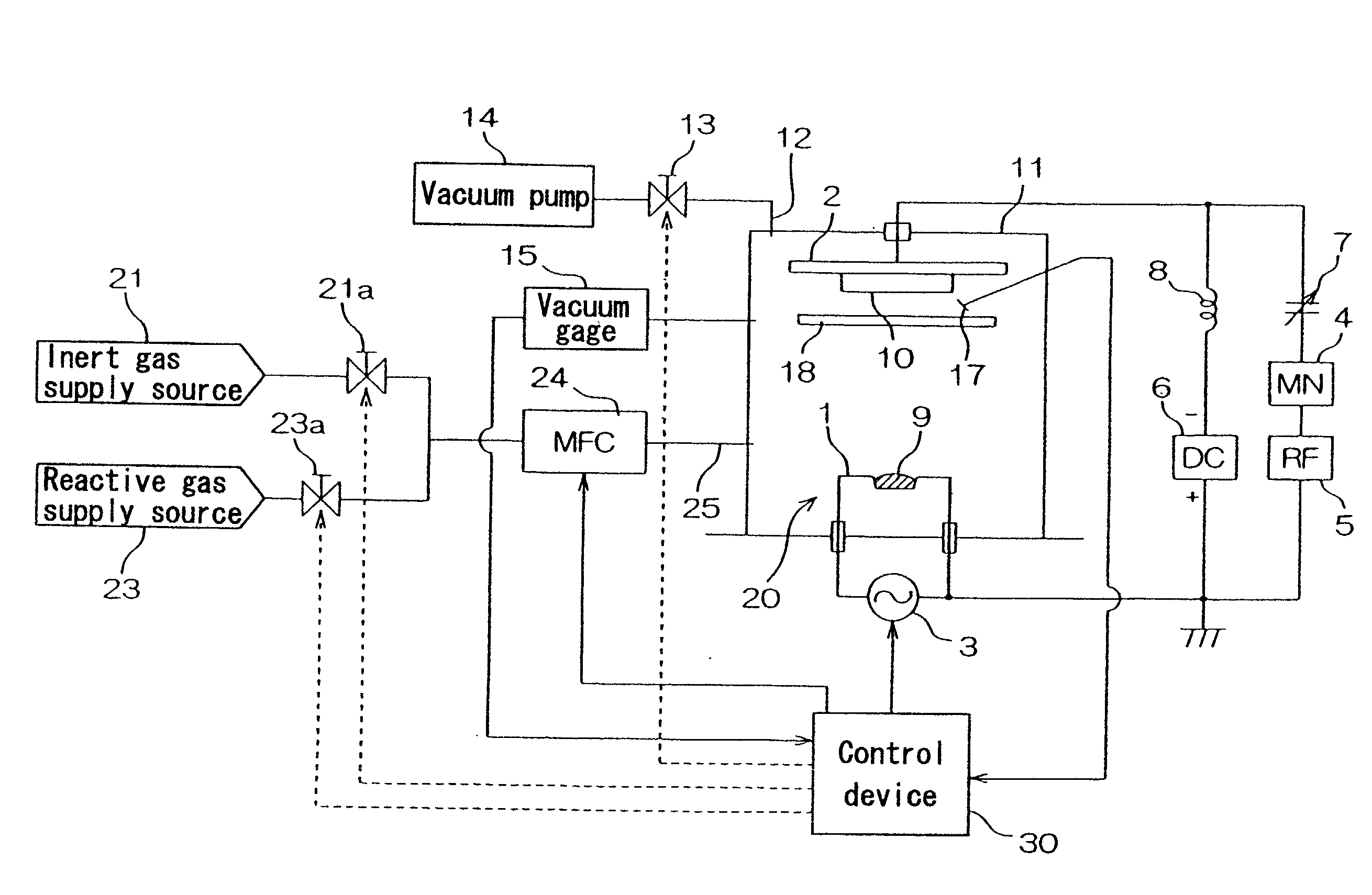

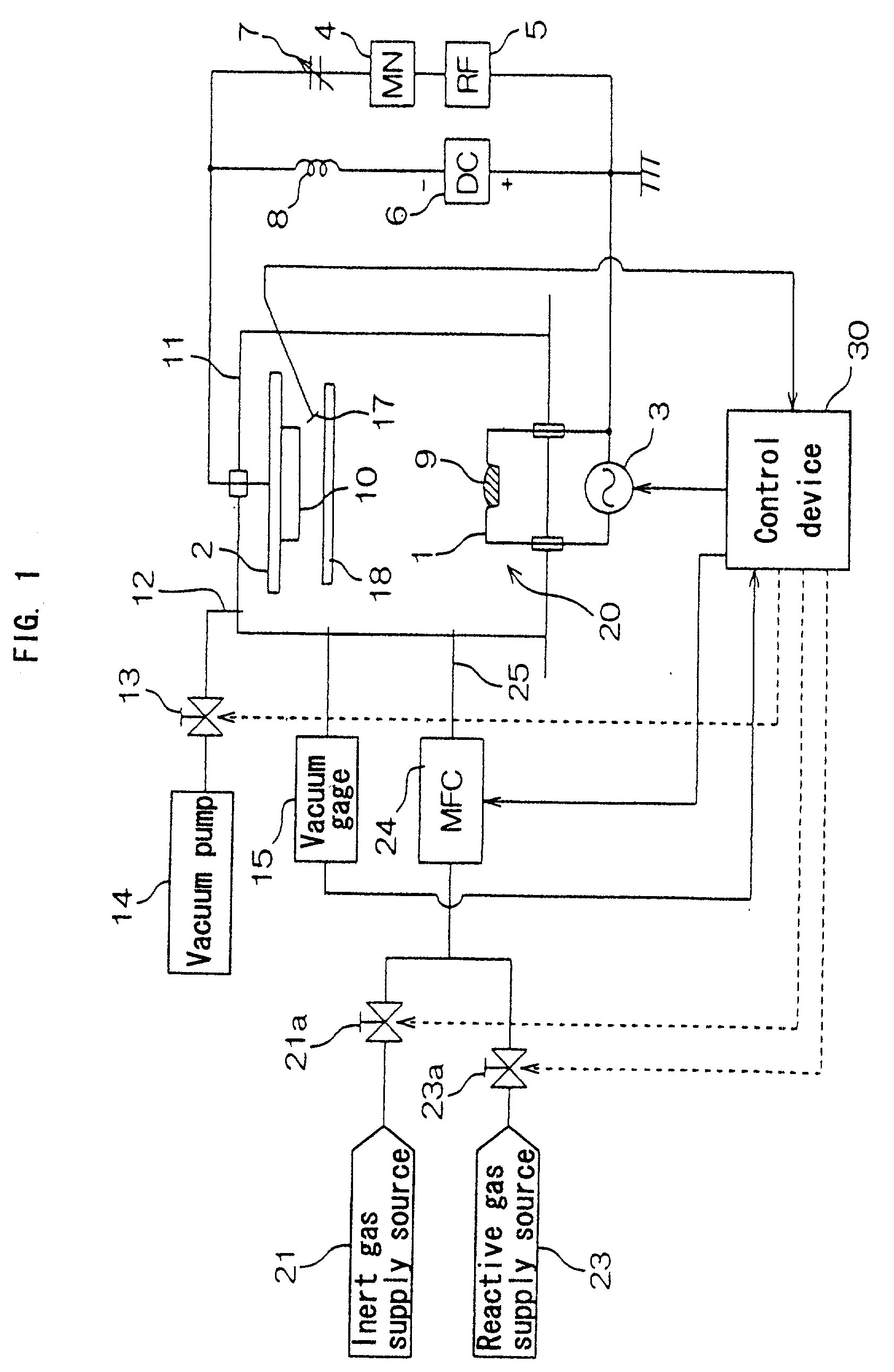

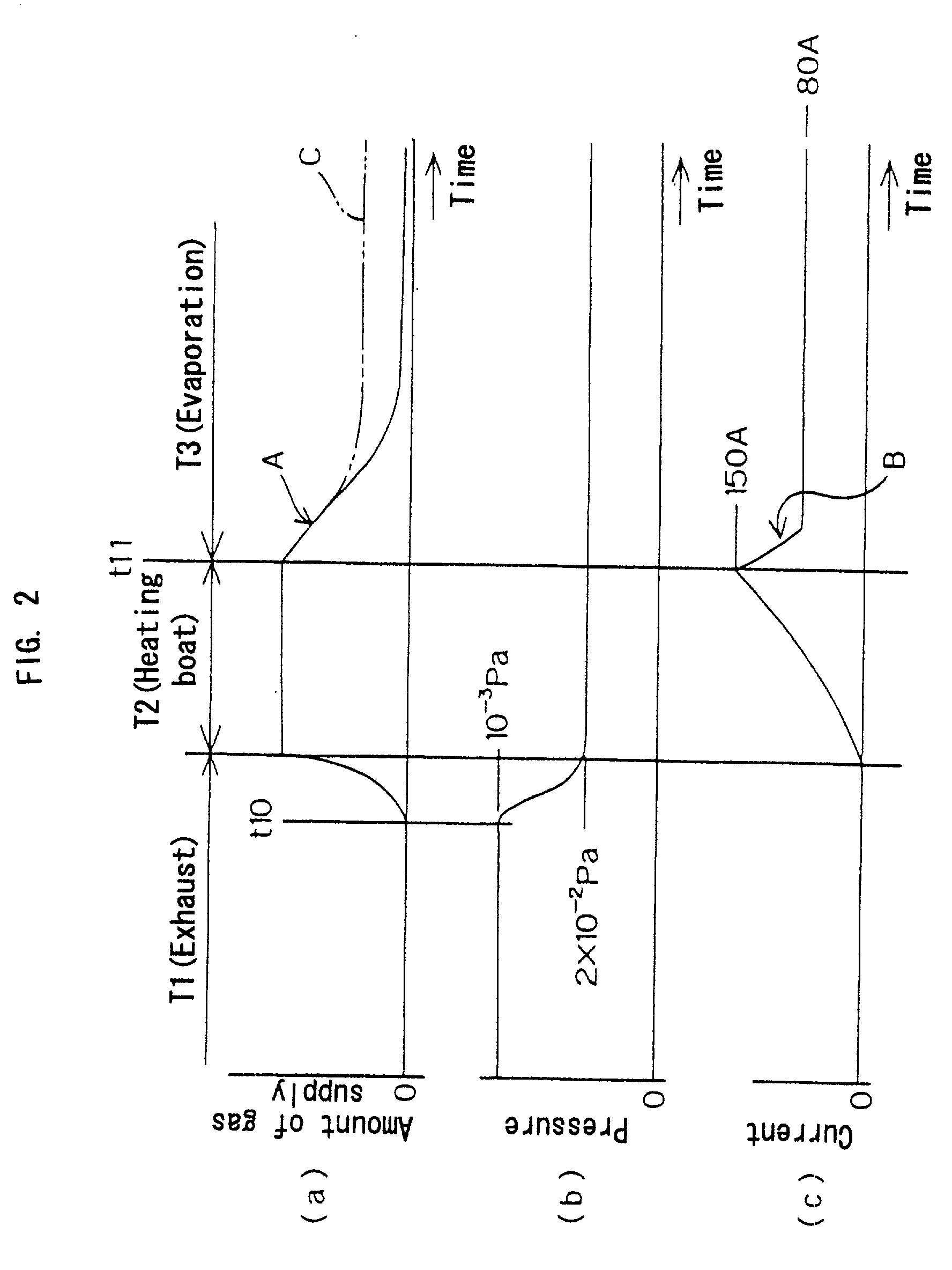

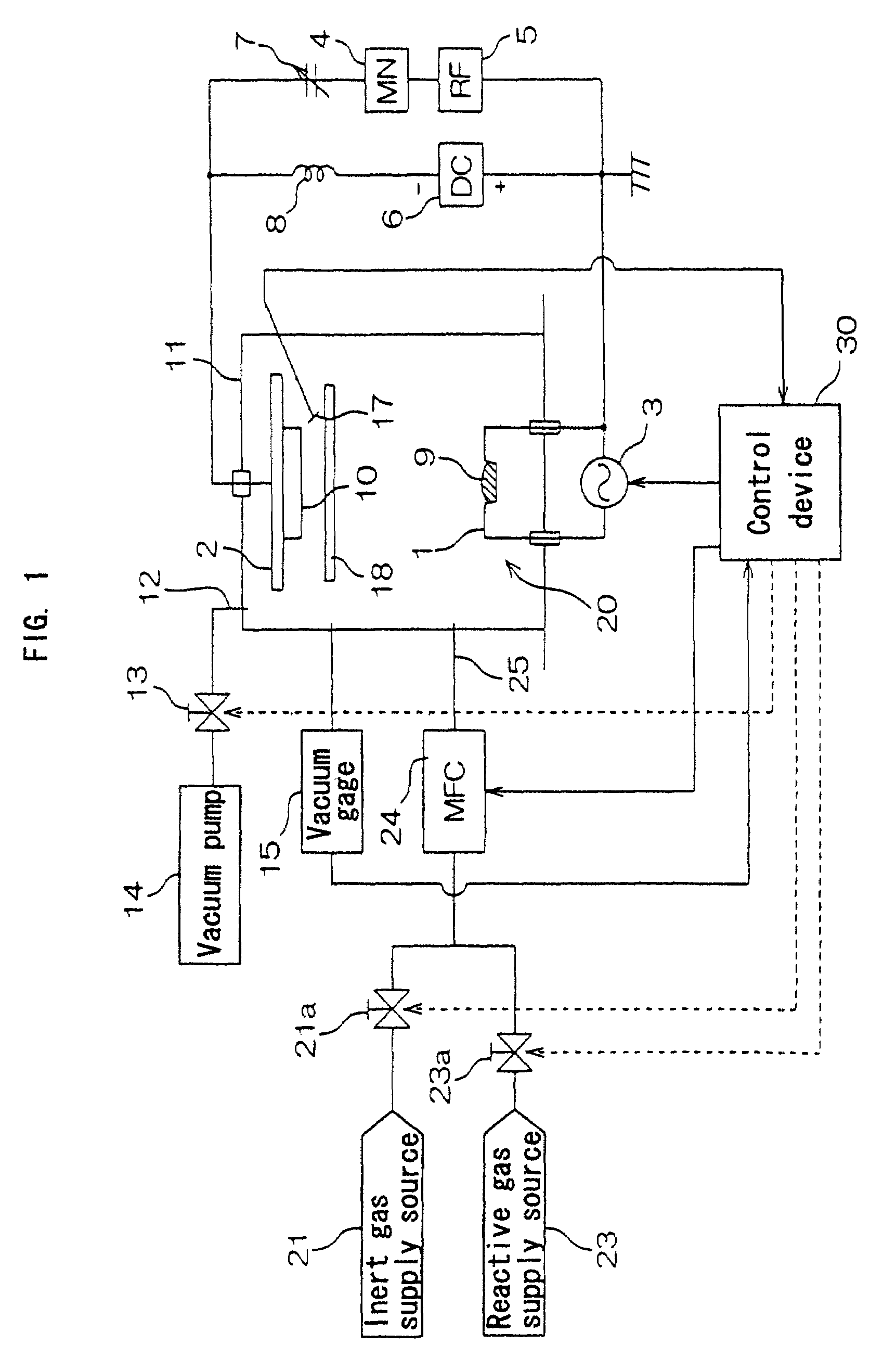

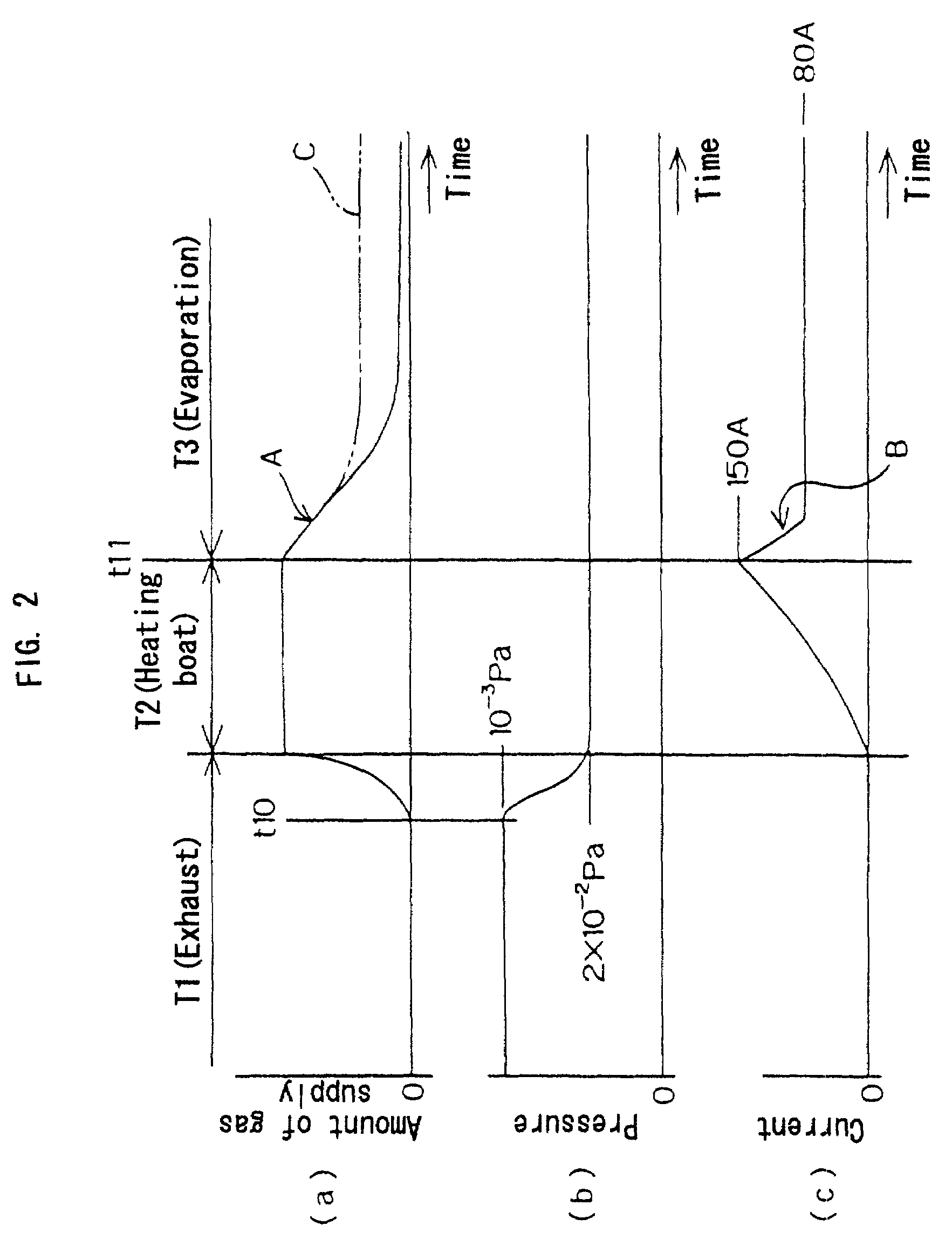

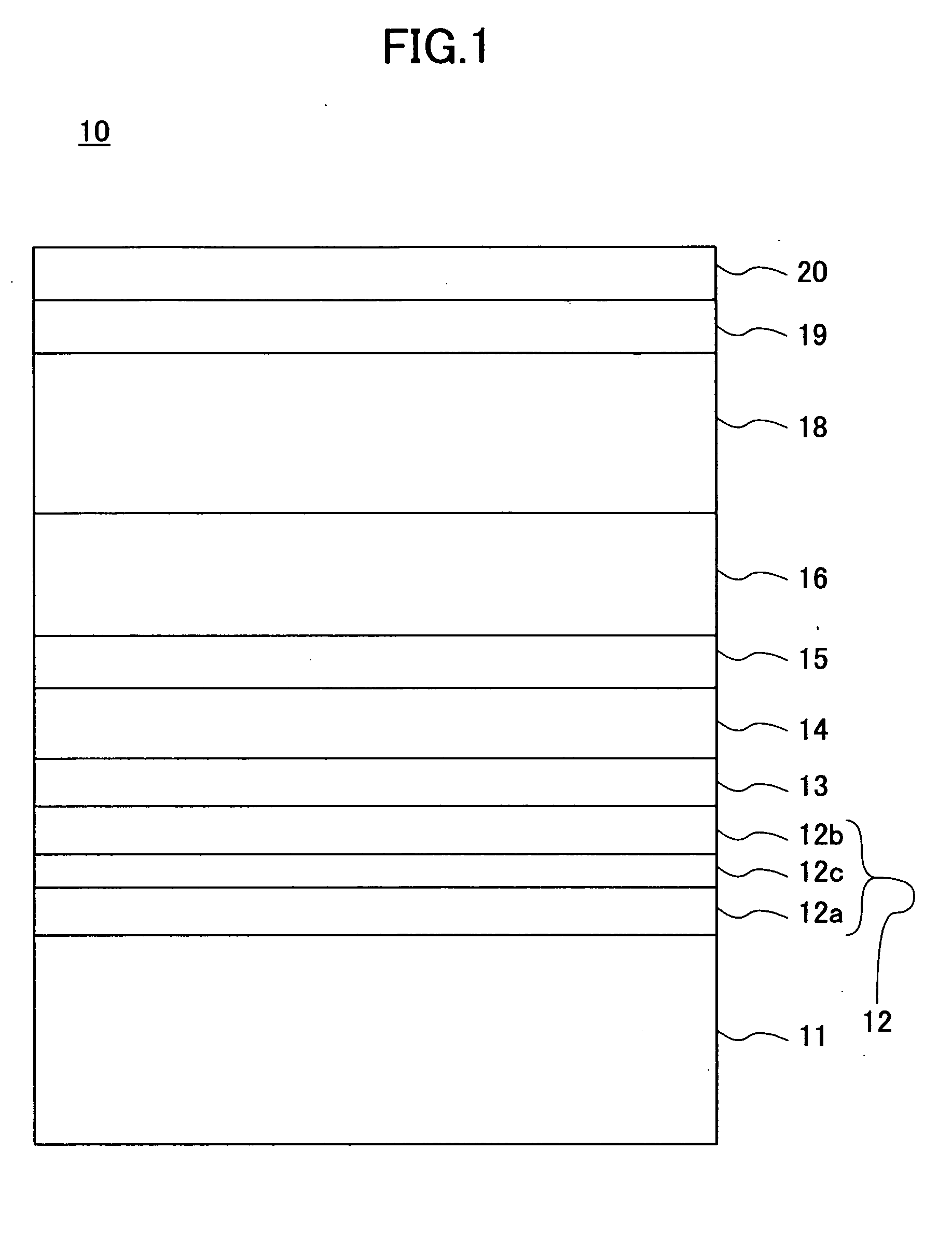

Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member , thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

ActiveUS20020126265A1Low surface roughnessGood crystal orientationVacuum evaporation coatingSputtering coatingCrystal orientationSingle crystal

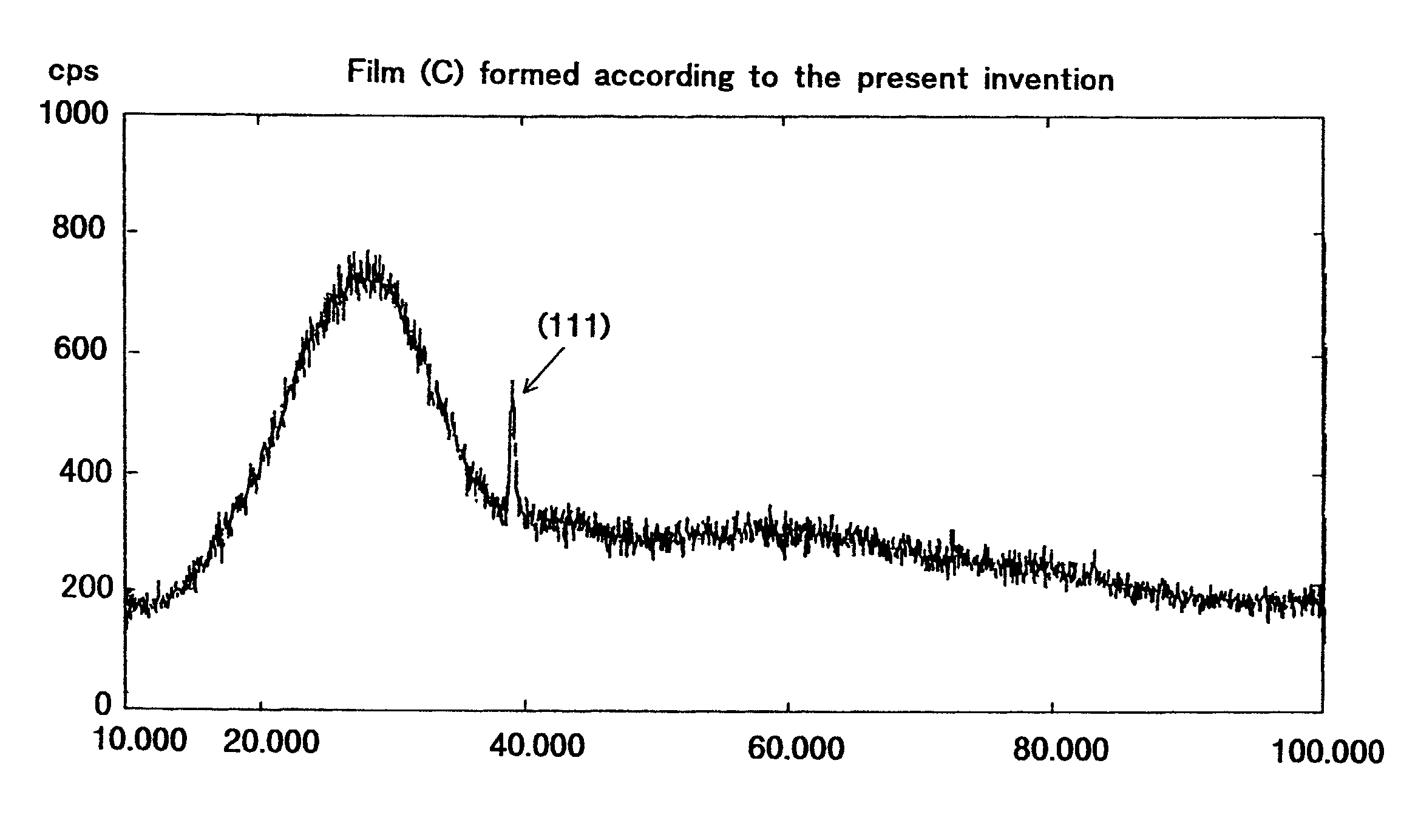

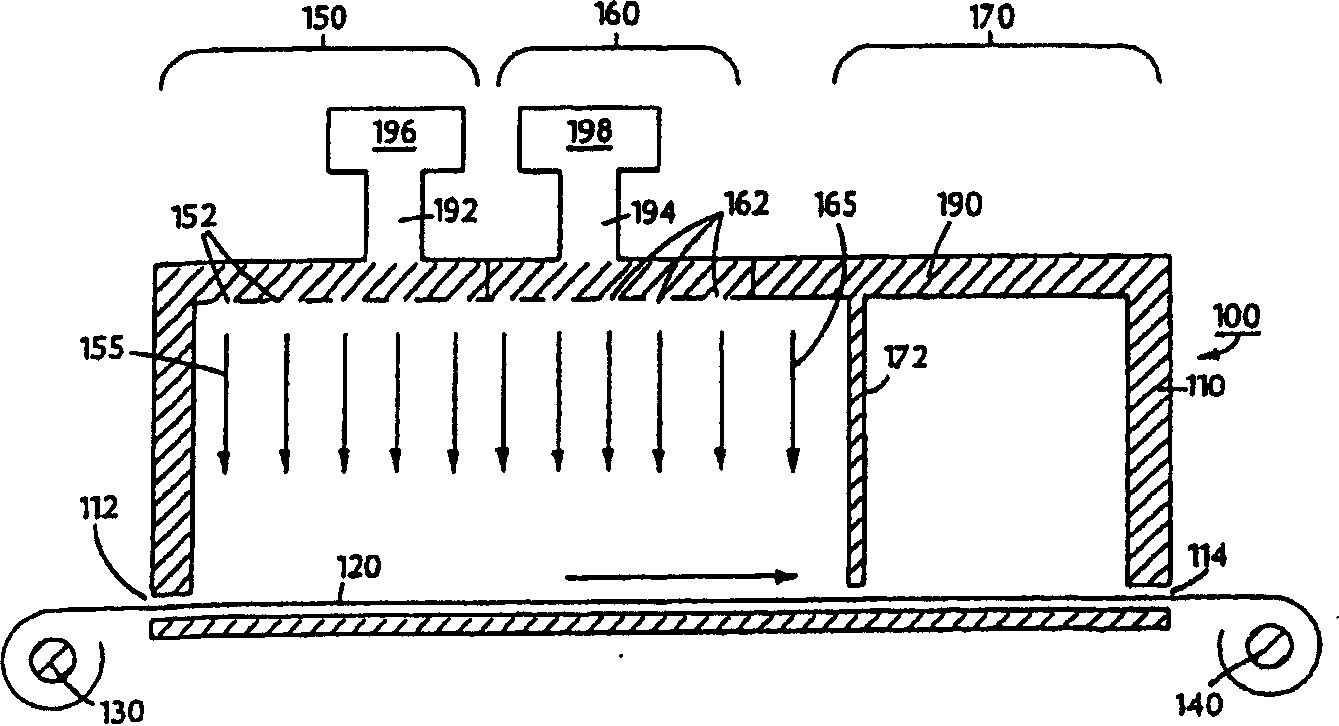

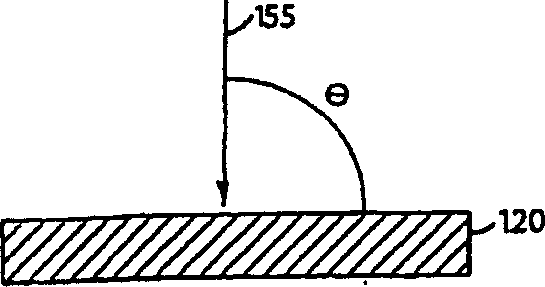

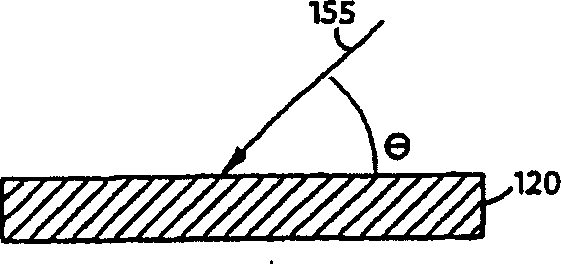

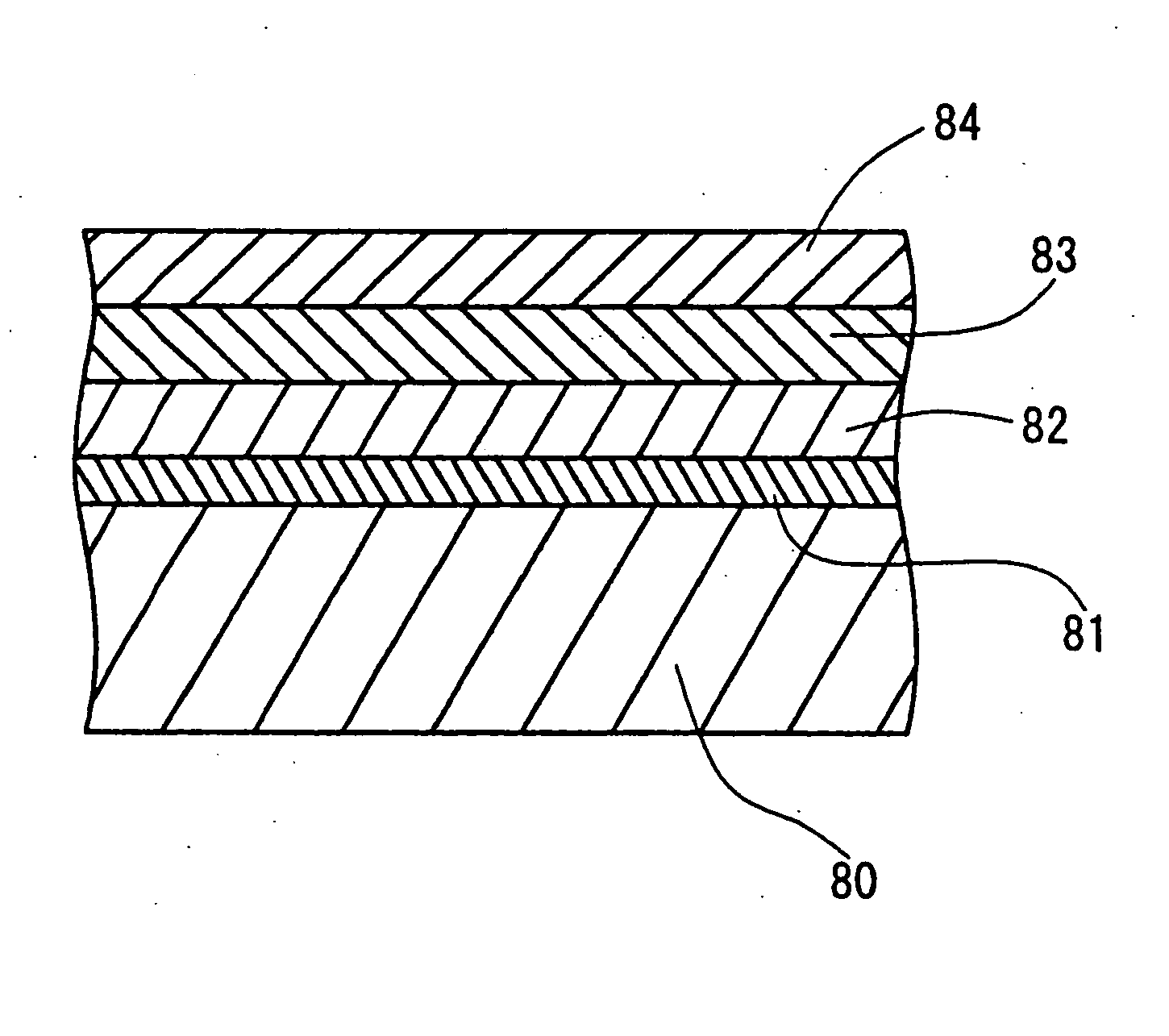

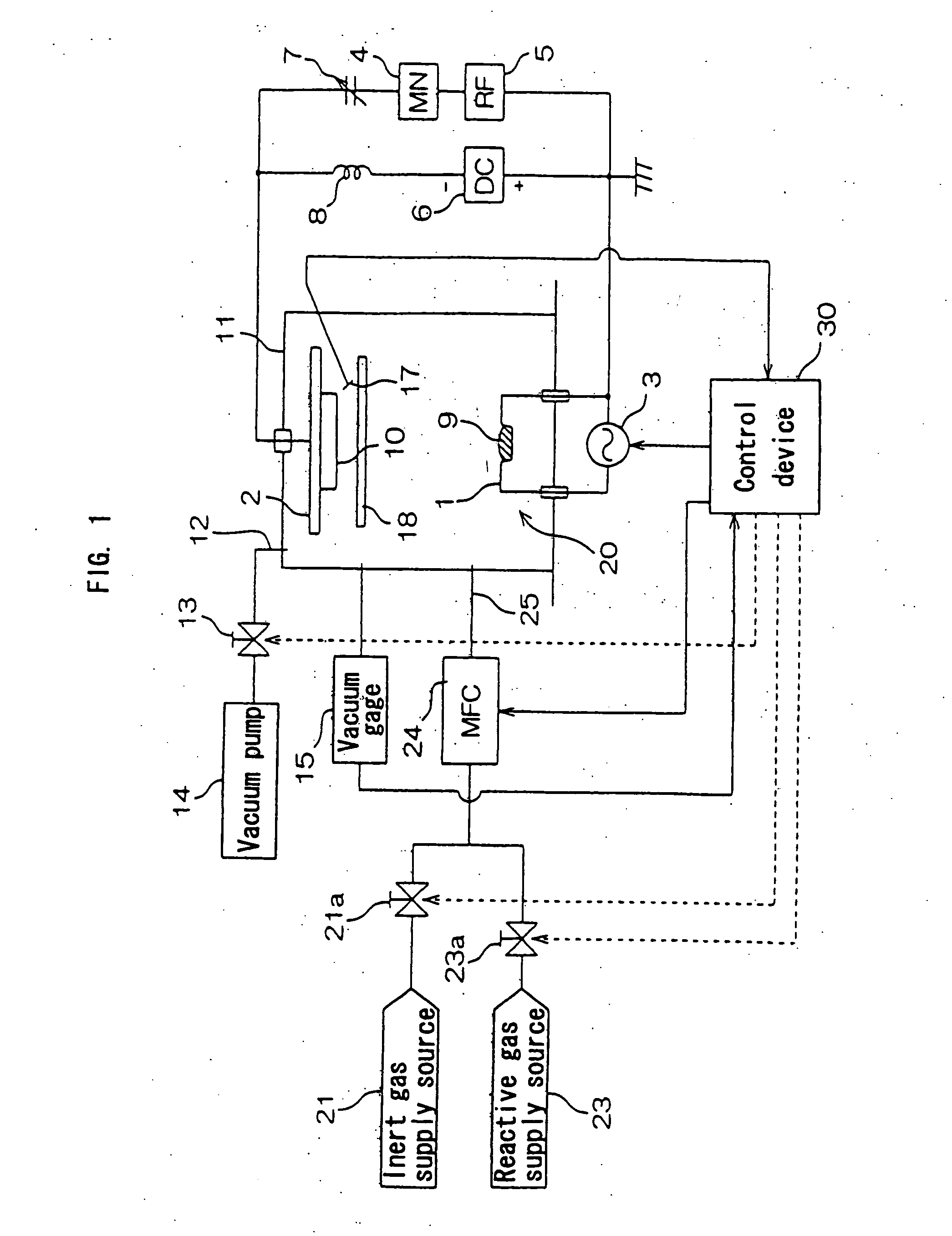

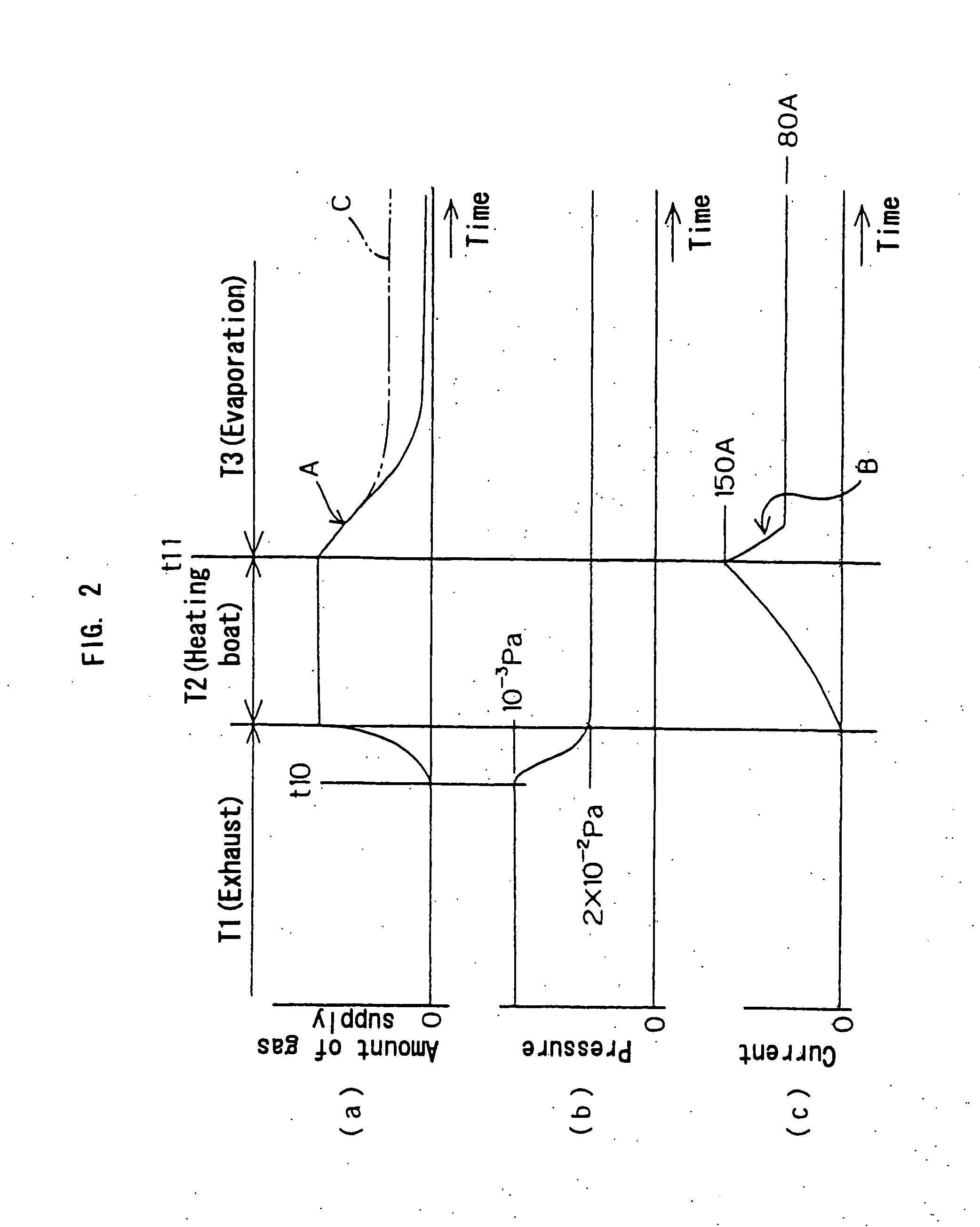

The metal film of the present invention is a dense film of a single crystal that has very low surface roughness and very good crystal orientation because an arithmetic mean roughness of the surface is not larger than 2 nm and a (111) peak intensity of X-ray diffraction is not less than 20 times the sum of all other peaks. Also the metal oxide film of the present invention is a dense film that includes less oxygen defects and almost no voids therein because a content of a non-oxidized metal is not higher than 1 mole % of a metal component that constitutes the metal oxide and a packing density is 0.98 or higher.

Owner:KYOCERA OPTEC

Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member, thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

ActiveUS7033679B2Reduce surface roughnessGood crystal orientationVacuum evaporation coatingGas discharge lampsPhysical chemistryCrystal orientation

The metal film of the present invention is a dense film of a single crystal that has very low surface roughness and very good crystal orientation because an arithmetic mean roughness of the surface is not larger than 2 nm and a (111) peak intensity of X-ray diffraction is not less than 20 times the sum of all other peaks. Also the metal oxide film of the present invention is a dense film that includes less oxygen defects and almost no voids therein because a content of a non-oxidized metal is not higher than 1 mole % of a metal component that constitutes the metal oxide and a packing density is 0.98 or higher.

Owner:KYOCERA OPTEC

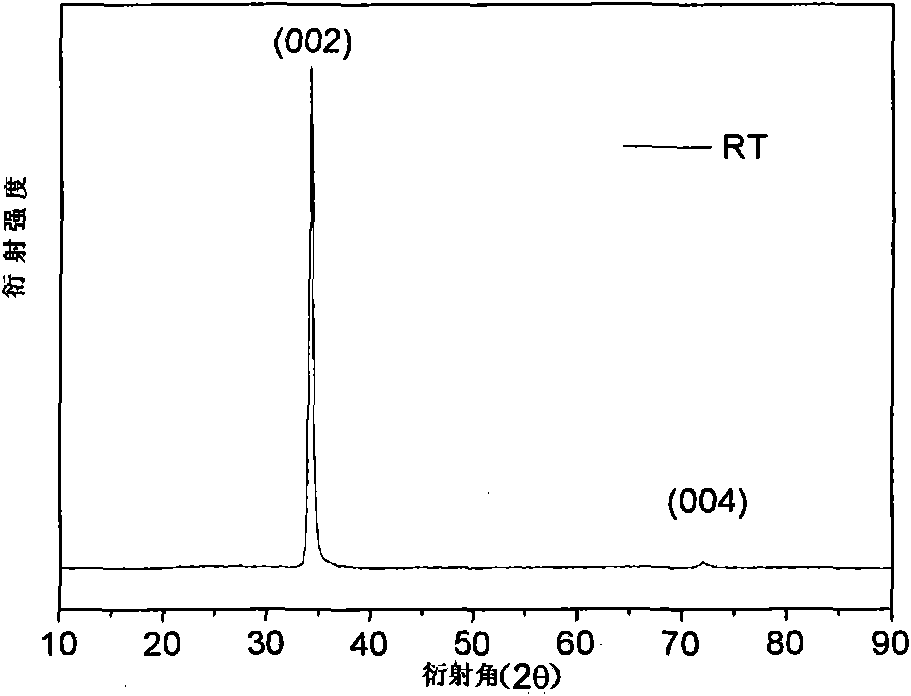

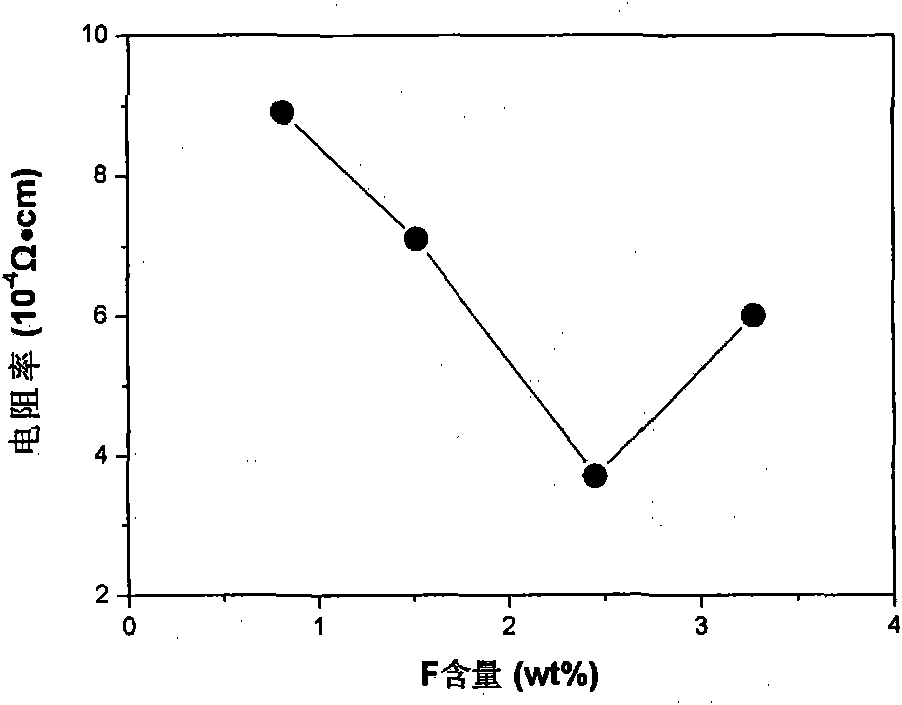

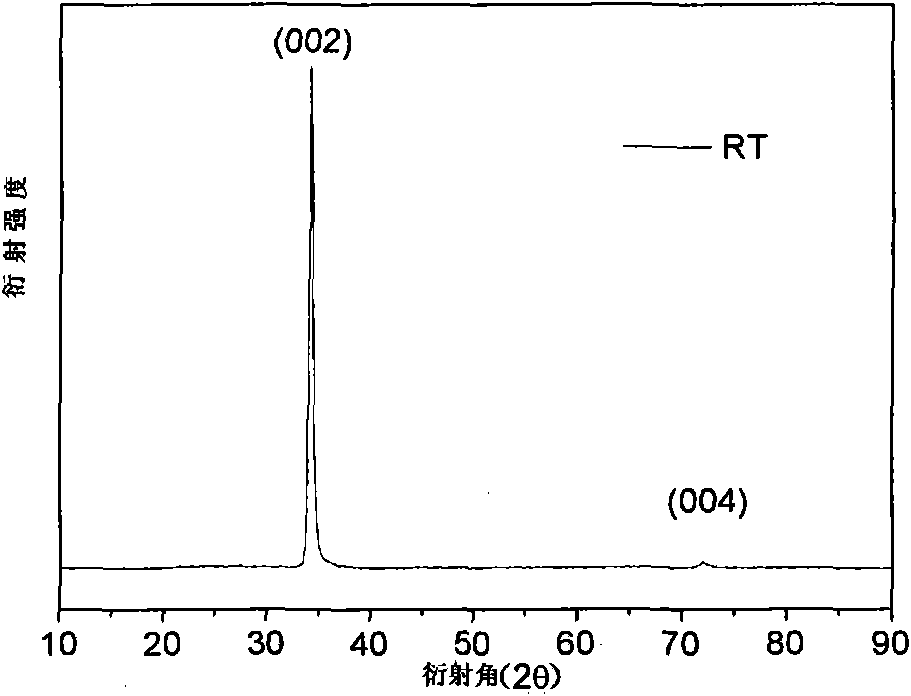

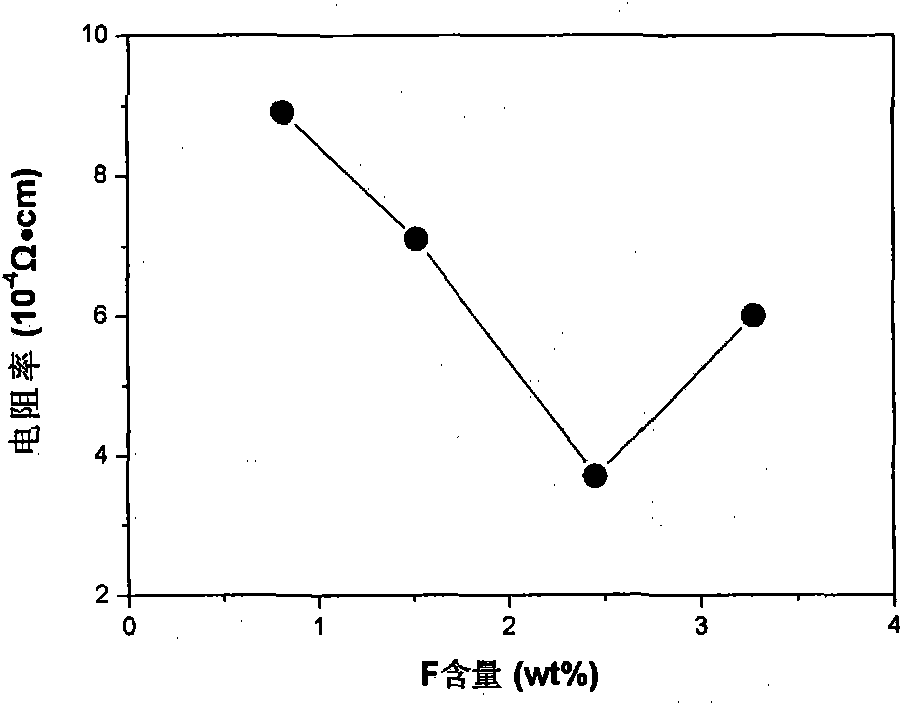

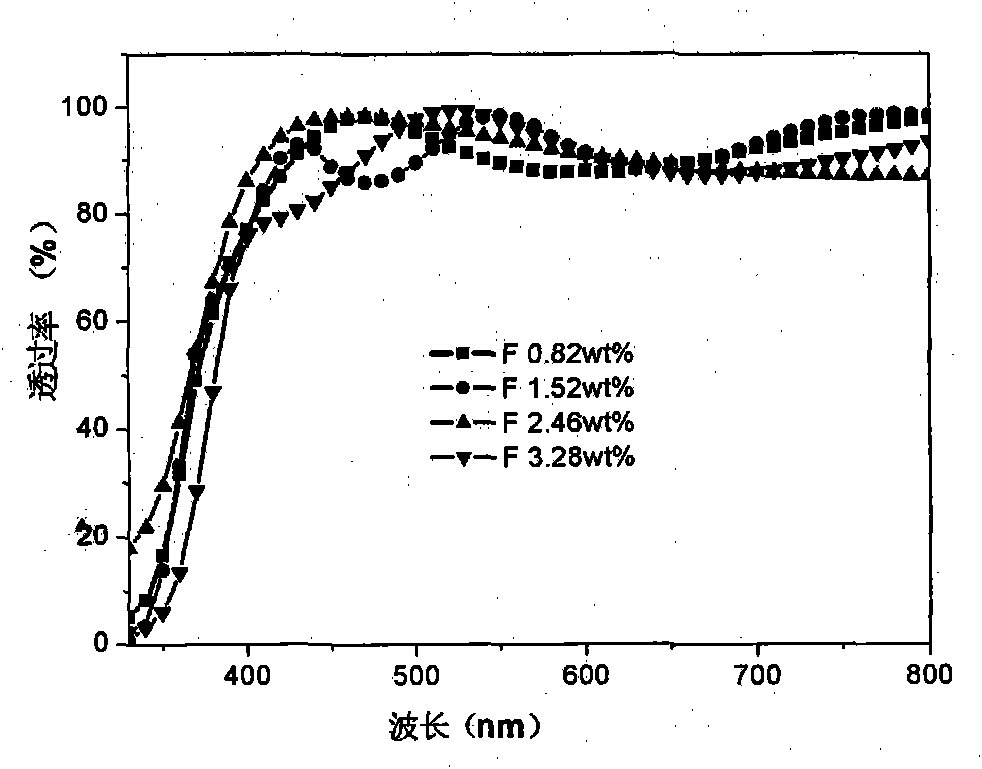

ZnO-based transparent conductive film co-doped with Al-F and preparation method thereof

InactiveCN101575697ASimultaneous dopingImprove conductivityVacuum evaporation coatingSputtering coatingSputteringRadio frequency magnetron sputtering

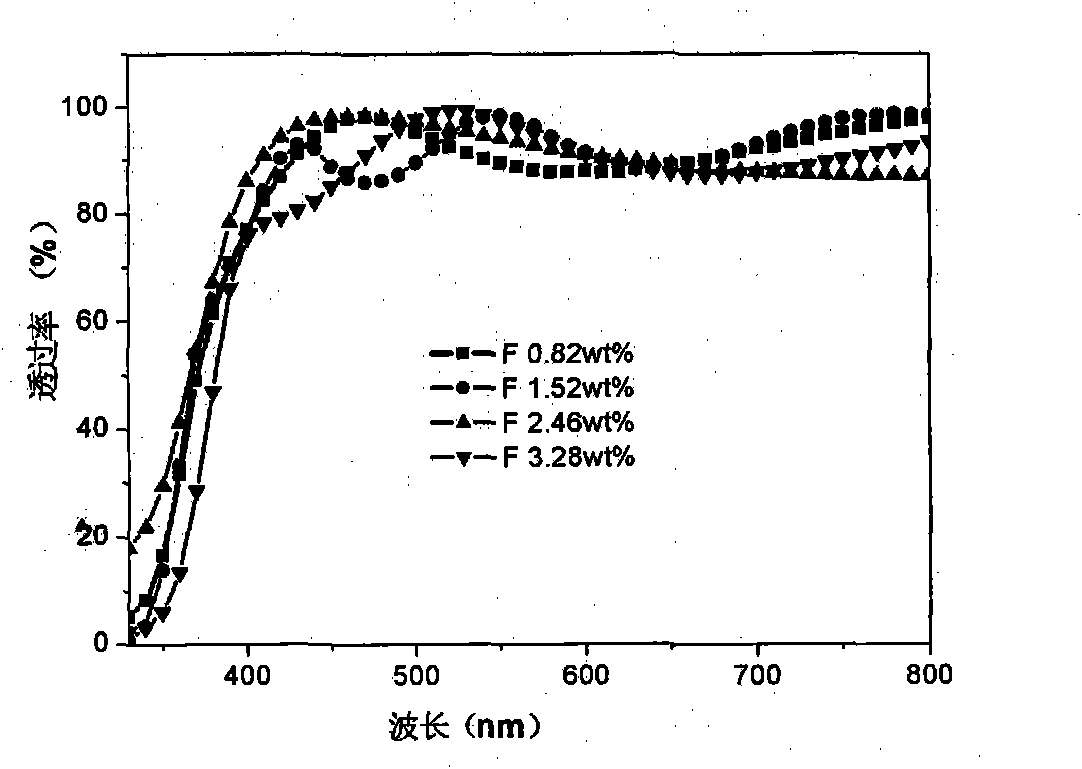

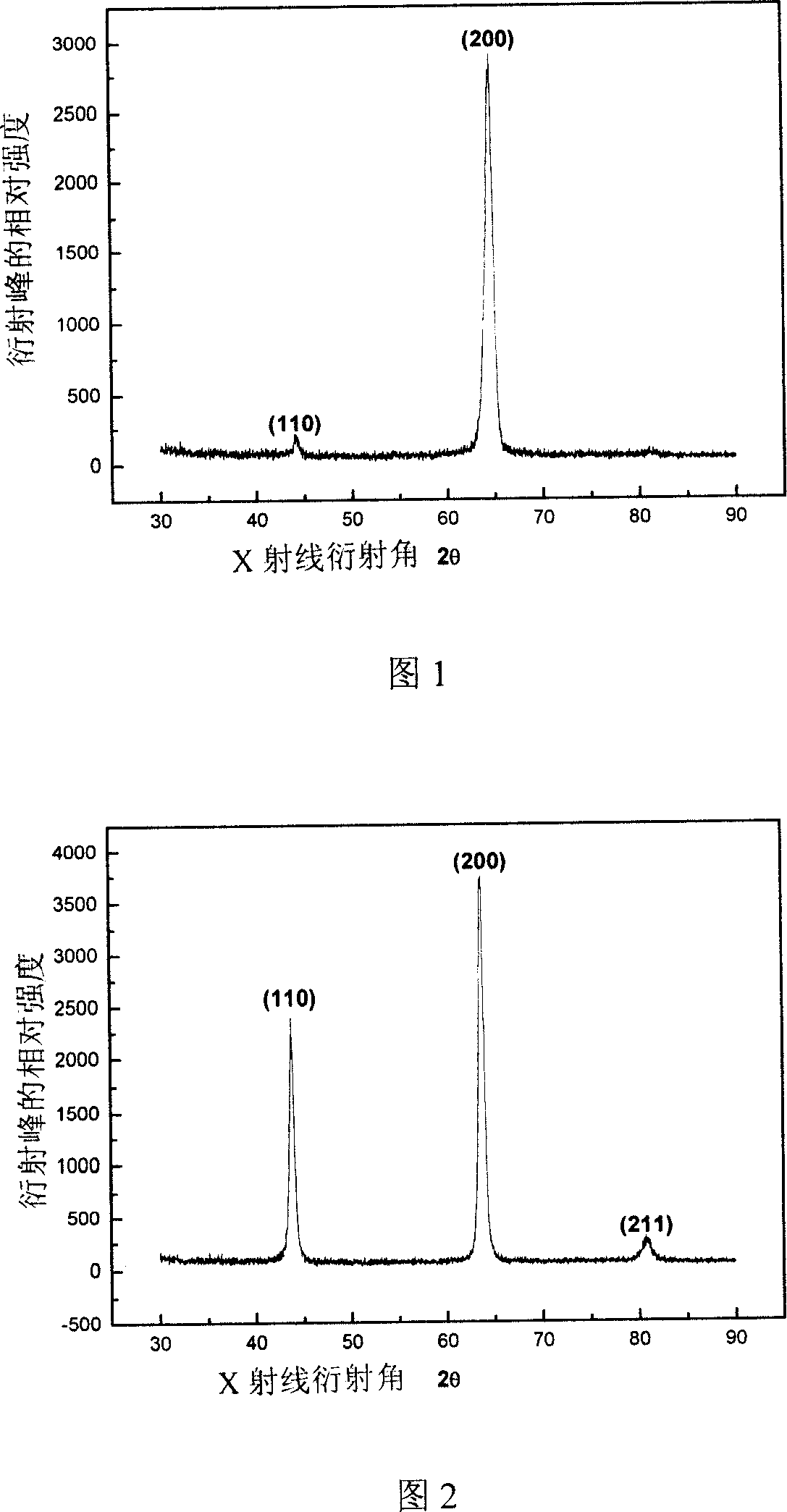

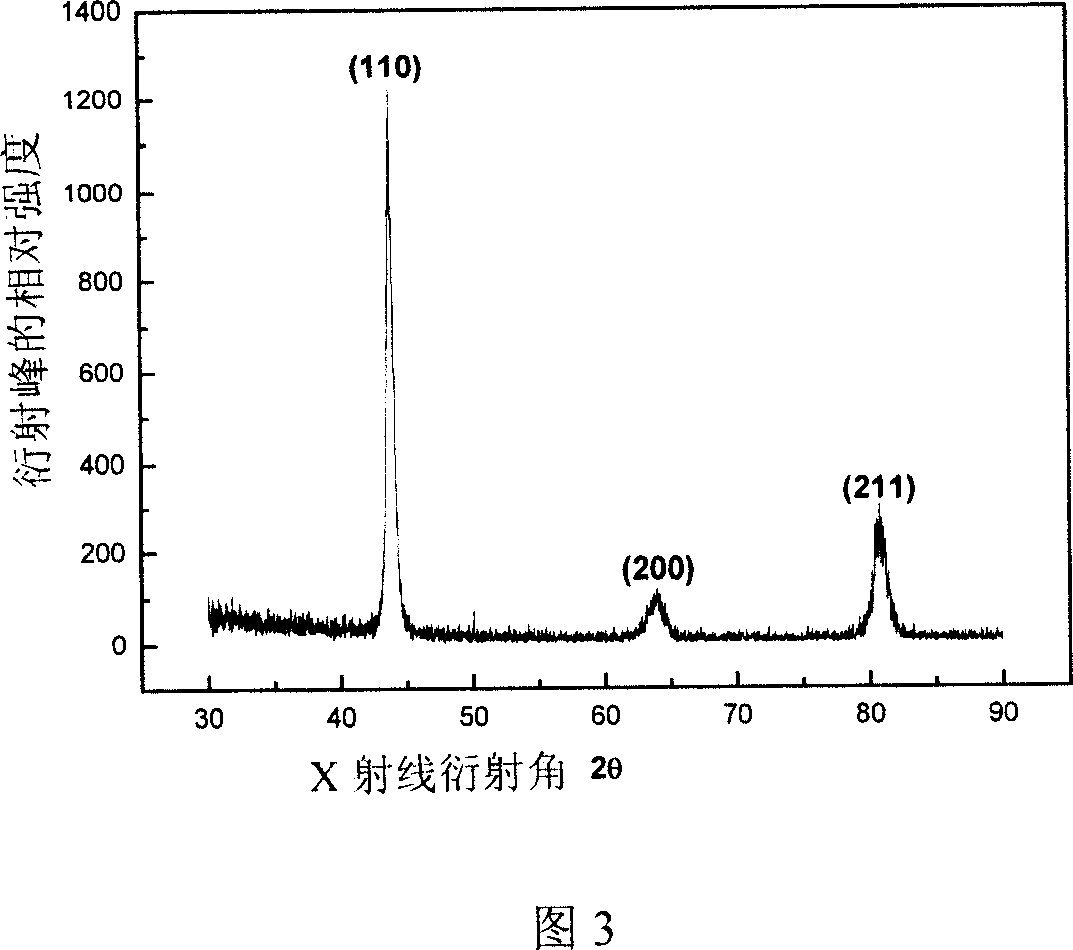

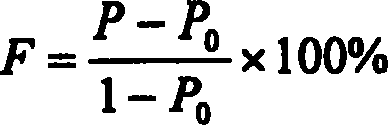

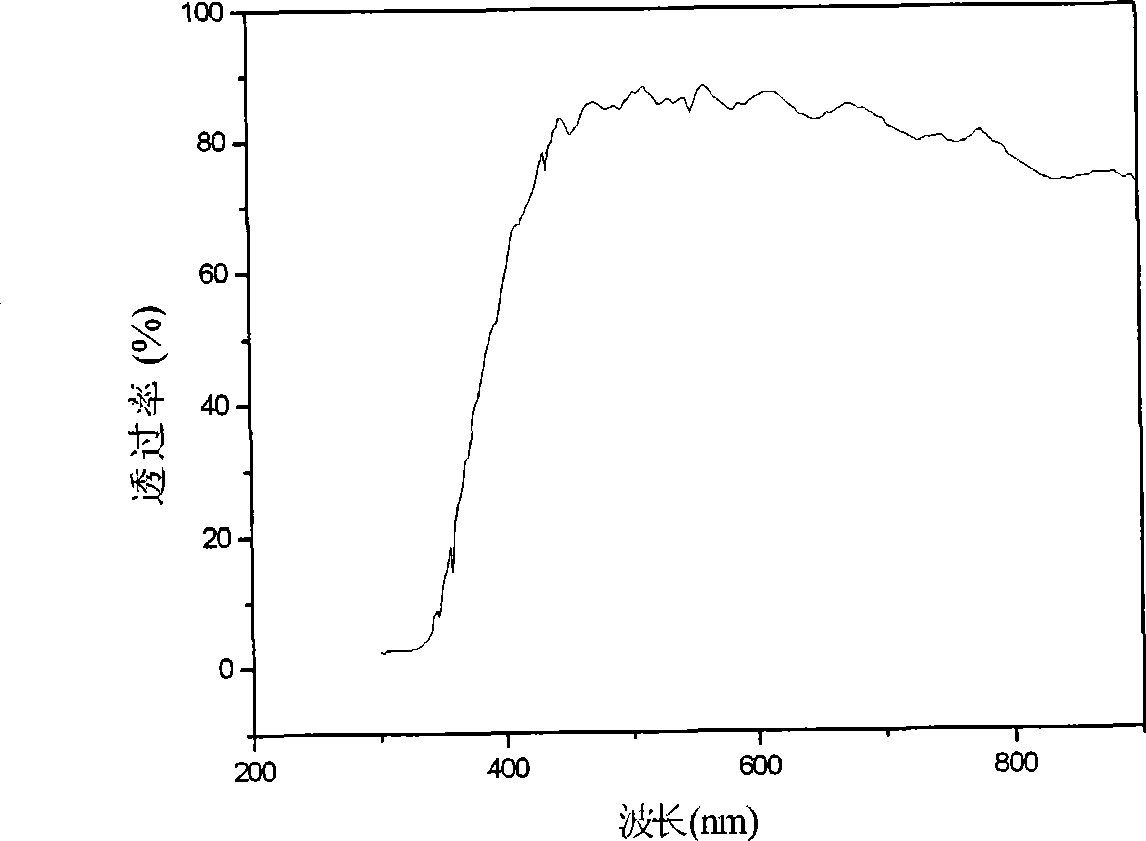

The invention belongs to the field of functional materials and relates to a ZnO-based transparent conductive film co-doped with Al-F and a preparation method thereof. The method is characterized in that the method comprises the following steps of: 1) firstly preparing a ZAFO target material, uniformly mixing AlF3, Al2O3 and ZnO powders to prepare the ZAFO target materials with different F contents respectively, wherein the ZAFO target materials contain, by weight percent (wt%): 0.5-3.0 of Al, 0.82-3.28 of F and the balance of ZnO; and 2) installing the prepared ZAFO target materials in the vacuum chamber of radio-frequency magnetism-controlled sputtering deposition equipment; utilizing a mechanical pump and a molecular pump to pump the vacuum chamber so that the vacuum degree is less than 3 multiplied by 10Pa; simultaneously, heating the substrate to the temperature of 25 DEG C-500 DEG C; adjusting the deposition process parameters and preparing the ZAFO transparent conductive film on the substrate by the radio-frequency magnetism-controlled sputtering. The method simplifies the coating process and improves the conductivity of the film and the transmittance of the visible light.

Owner:UNIV OF SCI & TECH BEIJING

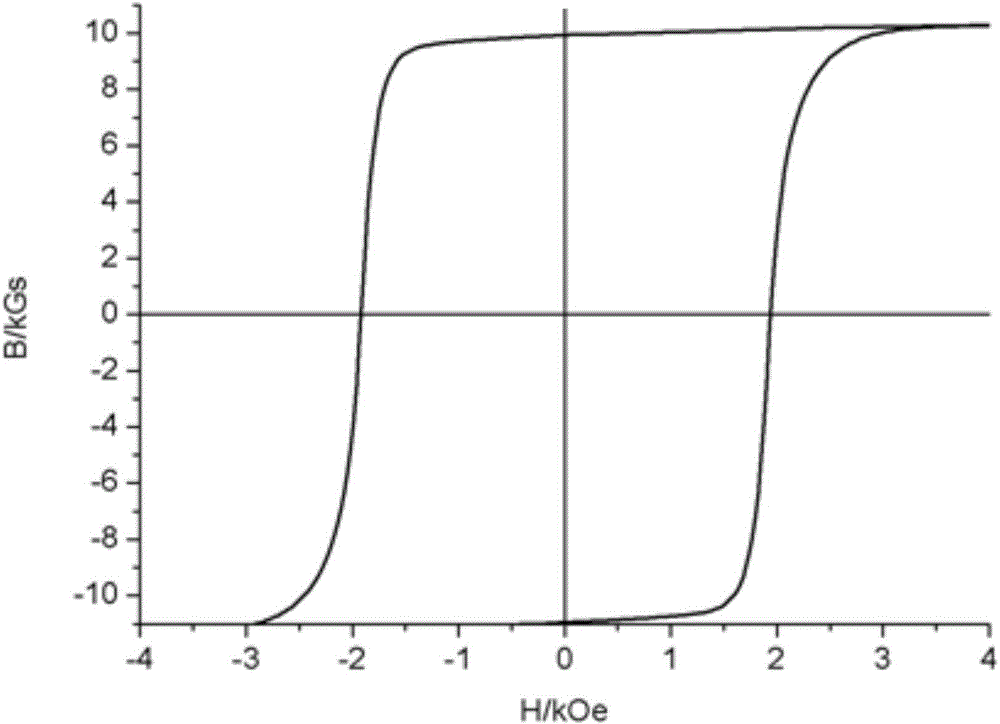

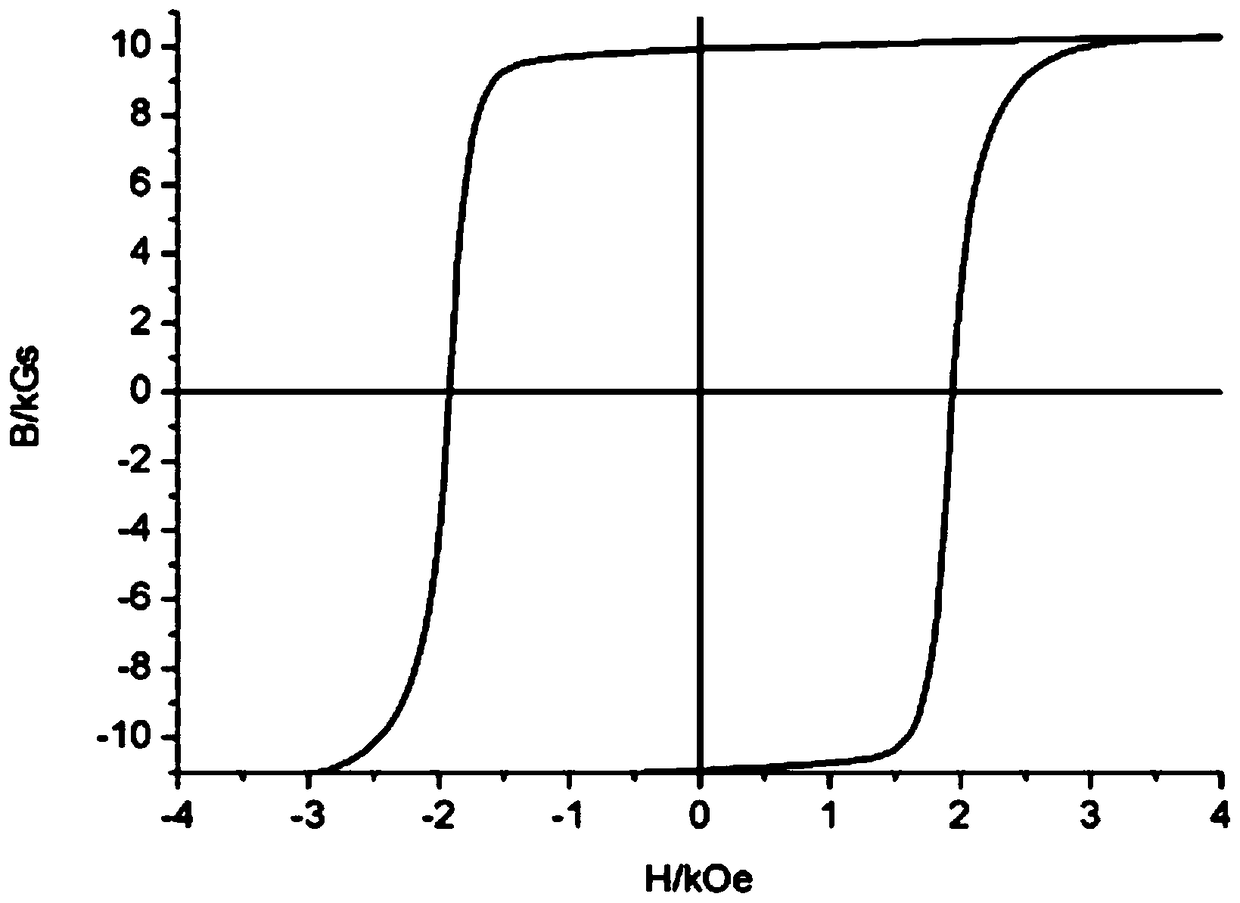

<100> Fe-Ga magnetostriction material on axial orientation and method of preparing the same

ActiveCN101109057ASimple structural designHigh magnetic field sensitivityFrom frozen solutionsMagnetostrictive material selectionBridgman methodRoom temperature

The invention discloses a <, a 100>, an axial orientation Fe-Ga magnetostriction material and the preparation method thereof. The material composites are Fe1-x-yGaxAly; wherein, x is between 16 per cent and 21 per cent or 25 per cent and 28 per cent; y is between 0 per cent and 10 per cent; the rest part is iron. The preparation method is that the raw material is melted under the protection of the inert gas, and the improved percy williams bridgman method is adopted to prepare the Fe-Ga magnetostriction material through the directional solidification; The heat treatment conditions are that the material is preserved at 1100 DEG C. to 1200 DEG C. for 0.5 hours to 24 hours, cooled with the furnace till 900 DEG C. to 750 DEG C. for 0.5 hours to 24 hours temperature preservation and then quenched or cooled by air to room temperature; or the material is preserved at 1100 DEG C. to 1200 DEG C. temperature for 0.5 hours to 24 hours and is cooled with the furnace till 500 to 700 DEG C..

Owner:GRIREM ADVANCED MATERIALS CO LTD

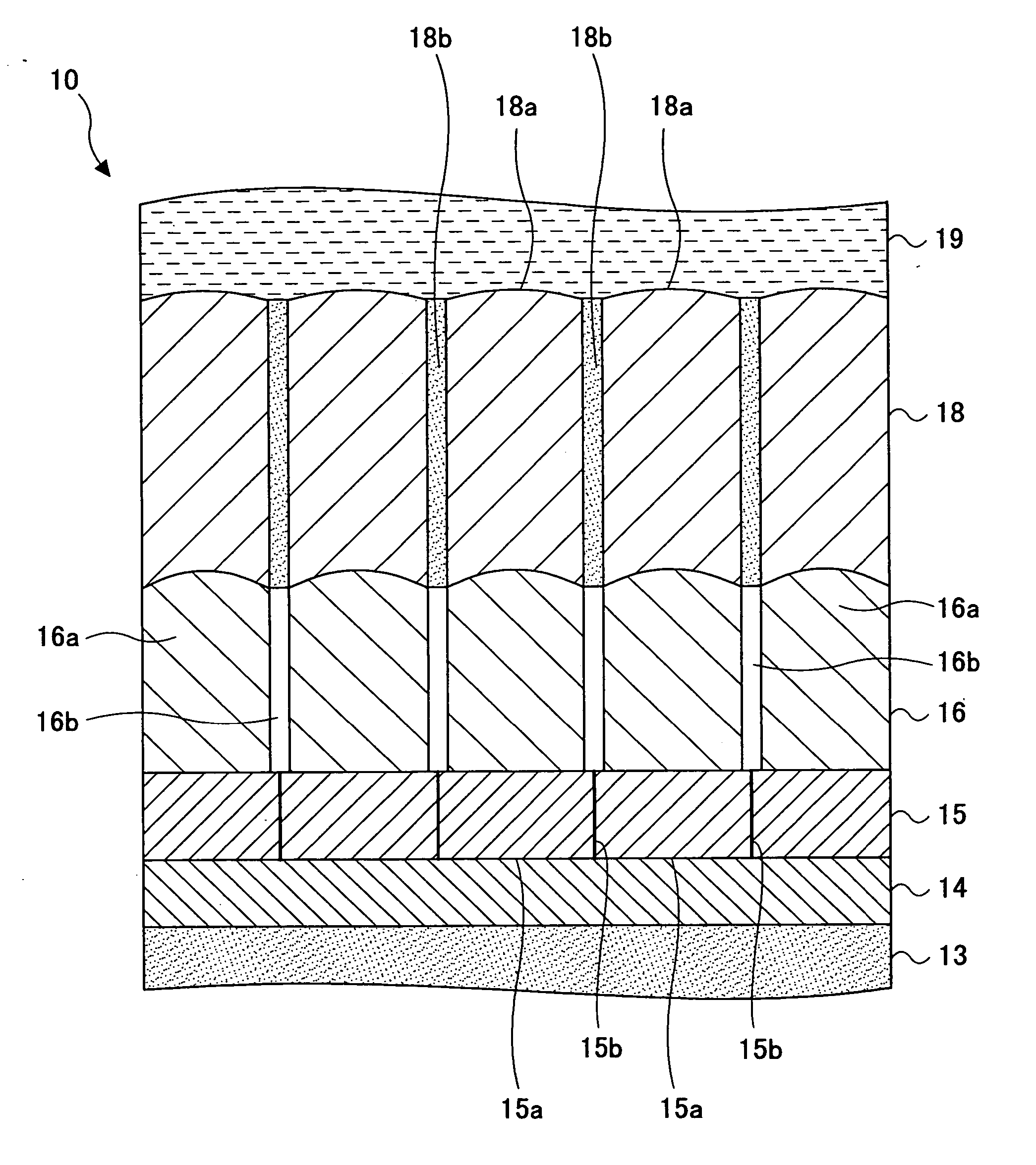

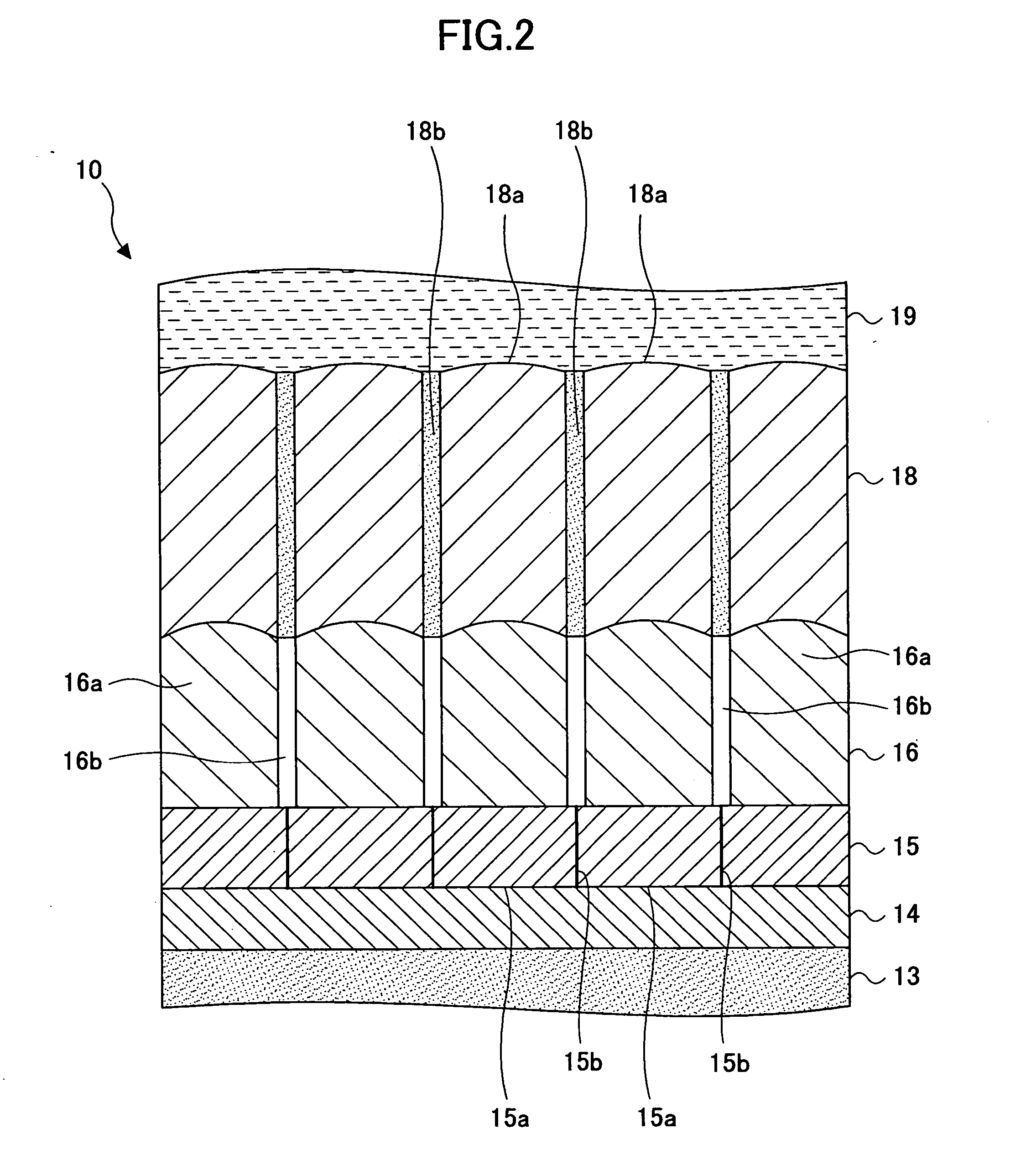

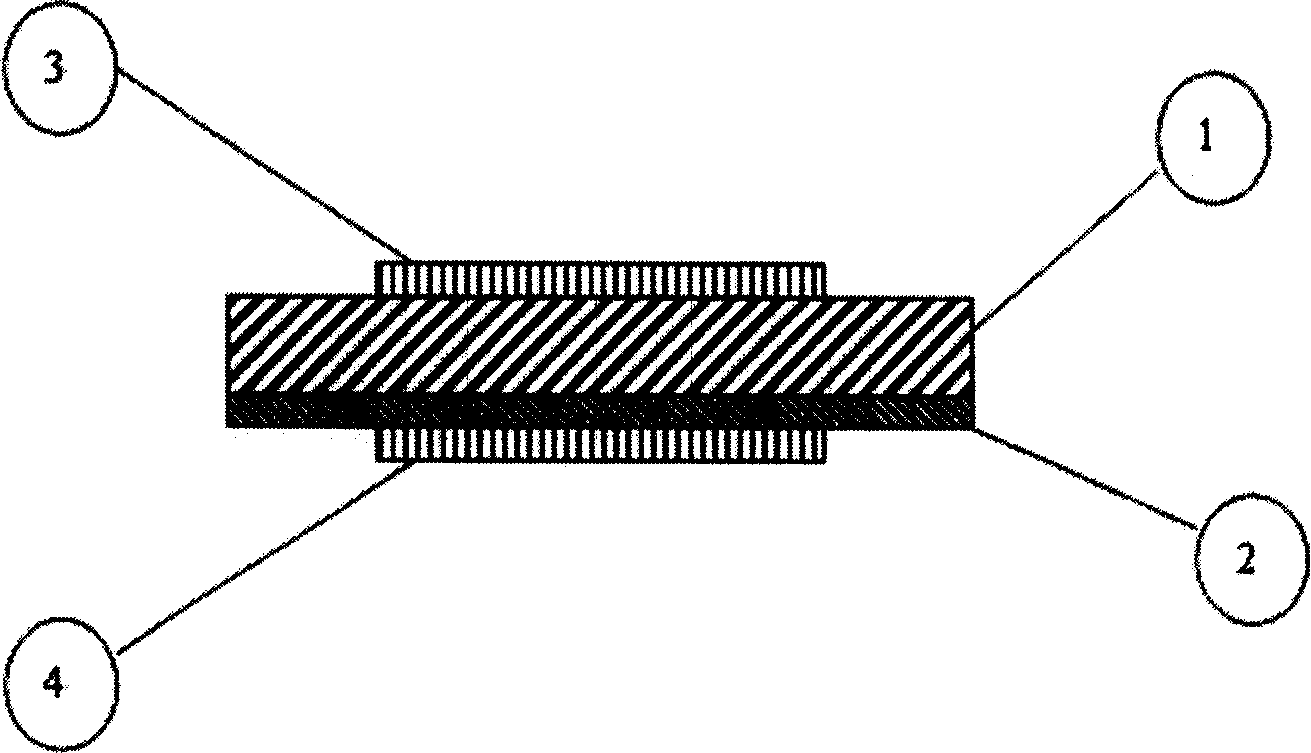

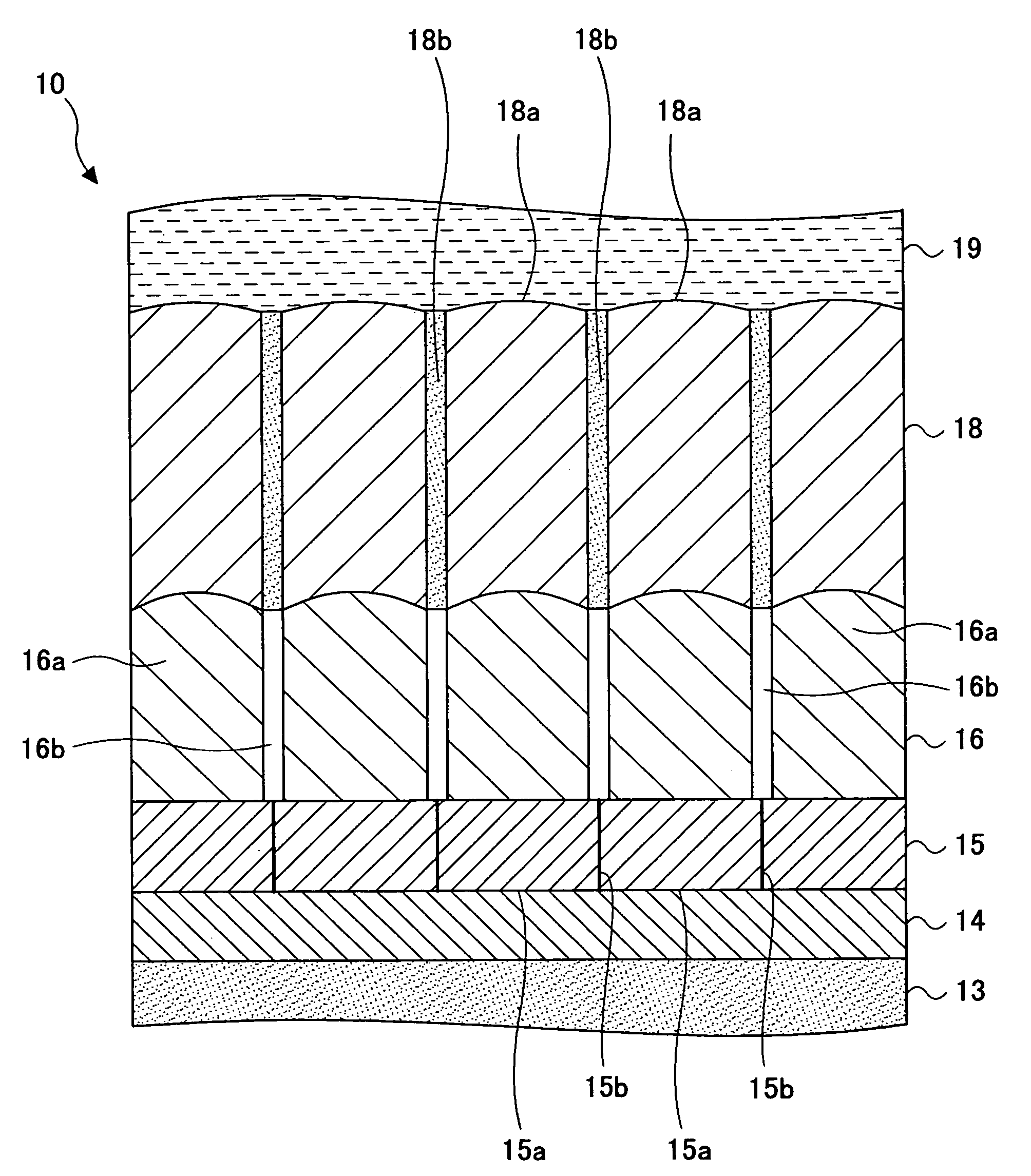

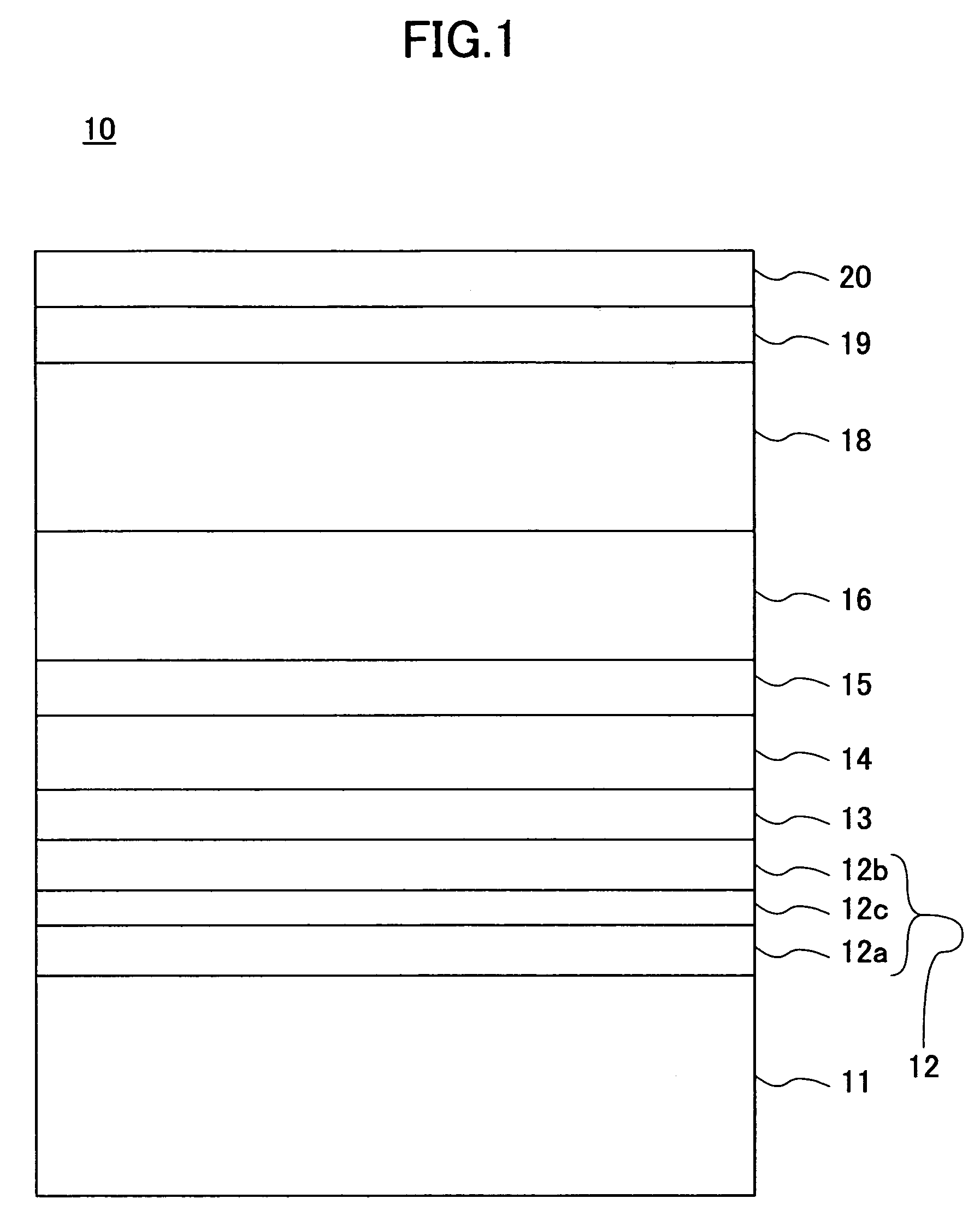

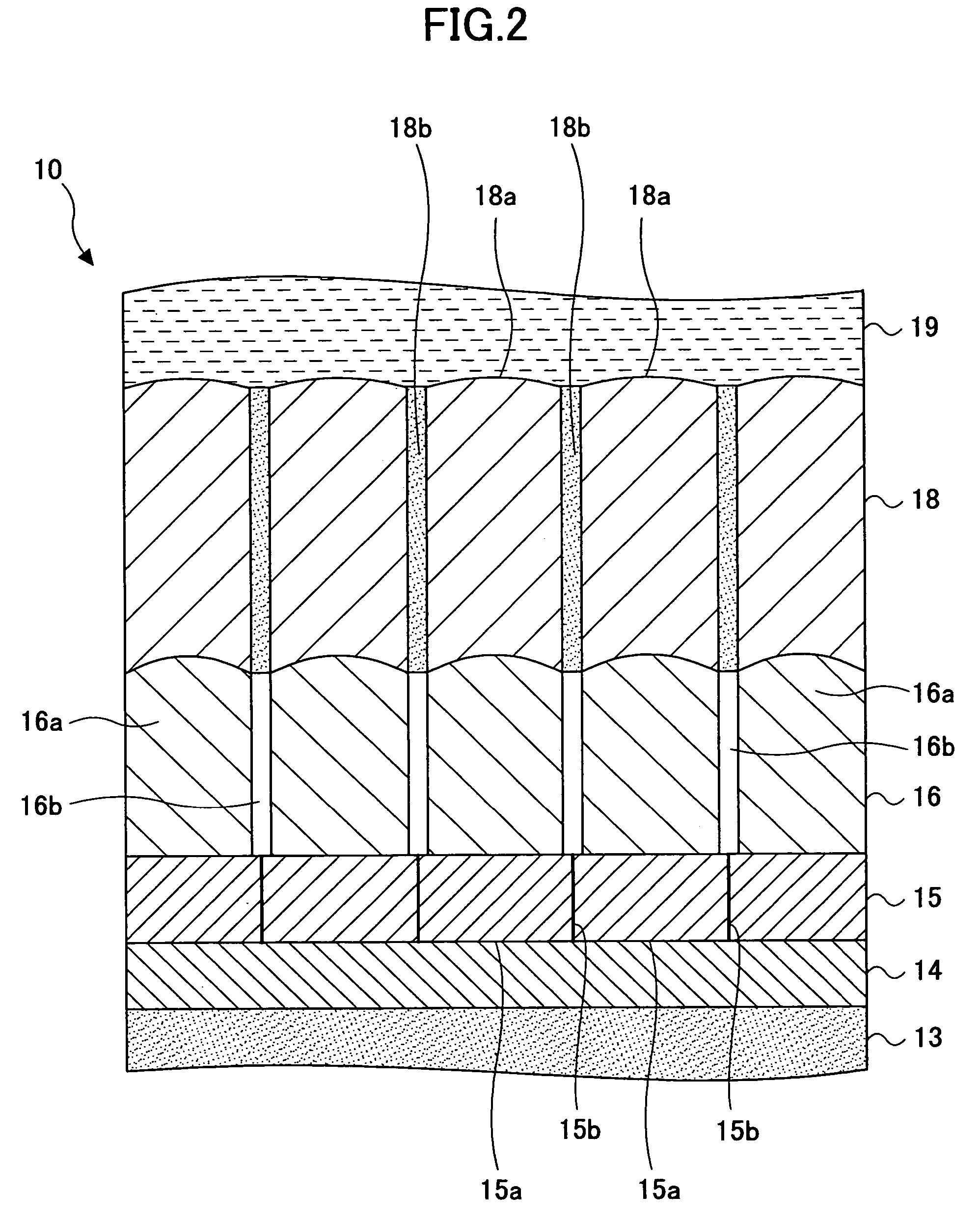

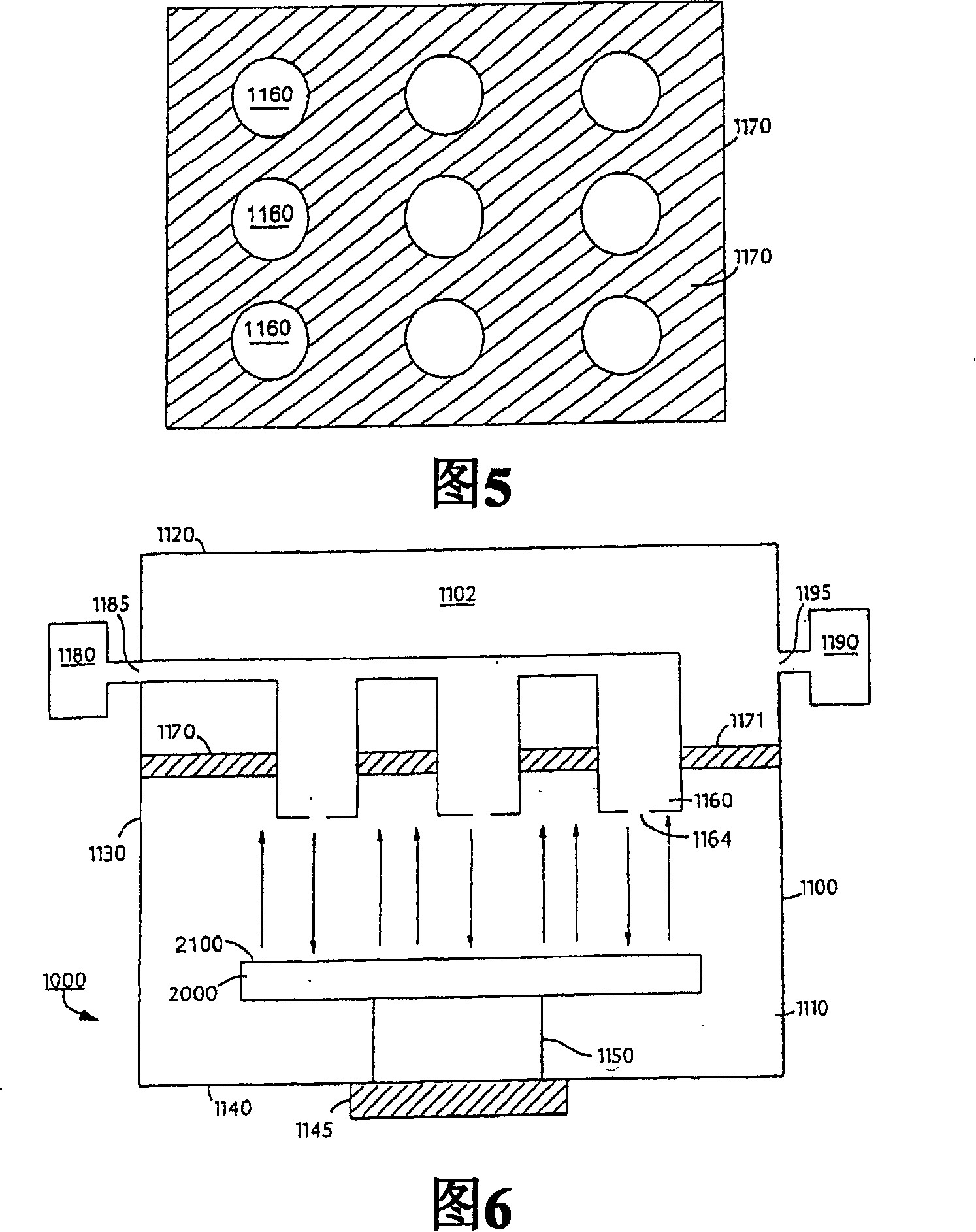

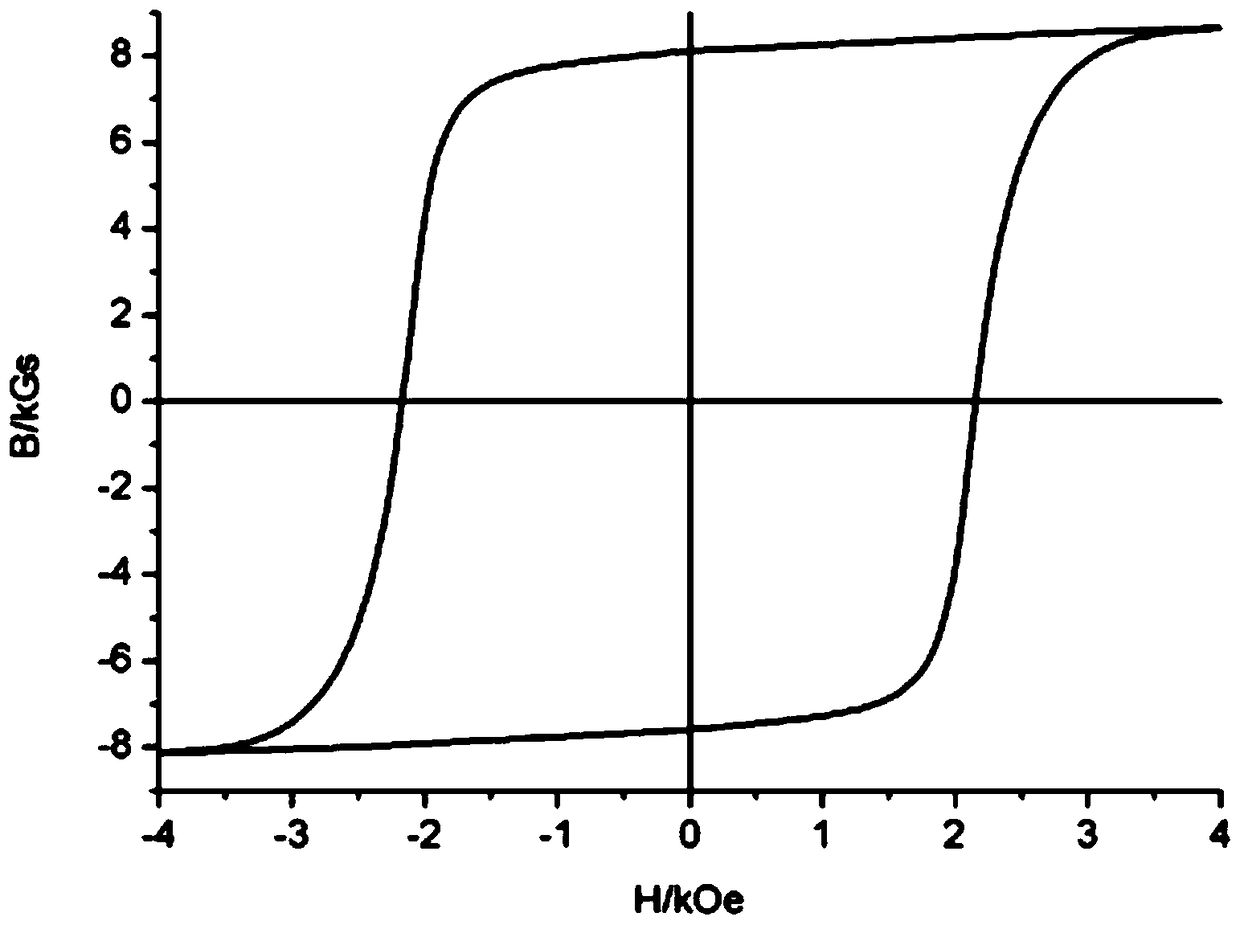

Perpendicular magnetic recording medium, method of manufacturing the same, and magnetic storage unit

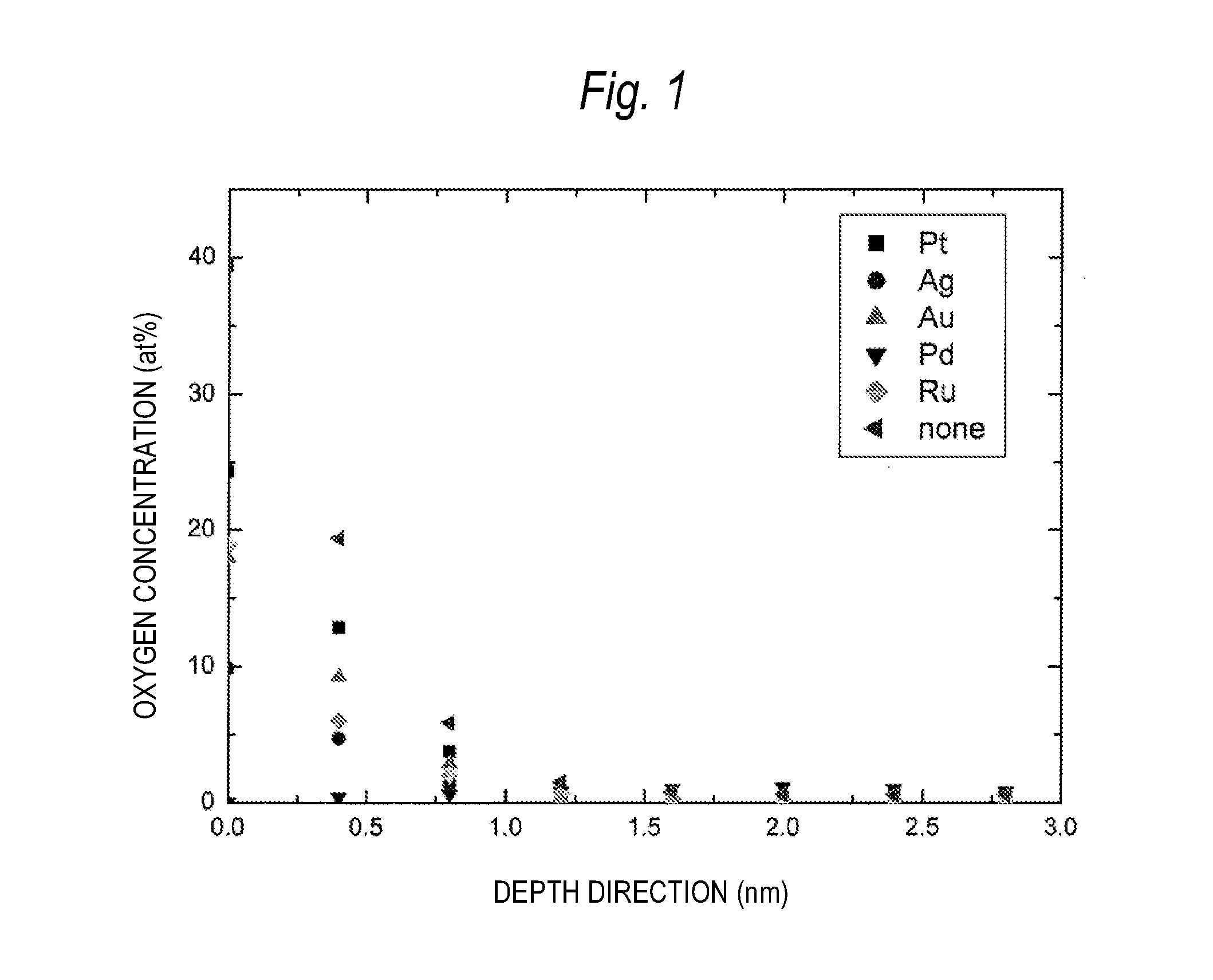

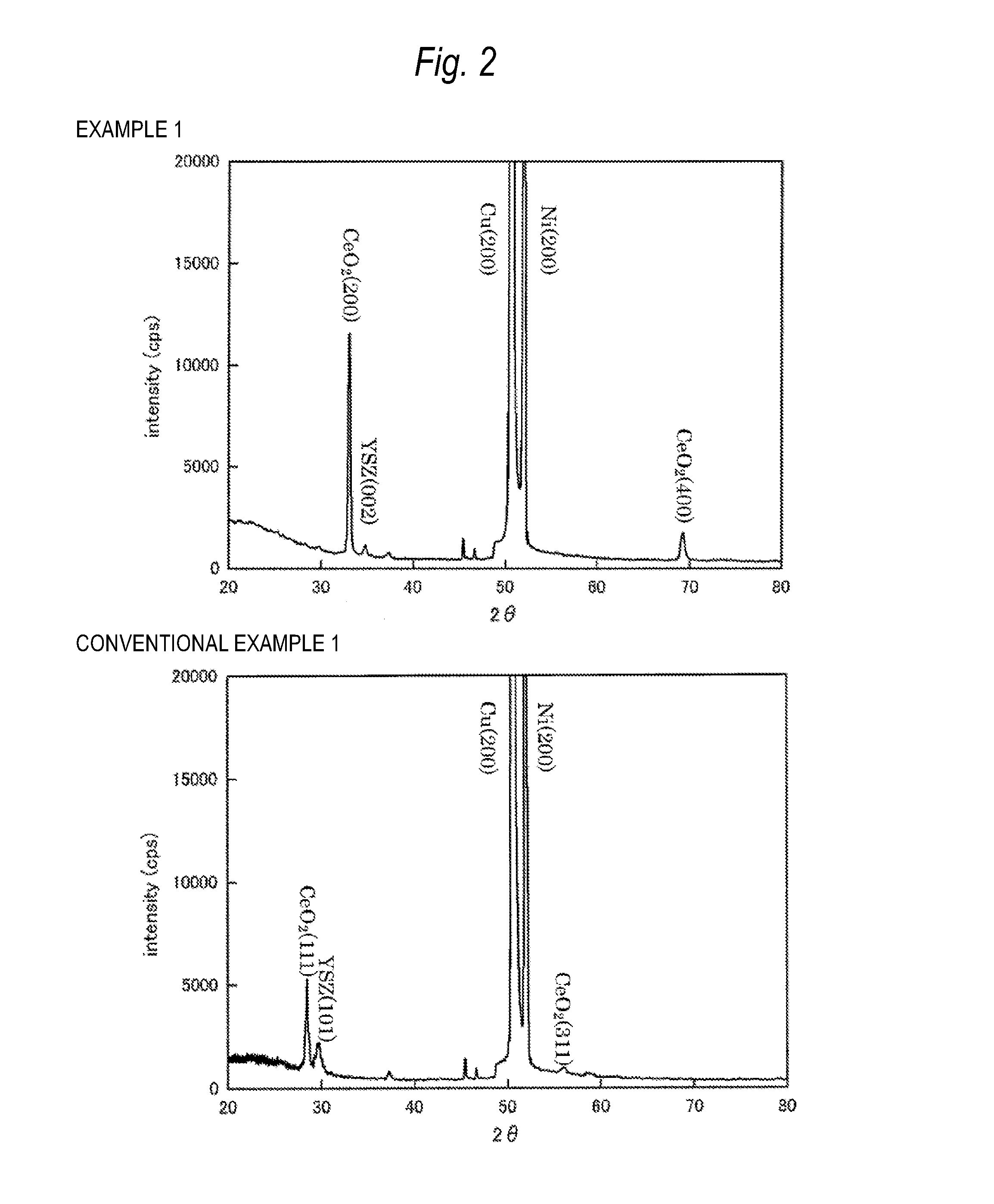

InactiveUS20070231608A1Good crystallinity and crystal orientationHigh recording densityVacuum evaporation coatingSputtering coatingCrystalliteMagnetic storage

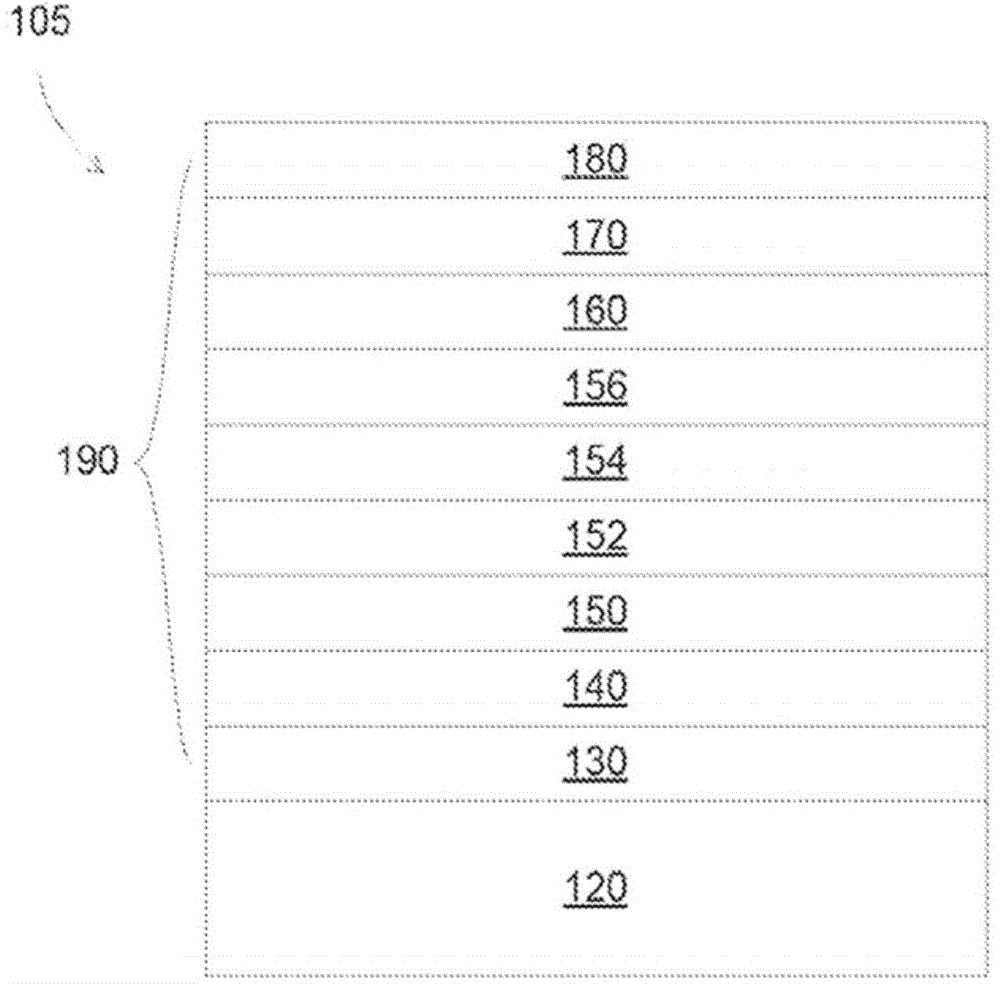

A perpendicular magnetic recording medium is disclosed that includes a substrate; a soft magnetic underlayer formed on the substrate; a seed layer of an amorphous material formed on the soft magnetic underlayer; an oxidation prevention layer formed on the seed layer; an underlayer formed on the oxidation prevention layer, the underlayer including multiple crystal grains formed of Ru or a Ru alloy having an hcp crystal structure, and a first air gap part configured to separate the crystal grains from each other; and a recording layer formed on the underlayer, the recording layer including multiple magnetic particles having a magnetocrystalline easy axis in a direction substantially perpendicular to the surface of the substrate, and one of a second air gap part and a non-magnetic non-solid-solution phase, the one being configured to separate the magnetic particles from each other. The oxidation prevention layer includes a noble metal element other than R.

Owner:SHOWA DENKO KK

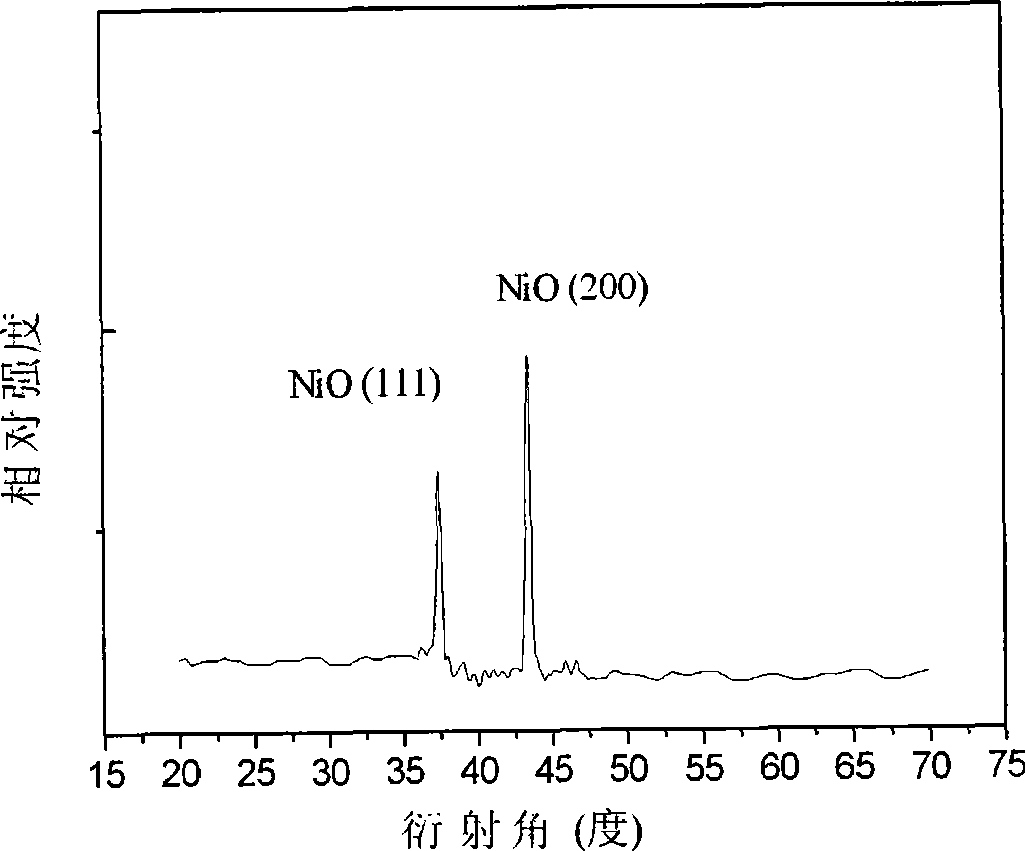

Method for preparing NiO transparent conductive film by two steps

InactiveCN101413102AEasy to manufactureLow priceVacuum evaporation coatingSputtering coatingCharge carrier mobilityElectron

The invention relates to a method for preparing a NiO transparent conductive film through two steps and belongs to the technical field of semiconductor optoelectronic material manufacture. The prior method adopts a complicated process for preparing a NiO ceramic target; and the NiO ceramic target is expensive and is easy to damage. In the process of preparing the NiO ceramic target by the prior method, the proportion of Ni atoms and O atoms is fixed so as to limit the adjusting range of the proportion of the Ni atoms and the O atoms in the prepared NiO transparent conductive film, thereby failing to meet difficult application requirements. Due to low-temperature growth, the film has more disadvantages, thereby causing the reduction of the mobility ratio of a current carrier in the film and greatly reducing the conductivity and the optical transmissivity of the NiO transparent conductive film. In step one of the method, a Ni film is prepared through sputtering the Ni target; and in step two, the obtained Ni film is positioned in an oxidation atmosphere, wherein the temperature is between 500 and 1,200 DEG C, the flow rate of oxygen gas is between 5 and 15 l / min, and time for thermal oxidization is between 30 and 180 minutes; and the Ni film is oxidized to form the NiO transparent conductive film.

Owner:CHANGCHUN UNIV OF SCI & TECH

Composite lithium ion battery cathode material and preparation method and application thereof

ActiveCN110635121ALower potentialImprove stabilitySecondary cellsPositive electrodesOctahedronCrystal orientation

The invention discloses a composite lithium ion battery cathode material and a preparation method and an application thereof. The composite lithium ion battery positive electrode material comprises alithium-rich manganese-based positive electrode material with a layered structure and a 5V high-voltage positive electrode material with a spinel structure, a chemical formula of the 5V high-voltage positive electrode material with the spinel structure is LiMaNbMn<2-a-b>O<4-c>S<c>, wherein a is greater than 0.01 and less than 0.5, b is greater than 0.1 and less than 1, c is greater than 0.001 andless than 0.5, M comprises any one or a combination of at least two of Ni, Cr, V, Fe, Cu and Co, N is doped cations, and S is doped anions. The obtained coating material has good crystal orientation,irreversible capacity loss of a lithium-rich phase can be effectively improved, moreover, oxygen atoms in the positive electrode material of the lithium battery are doped with polyanion groups, so loss of charging and discharging oxygen octahedrons under a high-voltage platform is reduced, a problem of voltage attenuation is relieved, and stability and the rate capability of the material are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Superconductor method and reactor

InactiveCN1539172AGood critical current densityGood critical currentPolycrystalline material growthSuperconductors/hyperconductorsComputer science

Owner:AMERICAN SUPERCONDUCTOR

Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member, thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

InactiveUS20060141267A1Reduce surface roughnessGood crystal orientationPolycrystalline material growthHandling using diffraction/refraction/reflectionX-rayCrystal orientation

Owner:KYOCERA OPTEC

Preparation of nanocrystalline lead zirconat-titanato-quartz composite structure piezoelectric sensing material

InactiveCN101481245AImprove piezoelectric performanceCompact structureLead zirconate titanatePiezoelectric coefficient

The invention relates to a preparation method of a nanocrystalline lead zirconate titanate-quartz composite structure piezoelectric sensing material. The preparation method comprises the following steps: firstly, preparing lead zirconate titanate (PZT) precursor sol, obtaining dry PZT gel by vacuum distillation, and then dissolving the dry gel into ethylene glycol monomethyl ether and adding mixture of glycerin and glacial acetic acid as drying control chemical reagents, thus preparing the PZT sol; and then spin-coating the PZT sol on surfaces of a quartz substrate and performing heat treatment to obtain a film, repeating spin-coating and heat treatment process to obtain a plurality of layers of films, and then performing crystallization treatment, thus obtaining the nanocrystalline PZT film by compounding the films on the quartz substrate and obtaining the nanocrystalline PZT-quartz composite structure piezoelectric sensing material. The characteristics of good piezoelectric property of the PZT and highly stable frequency of quartz crystals are fully utilized in the preparation method, and the PZT nanocrystalline structure compounded on the quartz substrate has the advantages of good crystallographic direction tendency, compact structure and higher piezoelectric coefficient.

Owner:SHANGHAI JIAO TONG UNIV

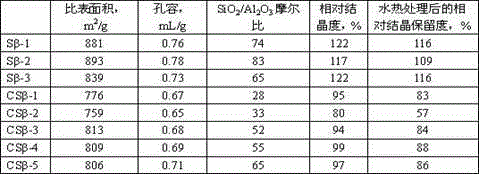

Lignin hydro-cracking catalyst and preparation method thereof

ActiveCN106140278AGood crystal orientationReduce usageMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveCrystallinity

The invention discloses a lignin hydro-cracking catalyst which comprises an H beta molecular sieve and a hydrogenating active metal component, wherein the hydrogenating active metal component belongs to a group VIB and / or a group VIII; the pore volume of the catalyst is 0.5-0.8 mL / g, the total specific surface area is 600-800 m<2> / g, the mesoporous specific surface area is 400-450 m<2> / g, and the micropore specific surface area is 300-370 m<2> / g; the H beta molecular sieve has the following properties that the molar ratio of SiO2 to Al2O3 is 60:100, the specific surface area is 700-900 m<2> / g, the pore volume is 0.6-0.9 mL / g, and the relative crystallinity is 100-148 percent. The catalyst is prepared by adopting an impregnation method. The catalyst adopts a beta-type molecular sieve with high silica-alumina ratio, high crystallinity, large specific surface area and a special channel structure as an acidic component and has higher reaction activity and higher liquid yield for lignin hydro-cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

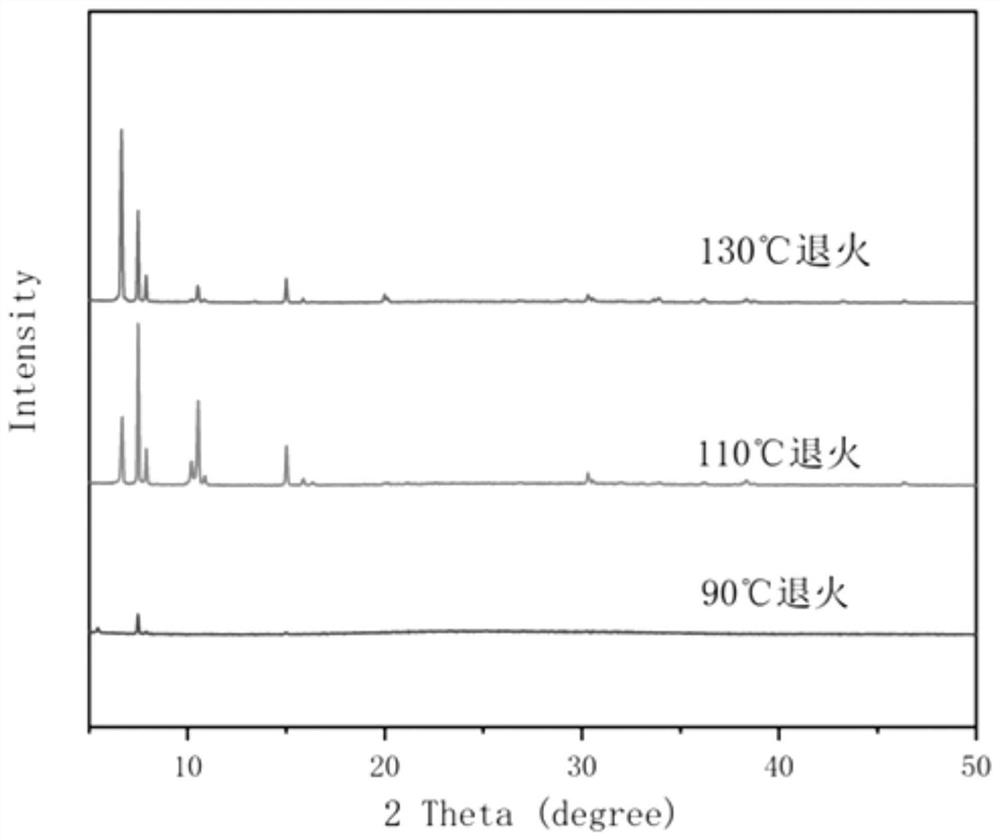

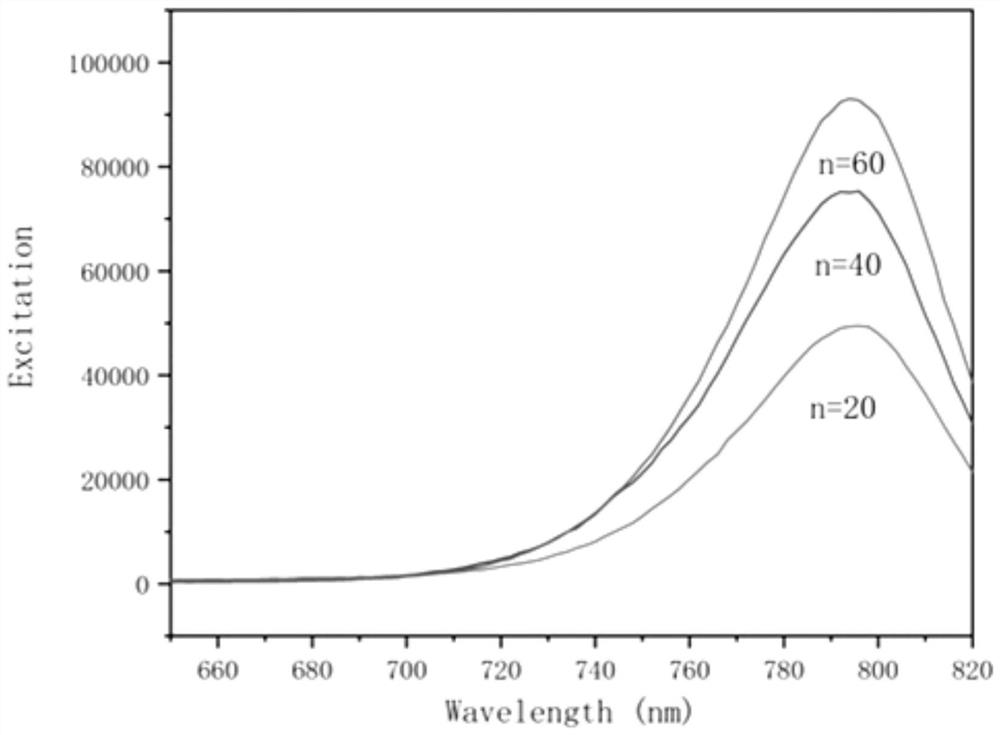

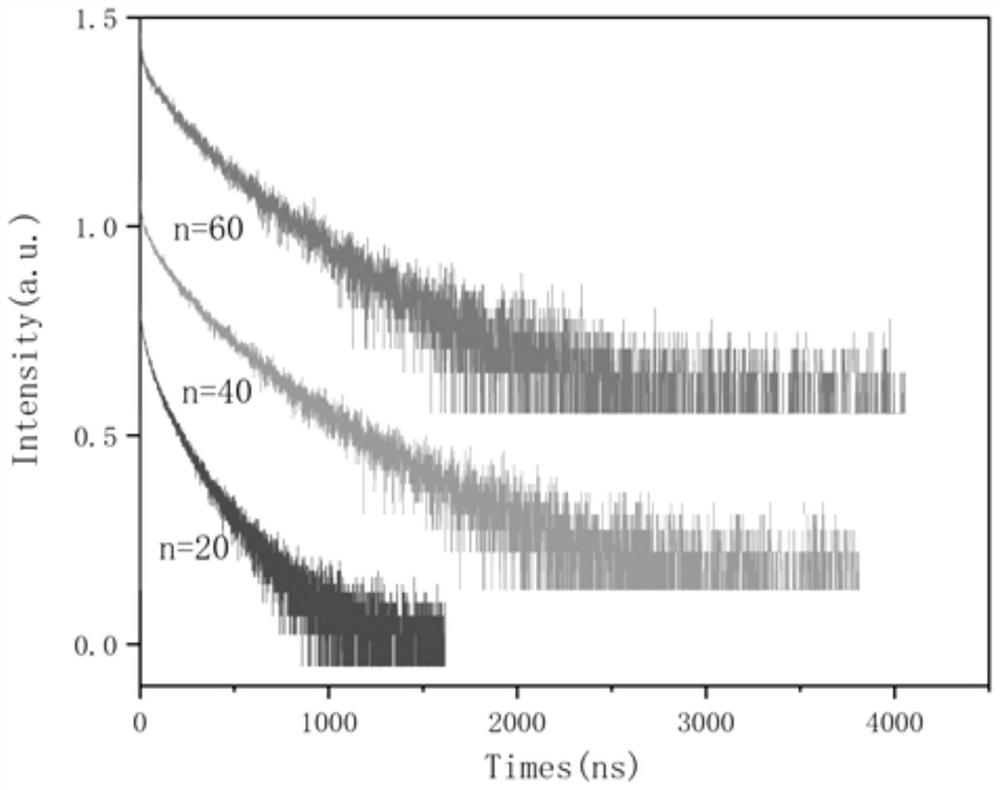

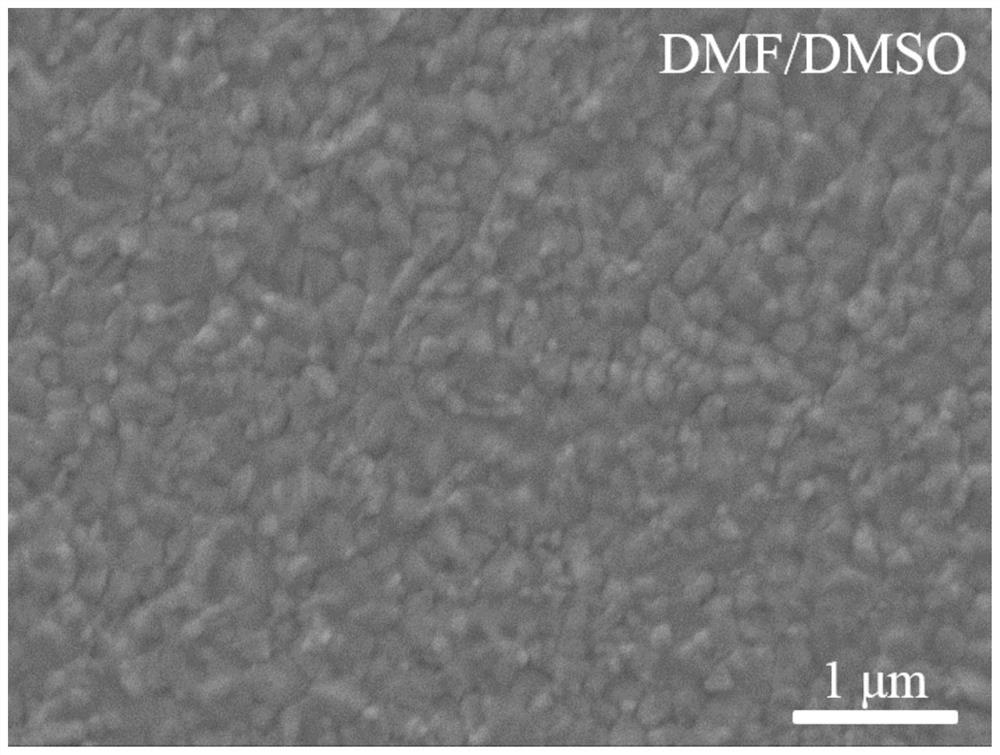

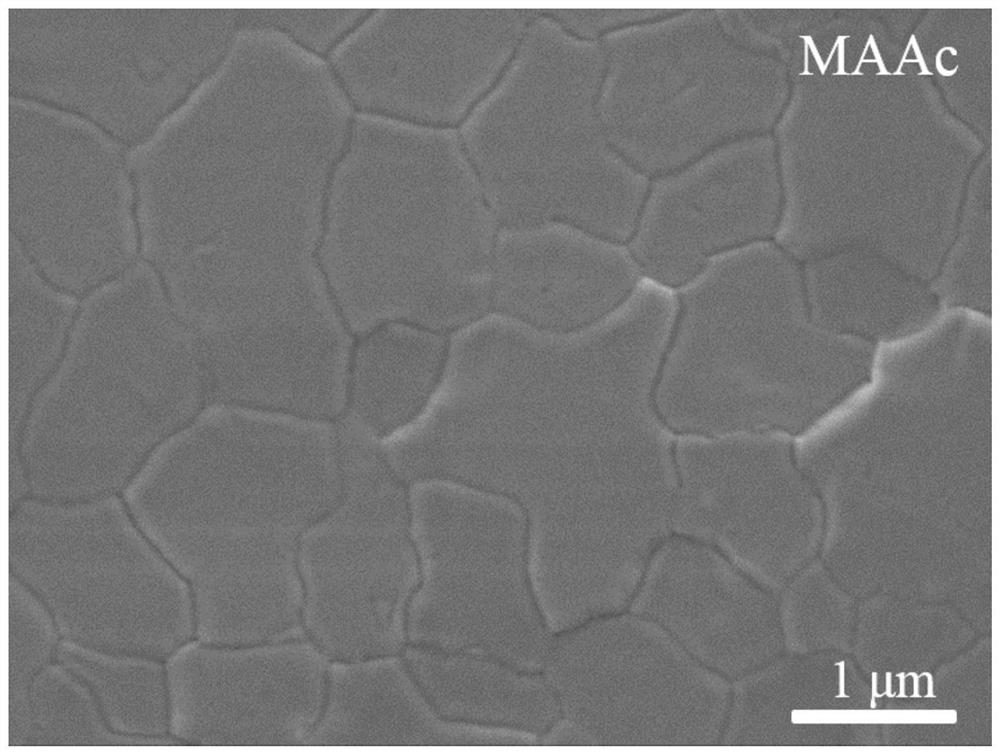

Two-dimensional perovskite thin film material, solar cell and preparation method of two-dimensional perovskite thin film material

ActiveCN113285027AImprove performanceImprove stabilityFinal product manufactureSolid-state devicesSolar batteryFilm material

The invention discloses a two-dimensional perovskite thin film material, a solar cell and a preparation method of the two-dimensional perovskite thin film material. Lead iodide, formamidine iodide, chloromethylamine, calcium bromide and calcium iodide are used as raw materials, dimethylformamide and dimethyl sulfoxide are used as a mixed solvent to prepare a perovskite precursor solution, and the film material is obtained through annealing after spin coating. The solar cell sequentially comprises a conductive substrate, an electron transport layer and a perovskite light absorption layer, a perovskite precursor solution is spin-coated on the conductive substrate coated with the electron transport layer, and the two-dimensional perovskite solar cell is prepared after annealing. The two-dimensional perovskite thin film material is used as a perovskite light absorption layer material in a solar cell. The chemical composition of the two-dimensional perovskite thin film is (CaBr) 2 (FA) n-1PbnI3n + 1, wherein FA is formamidine cations. According to the preparation method provided by the invention, the two-dimensional perovskite thin film material with relatively high crystallinity and relatively good performance can be obtained so that the photoelectric performance and efficiency of the perovskite solar cell are improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

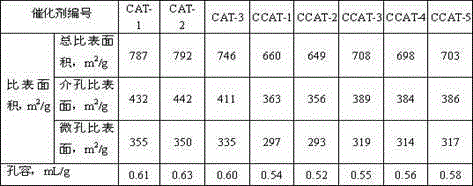

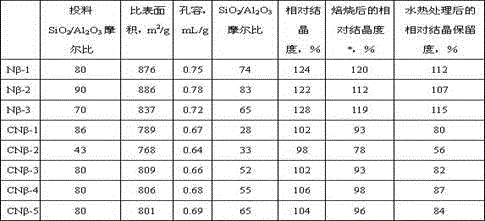

Diesel oil hydrogenation modification catalyst and preparation method thereof

ActiveCN106140253AGood crystal orientationReduce usageMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveCrystallinity

The invention discloses a diesel oil hydrogenation modification catalyst and a preparation method thereof. The catalyst comprises a hydrogenating active metal component and a carrier; the carrier comprises a beta molecular sieve, macroporous alumina and a binder; with the weight of the carrier as a benchmark, the content of the beta molecular sieve is 5-30 wt%, the content of the macroporous alumina is 20-65 wt%, and the content of the binder is 15-50 wt%; the beta molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 60-100, the specific surface area is 505-850 m<2> / g, the pore volume is 0.35-0.60 mL / g, and the relative crystallinity degree is 100%-148%; the relative crystallinity degree of the beta molecular sieve subjected to water steam hydrothermal treatment is more than or equal to 95%. The catalyst has the characteristics of high diesel oil product yield, good product quality, especially low condensation point of the diesel oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

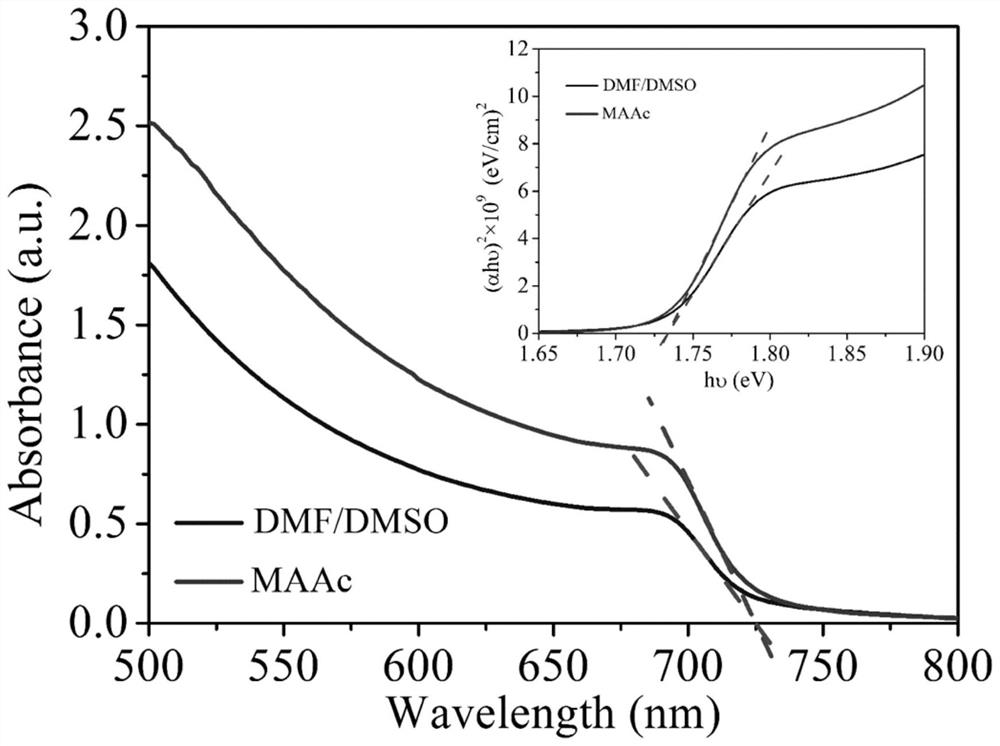

Wide-band-gap perovskite solar cell and preparation and application thereof

PendingCN112542549AEasy to operateLow cost of preparationSolid-state devicesSemiconductor/solid-state device manufacturingMETHYLIODIDALead iodide

The invention relates to a wide-band-gap perovskite solar cell and a preparation method and application thereof, which belong to the field of photoelectric materials and devices. The preparation method comprises the following steps of dissolving lead iodide, lead bromide, methyl ammonium iodide and methyl ammonium bromide in an ionic liquid methylammonium acetate according to a molar ratio of 3: 1: 3: 1 to prepare a wide-band gap perovskite precursor solution, and spin-coating the precursor solution on ITO transparent conductive glass deposited with an electron transport material and an interface material in air by adopting a one-step heating spin-coating method, and after annealing treatment, forming the wide-band-gap perovskite thin film which is compact and smooth in surface, high in crystallinity, low in defect state density and good in crystal orientation. The prepared wide-band-gap perovskite solar cell has excellent photoelectric conversion efficiency and excellent device stability.

Owner:NANJING UNIV OF TECH

Perpendicular magnetic recording medium, method of manufacturing the same, and magnetic storage unit

InactiveUS7732070B2Good crystalline orientationImprove recording densityRecord information storageCoating by sputteringSolid massMagnetic storage

A perpendicular magnetic recording medium is disclosed that includes a substrate; a soft magnetic underlayer formed on the substrate; a seed layer of an amorphous material formed on the soft magnetic underlayer; an oxidation prevention layer formed on the seed layer; an underlayer formed on the oxidation prevention layer, the underlayer including multiple crystal grains formed of Ru or a Ru alloy having an hcp crystal structure, and a first air gap part configured to separate the crystal grains from each other; and a recording layer formed on the underlayer, the recording layer including multiple magnetic particles having a magnetocrystalline easy axis in a direction substantially perpendicular to the surface of the substrate, and one of a second air gap part and a non-magnetic non-solid-solution phase, the one being configured to separate the magnetic particles from each other. The oxidation prevention layer includes a noble metal element other than Ru.

Owner:SHOWA DENKO KK

Preparation method for polycrystalline mercury iodide film seed crystal layer

InactiveCN103820851ASolve the removal problemAvoid pollutionPolycrystalline material growthSingle crystal growth detailsVapour phase epitaxyMercury(II) iodide

The invention belongs to the field of chemical liquid phase deposition, particularly relates to a preparation method for a polycrystalline mercury iodide film seed crystal layer and solves the problems that the pollution of solvent and reaction by-products are difficult to remove during solution precipitation in the prior art. According to the preparation method for the polycrystalline mercury iodide film seed crystal layer, provided by the invention, yellow mercury oxide (HgO) and hydroiodic acid (HI) are used as basic materials, and the reaction rate between the HgO and (HI) is controlled by adjusting the concentration of the HI added into a system, so that fine mercury iodide particles are generated. The generated fine mercury iodide particles deposit on a substrate (electrode) material to form a layer of homogeneous film, so that directional crystal nucleuses are provided for gas phase epitaxial growth, thereby increasing one-way growth probability of the film.

Owner:XIAN TECHNOLOGICAL UNIV

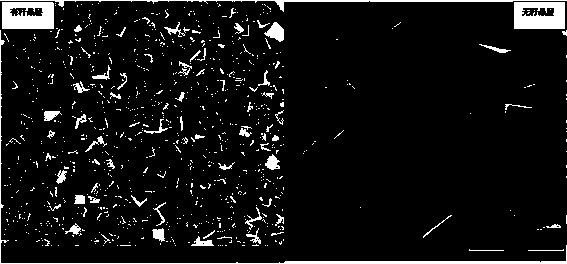

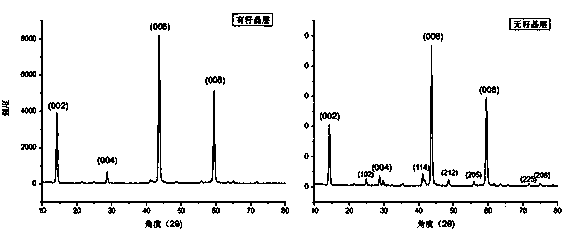

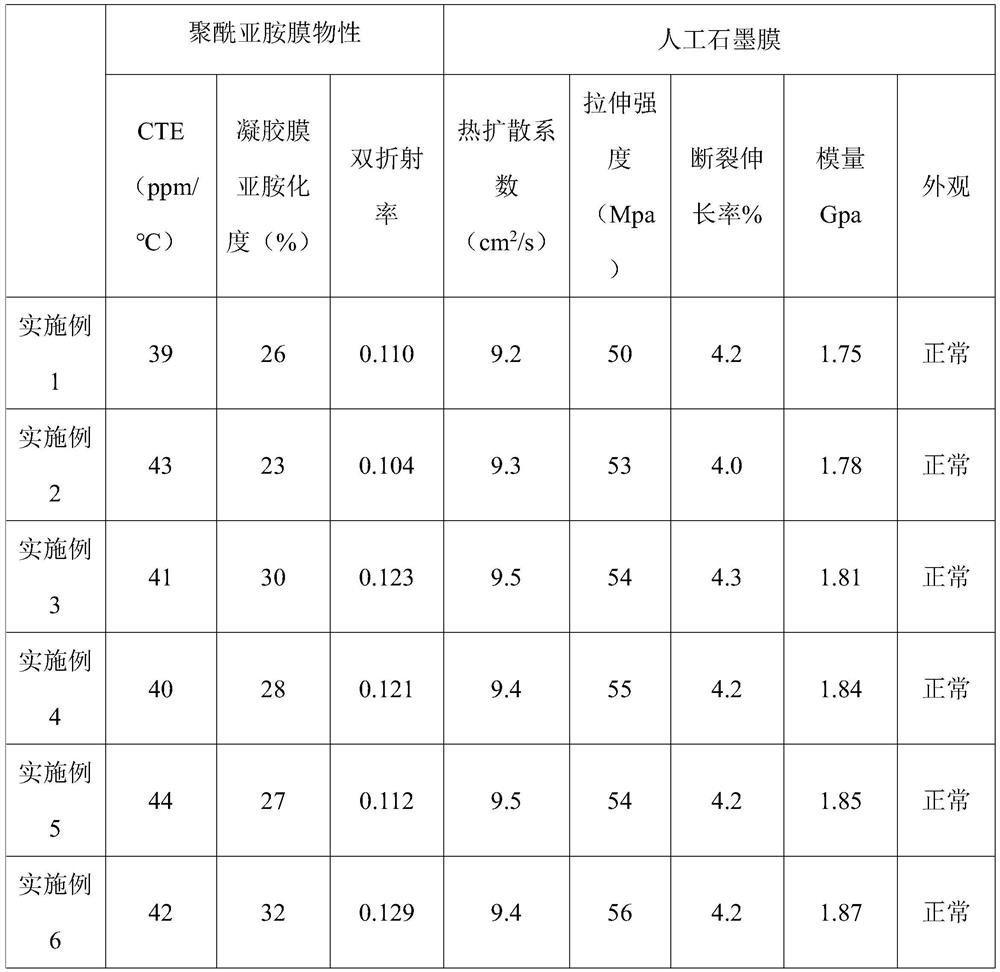

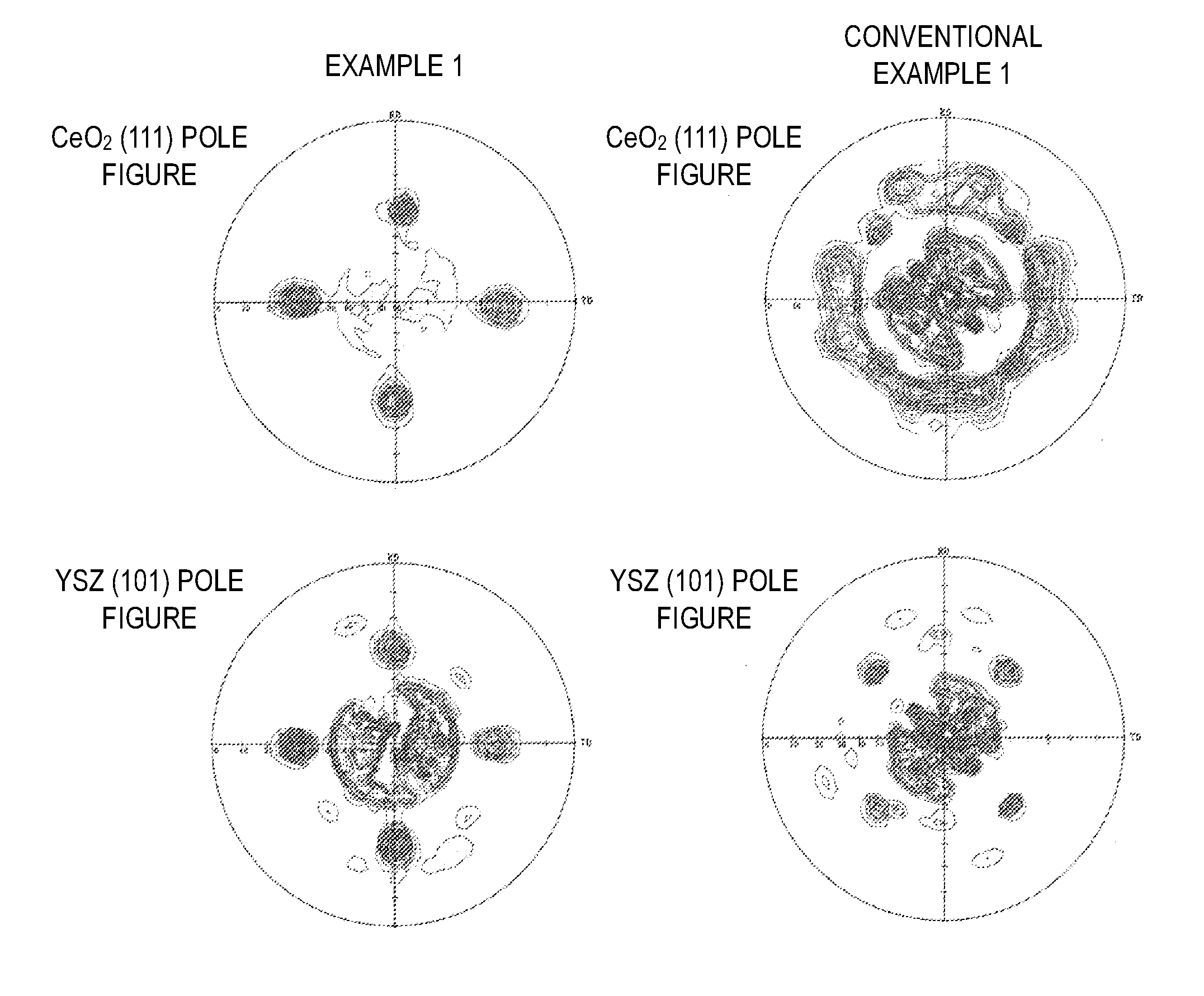

Polyimide film for artificial graphite film, preparation method of polyimide film and artificial graphite film

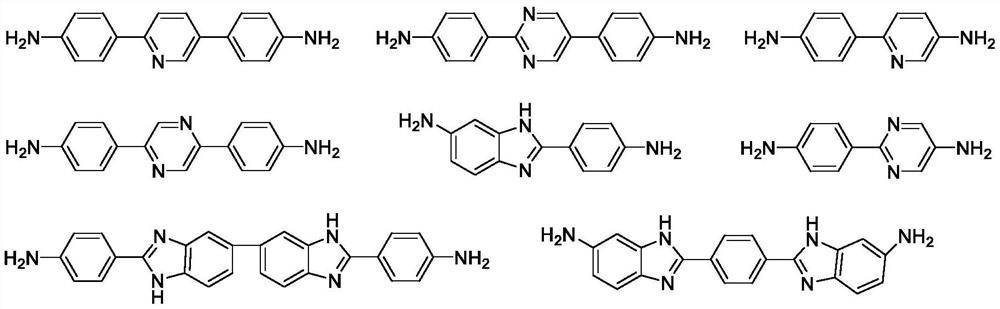

PendingCN112574410AGood crystal orientationHigh birefringenceCarbon compoundsPolymer scienceNaphthalenetetracarboxylic dianhydride

The invention provides a polyimide film for an artificial graphite film, a preparation method of the polyimide film and the artificial graphite film. The polyimide film is formed by polymerizing dianhydride and diamine; the diamine is selected from p-phenylenediamine or 4,4'-diaminodiphenyl ether; the dianhydride comprises dianhydride A and dianhydride B, and the dianhydride A is selected from oneof 3,3',4,4'-biphenyl tetracarboxylic dianhydride or pyromellitic dianhydride; and the dianhydride B is selected from one or two of 1,4,5,8-naphthalene tetracarboxylic dianhydride, binaphthalene dianhydride or perylene anhydride. By regulating and controlling the formula of the polyimide film, the imidization degree is improved, the obtained polyimide film is good in crystal orientation and highin birefringence, and the obtained artificial graphite film is excellent in performance.

Owner:浙江中科玖源新材料有限公司

Seed layer for ZnO and doped- ZnO o thin film nucleation and methods of seed layer deposition

InactiveCN104582953APromote formationStrong low temperature crystallization tendencyPolycrystalline material growthAfter-treatment detailsCrystal orientationOptoelectronics

Owner:INTERMOLECULAR

Polyimide film and graphite film

PendingCN112608474AGood crystal orientationIncrease the degree of imidizationCarbon compoundsThermal conductivityPyromellitic acid dianhydride

The invention provides a polyimide film and a graphite film, the polyimide film is obtained by polymerization of pyromellitic dianhydride, 4,4'-diaminodiphenyl ether and a second diamine monomer accounting for 1-50 mol% of a diamine monomer, the second diamine monomer is a diamine monomer containing a nitrogen heterocyclic ring, the imidization degree and the crystal orientation of polyimide are improved through formula regulation and control, and the obtained polyimide graphite film has excellent thermal conductivity and mechanical properties.

Owner:浙江中科玖源新材料有限公司

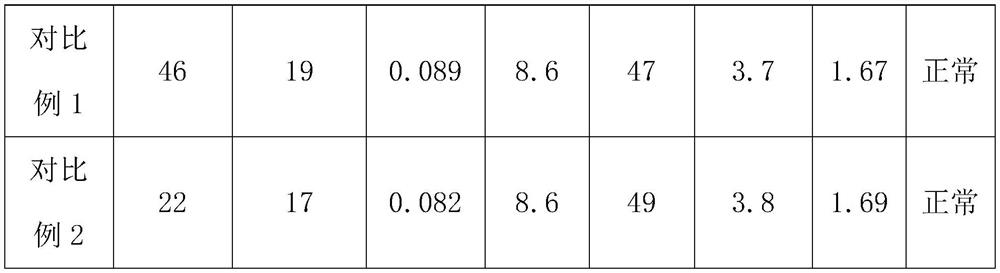

Oriented substrate for use in formation of epitaxial film, and method for producing same

InactiveUS20160163425A1Improve adhesionLoose conditionsPolycrystalline material growthSuperconductors/hyperconductorsHydrogen contentCopper

The present invention provides a textured substrate for forming an epitaxial film, including a textured metal layer on at least one surface of the layer, the textured metal layer including a copper layer having a cube texture, the textured metal layer having, on a surface of the layer, palladium added in an amount of 10 to 300 ng / mm2 per unit area, the hydrogen content of the surface of the textured metal layer being 700 to 2000 ppm. This textured substrate is produced through a step of adding 10 to 300 ng / mm2 per unit area of palladium by strike plating to a surface of the copper layer having a cube texture.

Owner:TANAKA PRECIOUS METAL IND

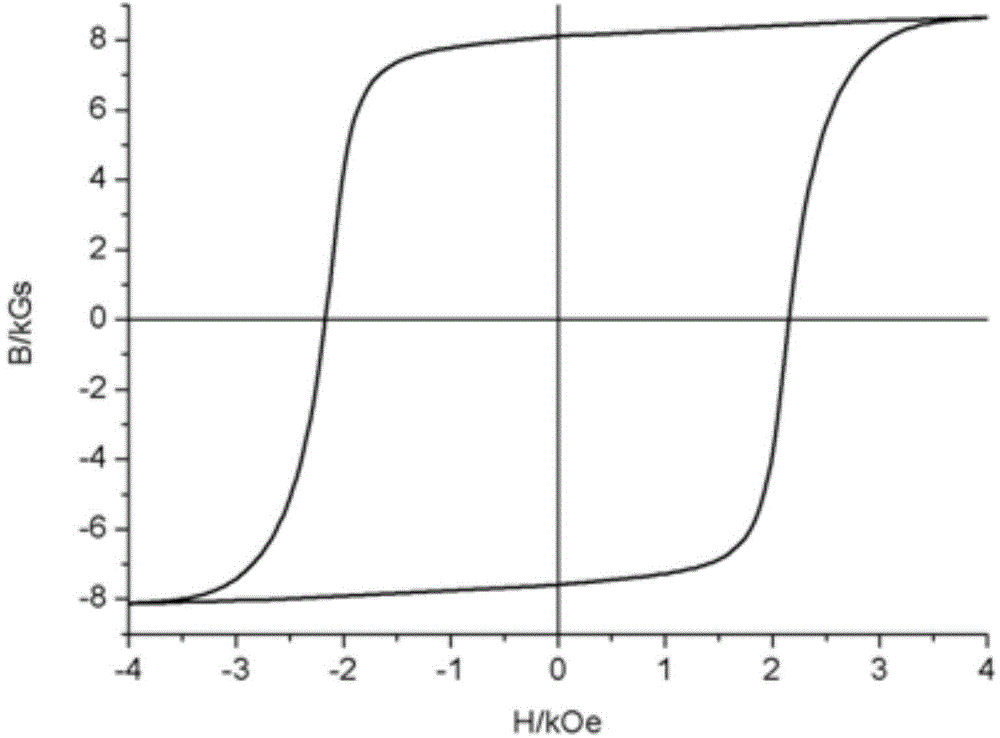

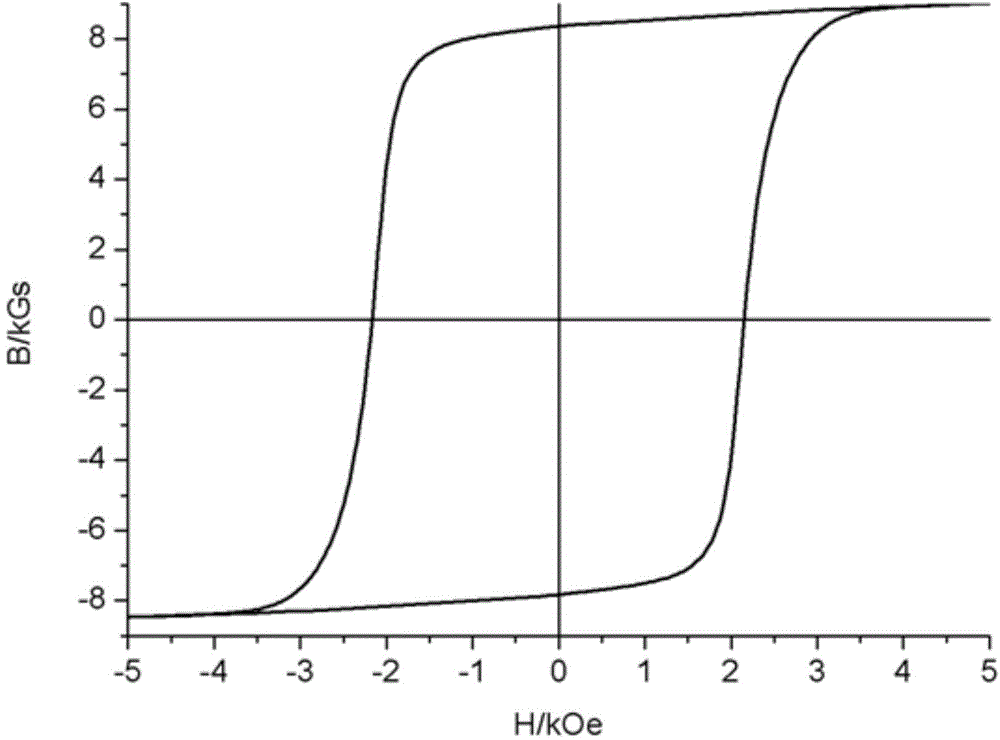

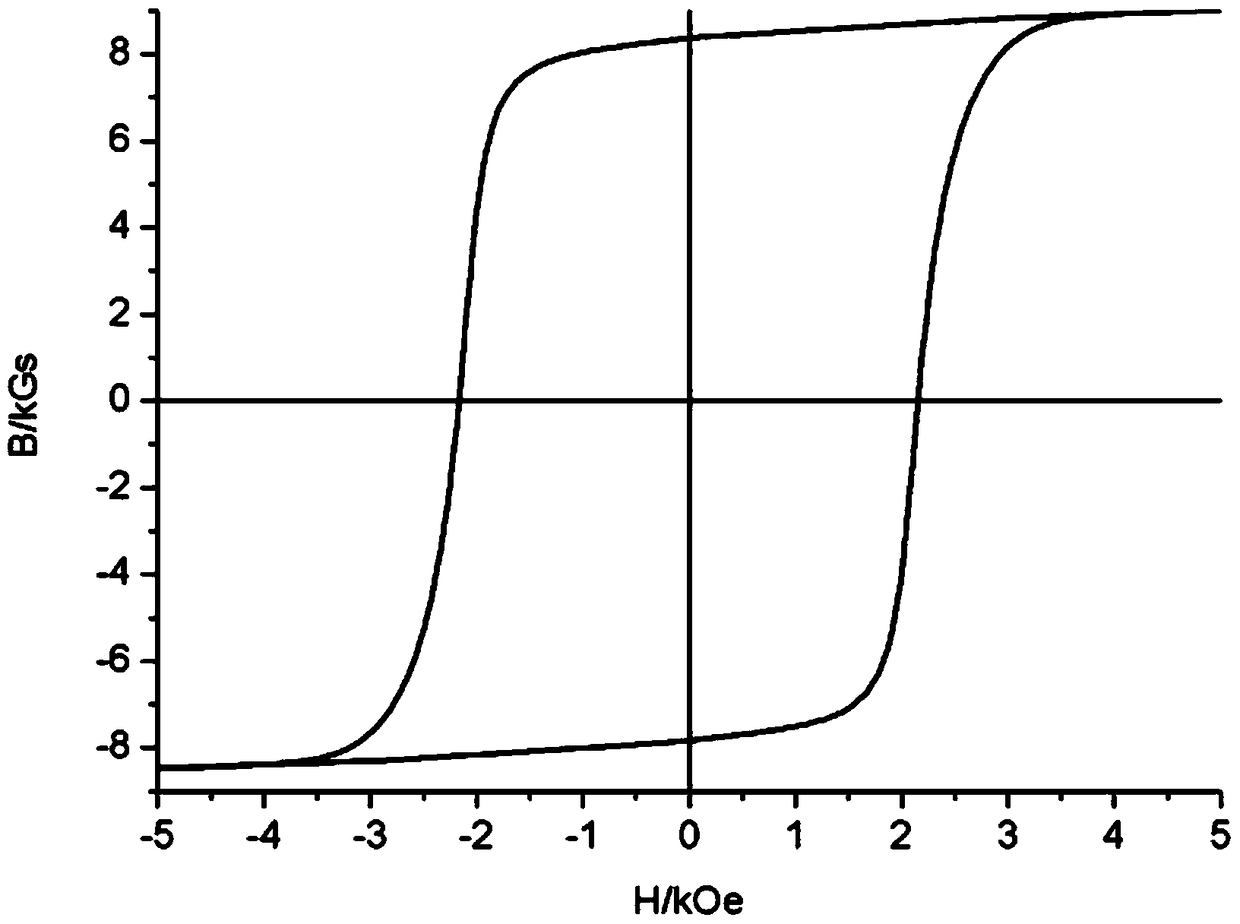

High-performance permanent magnet material and production method thereof

The invention provides a high-performance permanent magnet material and a production method thereof, and particularly provides a permanent magnet material. The permanent magnet material comprises, by total weight, 30-50% of cobalt, 6-10% of titanium, 12-16% of nickel and 6-10% of aluminum. The permanent magnet material has excellent physical and magnetic performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Textured substrate for epitaxial film formation, and method for manufacturing the same

ActiveUS9242433B2Good crystal orientationImprove adhesionSuperconductor detailsFrom chemically reactive gasesSurface roughnessCopper

The present invention relates to a textured substrate for epitaxial film formation, comprising a textured metal layer at least on one side, wherein the textured metal layer includes a copper layer having a cube texture and a nickel layer having a thickness of 100 to 20000 nm formed on the copper layer; the nickel layer has a nickel oxide layer formed on a surface thereof, having a thickness of 1 to 30 nm, and including a nickel oxide; and the nickel layer further includes a palladium-containing region formed of palladium-containing nickel at an interface with the nickel oxide layer. The top layer of the textured substrate, i.e. the nickel oxide layer, has a surface roughness of preferably 10 nm or less.

Owner:TANAKA PRECIOUS METAL IND

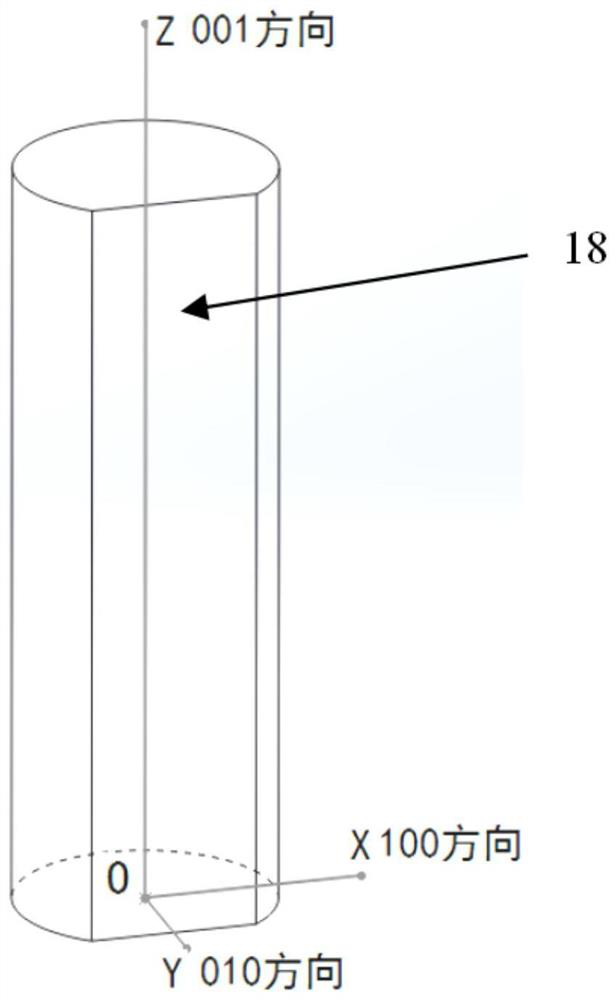

A Casting Method of Single Crystal Superalloy Blade with Precise Control of Three-dimensional Crystal Orientation

ActiveCN109513881BImprove integrityGood crystal orientationPolycrystalline material growthFoundry mouldsSingle crystal superalloyCrystal orientation

The invention discloses a casting method of a single-crystal superalloy blade capable of finely controlling three-dimensional crystal orientation. The method includes manufacturing a set of precision casting modules, preparing a nickel-based superalloy seed segment, pressing wax, the seed segment and a wax mold Assembling, mold shell preparation, and casting, the method provided by the invention can not only accurately control the primary crystal orientation of the crystal within 5°, but also can control the secondary crystal orientation within 5° to obtain high-precision three-dimensional crystal orientation requirements, thereby greatly Improve the service performance and mass production pass rate of single crystal turbine blades.

Owner:ANHUI YINGLIU HANGYUAN POWER TECH CO LTD

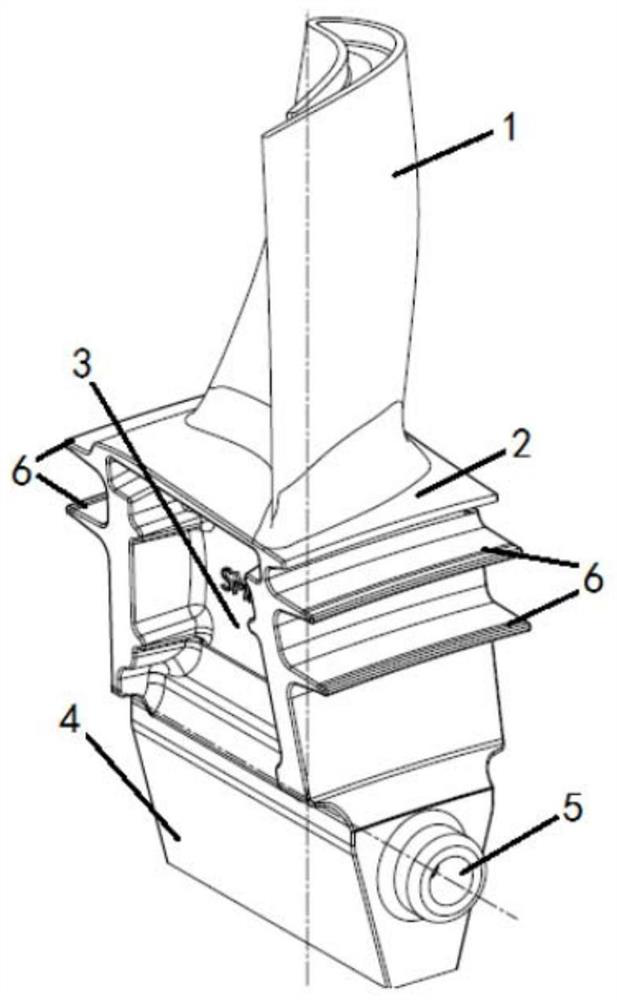

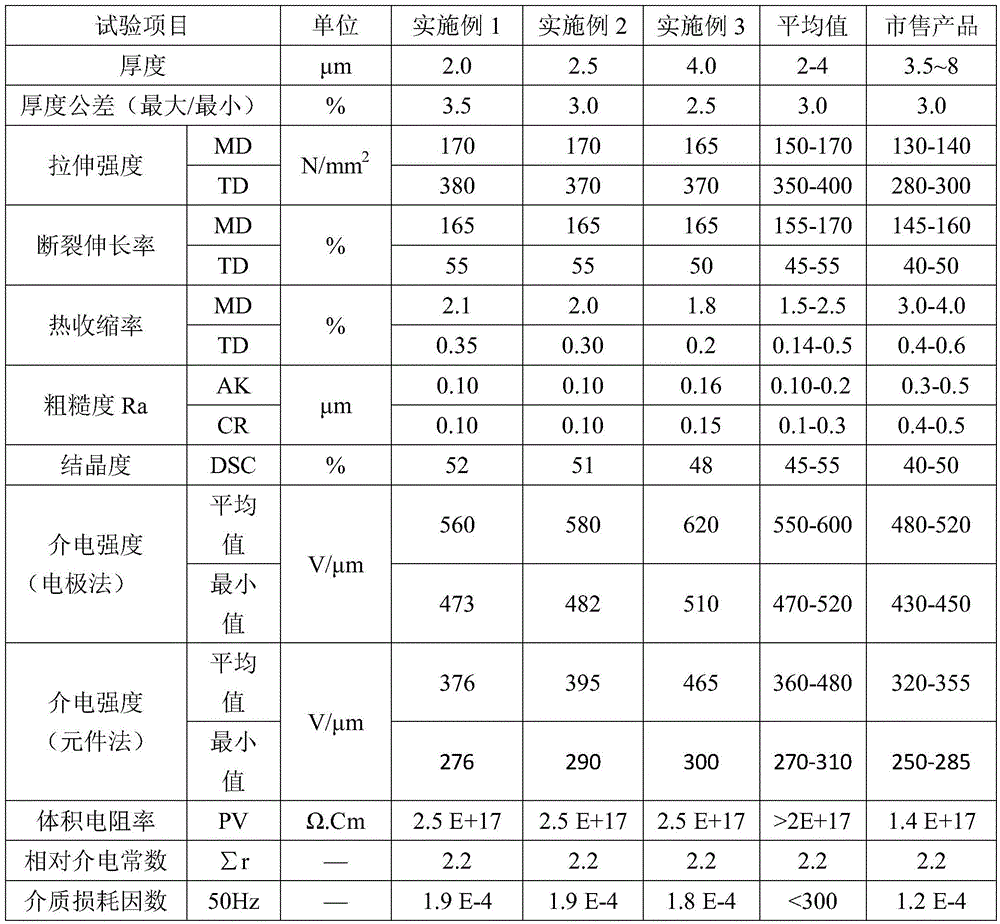

A kind of high-performance ultra-thin polypropylene capacitor film and its manufacturing method

ActiveCN103434151BImprove thickness uniformityImprove isotropyFlat articlesPolymer scienceHigh voltage capacitors

The invention relates to a high-performance ultrathin polypropylene capacitor film and a preparation method thereof. The preparation method comprises the following steps: with high-purity electrician-grade polypropylene as raw material, sequentially carrying out melt extrusion and casting, then carrying out bidirectional synchronous drawing in a drawing ratio of 40-50 times, then cooling for sizing, carrying out trimming and corona treatment, thus obtaining the polypropylene capacitor film finished product with the thickness of 2-4 micrometers. The polypropylene capacitor film prepared by adopting the preparation method has the thermal shrinkage in a machine direction (MD) of 1.5-2.5% and the thermal shrinkage in a transverse direction (TD) of 0.15-0.5% and is especially applicable to a dielectric insulating film in a high-capacity, small-volume, high-power, direct-current and high-voltage capacitor.

Owner:永威(天津)科技有限公司

ZnO-based transparent conductive film co-doped with Al-F and preparation method thereof

InactiveCN101575697BImprove conductivityGood visible light transmittanceVacuum evaporation coatingSputtering coatingSputteringRadio frequency magnetron sputtering

The invention belongs to the field of functional materials and relates to a ZnO-based transparent conductive film co-doped with Al-F and a preparation method thereof. The method is characterized in that the method comprises the following steps of: 1) firstly preparing a ZAFO target material, uniformly mixing AlF3, Al2O3 and ZnO powders to prepare the ZAFO target materials with different F contentsrespectively, wherein the ZAFO target materials contain, by weight percent (wt%): 0.5-3.0 of Al, 0.82-3.28 of F and the balance of ZnO; and 2) installing the prepared ZAFO target materials in the vacuum chamber of radio-frequency magnetism-controlled sputtering deposition equipment; utilizing a mechanical pump and a molecular pump to pump the vacuum chamber so that the vacuum degree is less than3 multiplied by 10<-3>Pa; simultaneously, heating the substrate to the temperature of 25 DEG C-500 DEG C; adjusting the deposition process parameters and preparing the ZAFO transparent conductive filmon the substrate by the radio-frequency magnetism-controlled sputtering. The method simplifies the coating process and improves the conductivity of the film and the transmittance of the visible light.

Owner:UNIV OF SCI & TECH BEIJING

Superconductor method and reactor

InactiveCN100367525CGood critical currentGood critical current densityPolycrystalline material growthFrom normal temperature solutionsEnvironmental geology

Owner:AMERICAN SUPERCONDUCTOR

A kind of high-performance permanent magnet material and preparation method thereof

The invention provides a high-performance permanent magnet material and a production method thereof, and particularly provides a permanent magnet material. The permanent magnet material comprises, by total weight, 30-50% of cobalt, 6-10% of titanium, 12-16% of nickel and 6-10% of aluminum. The permanent magnet material has excellent physical and magnetic performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

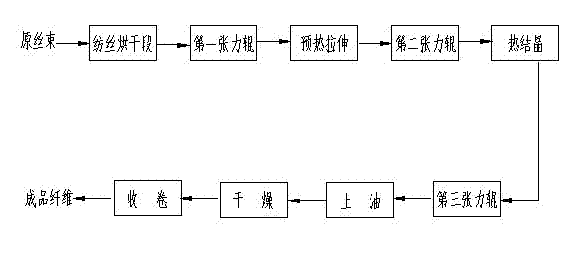

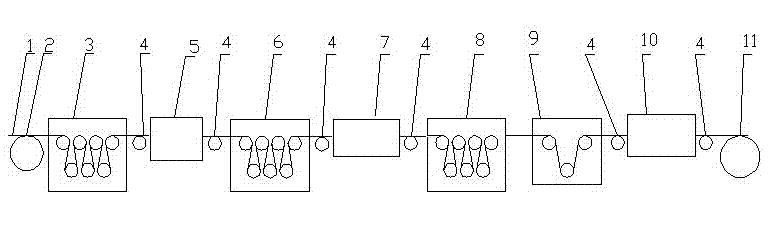

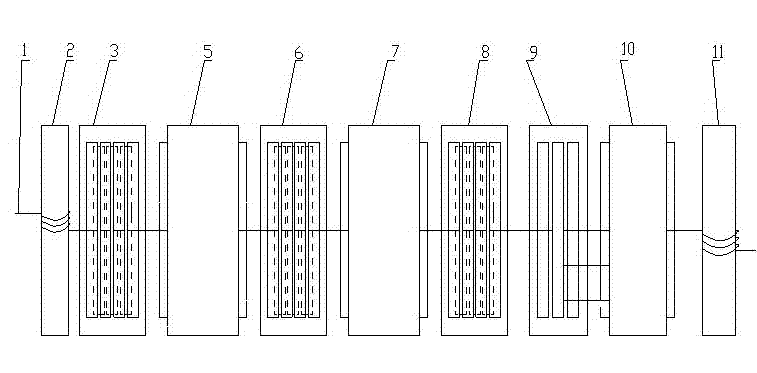

Aramid fiber III on-line thermal treating process and device thereof

InactiveCN101798720BReduce processingReduce production efficiencyTextiles and paperSpinningThermal treatment

The invention relates to aramid fiber III on-line thermal treating process and device thereof, which belongs to the technical field of special fiber. The aramid fiber III on-line thermal treating process comprises the following steps of: dividing the thermal treating process into a thermal drawing process and a thermal crystallization process; after aramid fiber III raw filament passes through a spinning drying section, directly winding on a first tension roller without coiling and uncoiling; guiding into a first tunnel furnace, and pretreating in the inert gas atmosphere under the conditionsof the temperature of 150-350 DEG C and draw ratio of 1-8%; guiding into a second tunnel furnace, and thermally treating in the inert gas or air under the conditions of the temperature of 360-550 DEGC and no drawing; applying oil to the obtained filament, drying and coiling to obtain the finished fiber with the strength more than 5.15GPa. By arranging a guide-in filament separating device and a guide-out filament separating device at both ends of the tunnel furnace, the invention can carry out thermal treatment on multiple filaments simultaneously, thereby greatly enhancing the production capability and decreasing the energy consumption.

Owner:四川辉腾科技股份有限公司

<100> Fe-Ga magnetostriction material on axial orientation and method of preparing the same

ActiveCN101109057BImprove performanceGood crystal orientationFrom frozen solutionsMagnetostrictive material selectionBridgman methodRoom temperature

The invention discloses a <, a 100>, an axial orientation Fe-Ga magnetostriction material and the preparation method thereof. The material composites are Fe1-x-yGaxAly; wherein, x is between 16 per cent and 21 per cent or 25 per cent and 28 per cent; y is between 0 per cent and 10 per cent; the rest part is iron. The preparation method is that the raw material is melted under the protection ofthe inert gas, and the improved percy williams bridgman method is adopted to prepare the Fe-Ga magnetostriction material through the directional solidification; The heat treatment conditions are thatthe material is preserved at 1100 DEG C. to 1200 DEG C. for 0.5 hours to 24 hours, cooled with the furnace till 900 DEG C. to 750 DEG C. for 0.5 hours to 24 hours temperature preservation and then quenched or cooled by air to room temperature; or the material is preserved at 1100 DEG C. to 1200 DEG C. temperature for 0.5 hours to 24 hours and is cooled with the furnace till 500 to 700 DEG C..

Owner:GRIREM ADVANCED MATERIALS CO LTD

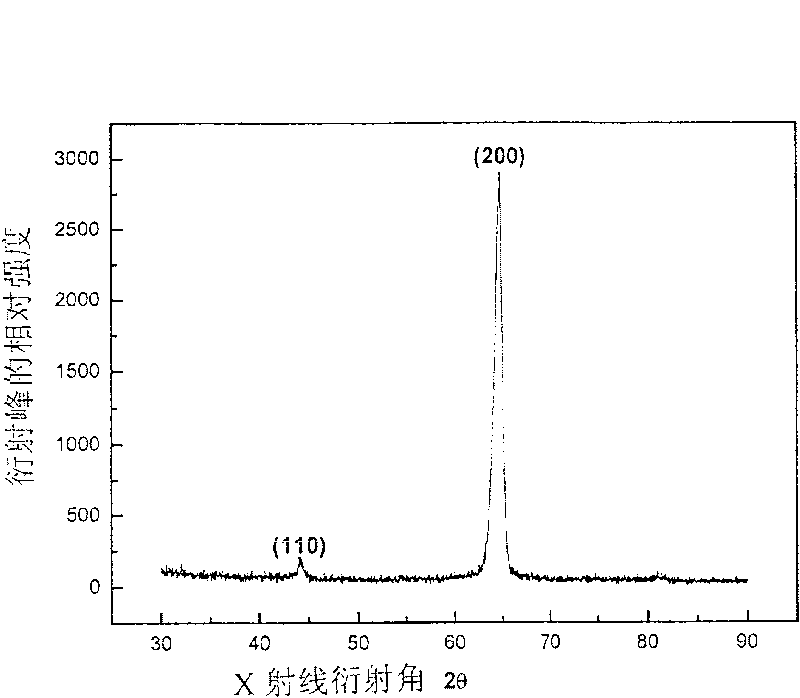

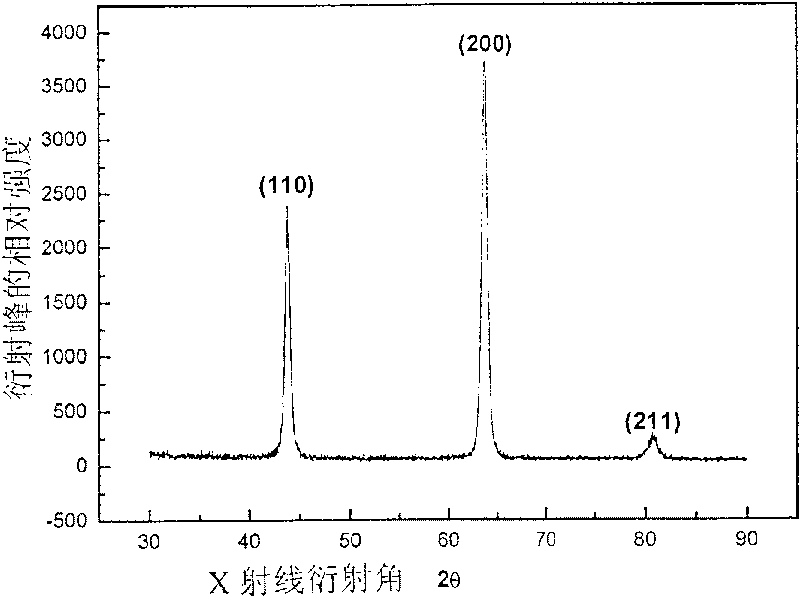

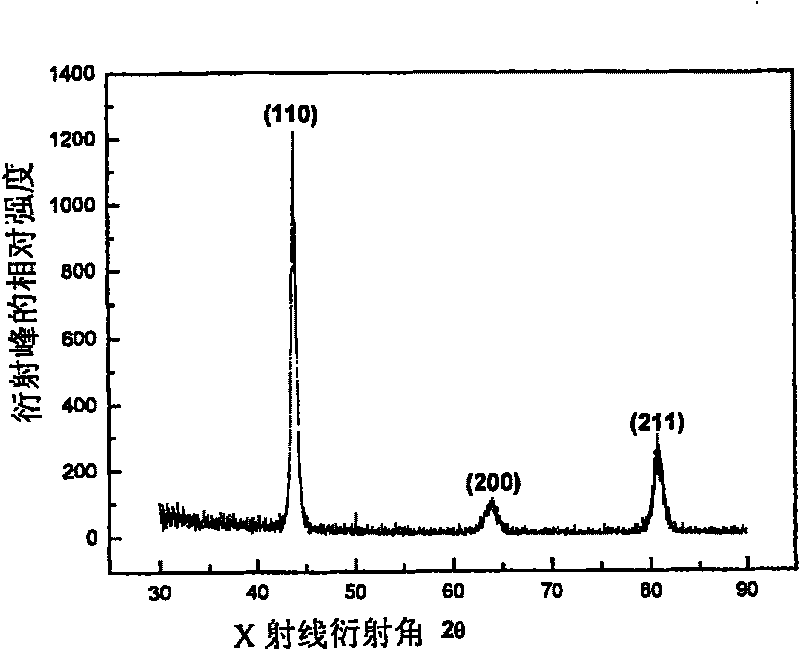

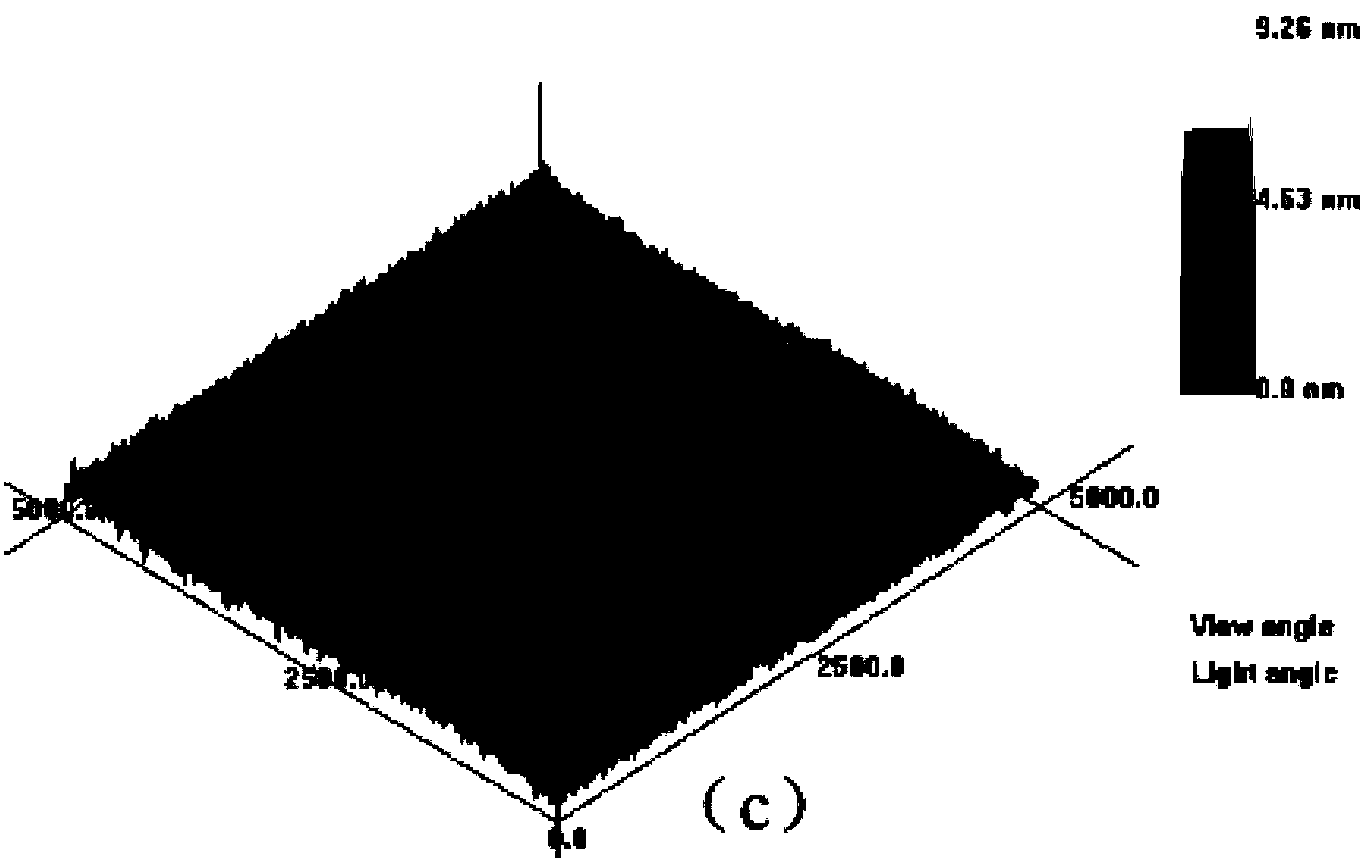

Preparation method of film bulk acoustic resonator lower electrode

InactiveCN103290367BReduce surface roughnessSimple structureImpedence networksVacuum evaporation coatingThin-film bulk acoustic resonatorAcoustic wave

The invention relates to a preparation method of a film bulk acoustic resonator lower electrode, which aims at solving the problems of an existing Mo (molybdenum) film obtained by an ordinary process that the surface is rough, the structural and geometric uniformity is poor, the electric and acoustic performance can hardly meet the piezoelectric pile electrode requirement, the characteristic difference between the Mo film and an AlN film is large and the combination strength is low. The preparation method comprises the following steps of: A, washing a monocrystal silicon substrate material; B, carrying out the ion cleaning on the surface of a monocrystal silicon substrate; C, depositing the Mo film on the surface of the monocrystal silicon substrate; D, carrying out the nitrogen treatment on the surface of the Mo film. The Mo film electrode prepared by the method is smooth in surface, low in coarseness, good in structural and geometric uniformity and excellent in electric and acoustic performance. The preparation method can be applicable to the technical field of an electronic material.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com