Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member, thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

a metal film and film coating technology, applied in the direction of ion implantation coating, crystal growth process, coating, etc., can solve the problems of difficult to achieve high reflectivity, metal film such as thin silver film formed by vacuum deposition is extremely vulnerable to the influence of the environment, and metal film may be blackened and peel off, etc., to achieve good crystal orientation, low surface roughness, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

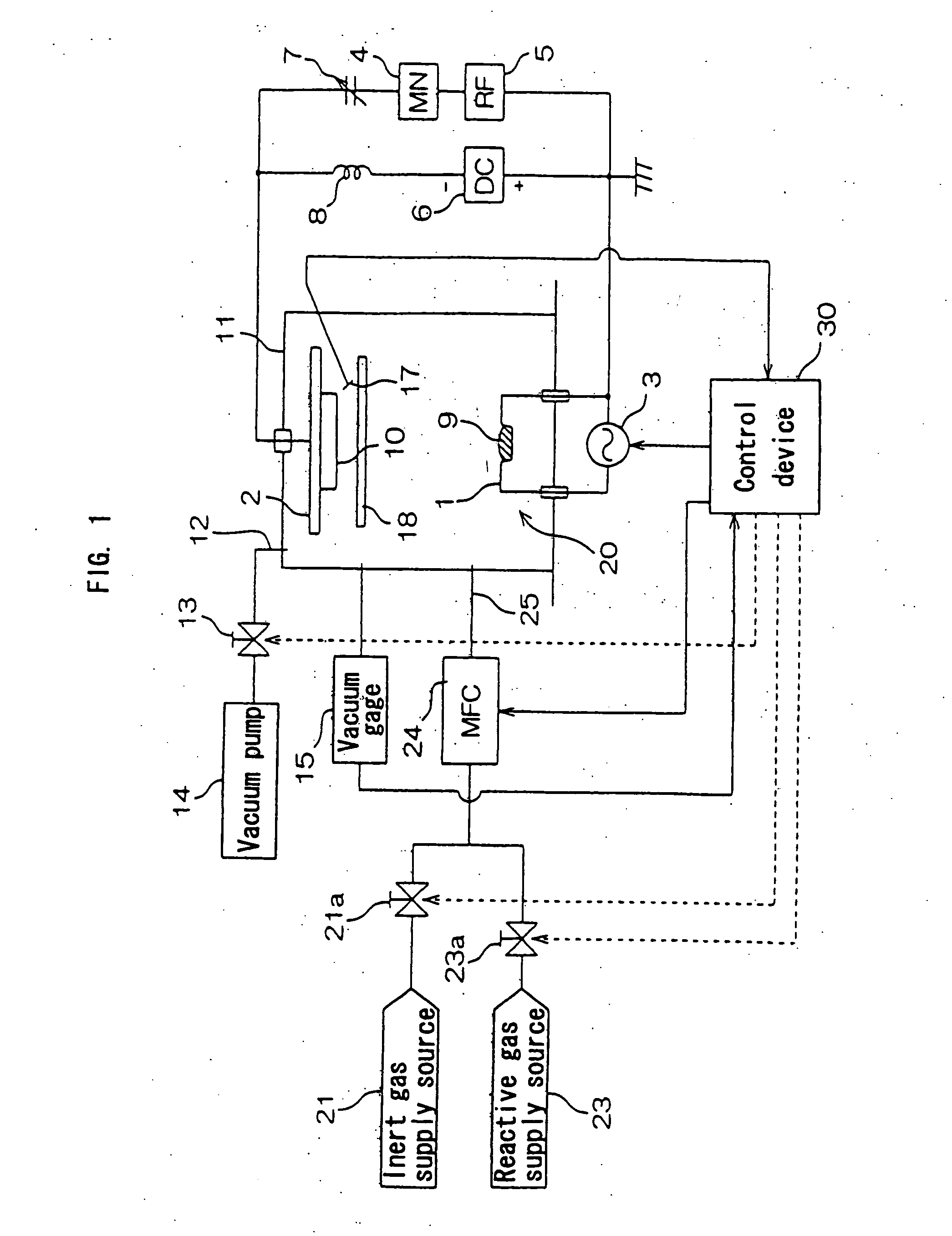

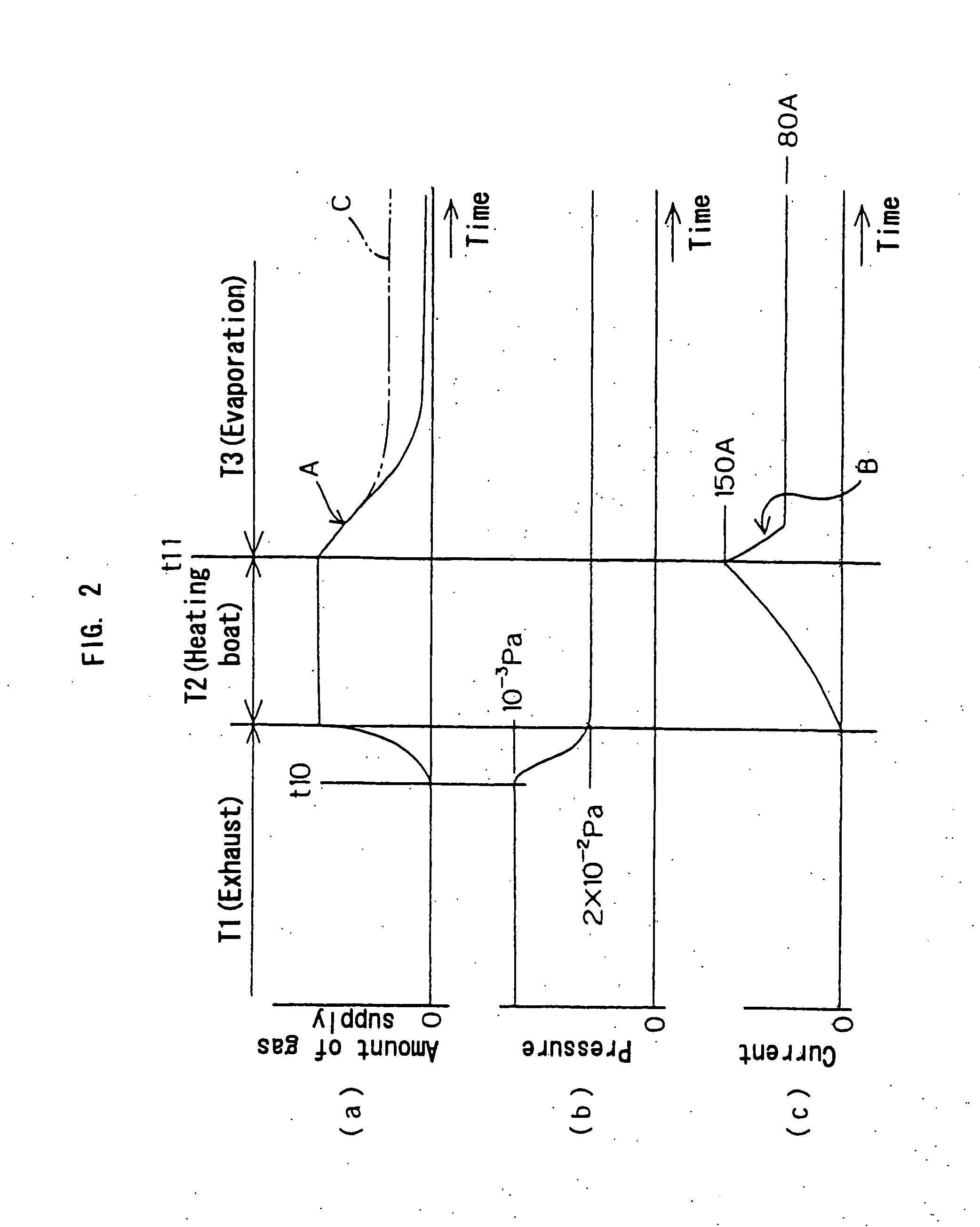

[0198] A silver film was formed in the process shown in FIG. 2 by using the thin film forming apparatus shown in FIG. 1, under the following conditions.

[0199] Substrate 10: A glass sheet 3 mm in thickness.

[0200] Evaporation material 9: Silver.

[0201] Gas introduced into the chamber 11: Argon gas.

[0202] Power supplied from the high frequency power source 5 to the substrate holding section 2: 85 mW / cm2 (power supplied per unit area of the substrate holding section 2) at frequency 13.56 MHz.

[0203] DC voltage source 6: Cathode connected to the substrate holding section 2 and anode connected to the boat 1.

[0204] Voltage applied by the DC voltage source 6 to the substrate holding section 2: 230 V.

[0205] Chamber 11: Electrically floated without grounding.

[0206] Rate of forming the metal film: 18 Å / second.

[0207] (a) Early Stage of Forming Metal Film (Period T2 shown in FIG. 2)

Pressure in the chamber 11: Constant at 2×10−2 Pa.

Current supplied from the heating power source 3 to th...

example 2

(Formation of Chromium Oxide)

[0234] A chromium oxide film was formed in the process shown in FIG. 2 by using the thin film forming apparatus shown in FIG. 1, under the following conditions.

[0235] Substrate 10: A glass sheet 3 mm in thickness.

[0236] Evaporation material 9: Chromium (purity 99.9%).

[0237] Gas introduced into the chamber 11: Argon gas and oxygen gas.

[0238] Power supplied from the high frequency power source 5 to the substrate holding section 2: 85 mW / cm2 (power supplied per unit area of the substrate holding section 2) at frequency 13.56 MHz.

[0239] DC voltage source 6: Cathode connected to the substrate holding section 2 and anode connected to the boat 1.

[0240] Voltage applied by the DC voltage source 6 to the substrate holding section 2: 230 V.

[0241] Chamber 11: Electrically floated without grounding.

[0242] Rate of forming the metal oxide film: 15 Å / second.

[0243] (A) Early Stage of Forming Metal Oxide Film (Period T2 Shown in FIG. 2)

Pressure in the chamber...

example 3

(Formation of Titanium Oxide Film)

[0259] Titanium oxide film was formed on the surface of a substrate so that an equation: n×d=3λ0 / 4 (n is refractive index of titanium oxide, d is thickness of titanium oxide film and λ0=580 nm) is satisfied, in the same manner as in Example 2, except for using titanium as the evaporation material and changing the output power of the high frequency power source 5 to 78 mW / cm2.

1. Transmittance and Reflectivity

[0260] Transmittance and reflectivity of the titanium oxide film obtained in Example 3 were measured with a photometer (spectrophotometer U-4000 manufactured by Hitachi Limited). The results are shown in FIG. 22. As shown in FIG. 22, transmittance was almost equal to the theoretical value of pure titanium oxide. Theoretical values were the refractive index shown in the list of fundamental physical properties (published by Kyoritsu Publishing Co., Ltd. on May 15, 1972) and the value of reflectivity calculated from the value of coating materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| incident angles | aaaaa | aaaaa |

| arithmetic mean roughness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com