Preparation method of film bulk acoustic resonator lower electrode

A thin-film bulk acoustic wave and resonator technology, which is applied in electrical components, ion implantation plating, coating, etc., can solve the problem that the electrical and acoustic properties are difficult to meet the requirements of piezoelectric stack electrodes, the characteristics of AlN thin films vary greatly, and the structure and geometry are uniform Poor performance and other problems, to achieve the effect of excellent electrical and acoustic performance, good structural and geometric uniformity, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the preparation method of the lower electrode of a kind of film bulk acoustic resonator in this embodiment is carried out according to the following steps:

[0019] Step 1. Put the monocrystalline silicon wafer substrate in acetone, alcohol and deionized water in sequence, wash it for 20-30 minutes under the condition of ultrasonic power of 250W-550W, and then dry it;

[0020] Step 2: Install the Mo target in the cathode arc source, place the monocrystalline silicon wafer substrate obtained in step 1 on the sample stage in the vacuum chamber of the filter cathodic arc deposition equipment, and evacuate to 1.0×10 -6 Torr~9.9×10 -6 Ar gas is introduced after Torr, and the flow rate of Ar gas is controlled to be 40sccm~60sccm. When the pressure in the vacuum chamber reaches 8.0×10 -5 Torr~1.0×10 -4 During Torr, turn the sample stage to the ion cleaning position, perform ion cleaning on the surface of the single crystal silicon substrate for 10min...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the ultrasonic power is 300W-500W and then cleaned for 22min-28min and then dried. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, the ultrasonic power is 400W and then cleaned for 25 minutes and then dried. Other steps and parameters are the same as those in Embodiment 1.

PUM

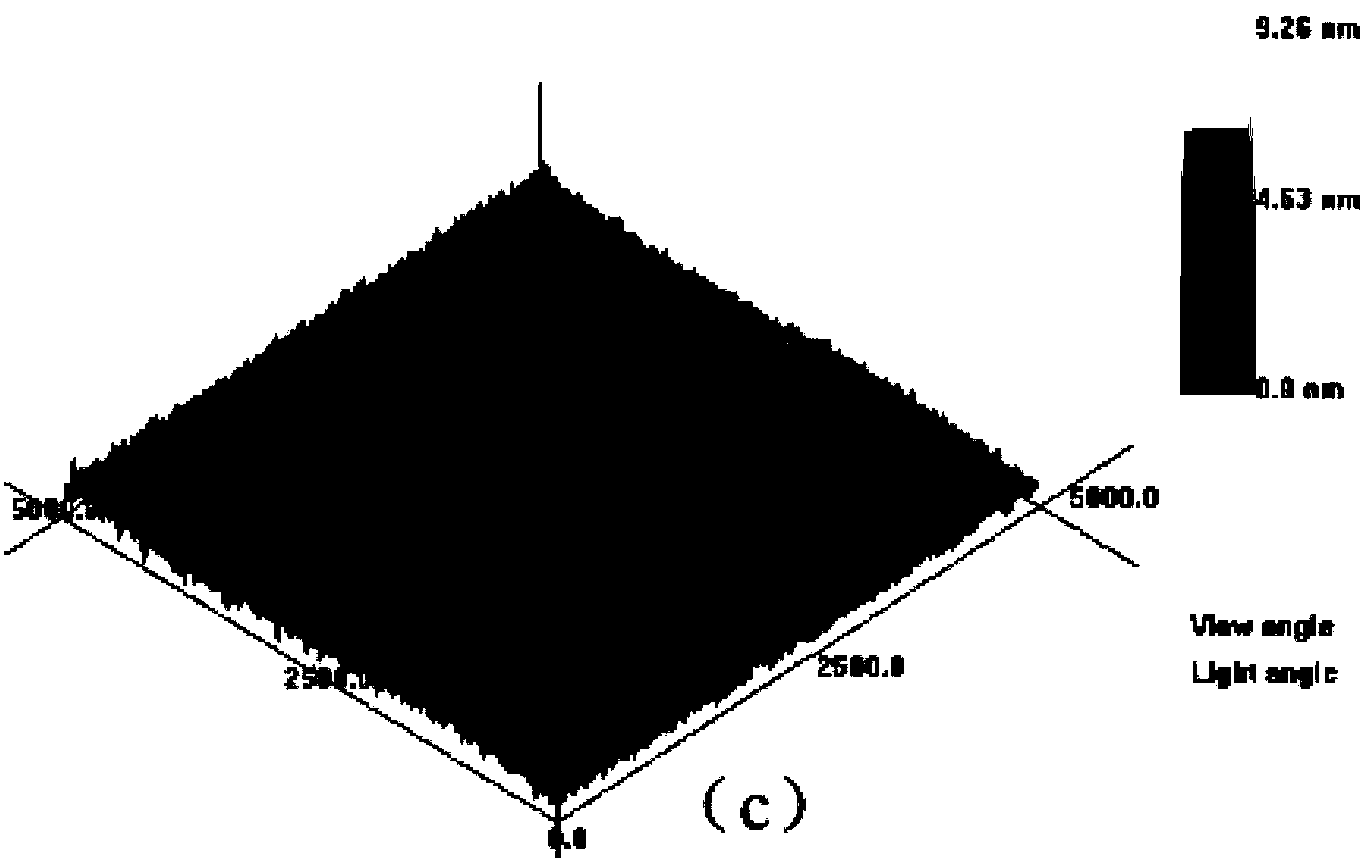

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com