Lignin hydro-cracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, which is applied in the field of catalysts for preparing high-performance bio-oil and its preparation, can solve the problems of poor thermal stability, hydrothermal stability, and low crystallinity, and achieve good stability, high crystallinity, Good cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

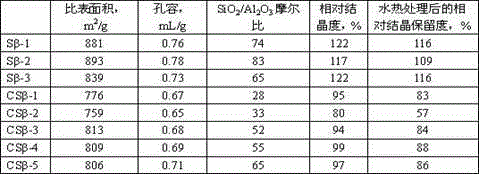

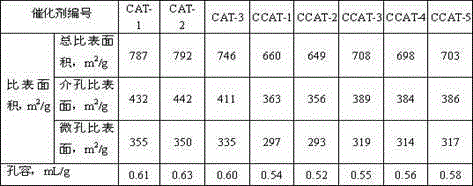

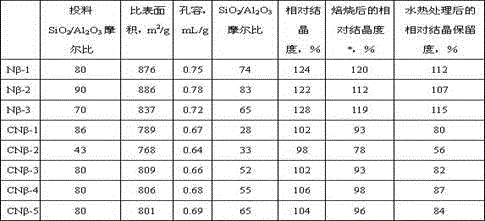

Examples

Embodiment 1

[0044] (1) Preparation of amorphous silicon-aluminum precursor

[0045] The preparation concentration is 40g Al 2 o 3 / L sodium aluminate working solution, take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 120g SiO 2 / L sodium silicate working solution. Take 200mL of sodium aluminate working solution and place it in a gel-forming tank, then add 50mL of sodium silicate working solution, control the reaction temperature at 18°C, and inject CO with a concentration of 50 v% 2 gas, stop passing CO when the pH reaches 10.2 2 , then add 50mL of sodium silicate working solution, and then ventilate and stabilize for 20 minutes to obtain an amorphous silicon-aluminum precursor. The amorphous silicon-alumina precursor is based on the total weight of silicon dioxide and aluminum oxide, and the content in terms of silicon dioxide is 60wt%.

[0046] (2) Preparation of gel

[0047] Press Al 2 o 3 : SiO 2 : Na 2 O: H 2 O=1:80:1.5:240, TEAOH / SiO 2 = 0...

Embodiment 2

[0054] (1) Preparation of amorphous silicon-aluminum precursor

[0055] The preparation concentration is 50gAl 2 o 3 / L sodium aluminate working solution, take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 100g SiO 2 / L sodium silicate working solution. Take 200mL of sodium aluminate working solution and place it in a gel-forming tank, then add 60mL of sodium silicate working solution, control the reaction temperature at 20°C, and feed CO with a concentration of 50v%. 2 gas, stop passing CO when the pH reaches 10.0 2 , then add 40mL of sodium silicate working solution, and ventilate and stabilize for 20 minutes to obtain an amorphous silicon-aluminum precursor. The amorphous silicon-alumina precursor is based on the total weight of silicon dioxide and aluminum oxide, and the content in terms of silicon dioxide is 50wt%.

[0056] (2) Preparation of gel

[0057] Press Al 2 o 3: SiO 2 : Na 2 O: H 2 O=1:90:1.7:260, TEAOH / SiO 2 = 0.060 total ...

Embodiment 3

[0064] (1) Preparation of amorphous silicon-aluminum precursor

[0065] The preparation concentration is 50gAl 2 o 3 / L sodium aluminate working solution, take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 100g SiO 2 / L sodium silicate working solution. Take 160mL of sodium aluminate working solution and place it in a gel-forming tank, then add 45mL of sodium silicate working solution, control the reaction temperature at 20°C, and feed CO with a concentration of 50v%. 2 gas, stop passing CO when the pH reaches 10.0 2 , then add 35mL of sodium silicate working solution, and then ventilate and stabilize for 20 minutes to obtain an amorphous silica-alumina precursor. The amorphous silica-alumina precursor is based on the total weight of silica and alumina, and the content in terms of silica is 50wt%.

[0066] (2) The preparation of the gel is the same as in Example 1, the difference is that: according to Al 2 o 3 : SiO 2 : Na 2 O: H 2 O=1:70:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com