Superconductor method and reactor

A technology of superconductors and reactive gases, applied in the usage of superconductor elements, the manufacture/processing of superconductor devices, and superconductivity devices, etc., can solve the problem of non-diffusion of chemical substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I

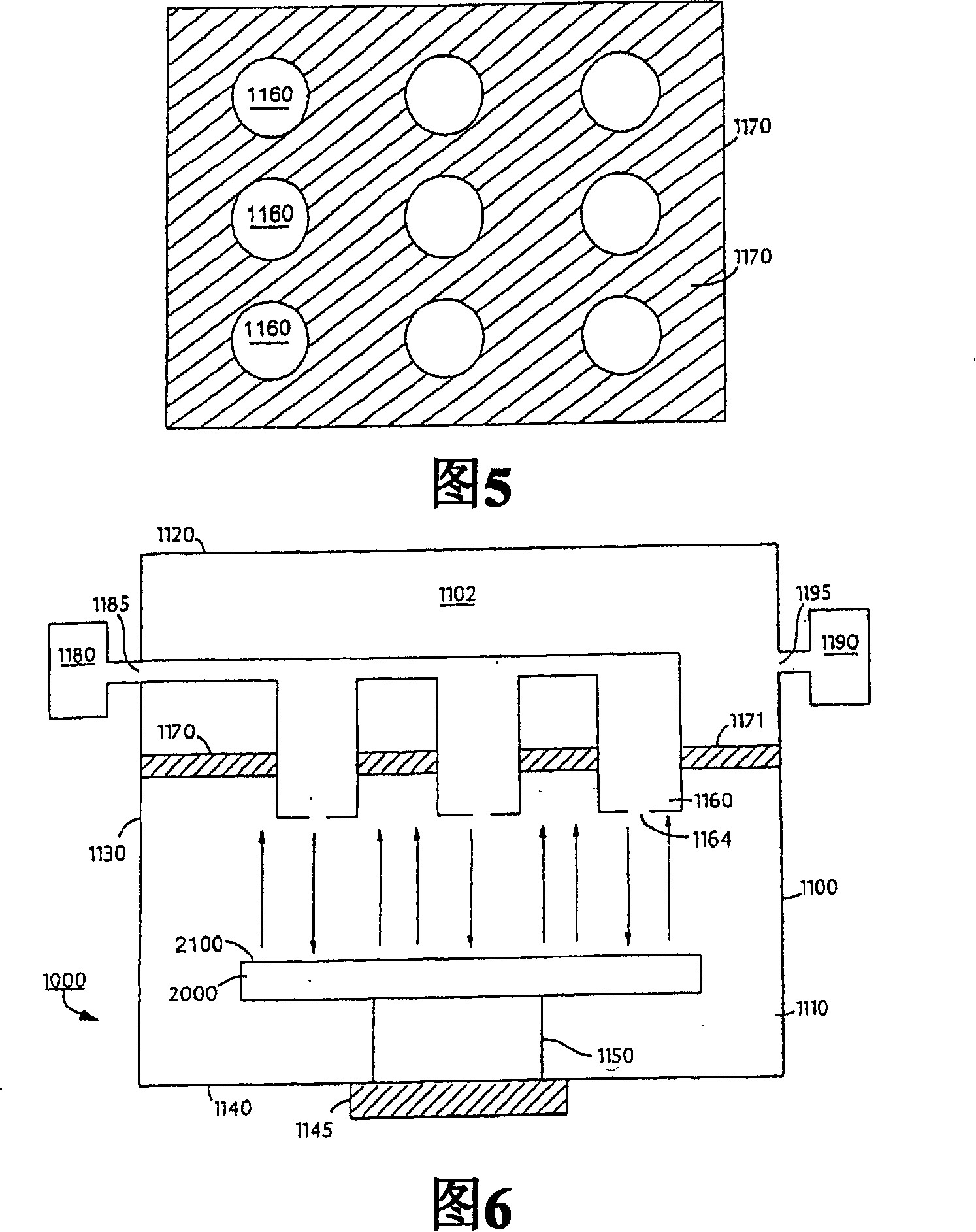

[0187] Epitaxial YBCO films were prepared as follows.

[0188] A biaxially textured 95 atomic percent nickel / five atomic percent tungsten alloy substrate was configured by cold rolling and annealing in strip form (75 mm thick and 1 cm wide). A 2 micron thick nickel layer was formed on the surface of the substrate, and a C2X2 sulfur superstructure was formed on the nickel layer.

[0189] Subsequent deposition of an epitaxial oxide buffer layer to form a structured substrate / Y 2 o 3 / YSZ / CeO 2 heap. Deposition of Y by electron beam vaporization 2 o 3 Seed layer (50 nm thick). Deposition of YSZ barrier layer (300 nm thick) and CeO by RF sputtering 2 Cap layer (30 nm thick).

[0190] A solution based on copper propionate, barium trifluoroacetate, and yttrium trifluoroacetate was coated on CeO 2 on the cap. The film is dried at 60°C in humid air and the resulting material is decomposed in a moist, oxygen atmosphere at a temperature up to 400°C, for the subsequent formatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com