Preparation method for polycrystalline mercury iodide film seed crystal layer

A technology of mercury iodide and seed crystal layer is applied in the field of preparation of polycrystalline mercury iodide thin film seed crystal layer, which can solve the problems of solvent contamination reaction by-products, difficult to remove, etc., and achieves easy popularization, easy operation, and solved removal problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

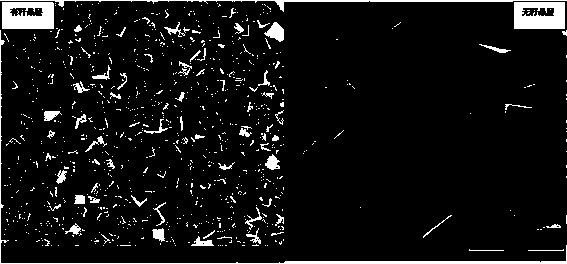

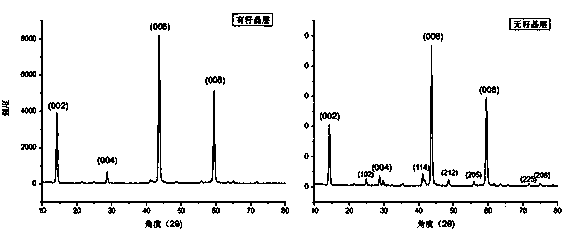

Image

Examples

Embodiment 1

[0025] A preparation method of a polycrystalline mercuric iodide film seed layer, comprising the following steps in sequence:

[0026] a. Preparation of the substrate: ITO conductive glass is selected as the substrate material for depositing the mercury iodide seed layer. First cut the ITO glass (thickness 1mm) into small square pieces of 10×10mm in size, and then clean the surface of the ITO glass substrate: put the ITO glass in acetone and 18MΩ high-purity deionized water for 15 minutes, and then use Rinse with deionized water three times. Then dry it under vacuum condition to get a clean and smooth ITO substrate.

[0027] b. Preparation of reaction solution: first add HI acid to 18MΩ high-purity deionized water to dilute until the concentration of HI in water is 20%, and place the diluted HI acid in a constant temperature preparation device with electromagnetic stirring, set The magnetic rotor rotates at 200 rpm. Then yellow mercury oxide according to [Hg 2+ ]: [I - ] ...

Embodiment 2

[0031] A preparation method of a polycrystalline mercuric iodide film seed layer, comprising the following steps in sequence:

[0032] a. Preparation of the substrate: ITO conductive glass is selected as the substrate material for depositing the mercury iodide seed layer. First cut the ITO glass (thickness 1mm) into small square pieces of 10×10mm in size, and then clean the surface of the ITO glass substrate: put the ITO glass in acetone and 18MΩ high-purity deionized water for 15 minutes, and then use Rinse twice with deionized water. Then dry it under vacuum condition to get a clean and smooth ITO substrate.

[0033] B, the preparation of reaction solution: at first HI acid is added appropriate amount of high-purity deionized water and diluted to the concentration of HI in water is 25%, and the diluted HI acid is placed in the constant temperature preparation device with electromagnetic stirring, set The rotation speed of the fixed magnetic rotor is 500rpm. Then yellow me...

Embodiment 3

[0037] A preparation method of a polycrystalline mercuric iodide film seed layer, comprising the following steps in sequence:

[0038] a. Preparation of the substrate: TFT conductive glass is selected as the substrate material for depositing the mercury iodide seed layer. First, cut the TFT glass (thickness 1mm) into small square pieces of 10×10mm, and then clean the surface of the ITO glass substrate: put the ITO glass into acetone and 18MΩ high-purity deionized water for 15 minutes, and then use Rinse with deionized water three times. Then dry it under vacuum condition to get a clean and smooth ITO substrate.

[0039] B, the preparation of reaction solution: at first HI acid is added appropriate amount of high-purity deionized water and diluted to the concentration of HI in water is 30%, and the diluted HI acid is placed in the constant temperature preparation device with electromagnetic stirring, set The rotational speed of the fixed magnet rotor is 200rpm. Then yellow m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com