Patents

Literature

69 results about "METHYLIODIDA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonylation process

ActiveUS20070293695A1Organic compound preparationPreparation by carbon monoxide or formate reactionHydrogen halideCarboxylic acid

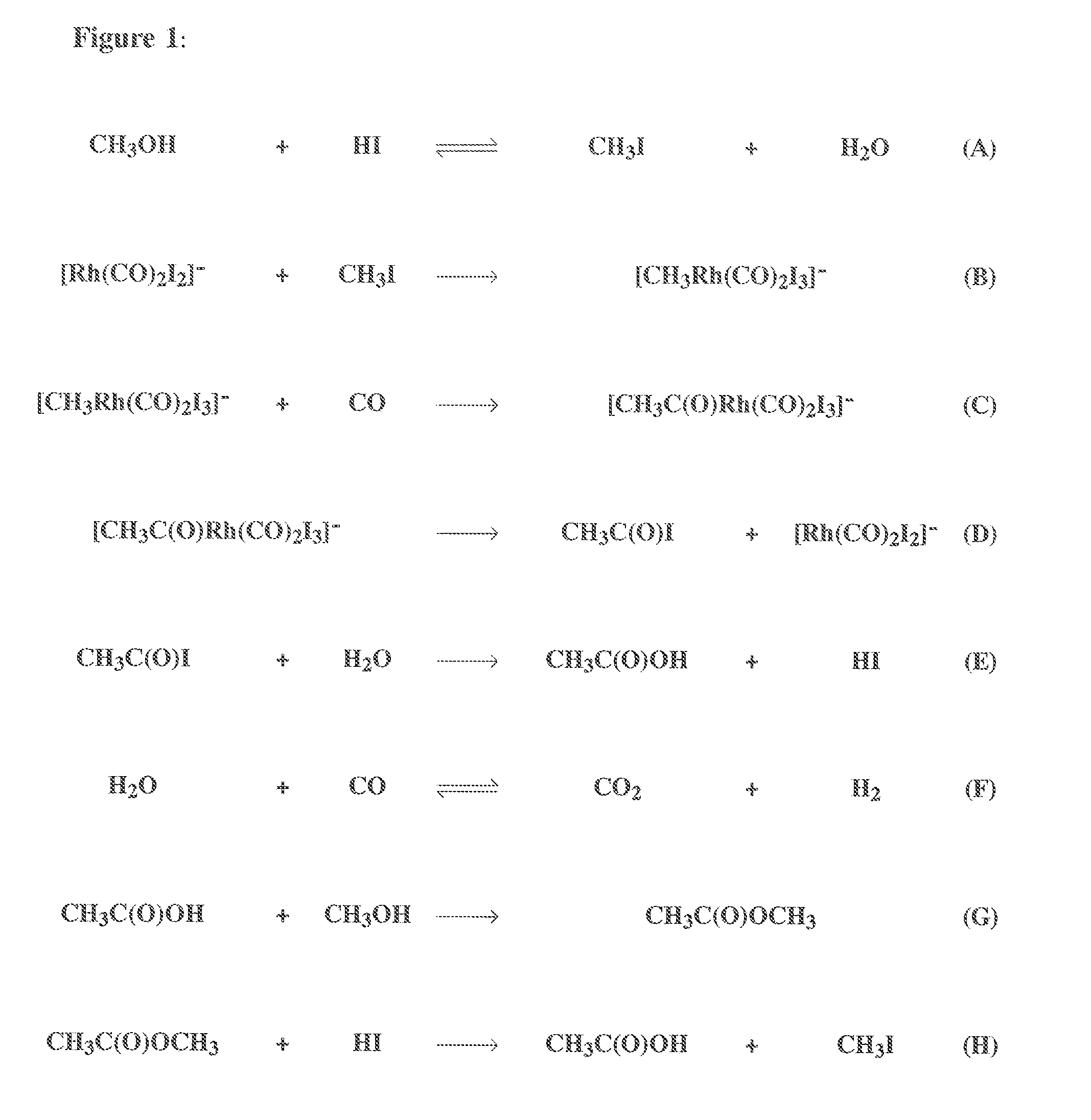

Disclosed is a carbonylation process for the production of carboxylic acids, carboxylic acid esters and / or carboxylic acid anhydrides wherein a carbonylation feedstock compound selected from one or more organic oxygenates such as alcohols, ethers, and esters is contacted with carbon monoxide in the presence of a carbonylation catalyst and one or more onium compounds. The carbonylation process differs from known carbonylation processes in that a halide compound such as a hydrogen halide, typically hydrogen iodide, and / or alkyl halide, typically methyl iodide, extraneous or exogenous to the carbonylation process is not fed or supplied separately to the process.

Owner:EASTMAN CHEM CO

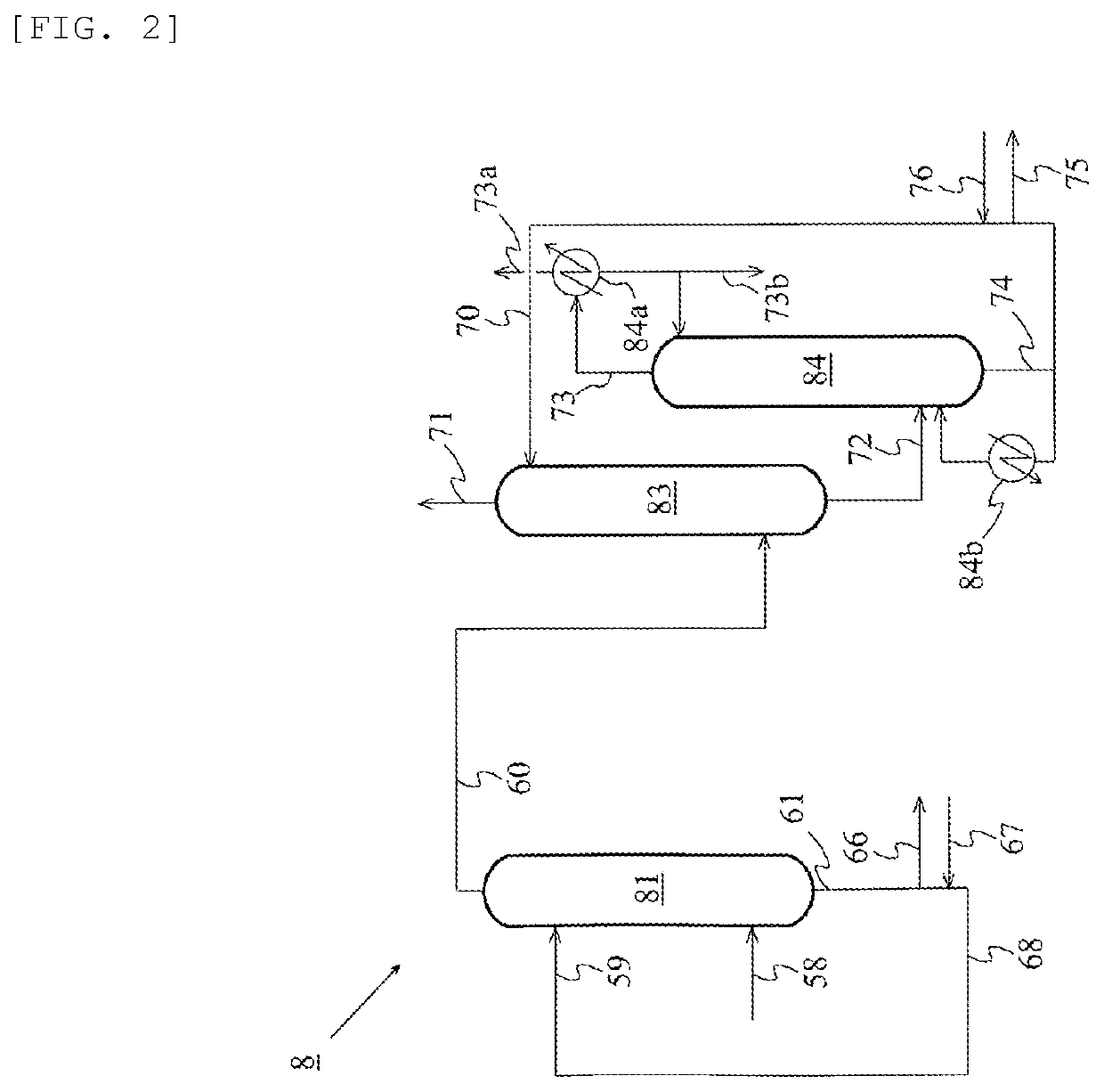

Process for producing acetic acid

ActiveUS20130303800A1Stable productionEfficient removalOrganic compound preparationCarboxylic preparation from carbon monoxide reactionPtru catalystDistillation

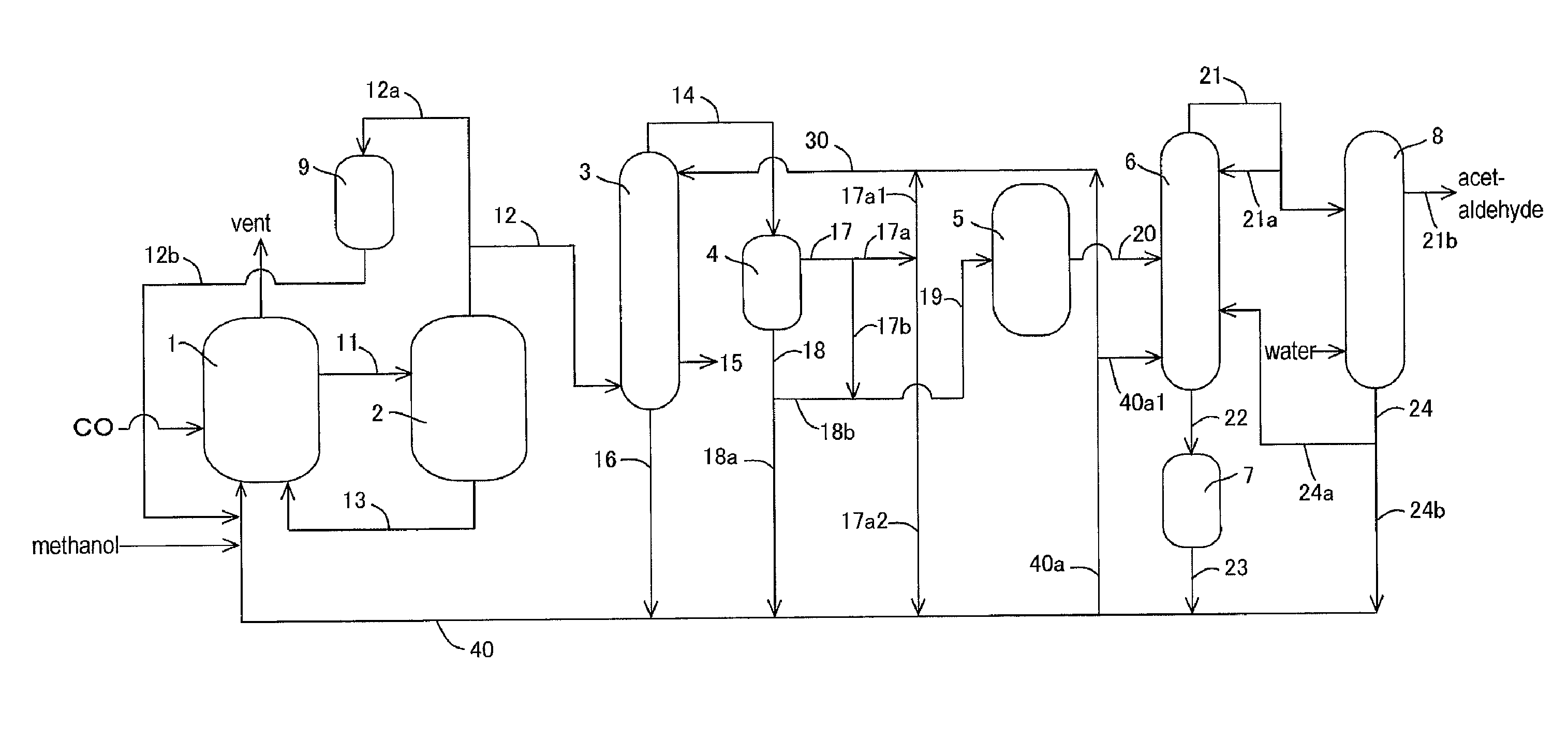

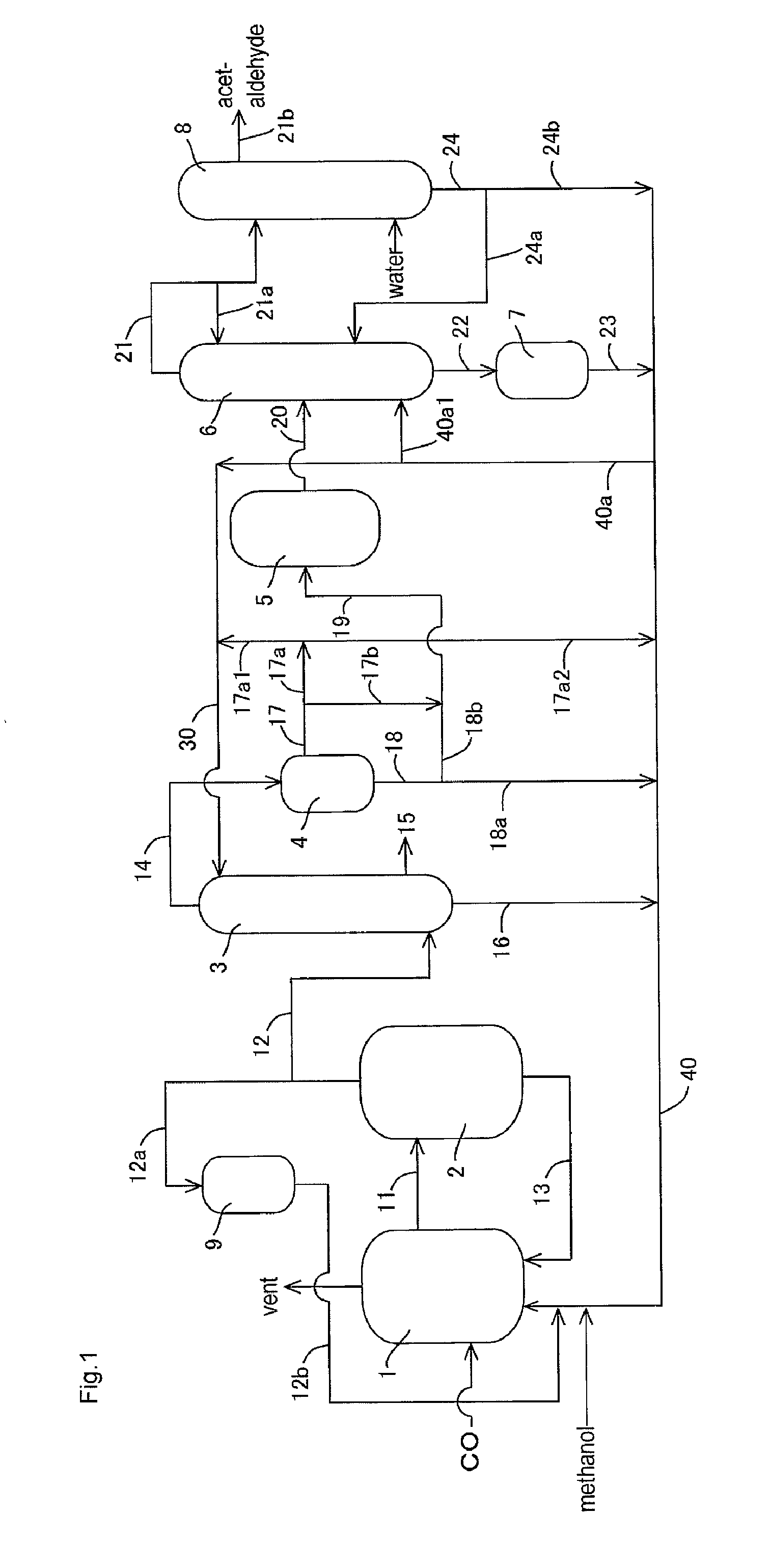

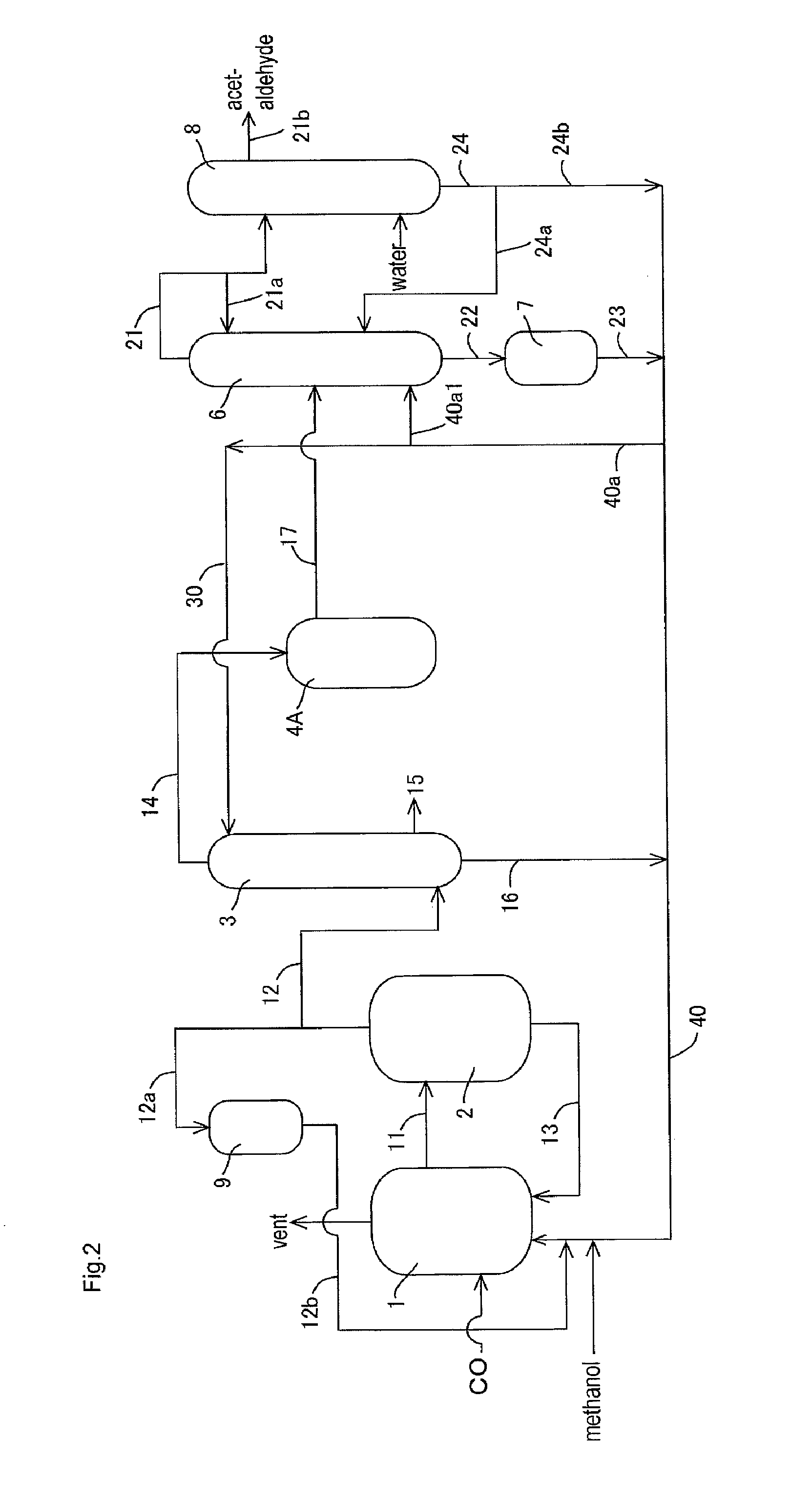

A process for stably producing high-purity acetic acid while efficiently removing acetaldehyde is provided.The process for producing acetic acid comprises a reaction step for allowing methanol to react with carbon monoxide in the presence of a metal catalyst, a halide salt, and methyl iodide; a step for continuously feeding a flasher with the reaction mixture and separating a lower boiling point component (2A) containing acetic acid and methyl iodide and a higher boiling point component (2B) containing the metal catalyst and the halide salt; a step for feeding a distillation column with the lower boiling point component (2A), and separating a lower boiling point component (3A) containing methyl iodide and acetaldehyde and a stream (3B) containing acetic acid to collect acetic acid; a condensation step for condensing and temporarily holding the lower boiling point component (3A) in a decanter and discharging the lower boiling point component (3A) from the decanter; and a step for separating the lower boiling point component (3A) discharged from the decanter into acetaldehyde and a liquid residue and recycling the liquid residue to the reaction system. In the condensation step, the amount of the lower boiling point component (3A) to be held is controlled based on a fluctuating flow rate of the lower boiling point component (3A) to be fed to the decanter.

Owner:DAICEL CHEM IND LTD

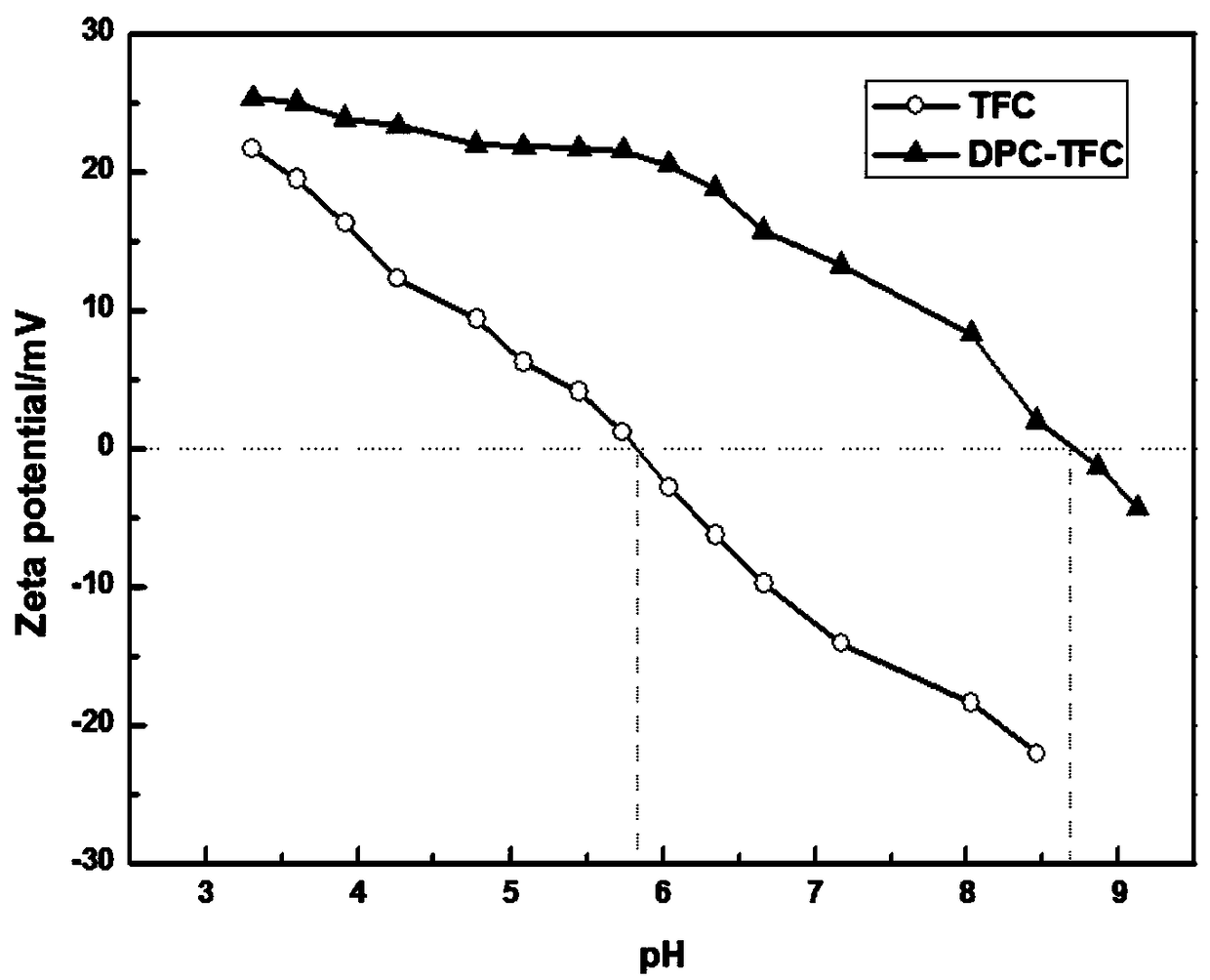

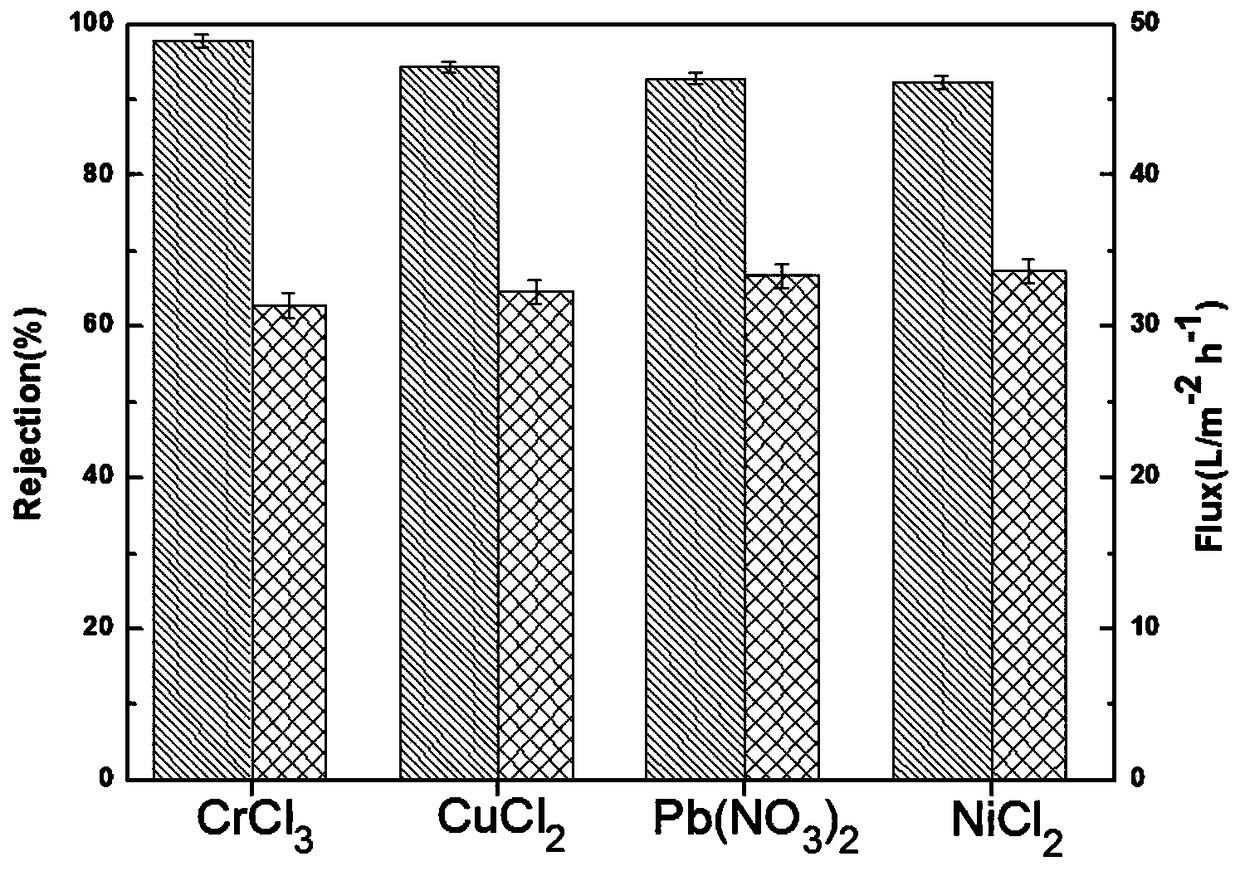

Preparation method and application of polyethyleneimine modified original ecological positively charged nanofiltration membrane

InactiveCN109200823AHigh retention rateShow Processing Application ForegroundMembranesWater/sewage treatment bu osmosis/dialysisActive agentPolyamide

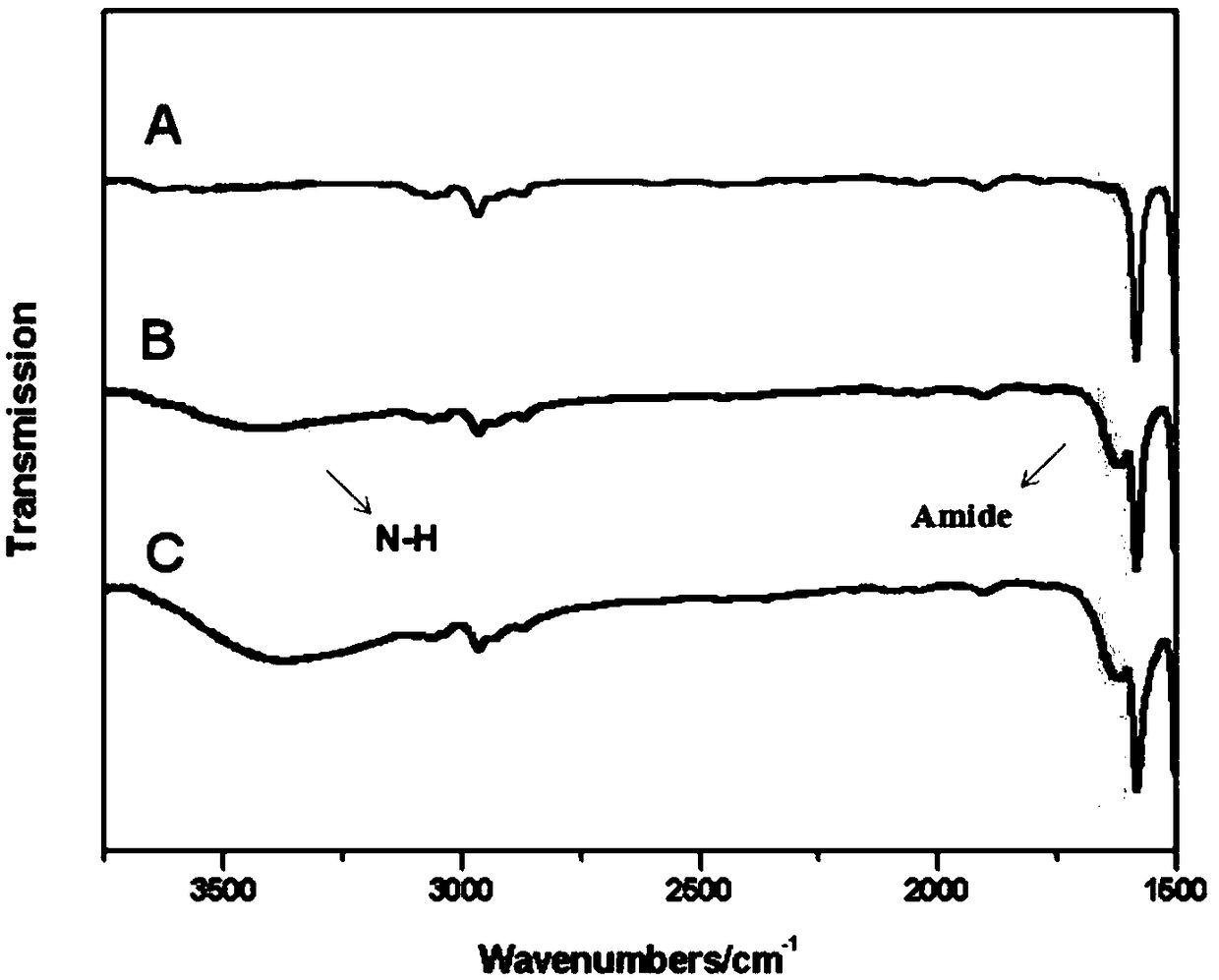

The invention discloses a preparation method and application of a polyethyleneimine modified original ecological positively charged nanofiltration membrane. The preparation method is carried out according to the following steps: (1) using an ultrafiltration membrane as a support membrane, a piperazine and diaminodipropylamine mixed aqueous solution as an aqueous phase and a trimesoyl chloride n-hexane solution as an organic phase to form an active separation layer on the support membrane by interfacial polymerization to obtain an original ecological polyethyleneimine nanofiltration membrane; (2) mixedly dissolving active agent 2-chloro-1-methyliodopyridine, sodium hydroxide and polyethyleneimine in deionized water to obtain a grafted aqueous solution; and (3) pouring the grafted aqueous solution into the surface of the original ecological polyethyleneimine nanofiltration membrane obtained in the step (1) for grafting reaction, then removing excess surface solution, washing with water,and drying to obtain the positively charged nanofiltration membrane. The application of the polyethyleneimine modified original ecological positively charged nanofiltration membrane in removal of dyes, toxic metal ions and monovalent and divalent cations can be provided, and the polyethyleneimine modified original ecological positively charged nanofiltration membrane has good rejection rate and stability.

Owner:ZHEJIANG UNIV OF TECH

Azeotrope-like compositions of 1-chloro-3,3,3-trifluoropropene and methyl iodide

An azeotropic or azeotrope-like composition comprising a mixture of methyl iodide, 1-chloro-3,3,3,-trifluoropropene, and optionally one or more of fluorocarbons and / or hydrofluorocarbons. The compositions are present as a gas, at temperatures of about 30° C. or below. The inventive compositions serve as a non-ozone-depleting gaseous fumigant which is useful in a variety of applications, in place of methyl bromide. These compositions serve as a drop-in replacement for gaseous methyl bromide, providing the benefits of a methyl iodide fumigant while also utilizing existing methyl bromide equipment.

Owner:HONEYWELL INT INC

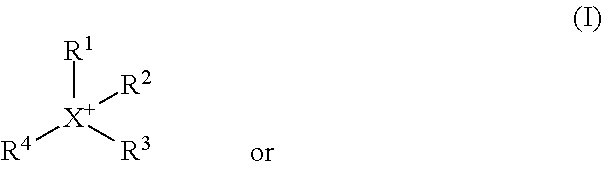

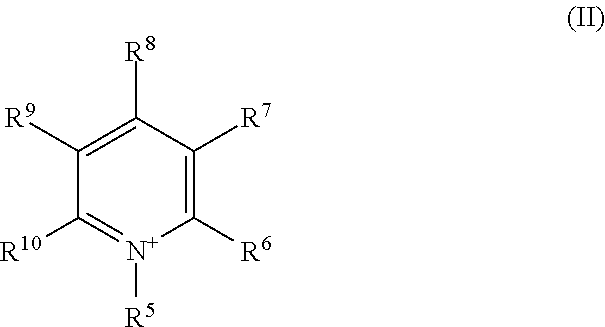

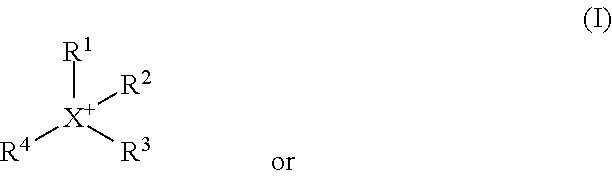

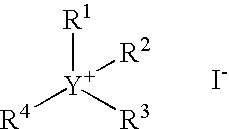

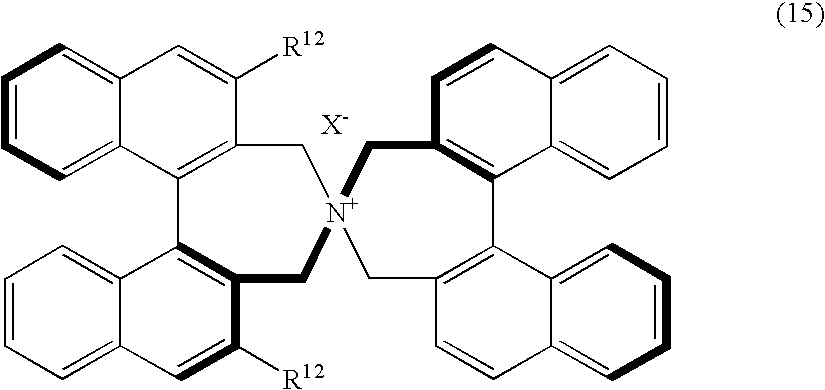

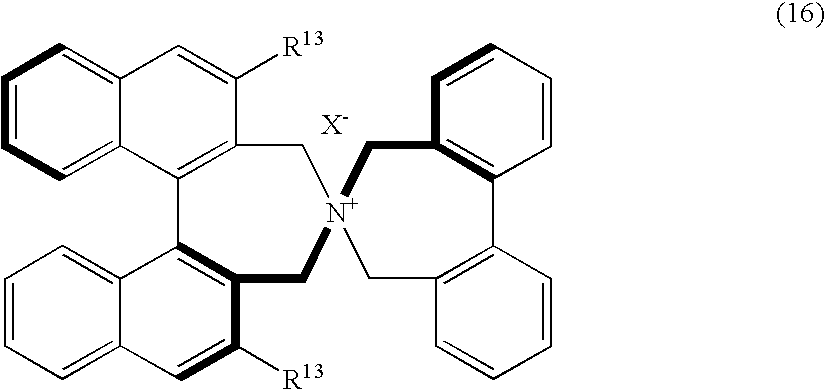

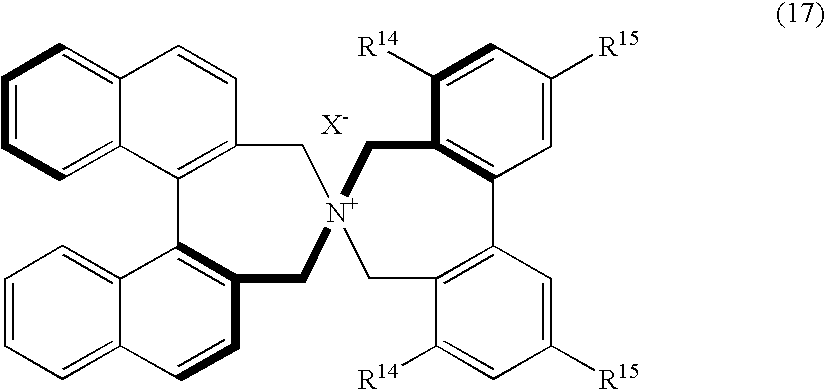

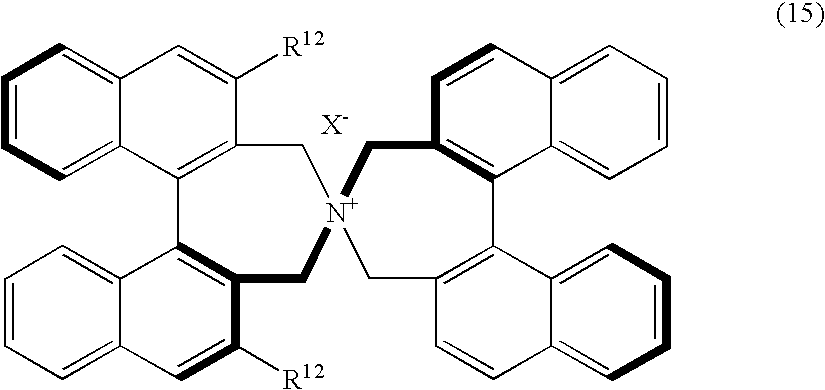

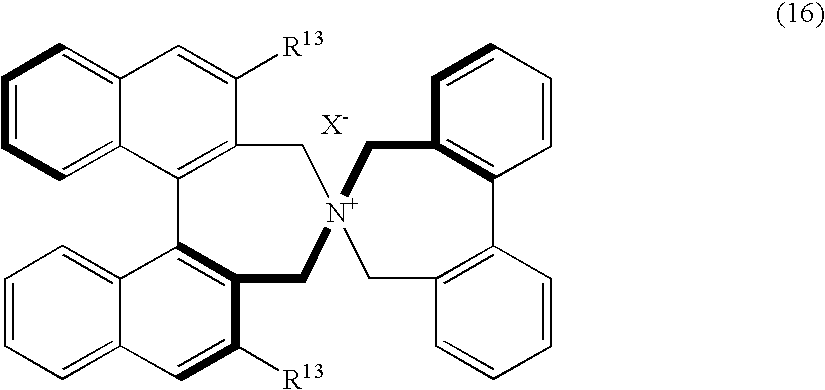

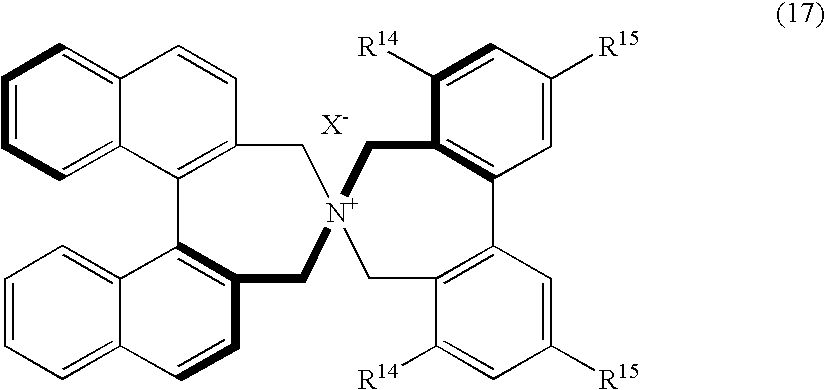

Optically active quaternary ammonium salt, process for producing the same, and process for producing optically active alpha-amino acid derivative with the same

InactiveUS20060183896A1High stereoselectivityHigh selectivitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMethyl group

(Object): There are provided (1) an optically active a-amino acid derivative, a stereoselectively useful intermediate for the synthesis of pharmaceutical or agrochemical products, which derivative is an optically active quaternary ammonium salt that, when used as an axially chiral spiro phase-transfer catalyst in the asymmetric alkylation of a glycine derivative, gives a high stereoselectivity toward substrates having a small molecule such as methyl iodide, or secondary alkyl halides, and a method for producing the same; and (2) a novel optically active quaternary ammonium salt that is a high performance axially chiral spiro phase-transfer catalyst used in the asymmetric alkylation of a glycine derivative, and in which each ring of the spiro-structure has the same structure that is advantageous in terms of the number of steps involved in the synthesis of the catalyst, and a method for producing the same and a method for recovering the same. (Solving means): To achieve the objects, (1) an axially chiral spiro-ammonium salt that incorporates an alkyl- or aryl-substituted silyl group as a substituent on the aromatic ring is used as a phase-transfer catalyst in the asymmetric alkylation of a glycine derivative, and (2) an axially chiral spiro-ammonium slat that incorporates a substituent encompassing a perfluoro alkyl group is used in the asymmetric alkylation of a glycine derivative and thereafter is recovered using a fluorous solvent.

Owner:TOSOH CORP

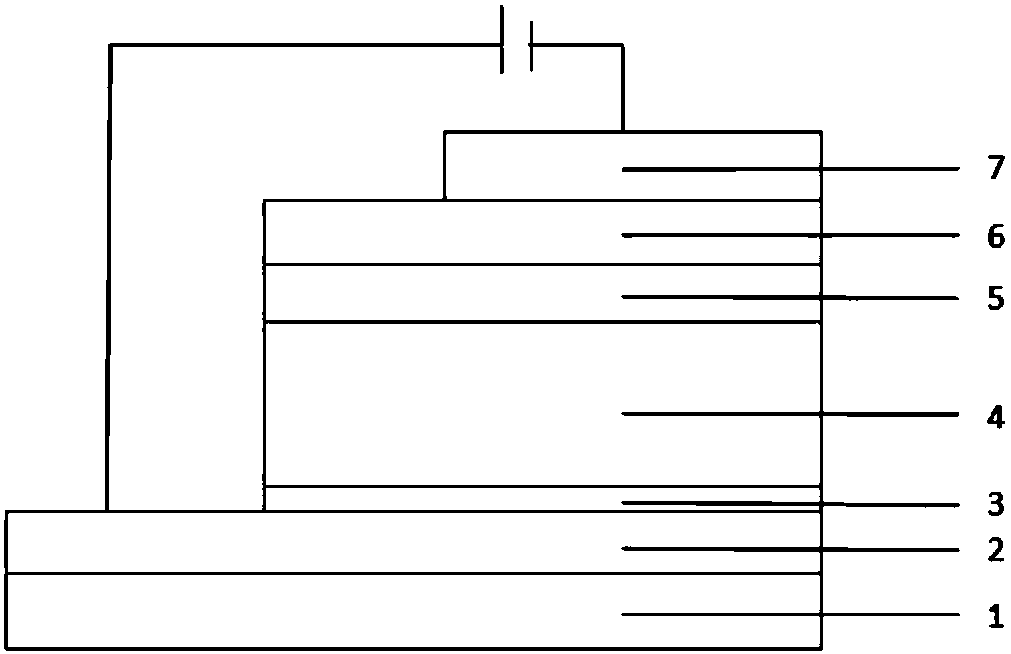

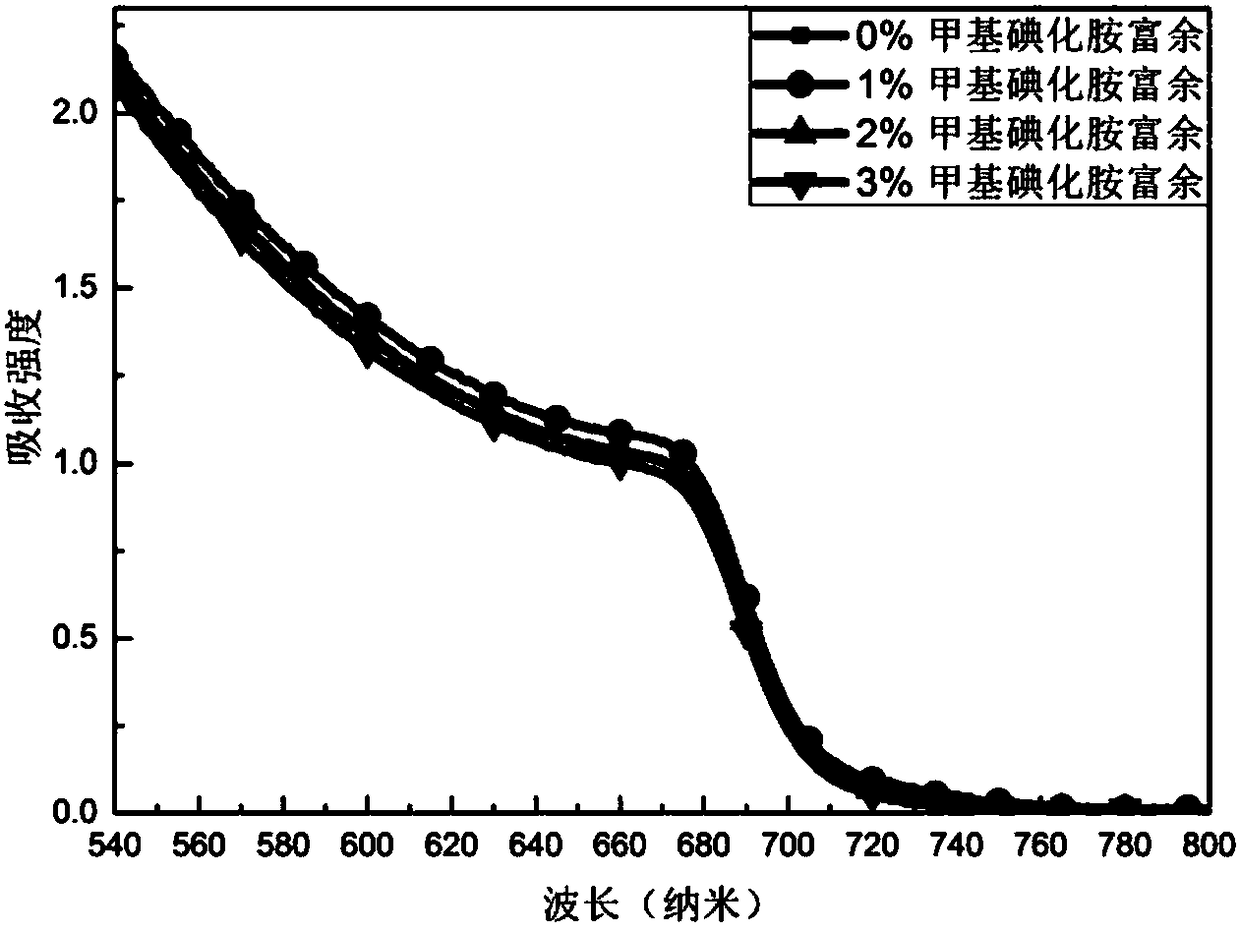

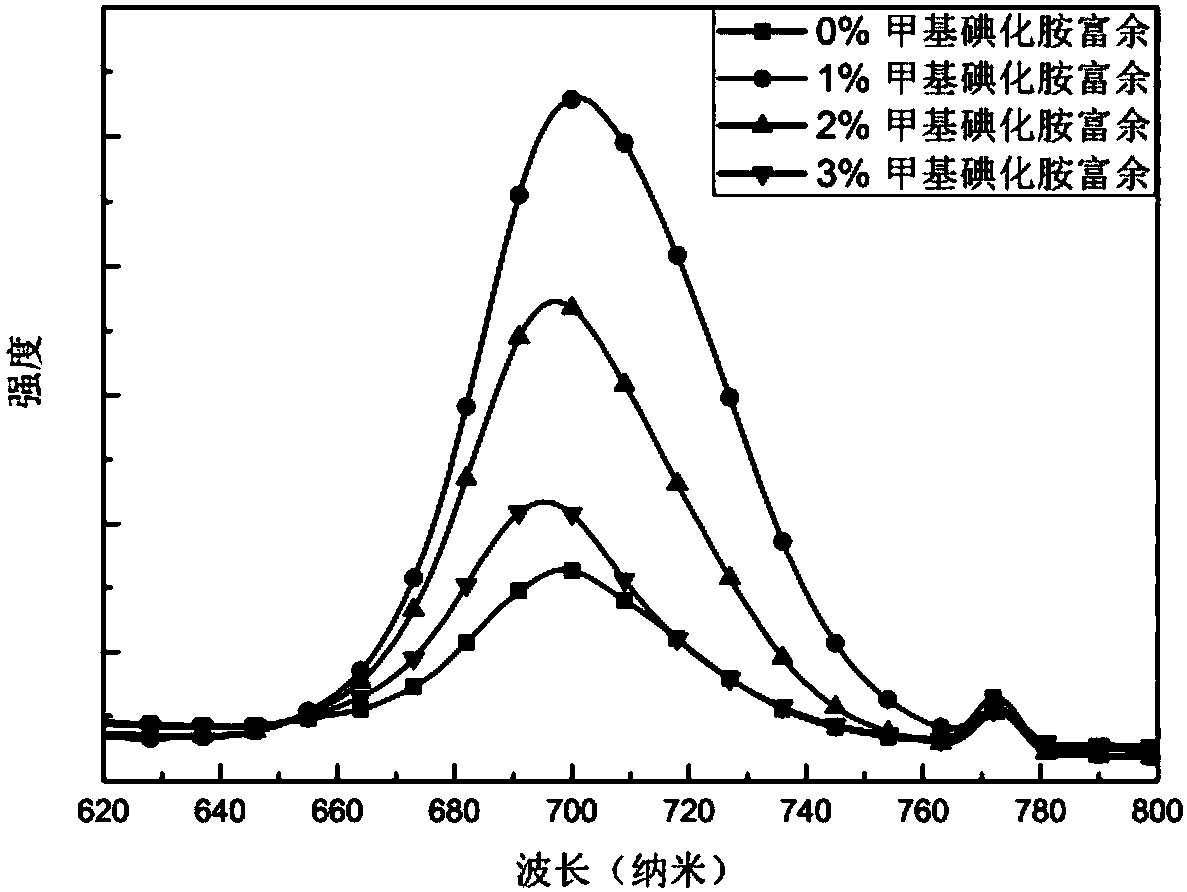

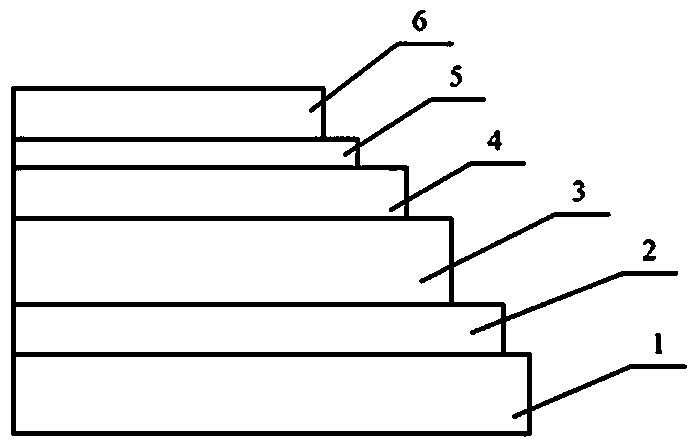

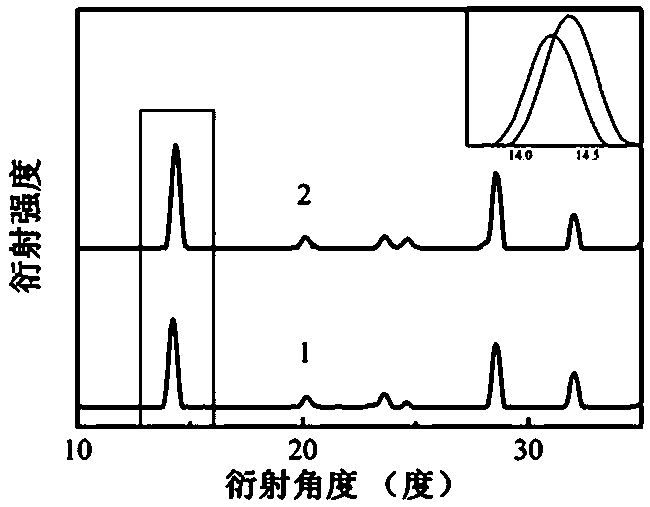

Light absorption layer material of solar cell, wide-band-gap perovskite solar cell and preparation method thereof

ActiveCN108389967AHigh crystallinityReduce defect densitySolid-state devicesSemiconductor/solid-state device manufacturingIodideCrystallinity

The invention discloses a light absorption layer material of a solar cell. The material is a perovskite material with 1-3%mol of remaining methylammonium iodide and in a molecular formula of (FA0.8MA0.2)0.95Cs0.05(I0.6Br0.4)3. The invention also discloses the wide-band-gap perovskite solar cell with the light absorption layer material as well as a preparation method of the solar cell. A light-absorption layer is prepared by adding excessive methylammonium iodide solid into a perovskite precursor solution and heating and crystallizing in an anti-solvent method. The phase separating degree of the perovskite light-absorption layer is reduced, the density of defects of a perovskite film is reduced, the crystallinity and stability of perovskite crystals are improved, an open-circuit voltage anda fill factor of a device can be improved, and the photoelectric conversion efficiency and stability of the solar cell are improved. The prepared solar cell is characterized by low temperature processing, and the cell of a large area can be prepared.

Owner:SOUTH CHINA UNIV OF TECH

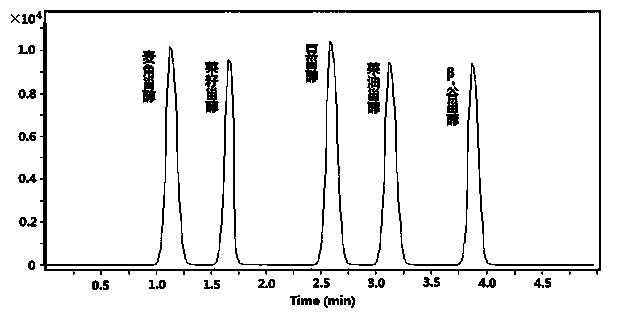

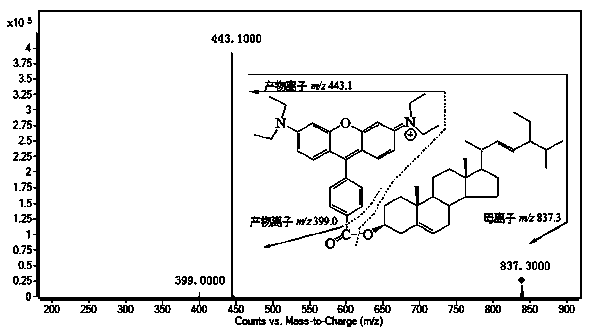

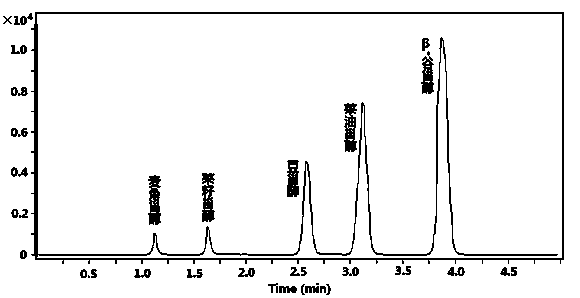

Detection and analysis method of phytosterol

The invention relates to a detection and analysis method of phytosterol. Firstly, the phytosterol is derivatized by using a derivatization reagent-4'-carboxyl rhodamine, and an ultra-high performance liquid chromatography triple quadrupole tandem mass spectrometry with a multi-reaction monitoring mode is used for carrying out qualitative and quantitative detection and analysis in the method. The method comprises the following steps: firstly, extracting the phytosterol by utilizing an ultrasonic assistance-dispersive liquid-liquid microextraction technique, then adding a 4'-carboxyl rhodamine acetonitrile solution, a 2-chlorine-1-methyl iodine pyridine acetonitrile solution and a 4-dimethyl aminopyridine acetonitrile solution into an obtained phytosterol extract for derivatization reaction, and finally analyzing and detecting by an ultra-high performance liquid chromatography triple quadrupole tandem mass spectrometry system. The method is moderate, rapid, and high in sensitivity, and has the important significance on the quality control of vegetable oil, beverages and medicinal materials which are rich in phytosterol.

Owner:QUFU NORMAL UNIV

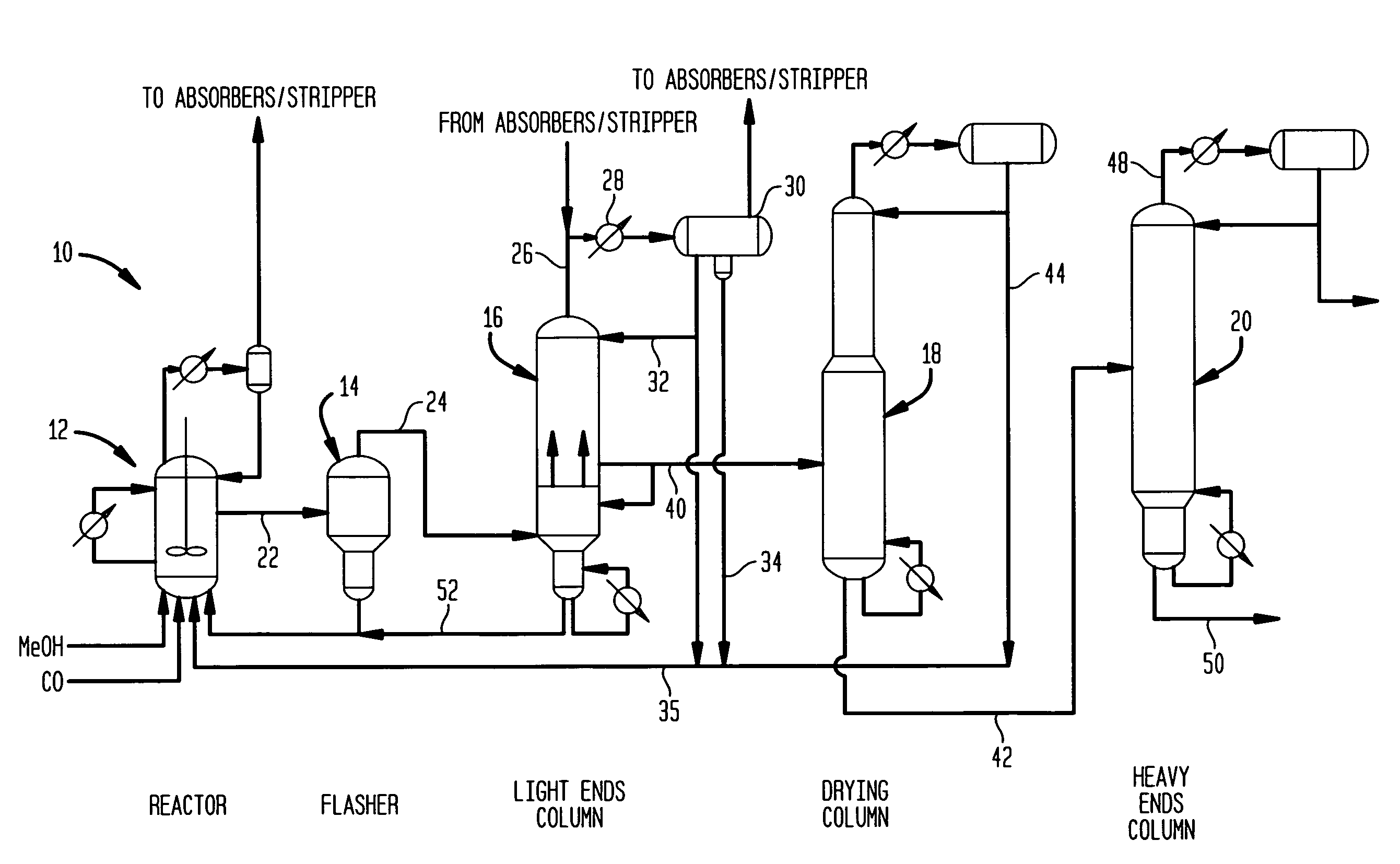

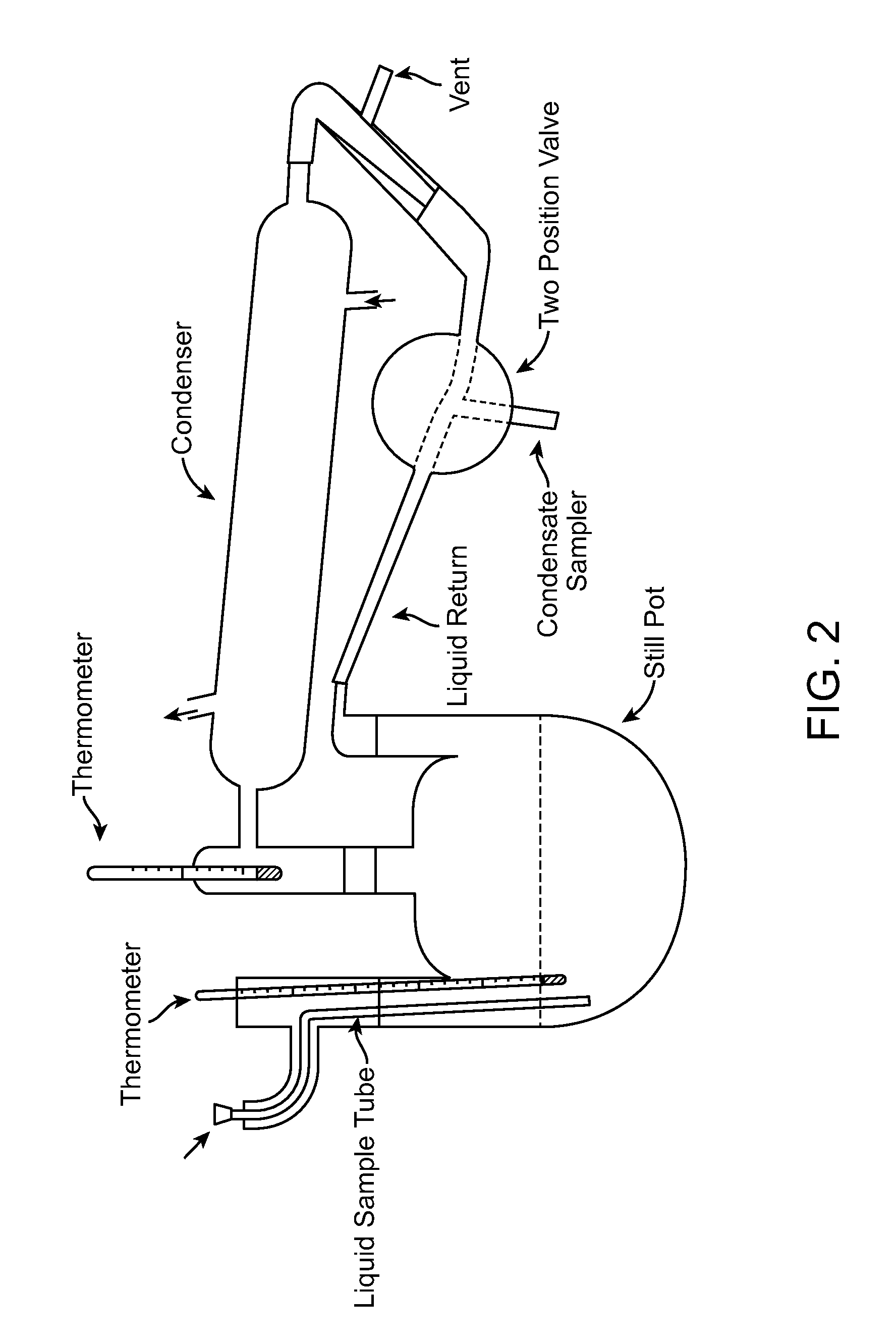

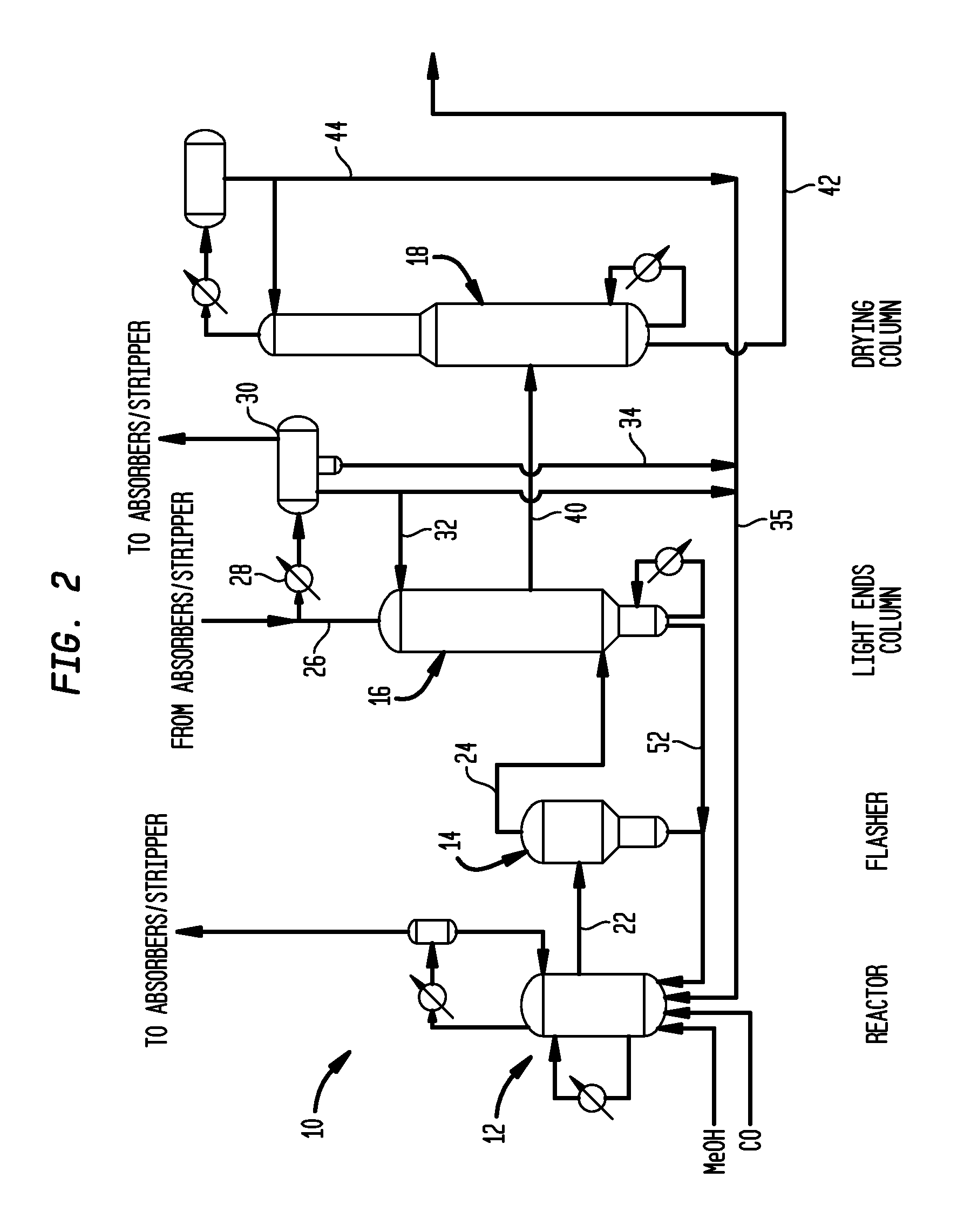

Method and apparatus for making acetic acid with improved purification

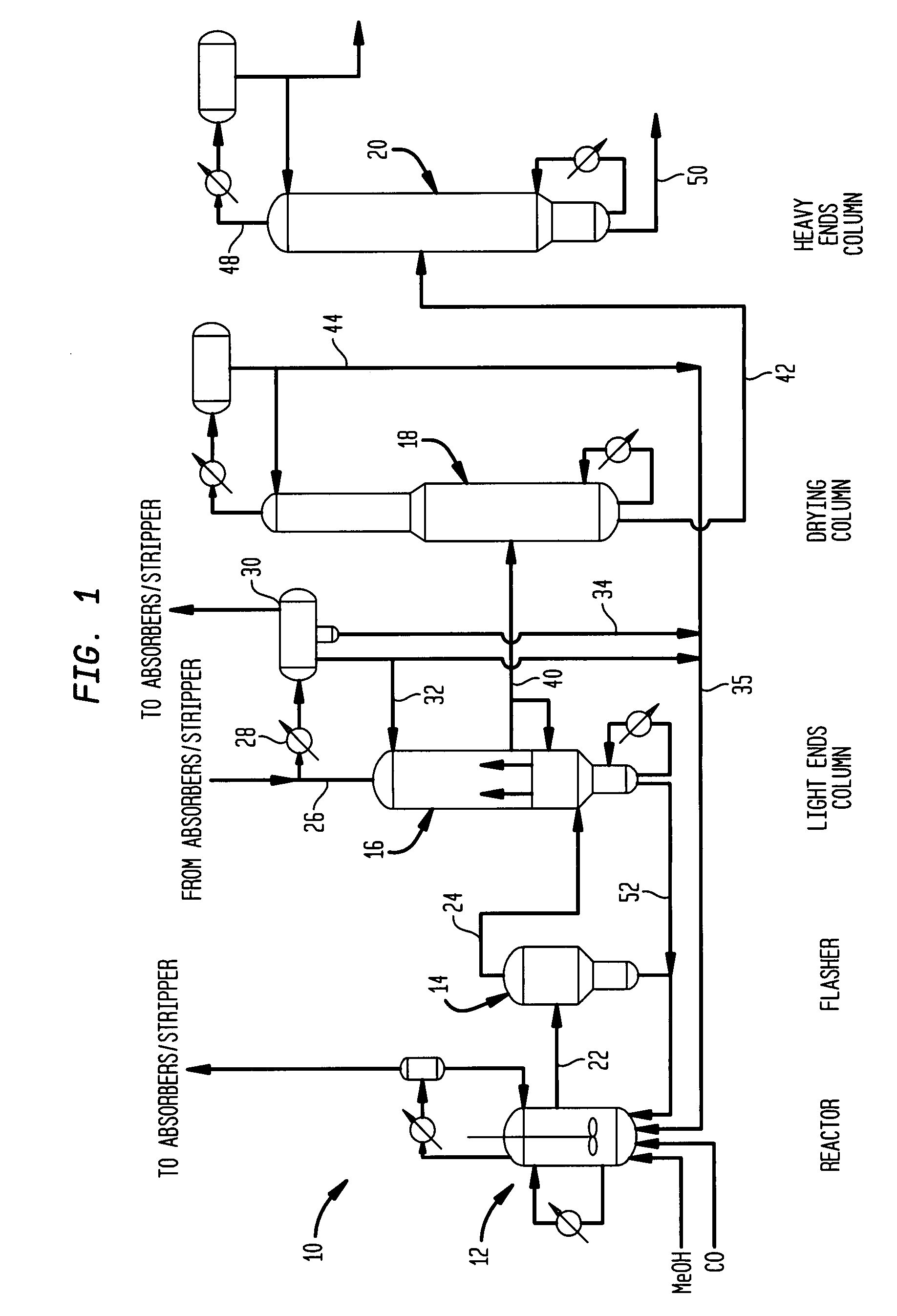

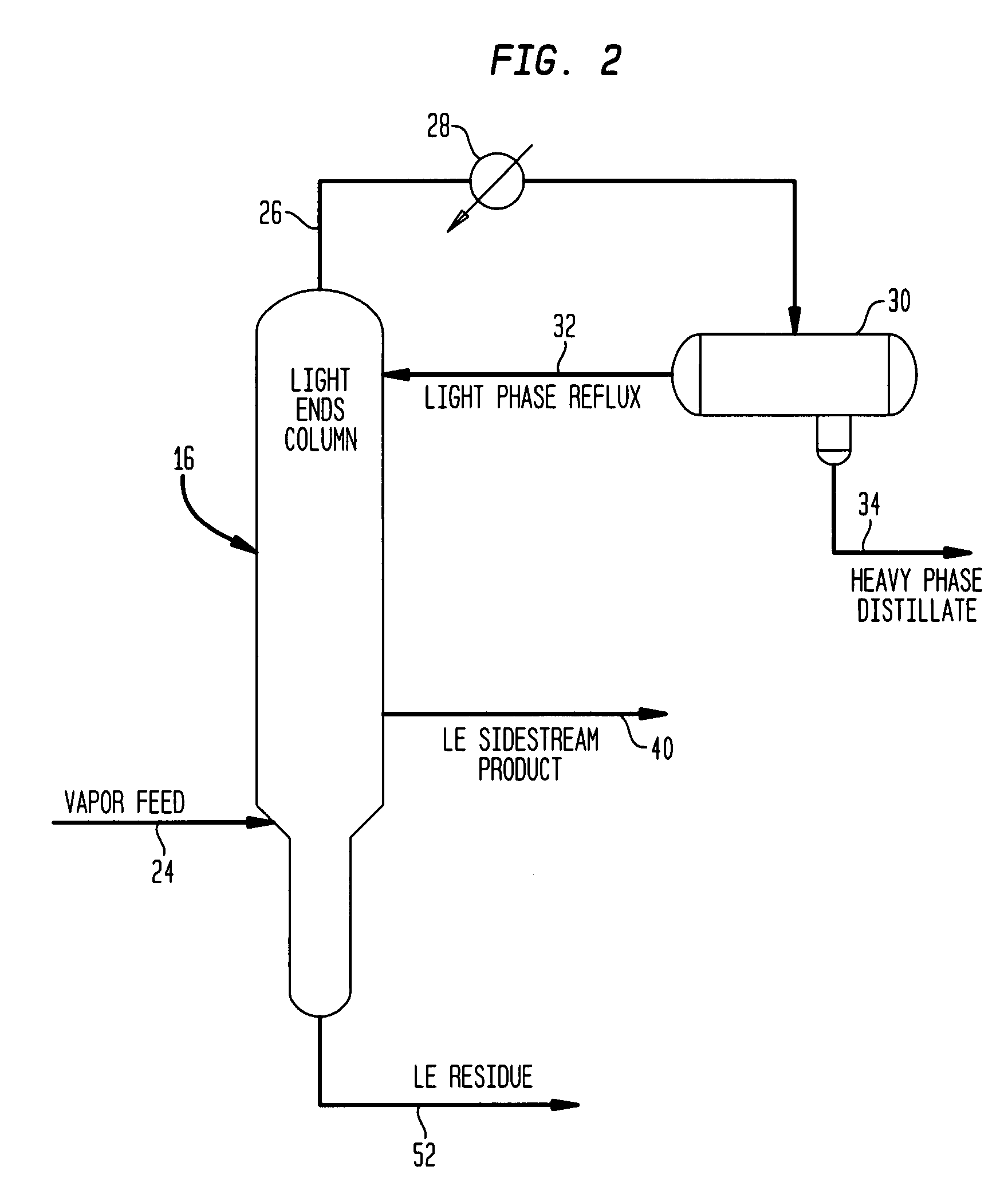

ActiveUS7619113B2Favorable VLELarge capacityGaseous chemical processesOrganic compound preparationAcetic acidMETHYLIODIDA

An improved method of producing acetic acid includes condensing overhead vapor from a light ends column and decanting the condensed vapor to a light phase and a heavy phase. The heavy phase consists predominantly of methyl iodide and at least a portion of the decanted heavy phase is refluxed to the light ends column. Acetic acid content of the light ends column overhead stream and water content of the light ends column product (sidedraw) stream are both decreased, improving purification efficiency.

Owner:CELANESE INT CORP

Magnesium borate crystal whisker super induced biomaterial and preparation method thereof

InactiveCN106496782AImprove impact performanceImprove aging resistanceShock resistanceMethyl benzoate

The invention discloses a magnesium borate crystal whisker super induced biomaterial and preparation method thereof, the biomaterial uses polypropylene, poly glycolic acid, and methyl benzoate as the main component, through adding poly-3-hydroxybutyric acid, trihydroxymethyl aminomethane, 2-thiol benzimidazole, di-amino-maleic acid, elhylene diamine tetraacetic acid, dodecyl trimethyl ammonium iodide, epoxidized soybean oil, naphthylacetic acid sodium, magnesium borate whisker, montmorillonite powder, light mass calcium carbonate, dispersant, and stabilizer, supplemented with mixing and stirring, high temperature sintering, crushing, high pressure calcinations, acid soaking, ultrasound dispersing, screw rod extruding, injection treatment and other processes, is prepared fully. The biomaterial super induced with magnesium borate crystal whisker has high low temperature shock resistance ability and high anti-aging property, can satisfy the requirements of each branch, and has relatively good application prospect.

Owner:金福兴

Methyl iodide removal from acetic acid waste stream

InactiveUS20110313217A1Organic compound preparationHalogenated hydrocarbon separation/purificationAlkaneAcetic acid

The invention is a method of removing methyl iodide from an alkane distillation bottoms stream of an acetic acid production process. The method comprises contacting the alkane distillation bottoms stream in the liquid phase with a phosphine or a phosphine-functionalized support, and recovering a treated alkane distillation bottoms stream having a reduced methyl iodide content.

Owner:LYONDELLBASELL ACETYLS

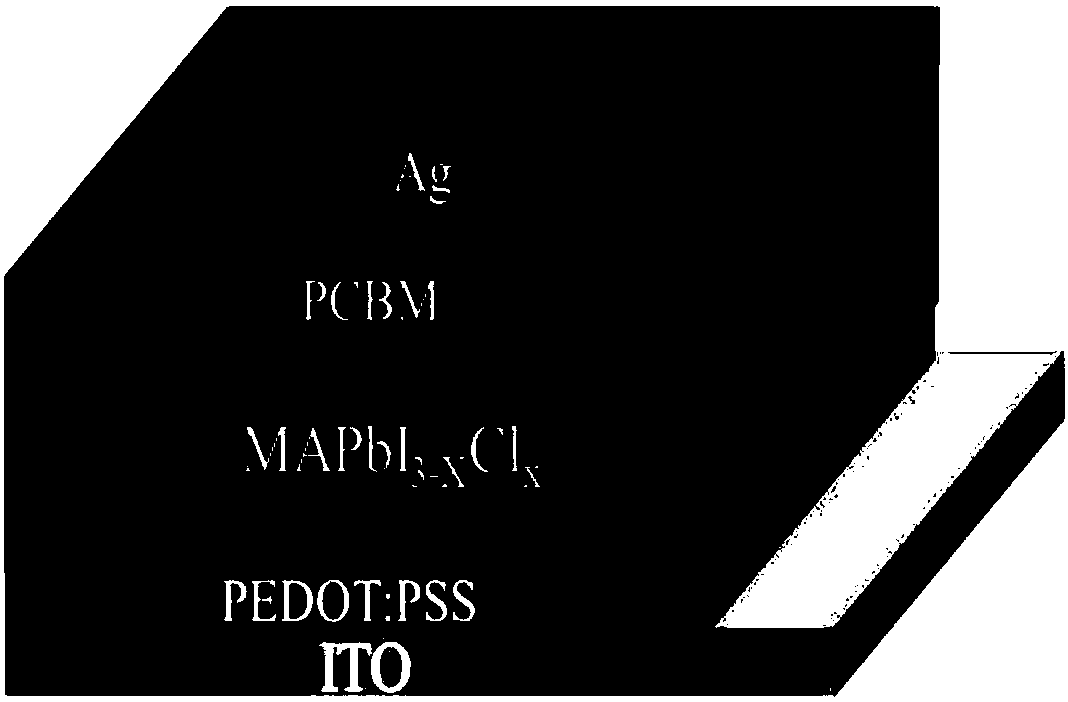

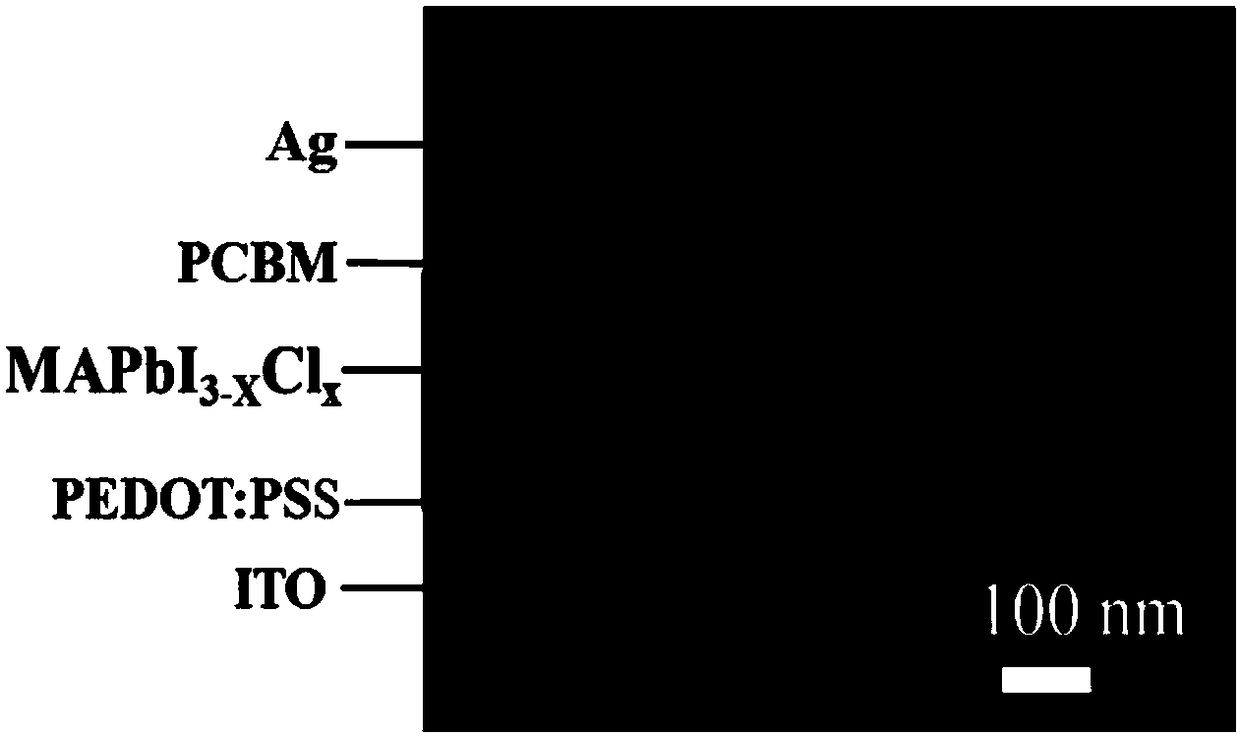

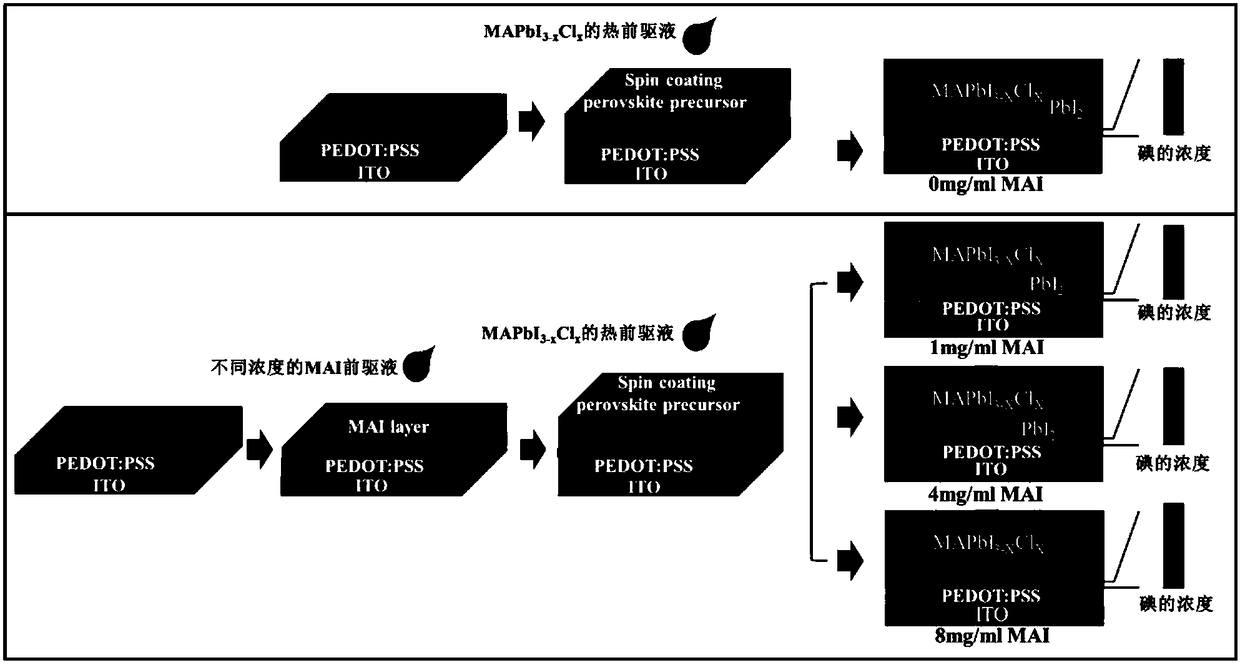

Method for preparing perovskite solar cell with high short-circuit current and high conversion efficiency, and product

ActiveCN108511606AIncrease concentrationIncrease short circuit currentFinal product manufactureSolid-state devicesPerovskite solar cellConduction band

The invention relates to a method for preparing a perovskite solar cell with high short-circuit current and high conversion efficiency, and a product, and belongs to the technical field of photovoltaics. The method comprises the following steps: firstly, a layer of methyl iodide amine is spin-coated on a hole transport layer; and then a hot precursor solution of MAPbI3-xClx is spin-coated on the methyl iodide amine layer; when the hot MAPbI3-xClx precursor solution is dropped onto the methyl iodide layer, the spin-coated methyl iodide layer is dissolved again, so that the concentration of iodine at the interface between the hole transport layer and an MAPbI3-xClx perovskite light absorbing layer is greater than that at other positions of the MAPbI3-xClx perovskite light absorbing layer; after annealing crystallization at the later stage, an iodide ion concentration gradient is formed on the MAPbI3-xClx perovskite layer at the interface between the hole transport layer and the MAPbI3-xClx perovskite light absorbing layer, and such a halogen concentration gradient increases the position of the perovskite conduction band, thereby facilitating the transport of holes, and further increasing the short circuit current and the conversion efficiency. The method is simple and easy to operate, can be directly promoted in large scale in industrial production, and has a potential application value in solar cells.

Owner:北京京通光能科技有限公司

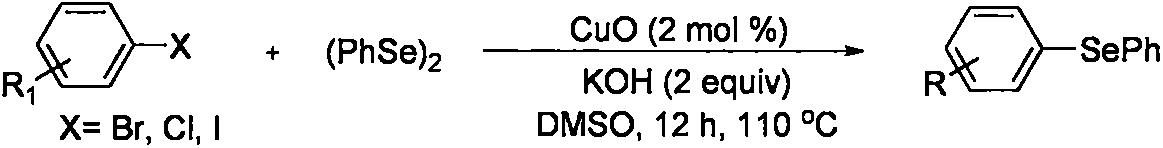

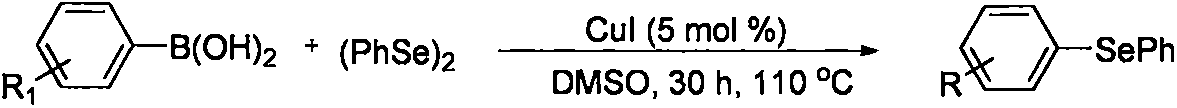

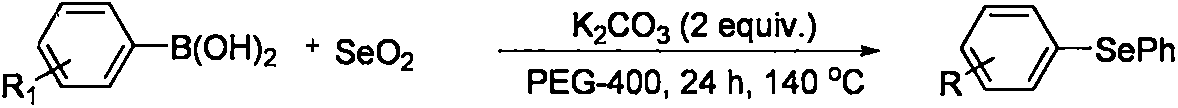

2-(2,4,6-trimethylbenzeneseleno)-5-methylbenzoxazole compound and preparation method thereof

The invention relates to a 2-(2,4,6-trimethylbenzeneseleno)-5-methylbenzoxazole compound and a preparation method thereof. The preparation method comprises the following steps: with 5-methylbenzoxazole and 2,4,6-trimethylphenyl iodide as reactive raw materials in an organic solvent, and elemental selenium as a selenide reagent, carrying out a cascade reaction under the jointed promotion effect ofa copper catalyst and alkali, thereby obtaining the 2-(2,4,6-trimethylbenzeneseleno)-5-methylbenzoxazole compound. The method is simple in reaction conditions, the product is high in yield and purity,a novel synthetic route and method can be developed for the 2-(2,4,6-trimethylbenzeneseleno)-5-methylbenzoxazole compound, and the compound has excellent application potential and research value.

Owner:WENZHOU MEDICAL UNIV

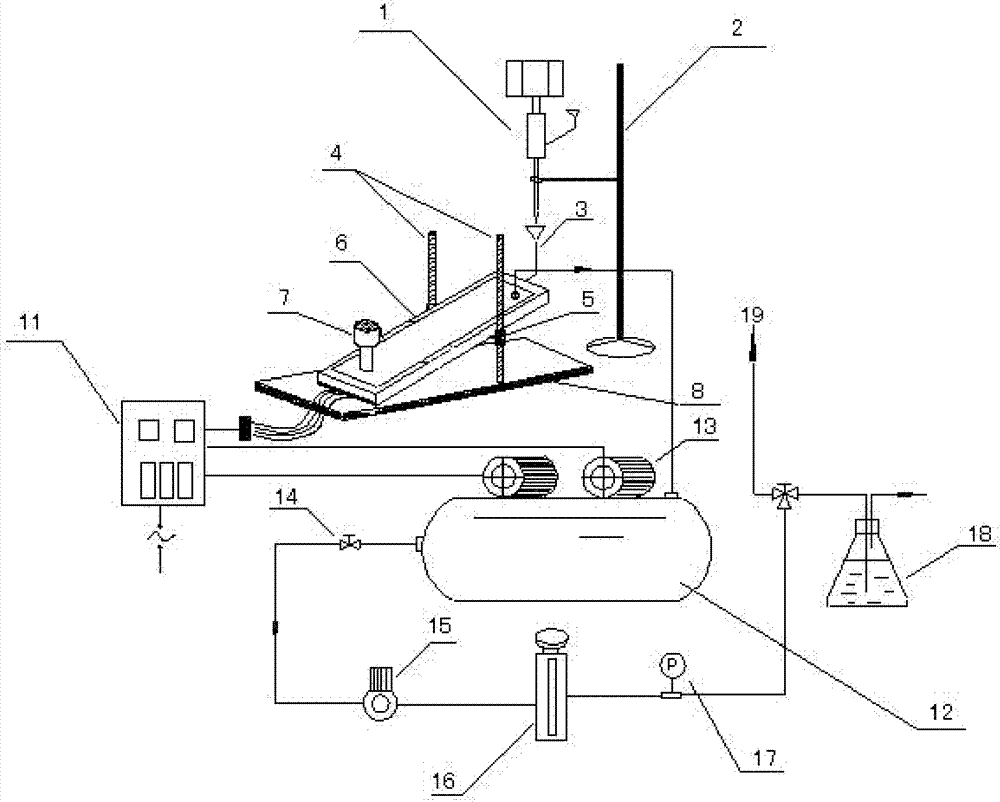

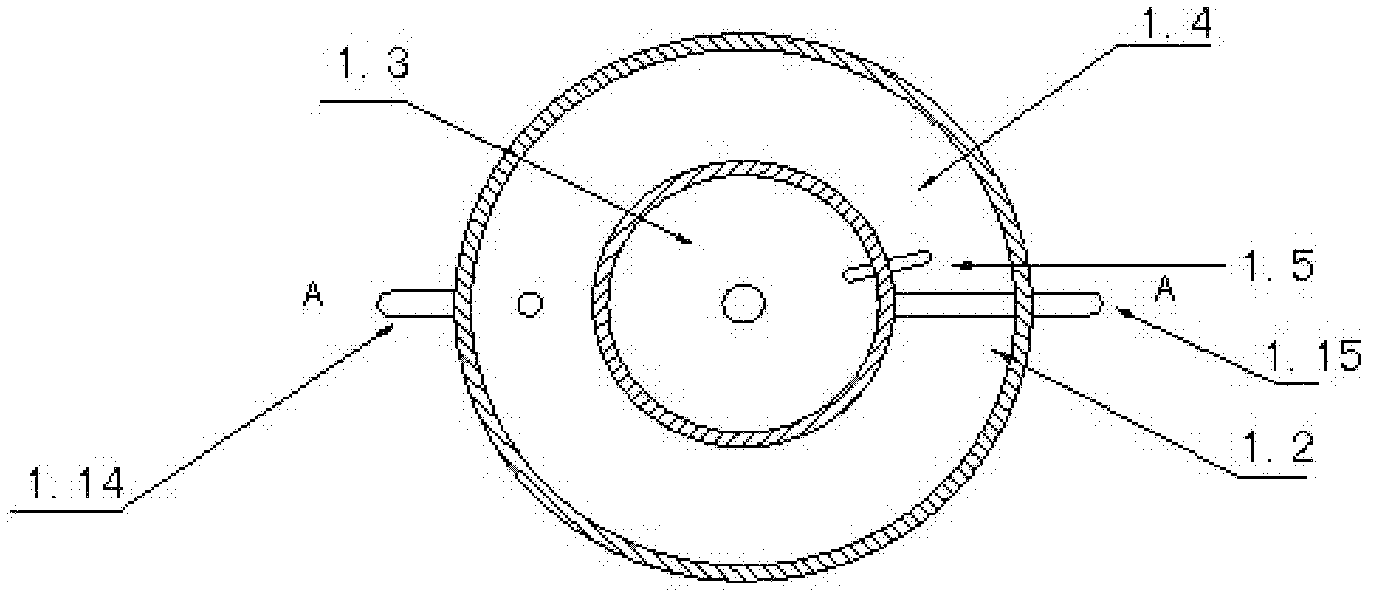

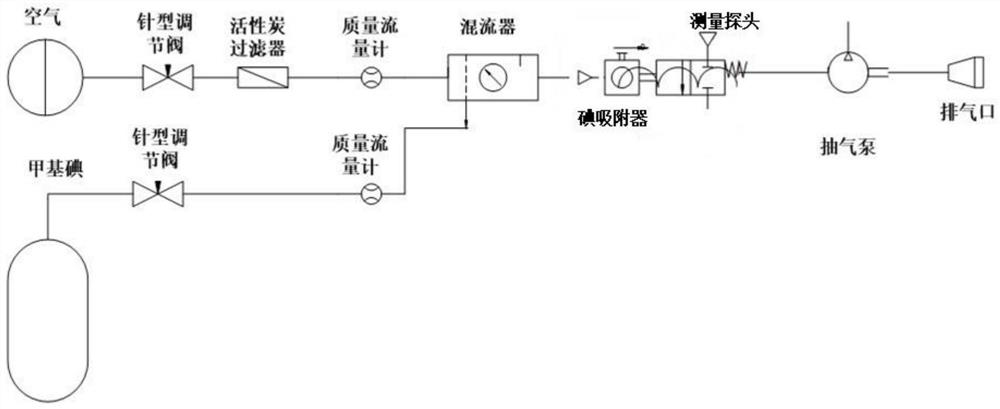

On-line measurement equipment and method for evaluating efficiency of iodine absorber by non-radioactive methyl iodide

PendingCN110715975AAvoid purchasingAvoid transportWithdrawing sample devicesMaterial analysis by electric/magnetic meansRadioactive gasGas detector

The invention relates to on-line measurement equipment for evaluating efficiency of an iodine absorber by non-radioactive methyl iodide. The on-line measurement equipment comprises an experiment reagent import assembly and an experiment reagent export assembly, wherein the experiment reagent import assembly is connected with an air inlet end of the iodine absorber, the experiment reagent export assembly is connected with an air outlet end of the iodine absorber, the experiment reagent import assembly comprises an experiment reagent import pipe, the experiment reagent import pipe is connected with an upstream acquisition pipe and an experiment reagent injection pipe, the experiment reagent export assembly comprises an experiment reagent export pipe, the experiment reagent export pipe is connected with the air outlet end of the iodine absorber, the experiment reagent export pipe is connected with a downstream acquisition pipe, the experiment reagent injection pipe is connected with an impulse-type methyl iodide gas generator, and the upstream acquisition pipe and the downstream acquisition pipe both are connected with a PID gas detector. In the on-line measurement equipment, the non-radioactive methyl iodide is used as an experiment reagent to perform efficiency test on the iodine absorber, the radioactive operation in efficiency experiment of the iodine absorber is prevented, anoperation risk is reduced, and the situation that radioactive gas is discharged caused by absorption efficiency disqualification of the iodine absorber or operation mistake during the experiment process is eliminated.

Owner:CHINA INST FOR RADIATION PROTECTION

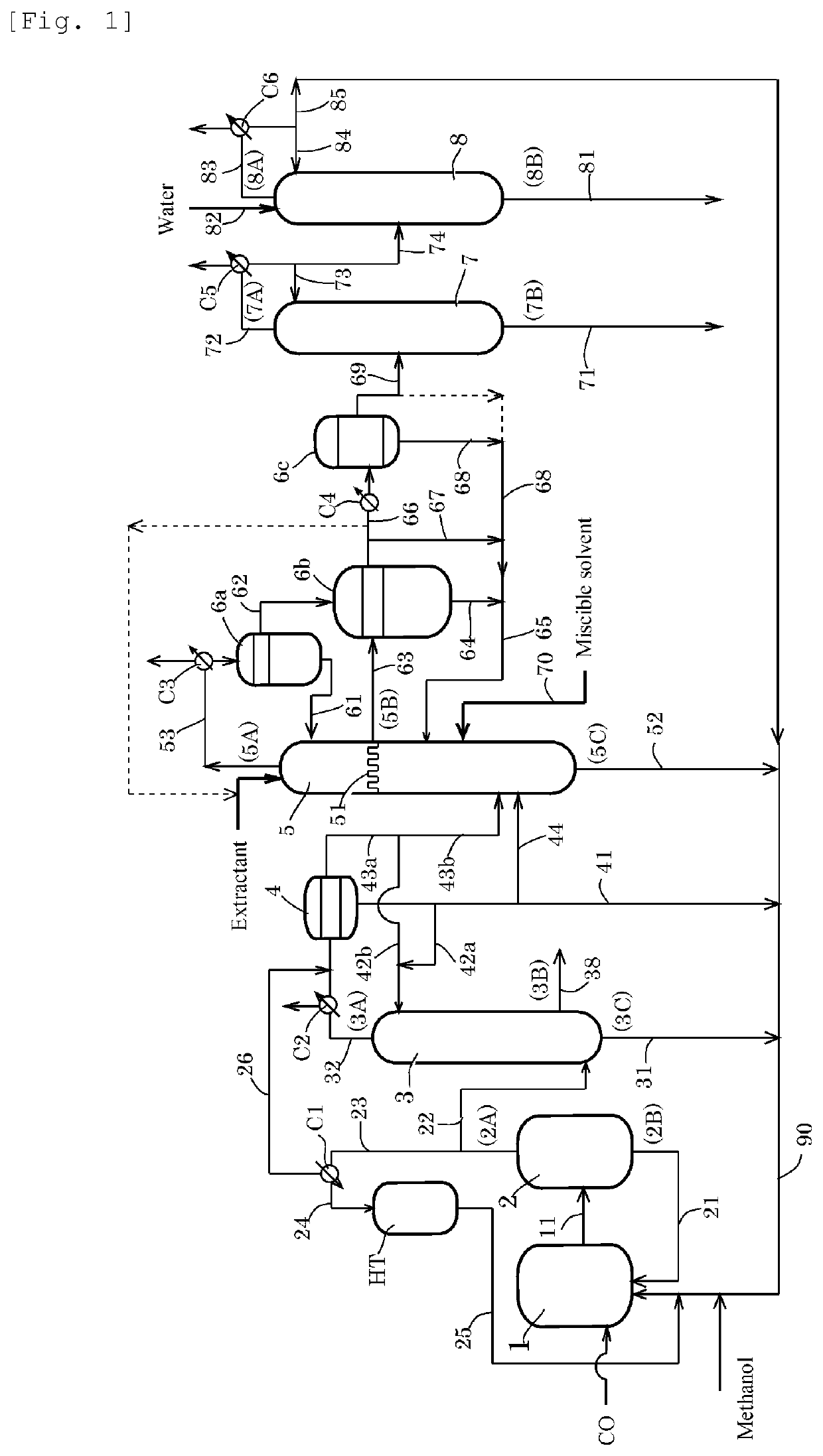

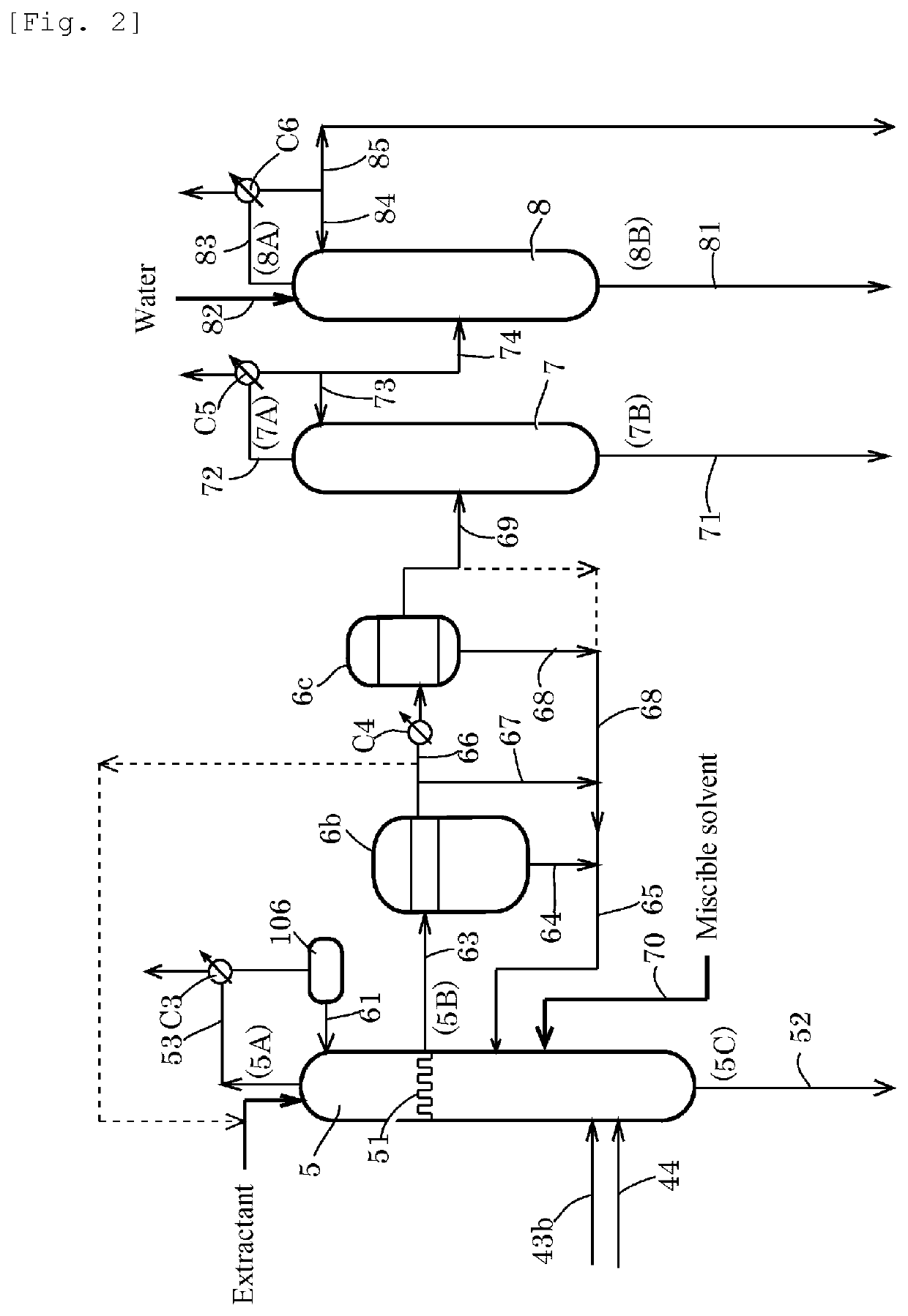

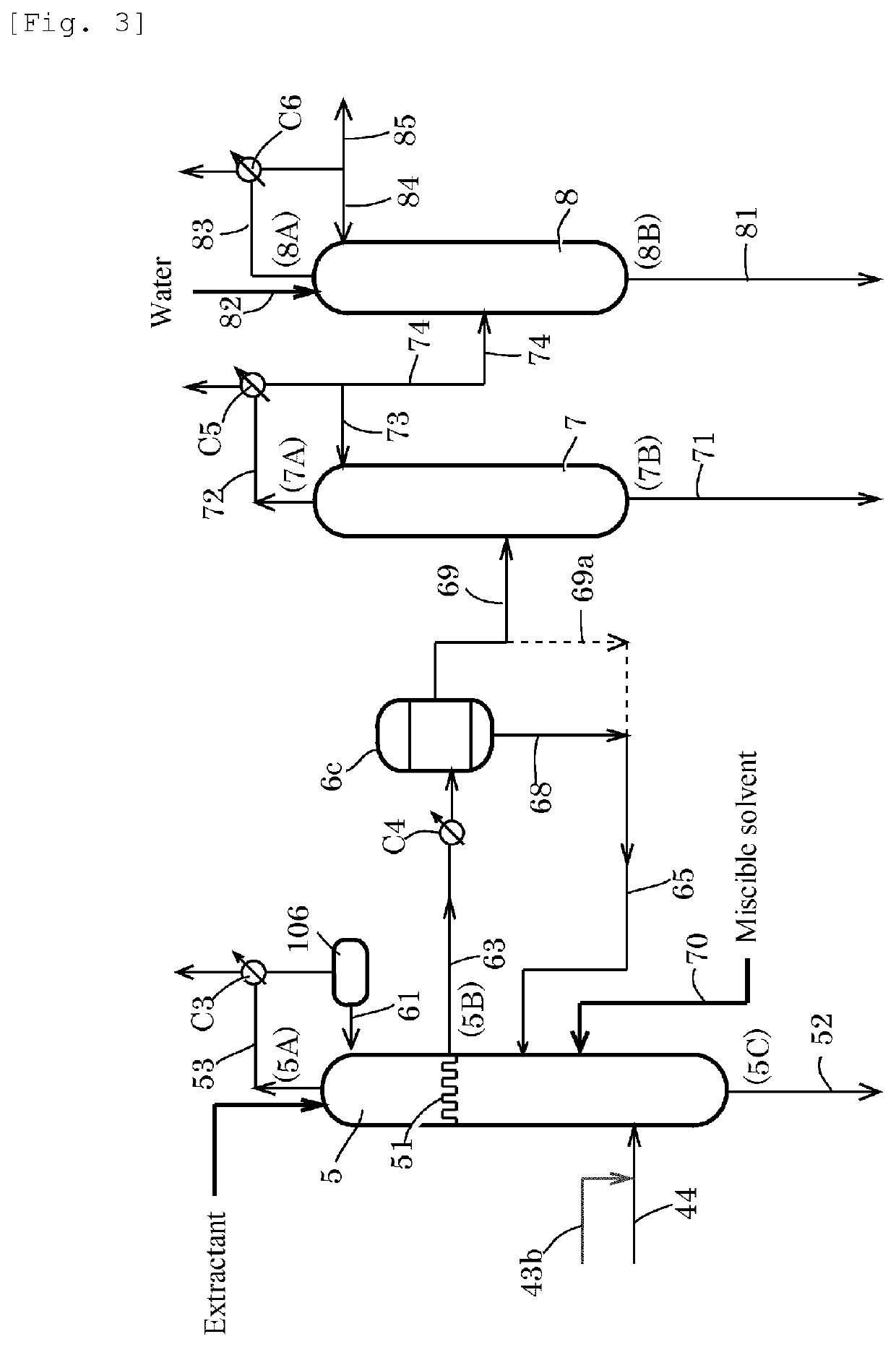

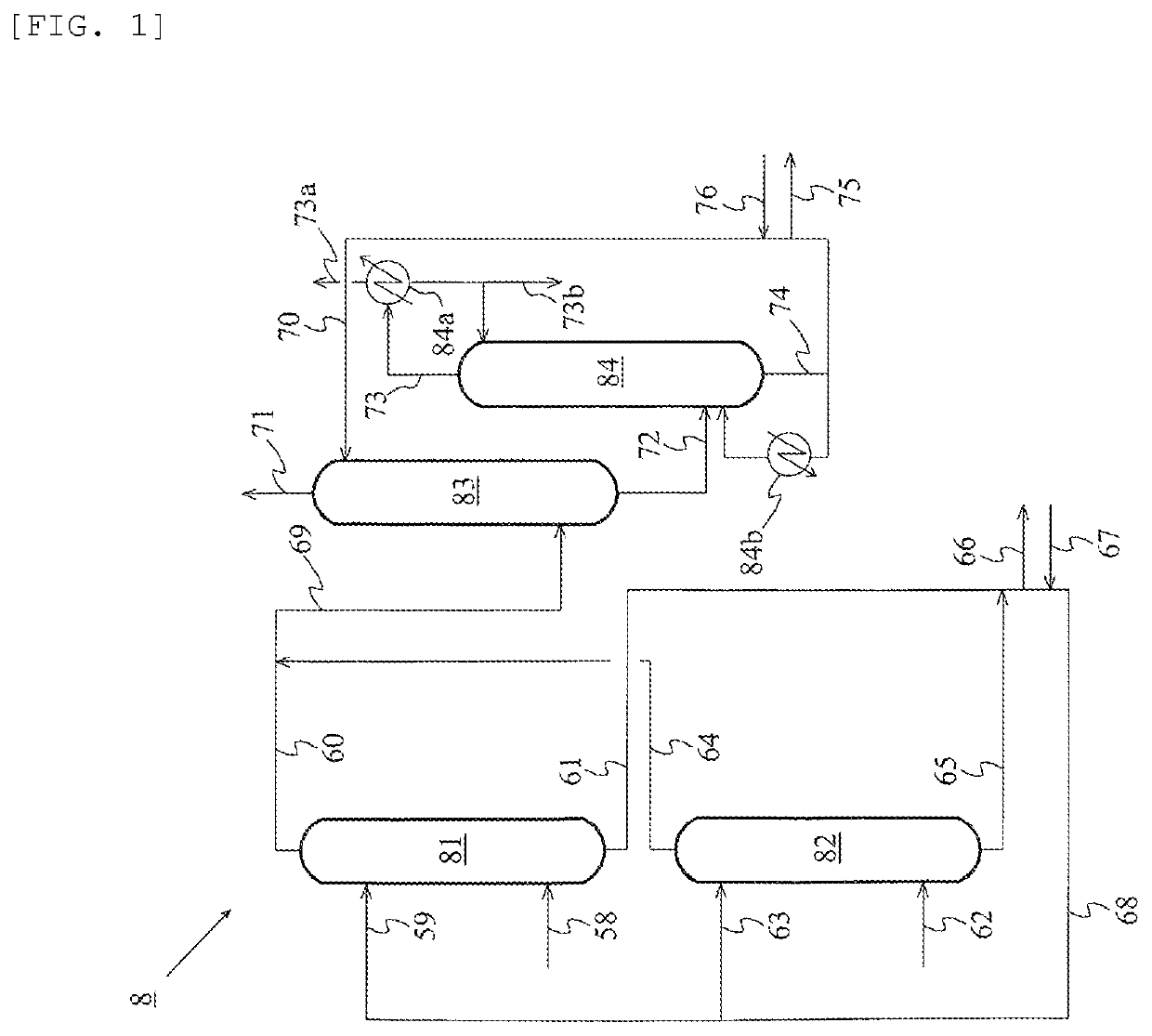

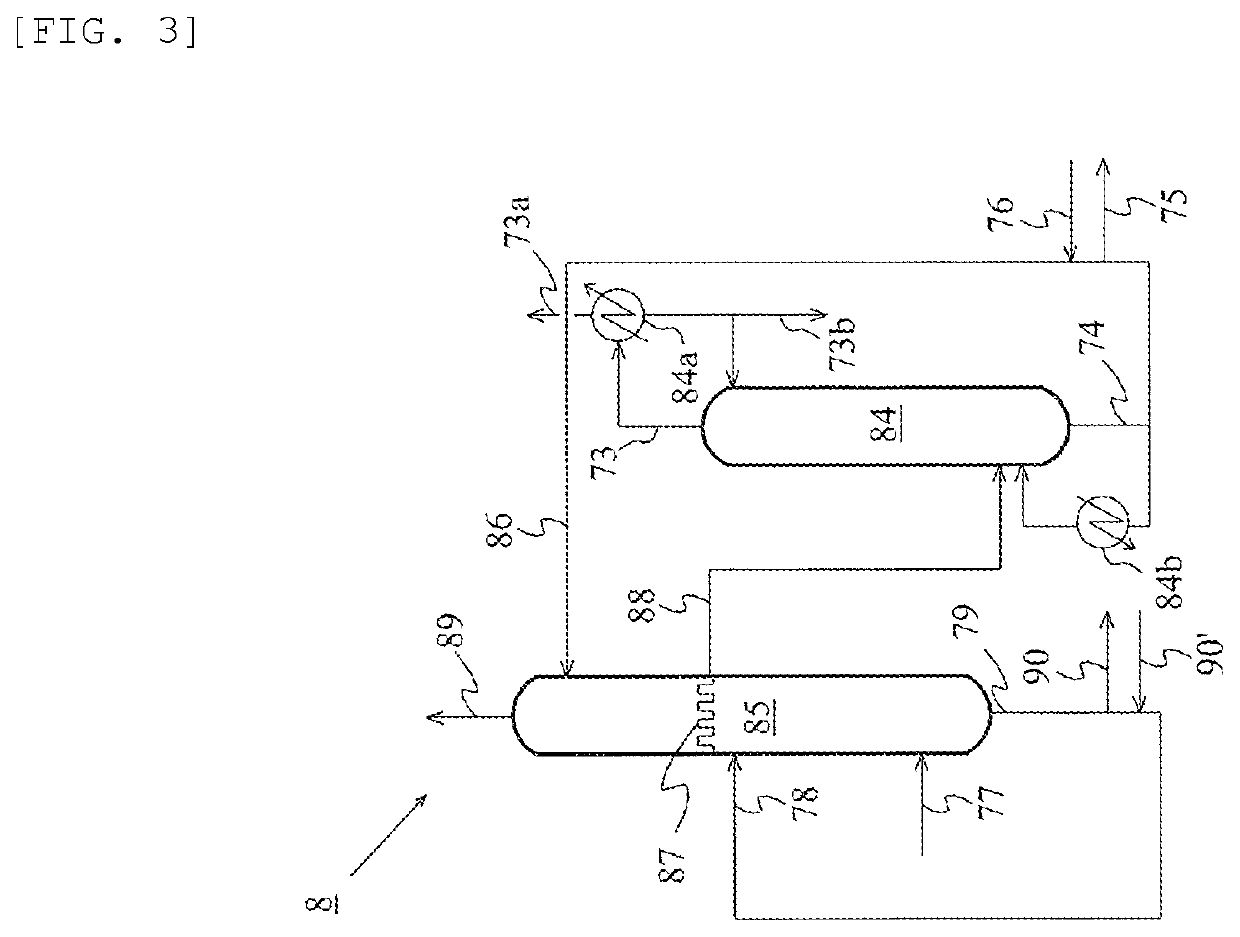

Process for producing acetic acid

ActiveUS10562836B2Efficient separationReduce the amount presentOrganic chemistry methodsVapor condensationAcetic acidPermanganate salt

A process for producing acetic acid while efficiently separating permanganate reducing compounds (PRC's) and methyl iodide is provided. PRC's are separated or removed from a mixed composition (3A) containing PRC's and methyl iodide by distilling the mixed composition in a distillation step (5) to form an overhead stream (5A), a side-cut stream (5B), and a lower stream (5C). In a distillation column of the distillation step (5), an extractant (e.g., water) extracting PRC's preferentially to methyl iodide is added to a concentration zone in which PRC's and methyl iodide are concentrated, and an extraction mixture falling from the concentration zone is withdrawn as the side-cut stream (5B).

Owner:DAICEL CHEM IND LTD

Process for the production of acetic acid

ActiveUS8742168B2Organic compound preparationCarboxylic preparation from carbon monoxide reactionPtru catalystIodide

Owner:LYONDELLBASELL ACETYLS

Bromine doped methylamine lead iodide perovskite solar cell and manufacturing method thereof

InactiveCN107240643BDoping is not easy to achieveUniform compositionFinal product manufactureSolid-state devicesMeth-Iodide

The invention belongs to the field of solar cells, in particular to an organic-inorganic hybrid perovskite solar cell. Bromine-doped methylamine-lead-iodide perovskite solar cell, the photosensitive layer of the solar cell is a bromine-doped methylamine-lead-iodide perovskite CH 3 NH 3 PB 3‑x Br x thin film, made from methylamine iodide CH 3 NH 3 I. Lead iodide PbI 2 After mixing, dissolve in N,N-dimethylformamide DMF and dimethyl sulfoxide DMSO mixed solvent to form CH 3 NH 3 PB 3 The perovskite precursor liquid is then made by spin-coating, cleaning process combined with multi-step atmosphere annealing process. in CH 3 NH 3 PB 3‑ x Br x In the film, the bromine content x has a value between 0.2 and 0.6. The invention also relates to a method for making the battery.

Owner:TAIYUAN UNIV OF TECH

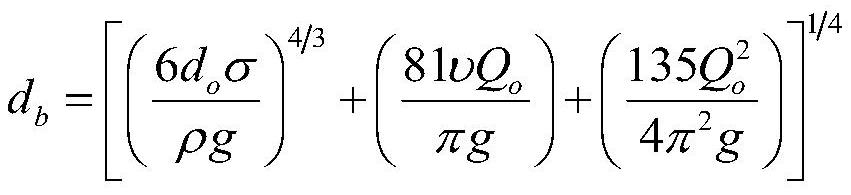

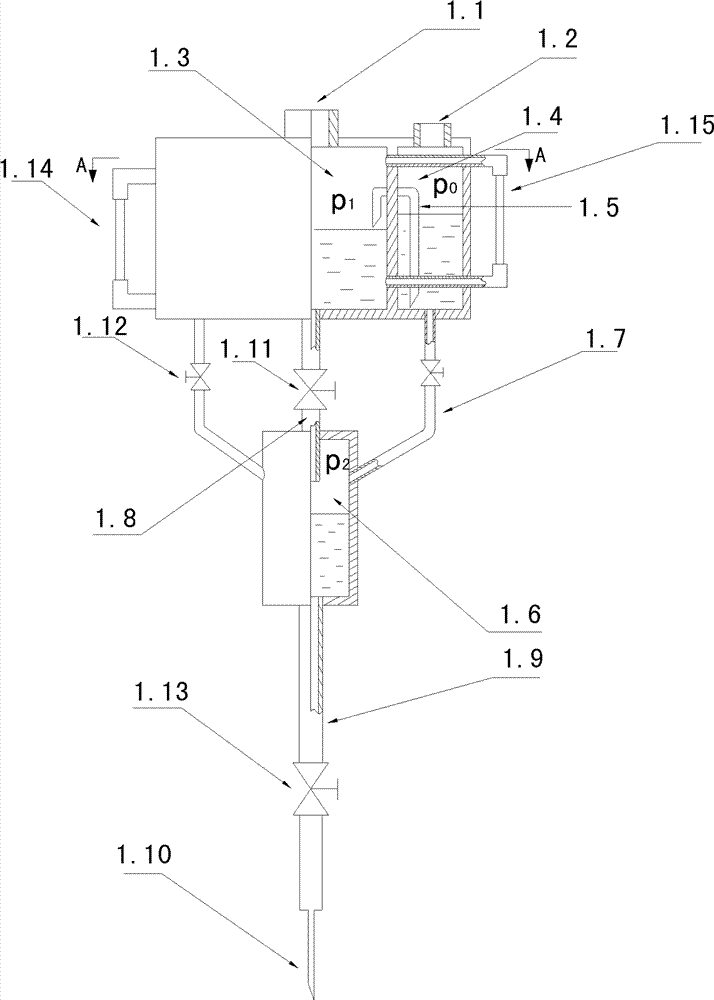

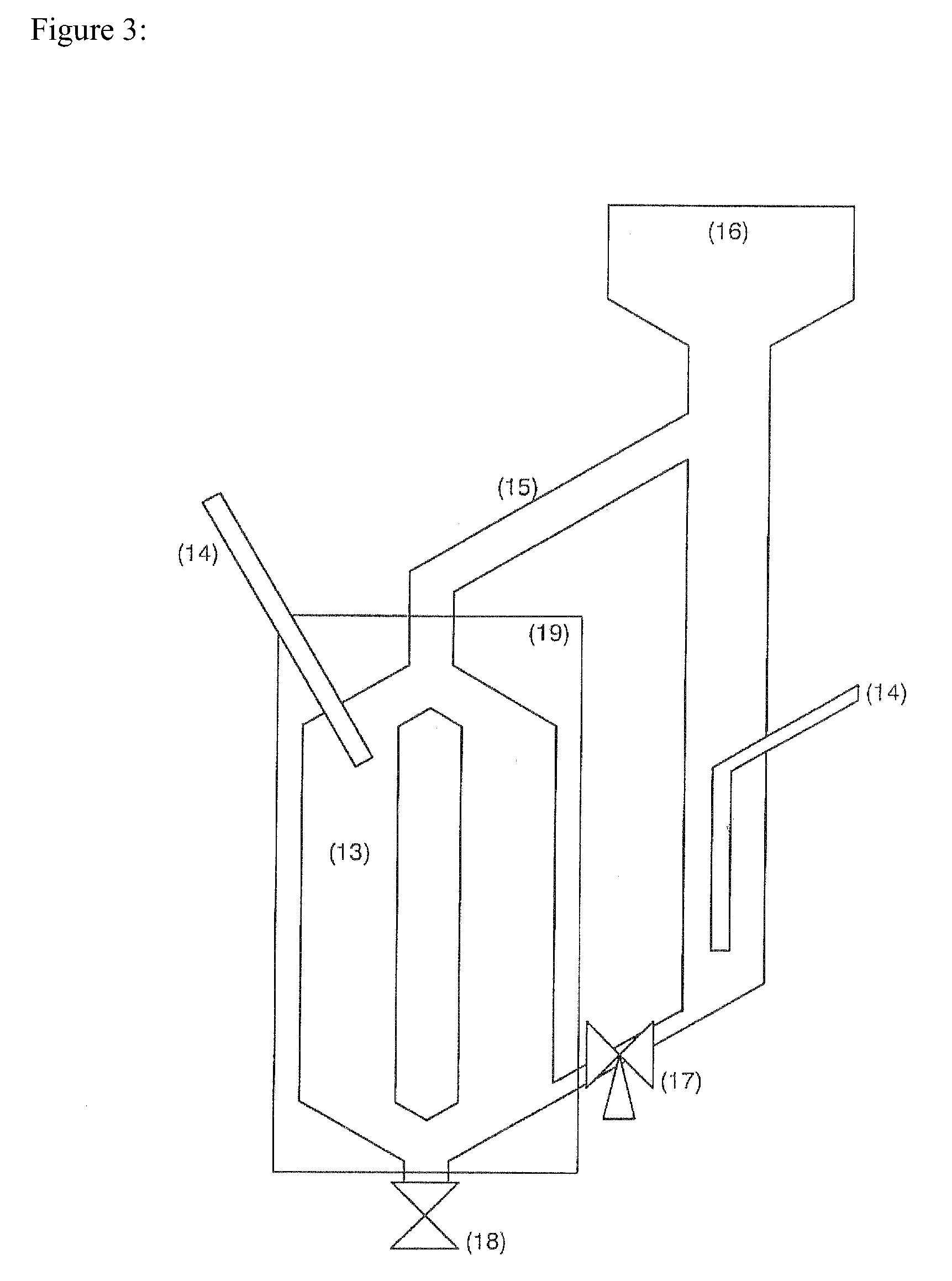

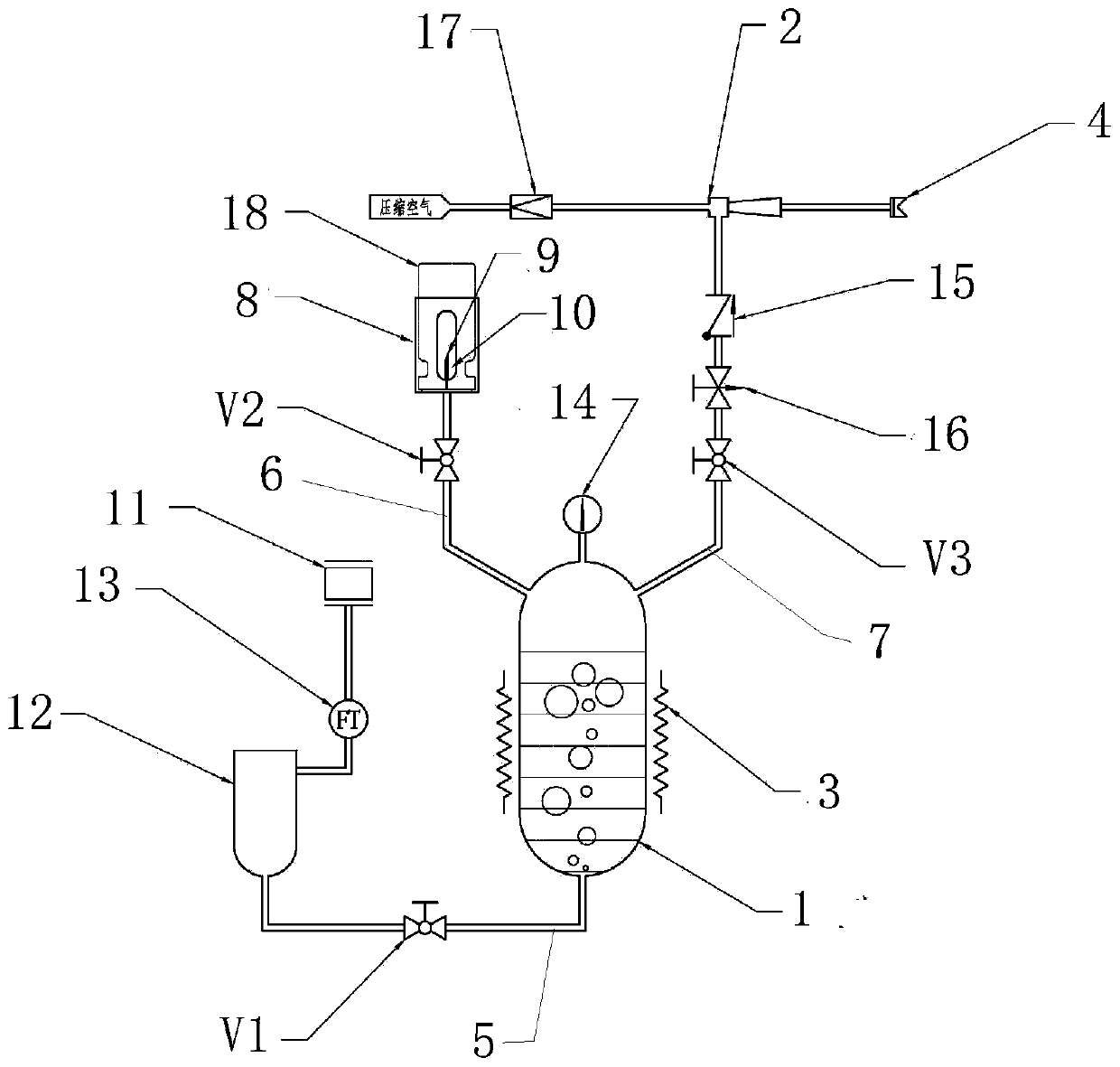

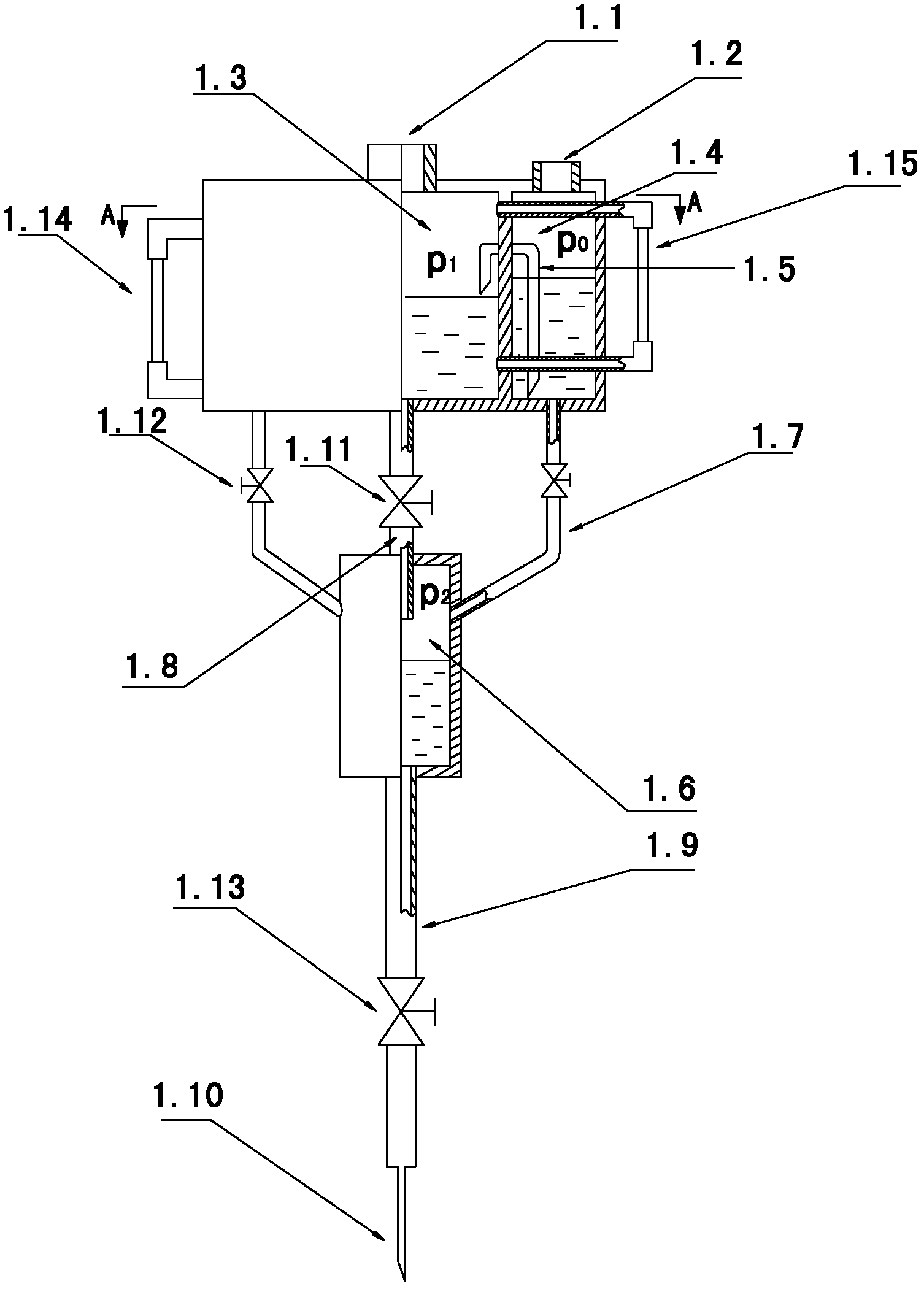

Methyl iodide gas generation method for iodine adsorber efficiency test and generator

PendingCN111006922AMeet the needs of useGuarantee the safety of lifeComponent separationPreparing sample for investigationLiquid stateProcess engineering

The invention provides a methyl iodide gas generation method for iodine adsorber efficiency test and a generator. The method comprises the following steps: A, enabling a generation cavity for storingliquid methyl iodide and a gasifying place to be in a negative pressure state; B, sucking the liquid methyl iodide into the generation cavity in the step A by virtue of negative pressure; C, injectingair flow into the generation cavity in the step B at the same time to enable the liquid methyl iodide in the generation cavity to form bubbles, and heating the injected methyl iodide to assist gasification when gasification is insufficient; and D, making the gasified methyl iodide and compressed air mixed and enter a test system, and testing the adsorption efficiency of an iodine adsorber. The generation method of the non-radioactive methyl iodide gas in the scheme can effectively meet the gas use requirements of iodine adsorber efficiency detection, has important guarantee for the personal safety of iodine adsorber efficiency test detection personnel, and is fast, stable and reliable in the whole generation process.

Owner:CHINA INST FOR RADIATION PROTECTION

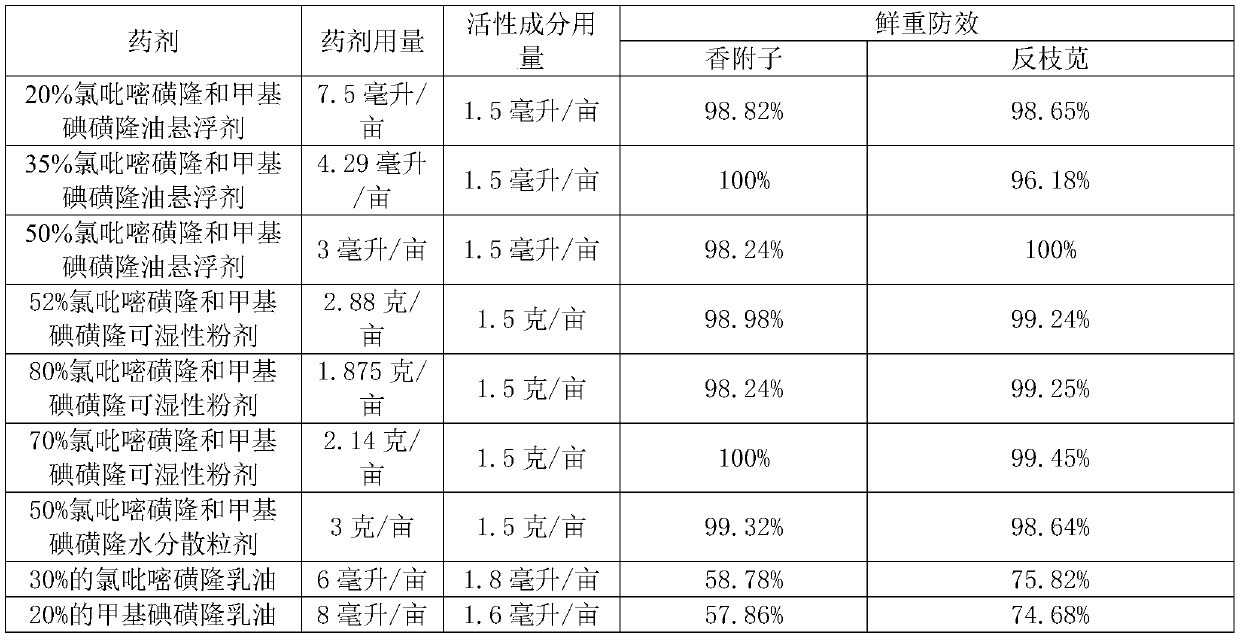

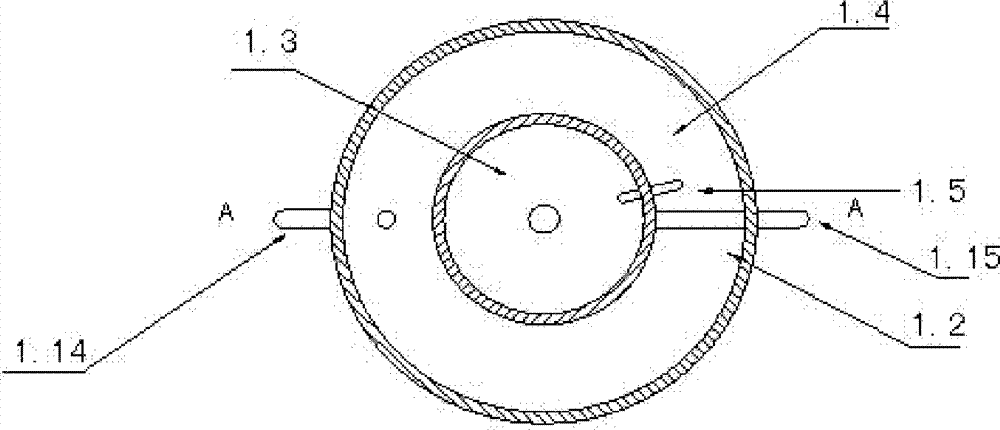

Dynamic distribution system of gaseous methyl iodine

ActiveCN102629493AContinuous and stable supplyStable concentrationNuclear energy generationCooling arrangementAxial compressorIodine

The invention aims to provide a dynamic distribution system of gaseous methyl iodine. The dynamic distribution system comprises a small-flow liquid supply device, a liquid vaporization chamber and an air compressor, wherein the small-flow liquid supply device is fixed on a bracket; an outlet of the small-flow liquid supply device is arranged in alignment with an inlet of the liquid vaporization chamber; the liquid vaporization chamber is arranged on a pedestal through a threaded supporting rod and a lifting threaded bushing which is matched with the threaded supporting rod; the angle of the liquid vaporization chamber can be adjusted through the lifting threaded bushing; an air suction port is formed below the liquid vaporization chamber; a hole which is connected with the air compressor is formed above the liquid vaporization chamber; an electric heating device is also arranged in the liquid vaporization chamber; and the air compressor is communicated with a gas application environment. According to the dynamic distribution system, long-time continuous stable supply of the small-flow methyl iodine liquid can be realized, and stable concentration of the methyl iodine at the outlet of the system is guaranteed. The suction effect of the air compressor enables that the liquid vaporization chamber is in a negative pressure state all the time; safety and reliability are guaranteed; and no injury is caused to the environment and the operation personnel. The system has the advantages of simple structure, reliable performance and easiness for implementation.

Owner:CHINA NUCLEAR POWER ENG CO LTD

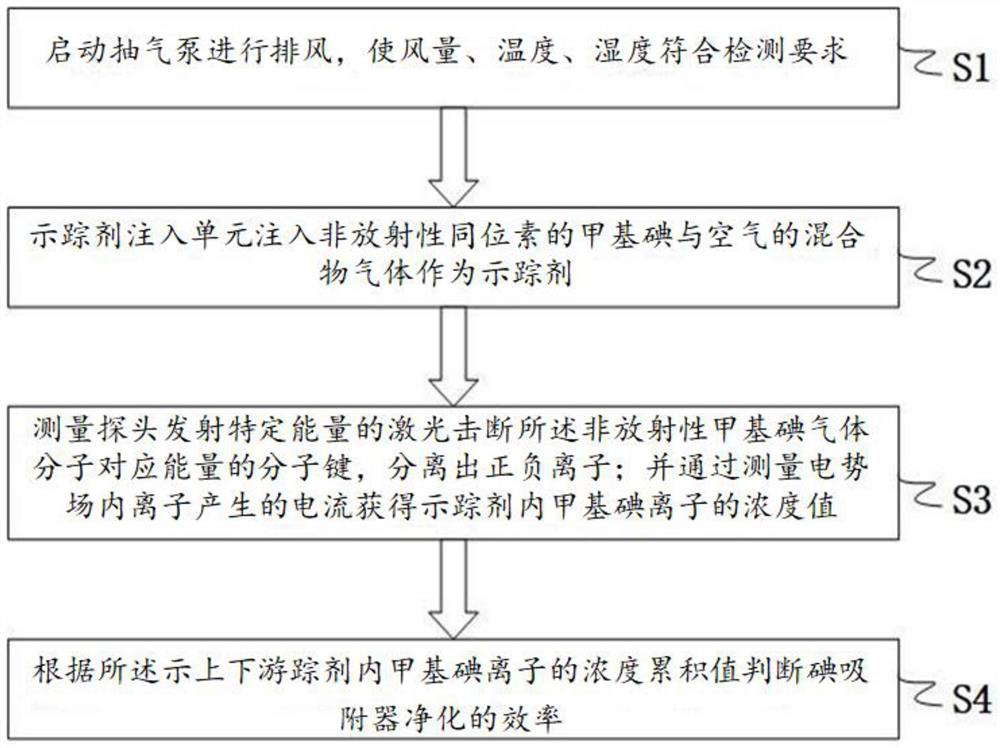

Non-radioactive method and device for measuring purification efficiency of iodine adsorber

PendingCN112763572AEliminate radiological risksMaterial analysis by electric/magnetic meansAir volumeMETHYLIODIDA

The invention provides a non-radioactive method and device for measuring the purification efficiency of an iodine adsorber, and the method comprises the steps: S1, a sucking pump is started to exhaust air, so that the air volume, temperature and humidity meet the detection requirements; S2, a tracer injection unit injects a non-radioactive isotope mixture gas of methyl iodide and air as a tracer; S3, a measuring probe emits laser with specific energy to break molecular bonds of corresponding energy of the non-radioactive methyl iodide gas molecules, positive and negative ions are separated out, and the concentration value of methyl iodide ions in the tracer agent is obtained by measuring current generated by ions in a potential field; and S4, the purification efficiency of the iodine adsorber is judged according to the concentration accumulated value of the methyl iodide ions in the upstream and downstream tracers. The radioactive risk in the process of non-radioactive measurement of the purification efficiency of the iodine adsorber is eliminated, and the engineering application requirement of efficiency measurement of the iodine adsorber is met.

Owner:LIAONING HONGYANHE NUCLEAR POWER

Method for producing acetic acid

ActiveUS10759730B2Efficient separationSignificant differenceHydrogen iodideOrganic compound preparationDistillationCarboxylic acid

Provided is an acetic acid production method that enables, in a scrubbing system, efficient separation and obtaining of methyl iodide and an absorbing solvent; restrainment of corrosion of the interior of a distillation column; efficient separation between and recovery of hydrogen iodide and methyl iodide; or sufficient recovery of hydrogen iodide. The acetic acid production method according to the present invention includes a first absorption step and a second absorption step. In the first absorption step, an offgas is brought into contact with a first absorbent to allow the first absorbent to absorb an iodine compound from the offgas, to give a first gas, where the first absorbent includes at least one of C2 or higher alcohols, esters of C3 or higher carboxylic acids, esters between carboxylic acids and C2 or higher alcohols, ethers, ketones, water, and basic aqueous solutions. In the second absorption step, the first gas is brought into contact with a second absorbent to allow the second absorbent to absorb an iodine compound from the first gas, where the second absorbent includes at least one of C2 or higher alcohols, esters of C3 or higher carboxylic acids, ethers, esters between carboxylic acids and C2 or higher alcohols, ketones, water, basic aqueous solutions, and acetic acid and differs in composition from the first absorbent.

Owner:DAICEL CHEM IND LTD

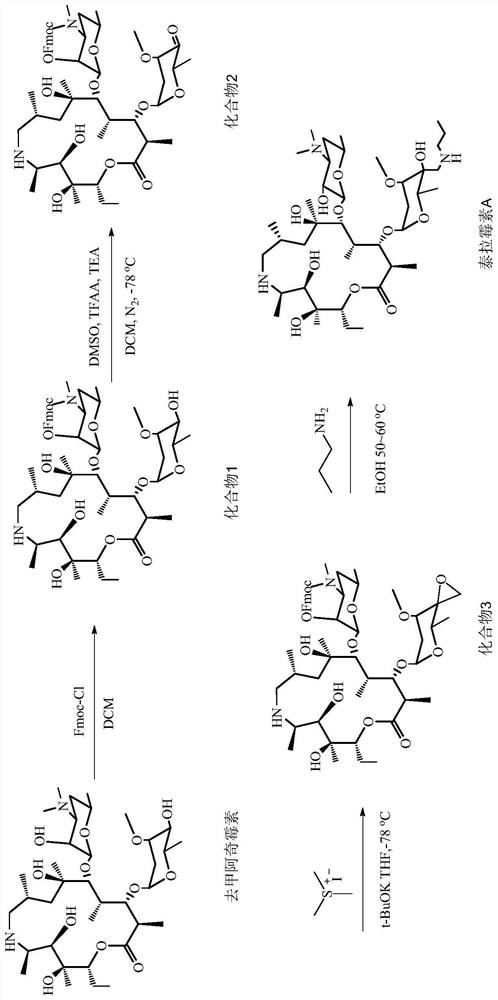

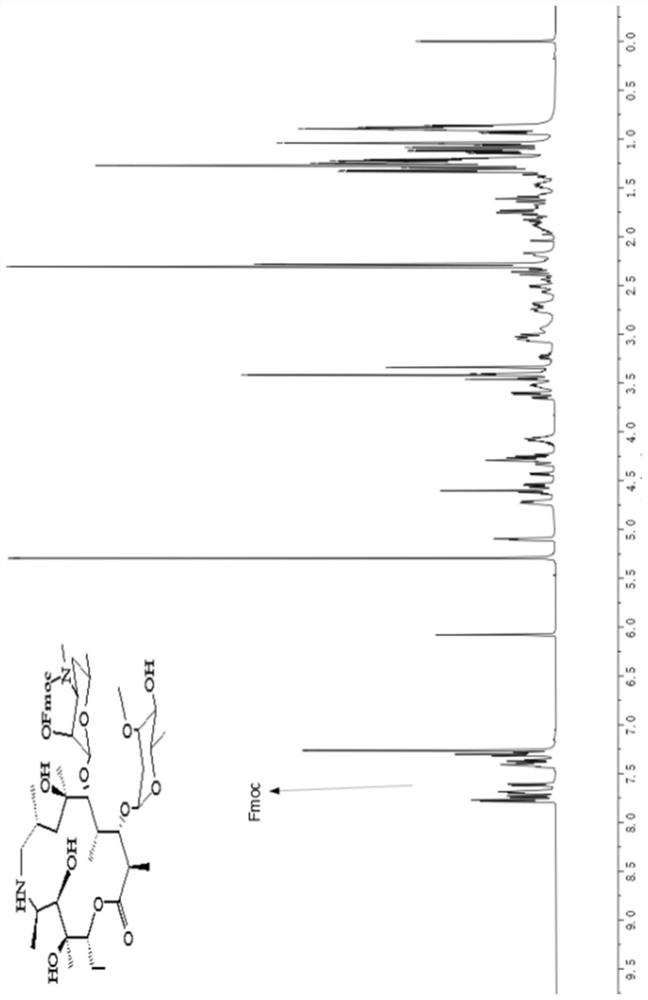

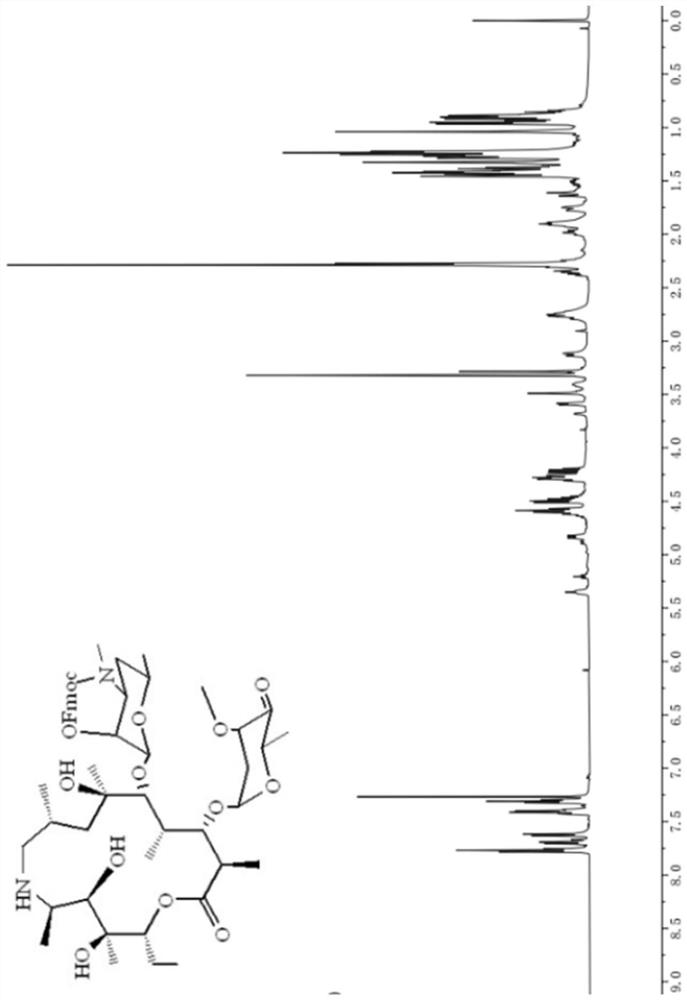

Tulathromycin synthesis method

PendingCN113493483AHigh selectivityHigh yieldSugar derivativesSugar derivatives preparationIodidePropylamine

Owner:SHANGHAI INST OF TECH

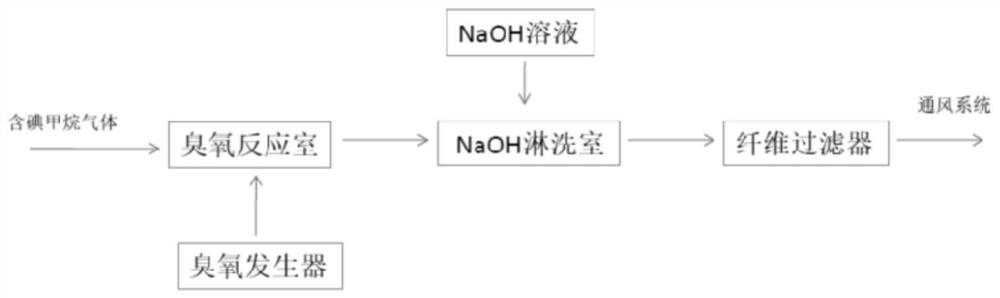

Method for removing radioactive methyl iodide gas

PendingCN112614605AGood removal effectSolve problems that are difficult to compressRadioactive decontaminationFiberPurification methods

The invention relates to a purification method of radioactive iodomethane-containing gas, which comprises the following steps: (1) under normal pressure, the radioactive iodomethane-containing gas passes through an ozone oxidation chamber at a certain gas flow velocity, and the ozone oxidation chamber is filled with ozone with a certain concentration; (2) introducing the gas flowing out of the ozone oxidation chamber into a sodium hydroxide leaching chamber, and spraying a sodium hydroxide leaching solution into the sodium hydroxide leaching chamber at a certain leaching flow, so that the gas to be treated forms aerosol; and (3) filtering the aerosol formed in the step (2) by using a fiber filter, and discharging the filtered gas into a ventilation system. According to the method, methyl iodide is placed in an ozone environment for an oxidation reaction, aerosol is finally formed through leaching of an alkaline solution, a fiber filter which is relatively easy to treat is used for removing, the purification efficiency is high, and final waste is easy to treat.

Owner:CHINA INST FOR RADIATION PROTECTION

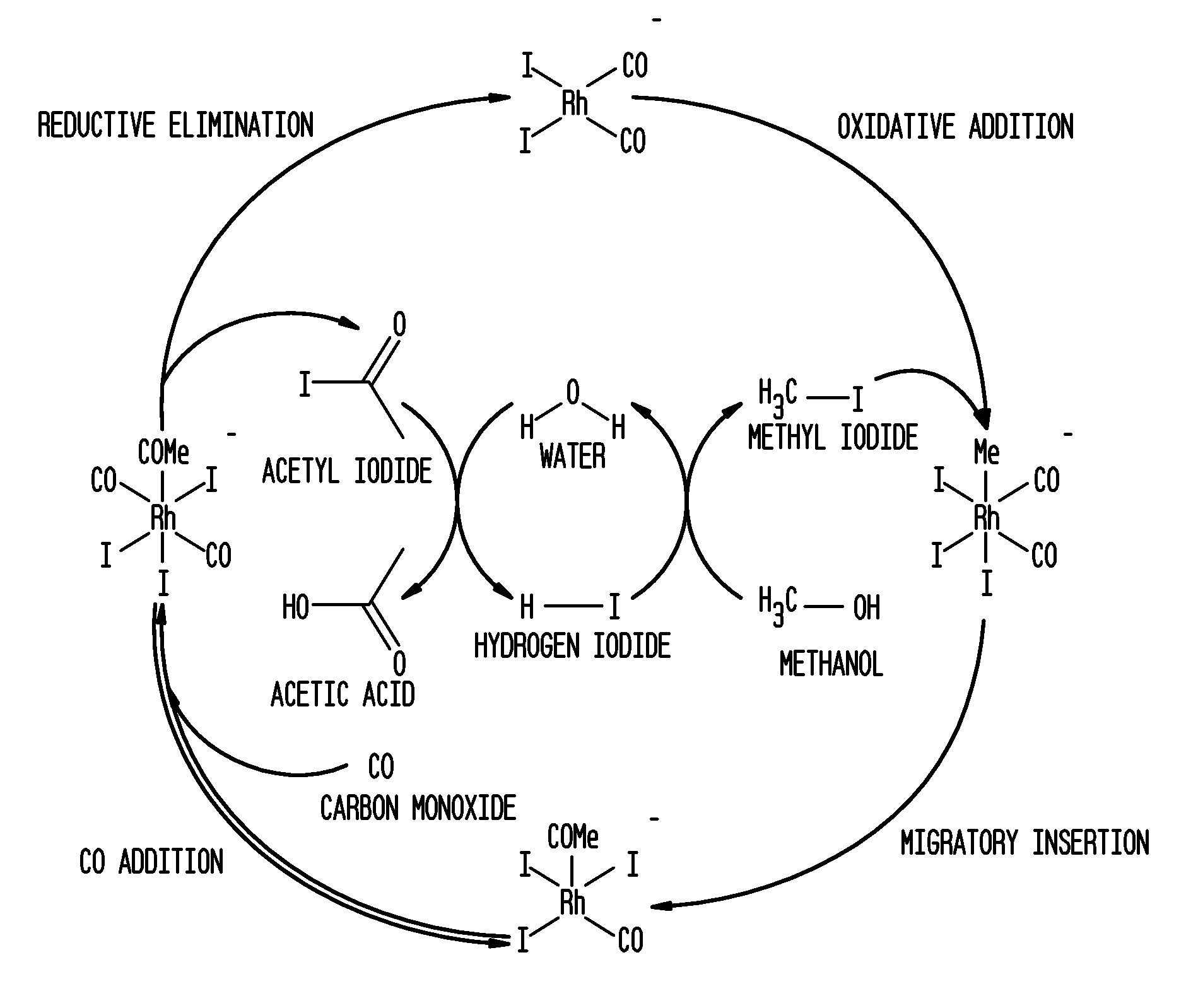

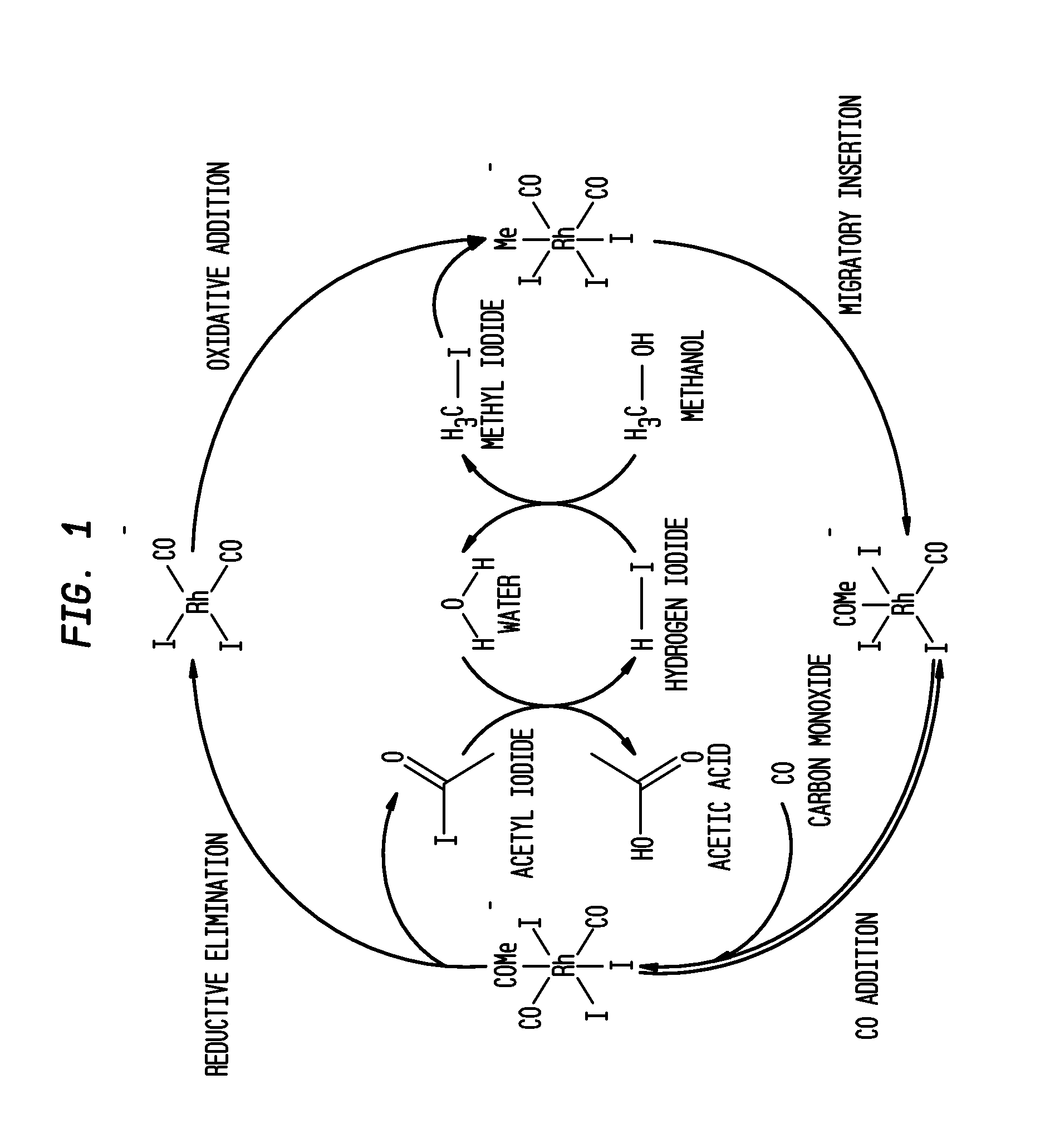

Methanol carbonylation process with rhodium catalyst and a lanthanide metal co-catalyst

ActiveUS8835681B2Catalyst stabilityIncrease chanceOrganic compound preparationCarboxylic preparation from carbon monoxide reactionLanthanideCatalytic metal

A carbonylation process for making acetic acid using a metallic co-catalyst composition, effective as a rhodium stabilizer and / or rate promoter, at molar ratios of metal / rhodium of about 0.5 to 40. The process includes reacting methanol with carbon monoxide in the presence of a rhodium-based catalytic metal complex with about 1 to 20 weight percent methyl iodide, less than about 8 weight % water and about 0.5 to about 30 weight percent methyl acetate. The crude acetic acid is flashed and further purified. This process is stable in the absence of a lithium iodide cocatalyst, or in low concentrations of lithium iodide, with an STY greater than 10 mol / L / hr.

Owner:CELANESE INT CORP

Optically active quaternary ammonium salt, process for producing the same, and process for producing optically active alpha-amino acid derivative with the same

InactiveUS7566779B2High stereoselectivityHigh selectivitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMethyl palmoxirate

There are provided (1) an optically active α-amino acid derivative, a stereoselectively useful intermediate for the synthesis of pharmaceutical or agrochemical products, which derivative is an optically active quaternary ammonium salt that, when used as an axially chiral spiro phase-transfer catalyst in the asymmetric alkylation of a glycine derivative, gives a high stereoselectivity toward substrates having a small molecule such as methyl iodide, or secondary alkyl halides, and a method for producing the same; and (2) a novel optically active quaternary ammonium salt that is a high performance axially chiral spiro phase-transfer catalyst used in the asymmetric alkylation of a glycine derivative, and in which each ring of the spiro-structure has the same structure that is advantageous in terms of the number of steps involved in the synthesis of the catalyst, and a method for producing the same and a method for recovering the same.(Solving means): To achieve the objects, (1) an axially chiral spiro-ammonium salt that incorporates an alkyl- or aryl-substituted silyl group as a substituent on the aromatic ring is used as a phase-transfer catalyst in the asymmetric alkylation of a glycine derivative, and (2) an axially chiral spiro-ammonium slat that incorporates a substituent encompassing a perfluoro alkyl group is used in the asymmetric alkylation of a glycine derivative and thereafter is recovered using a fluorous solvent.

Owner:TOSOH CORP

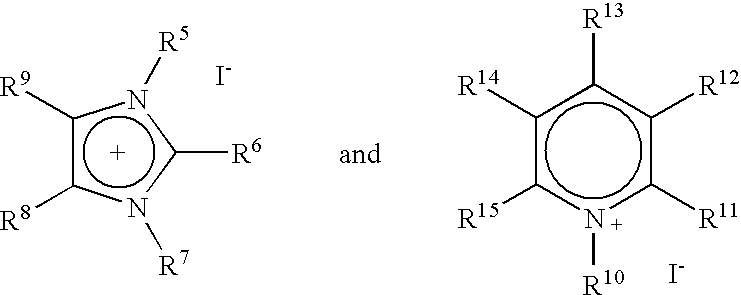

Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof

ActiveCN113135933ASimple structureGood water solubilityOrganic chemistryFluorescence/phosphorescencePotassium hexafluorophosphatePyridinium

The invention relates to a red light aggregation-induced emission material, in particular to an aggregation-induced emission material based on thieno[3,4-b]thiophene as well as a preparation method and application thereof. The preparation method comprises the following steps: by taking triphenylamine and thieno[3,4-b]thiophene as core units, synthesizing (E)-4-(2-(4-(4-(bis(4-methoxyphenyl)amino)phenyl)-2-(ethoxycarbonyl)thieno[3,4-b]thiophene-6-yl)vinyl)-1-methyl pyridinium iodide by using 4-(4-(bis(4-methoxyphenyl)amino)phenyl)-6-methylthieno[3,4-b]thiophene-2-carboxylic acid ethyl ester and 1,4-dimethyl pyridinium iodide; and dissolving the product into acetone, adding an aqueous solution of potassium hexafluorophosphate, and reacting to obtain the material. Fluorescence emission of the material is located in a near-infrared region, and the material is high in fluorescence brightness and can serve as a red light material to be applied to the field of imaging.

Owner:SHANXI UNIV

Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application

ActiveCN113135933BSimple structureGood water solubilityOrganic chemistryFluorescence/phosphorescencePotassium hexafluorophosphateMeth-

The invention relates to a class of red light aggregation-induced luminescent materials, in particular to a thieno[3,4-b]thiophene-based aggregation-induced luminescent material and a preparation method and application thereof. The light-emitting material uses triphenylamine and thieno[3,4-b]thiophene as core units, and uses 4-(4-(bis(4-methoxyphenyl)amino)phenyl)-6-methylthio Thieno[3,4-b]thiophene-2-carboxylic acid ethyl ester and 1,4-dimethylpyridinium iodide salt synthesis (E)-4-(2-(4-(4-(bis(4- methoxyphenyl)amino)phenyl)-2-(ethoxycarbonyl)thieno[3,4-b]thiophen-6-yl)vinyl)-1-methylpyridinium iodide salt, then dissolved in Acetone is added, and an aqueous solution of potassium hexafluorophosphate is added, and the material is prepared after the reaction. The fluorescence emission of the material is located in the near-infrared region, and the fluorescence brightness is strong, and can be used as a red light material in the imaging field.

Owner:SHANXI UNIV

Methyl-iodide-free carbonylation of an alcohol to its homologous aldehyde and/or alcohol

ActiveUS9365479B1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholIodide

Disclosed is a process for the reductive carbonylation of a low molecular weight alcohol to produce the homologous aldehyde and / or alcohol. The process includes conducting the reaction to produce the aldehyde in the presence of a single component catalyst complex composed of cobalt, an onium cation and iodide in a ratio of 1:2:4 without additional promoters. A ruthenium co-catalyst is used in the production of the homologous alcohol. The reductive carbonylation reaction does not require an additional iodide promoter and produces a crude reductive carbonylation product substantially free of methyl iodide.

Owner:EASTMAN CHEM CO

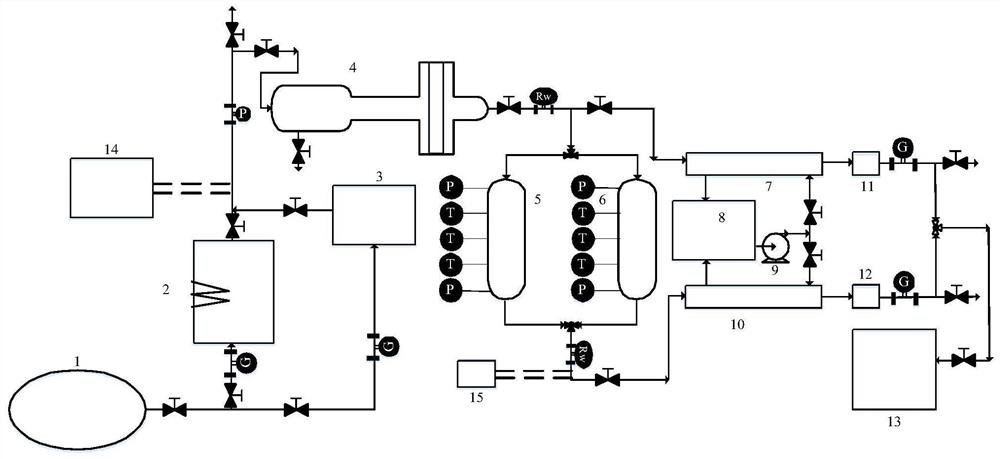

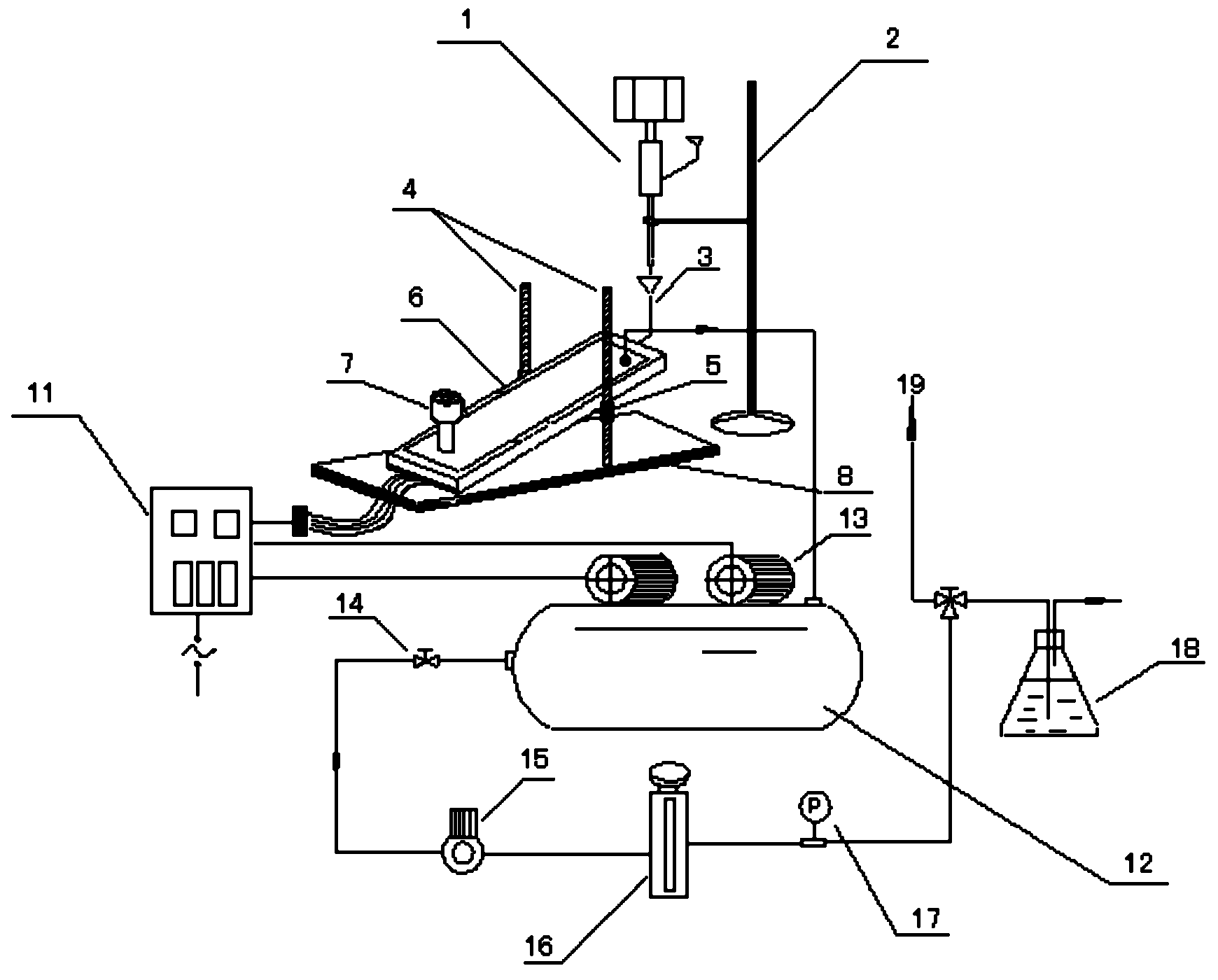

Experimental system for testing performance of methyl iodide adsorption material

ActiveCN113406124AVerify the adsorption effectRealize online measurementComponent separationMaterial analysis by transmitting radiationNuclear radiationTest performance

The invention relates to the technical field of nuclear radiation protection, and particularly discloses an experimental system for testing the performance of a methyl iodide adsorption material. S double-bed body structure with an experimental adsorption bed and a control bed symmetrically arranged is adopted and can be used for comparison verification of adsorption efficiency data to remove the influence of the adsorption performance of a substrate material. Meanwhile, the control bed can be used for working condition adjustment at the initial stage of the experiment, and influences of initial working condition adjustment and gas flow at the preheating stage of the experiment adsorption bed and the control bed on the performance of the adsorption material are reduced. According to the invention, performance testing can be carried out on different methyl iodide adsorption materials under thermal conditions of large-range temperature, pressure and the like, the functions are comprehensive, other matching devices are not needed, and the measurement precision is high.

Owner:CHINA NUCLEAR POWER ENG CO LTD

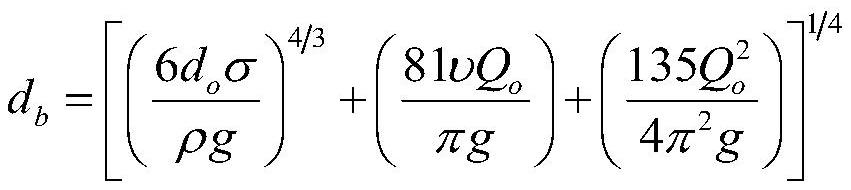

Herbicide containing halosulfuron-methyl

InactiveCN109997867AImprove herbicidal activitySynergisticBiocideAnimal repellantsHalosulfuron methylEcological environment

The invention relates to the technical field of pesticide compositions, in particular to a herbicide containing halosulfuron-methyl. The active ingredients of the herbicide are the halosulfuron-methyland methyl iodosulfuron, wherein the mass ratio of the halosulfuron-methyl to the methyl iodosulfuron is (2-5): (3-15). The herbicidal activity of the compounded halosulfuron-methyl and methyl iodosulfuron in the herbicide is higher than that of the separately used halosulfuron-methyl and methyl iodosulfuron for broadleaf grass and cyperaceae, and a synergistic effect is achieved; a weed controlspectrum is enlarged after the combination, and the dosage is also reduced; after the halosulfuron-methyl and the methyl iodosulfuron are compounded, the synergistic effect is shown within a certain ratio, the control effect of the composition is obviously improved than single agents, the dosage of a pesticide is reduced, the use frequency of the pesticide is reduced, the use cost of the pesticideis reduced, the adverse effect of the pesticide on the ecological environment is reduced, and the maintenance of the ecological balance is facilitated.

Owner:JIANGSU INST OF ECOMONES

Dynamic distribution system of gaseous methyl iodine

ActiveCN102629493BContinuous and stable supplyStable concentrationNuclear energy generationCooling arrangementDistribution systemEngineering

The invention aims to provide a dynamic distribution system of gaseous methyl iodine. The dynamic distribution system comprises a small-flow liquid supply device, a liquid vaporization chamber and an air compressor, wherein the small-flow liquid supply device is fixed on a bracket; an outlet of the small-flow liquid supply device is arranged in alignment with an inlet of the liquid vaporization chamber; the liquid vaporization chamber is arranged on a pedestal through a threaded supporting rod and a lifting threaded bushing which is matched with the threaded supporting rod; the angle of the liquid vaporization chamber can be adjusted through the lifting threaded bushing; an air suction port is formed below the liquid vaporization chamber; a hole which is connected with the air compressor is formed above the liquid vaporization chamber; an electric heating device is also arranged in the liquid vaporization chamber; and the air compressor is communicated with a gas application environment. According to the dynamic distribution system, long-time continuous stable supply of the small-flow methyl iodine liquid can be realized, and stable concentration of the methyl iodine at the outlet of the system is guaranteed. The suction effect of the air compressor enables that the liquid vaporization chamber is in a negative pressure state all the time; safety and reliability are guaranteed; and no injury is caused to the environment and the operation personnel. The system has the advantages of simple structure, reliable performance and easiness for implementation.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ffe4e33d-60e3-4da3-887b-42682ef7c6d8/HDA0003008492490000011.png)

![Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ffe4e33d-60e3-4da3-887b-42682ef7c6d8/HDA0003008492490000012.png)

![Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof Aggregation-induced emission material based on thieno[3,4-b]thiophene as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ffe4e33d-60e3-4da3-887b-42682ef7c6d8/HDA0003008492490000021.png)

![Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application](https://images-eureka.patsnap.com/patent_img/03f70a4a-438e-42f6-8e83-282e684423f9/HDA0003008492490000011.png)

![Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application](https://images-eureka.patsnap.com/patent_img/03f70a4a-438e-42f6-8e83-282e684423f9/HDA0003008492490000012.png)

![Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application Aggregation-induced luminescent material based on thieno[3,4-b]thiophene, its preparation method and application](https://images-eureka.patsnap.com/patent_img/03f70a4a-438e-42f6-8e83-282e684423f9/HDA0003008492490000021.png)