Methyl iodide gas generation method for iodine adsorber efficiency test and generator

The technology of a gas generator and an iodine adsorber is applied in the field of detection equipment in the nuclear field, and can solve the problems of high use cost, high operation requirements and high risk of radioactive leakage, and achieve the effect of fast, stable and reliable production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

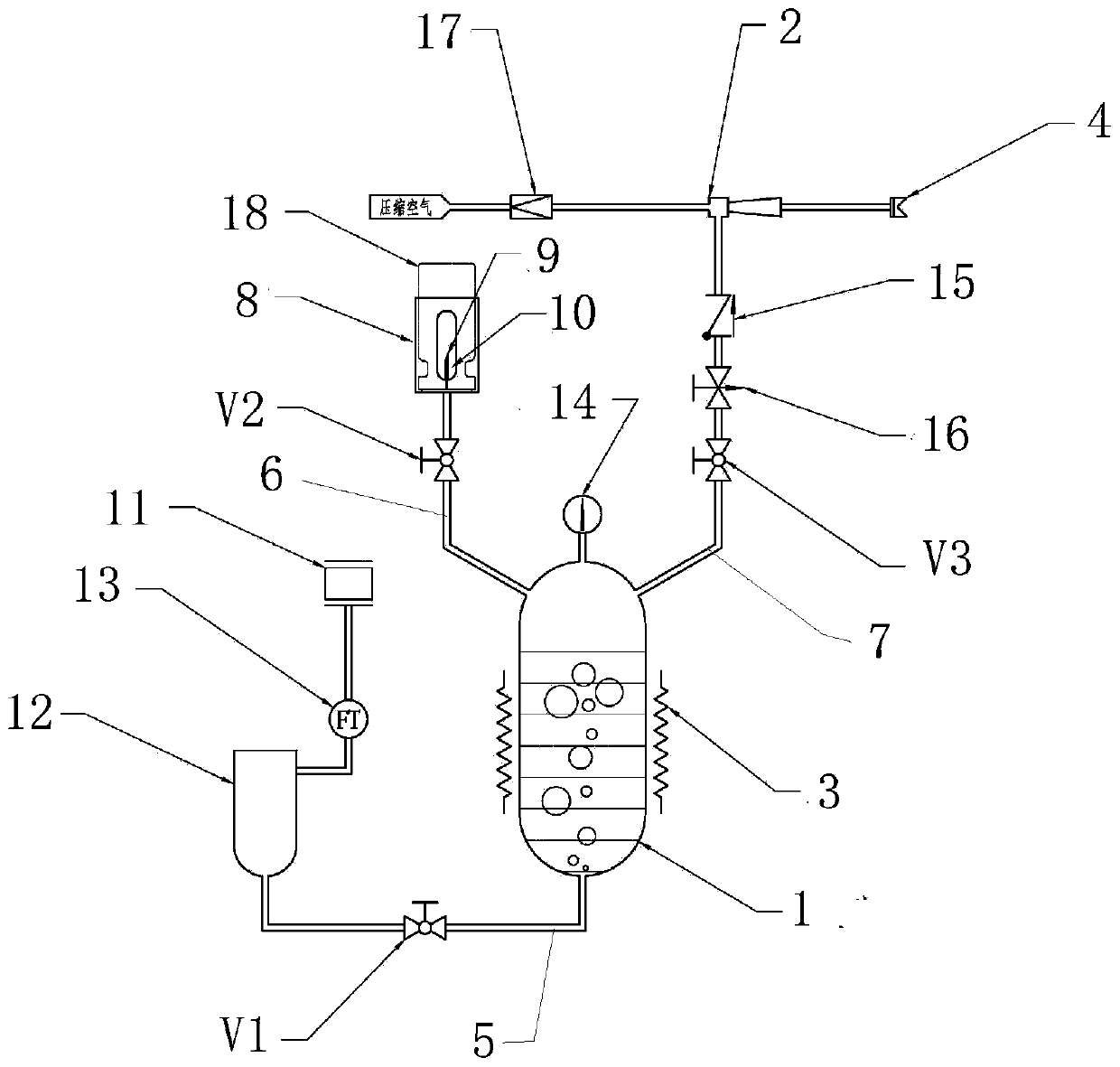

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Present embodiment at first provides a kind of methyl iodide gas generation method that is used for iodine adsorber efficiency detection, and it comprises the following steps:

[0023] S1. Vacuumize the generating chamber

[0024] Reduce the vacuum degree of the generating chamber used for storing liquid methyl iodide and gasification place to below -0.2 bar;

[0025] S2, add liquid methyl iodide

[0026] Adding a quantitative amount of liquid methyl iodide to the above-mentioned generating chamber in a vacuum state;

[0027] S3, gasification

[0028] Simultaneously, air flow is injected into the generation cavity in the above step B, so that the liquid methyl iodide in the generation cavity forms bubbling, and when the gasification is not enough, the injected methyl iodide is heated to assist gasification;

[0029] S4. Inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com