Dynamic distribution system of gaseous methyl iodine

A methyl iodide, dynamic technology, applied in the environment, medicine, and chemical industry, can solve the problems of unsuitable for long-term continuous use, complex structure, complex process, etc., and achieve long-term continuous and stable supply, easy to achieve, and stable concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

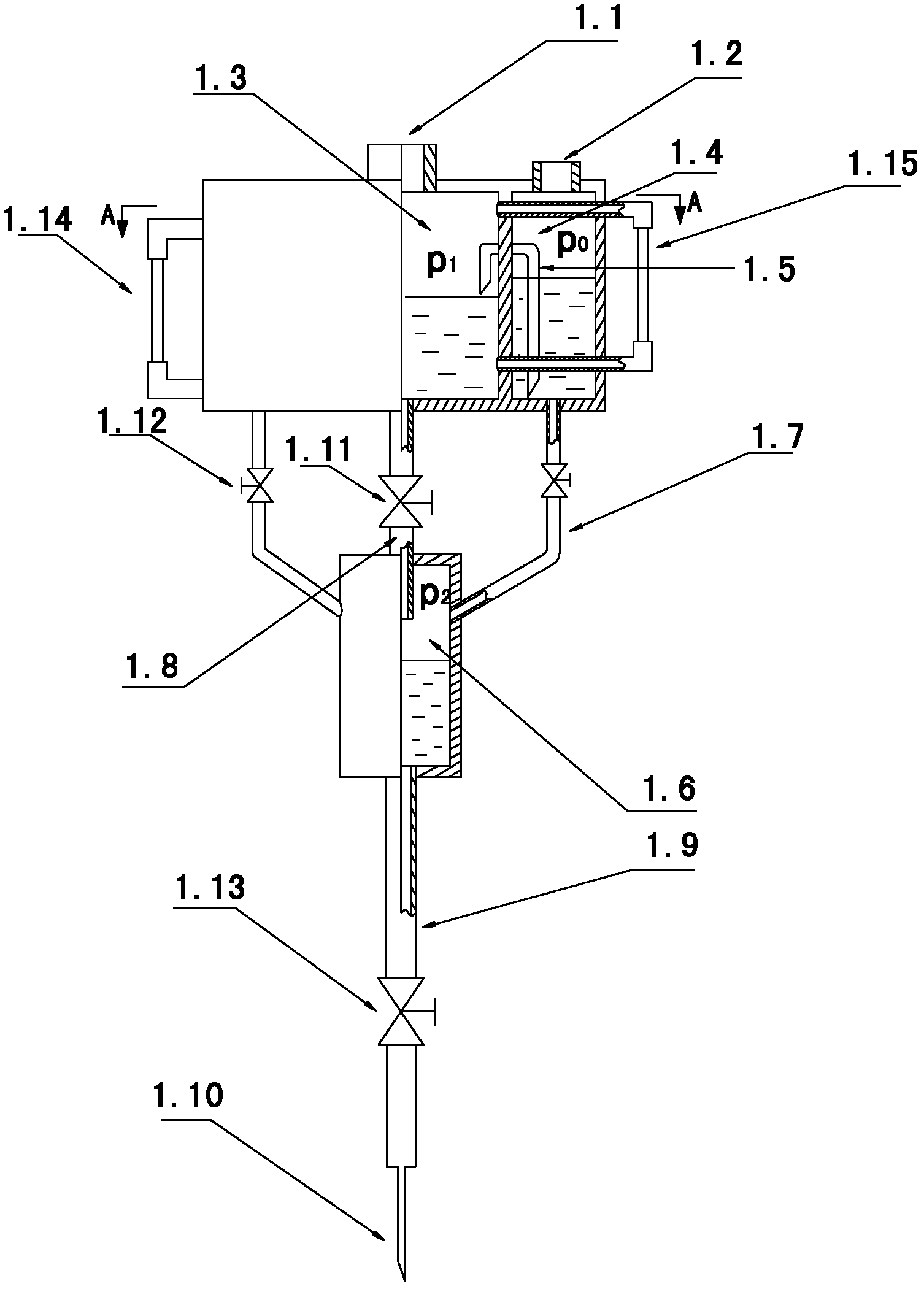

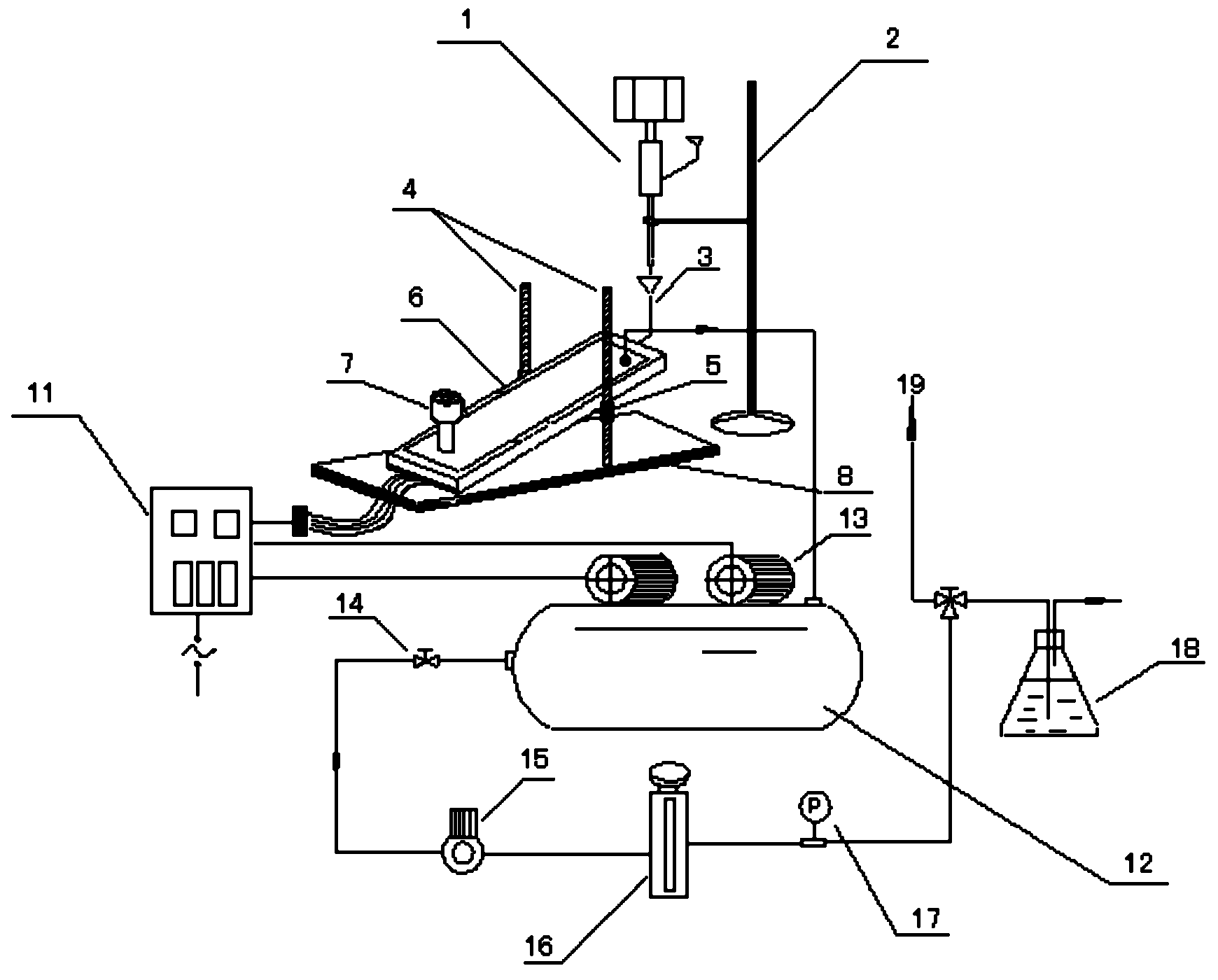

[0018] to combine Figure 1~4 , the present invention includes a liquid methyl iodide vaporization pressurized distribution system, which is mainly composed of a small flow liquid supply device 1, a support 2, a liquid vaporization chamber 6, a filter 7, a base 8 and a distribution system for realizing dynamic distribution of gaseous methyl iodide loop composition.

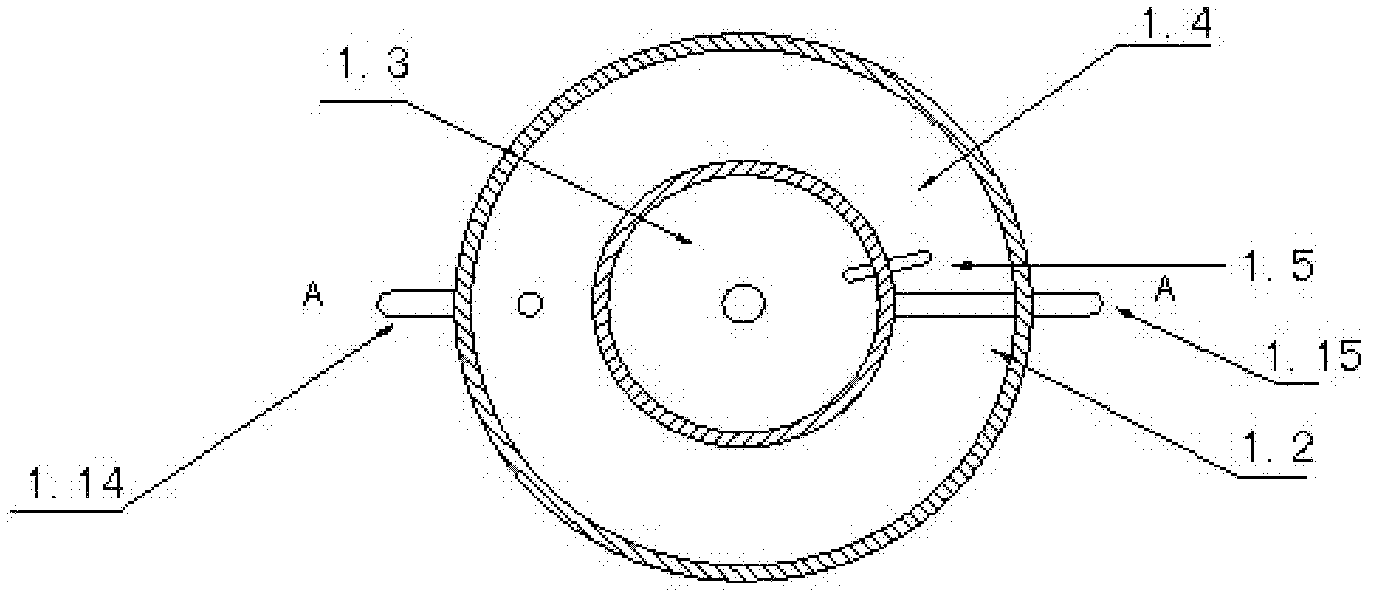

[0019] The above-mentioned small flow liquid supply device 1 is composed of a gas-liquid mixing chamber 1.6, a solution supply chamber 1.3, a solution supply chamber 1.4, a siphon tube 1.5, an upper guide tube 1.8 and a lower guide tube 1.9, the purpose of which is to ensure the flow of liquid under small flow conditions. The long-term stable supply of is obtained by the Bernoulli equation and the continuity equation: In the formula, G is the mass flow rate at the outlet of the device, and A 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com