Light absorption layer material of solar cell, wide-band-gap perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as increasing production costs, achieve the effects of reducing production costs, facilitating large-area roll-to-roll production, and inhibiting phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

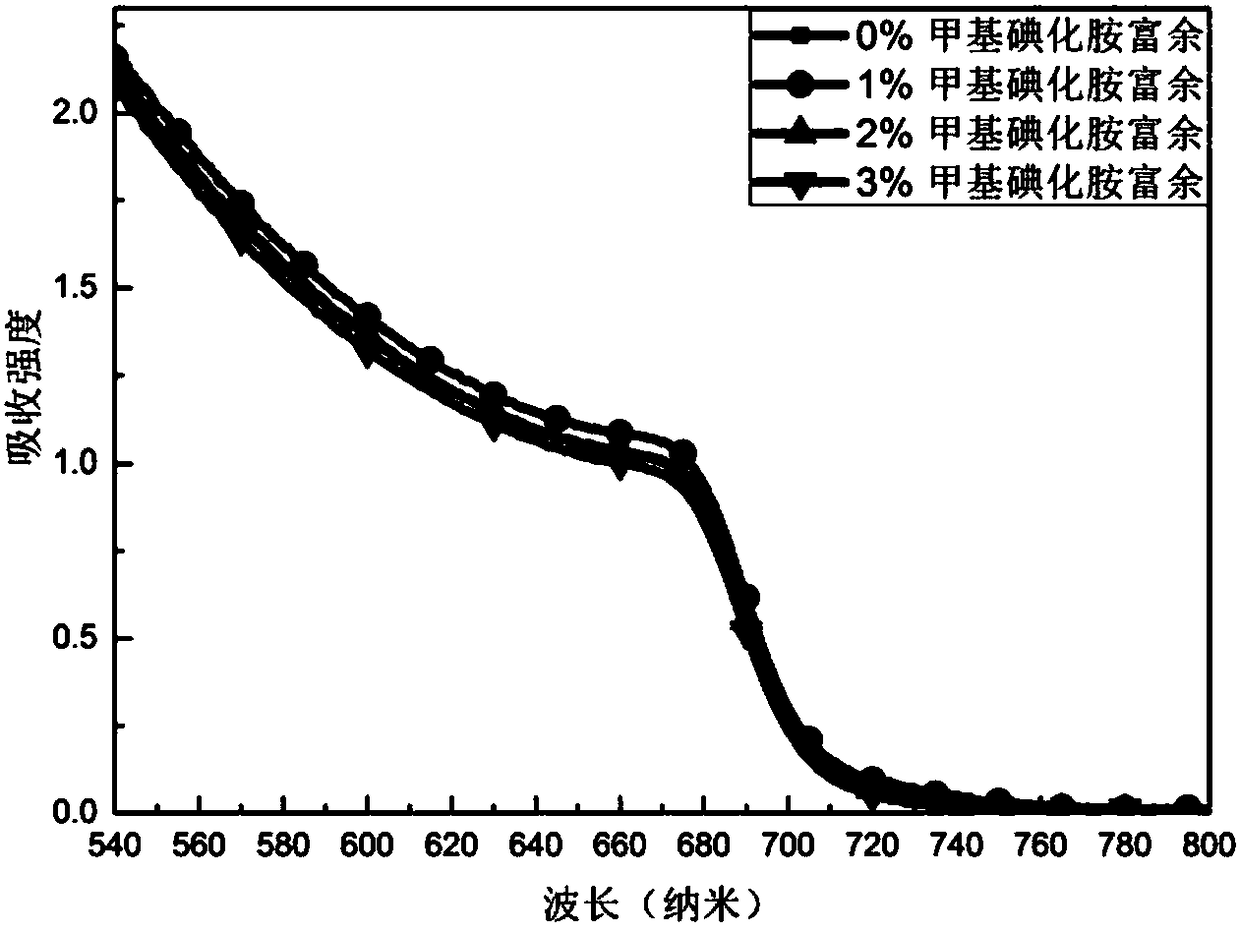

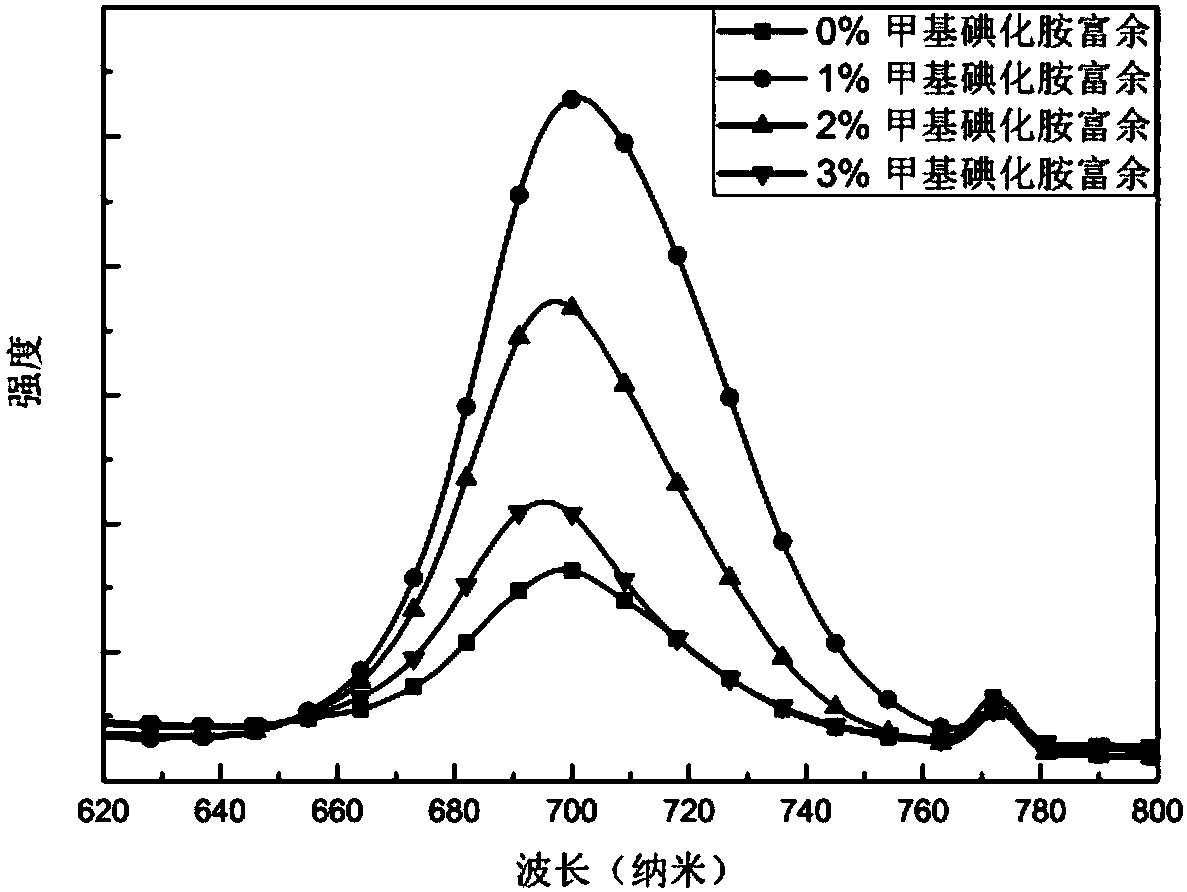

[0052] Step 1: Configure the perovskite precursor solution

[0053] (1) 196.1mg FAI, 19.5mg CsI, 276.6mg PbI 2 , 330.3mg PbBr 2 , 47.8mg MAI was mixed and dissolved in a mixed solvent of 800ulDMF and 200ulDMSO to prepare a perovskite precursor solution corresponding to the molar amount of Pb, recorded as 1% mol MAI-rich perovskite.

[0054] (2) Dissolving fullerene derivative PCBM powder in chlorobenzene solvent to prepare 20 mg / ml PCBM solution.

[0055] (3) Add KOH solution to Ni(NO 3 ) 2 In the aqueous solution, until the pH value reaches 10, stir vigorously to produce a large amount of green precipitate. The separated precipitate was heated in air at 270° C. for 2 h to obtain black nano-NiOx particles. The nano NiOx particles were dissolved in water to prepare a NiOx nanoparticle solution with a concentration of 20 mg / ml.

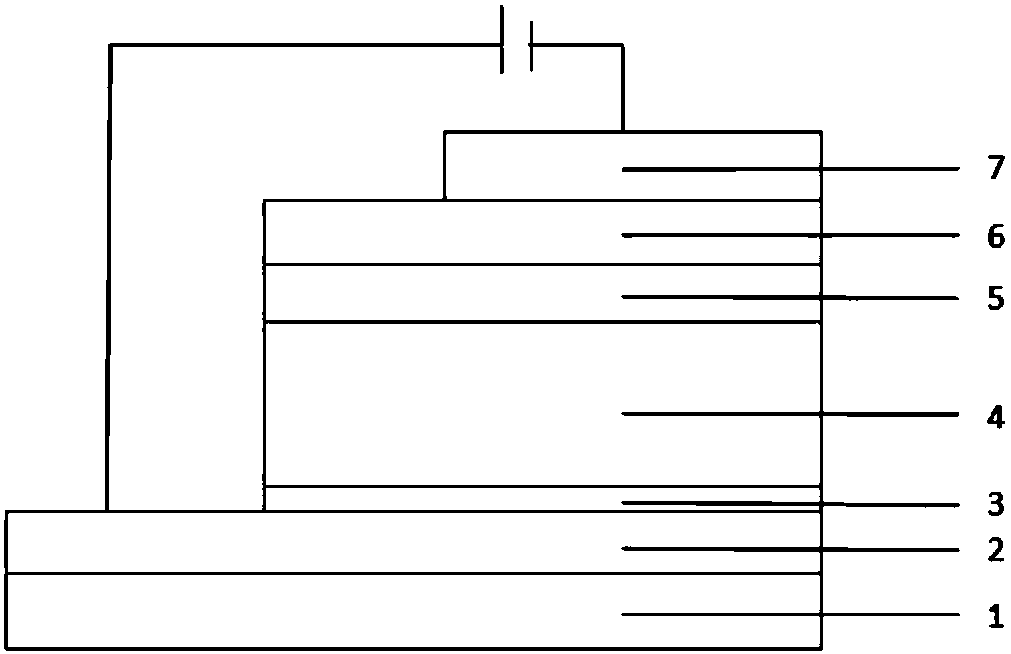

[0056] Step 2: Preparation of Thin Film Battery

[0057] (1) The glass substrate coated with the ITO layer was ultrasonically cleaned with aceto...

Embodiment 2

[0068] Step 1: Configure the perovskite precursor solution

[0069] (1) 196.1mg FAI, 19.5mg CsI, 276.6mg PbI 2 , 330.3mg PbBr 2 , 50.3mg MAI was mixed and dissolved in a mixed solvent of 800ulDMF and 200ulDMSO to prepare a perovskite precursor solution corresponding to the molar amount of Pb, recorded as 2%mol MAI-rich perovskite.

[0070] (2) Dissolving fullerene derivative PCBM powder in chlorobenzene solvent to prepare 20 mg / ml PCBM solution.

[0071] (3) Add KOH solution to Ni(NO 3 ) 2 In the aqueous solution, until the pH value reaches 10, stir vigorously to produce a large amount of green precipitate. The separated precipitate was heated in air at 270° C. for 2 h to obtain black nano-NiOx particles. The nano NiOx particles were dissolved in water to prepare a NiOx nanoparticle solution with a concentration of 20 mg / ml.

[0072] Step 2: Preparation of Thin Film Battery

[0073] (1) The glass substrate coated with the ITO layer was ultrasonically cleaned with aceton...

Embodiment 3

[0084] Step 1: Configure the perovskite precursor solution

[0085] (1) 196.1mg FAI, 19.5mg CsI, 276.6mg PbI 2 , 330.3mg PbBr 2 , 52.8mg MAI was mixed and dissolved in a mixed solvent of 800ulDMF and 200ulDMSO to prepare a perovskite precursor solution corresponding to the molar amount of Pb, recorded as 3% mol MAI-rich perovskite.

[0086] (2) Dissolving fullerene derivative PCBM powder in chlorobenzene solvent to prepare 20 mg / ml PCBM solution.

[0087] (3) Add KOH solution to Ni(NO 3 ) 2 In the aqueous solution, until the pH value reaches 10, stir vigorously to produce a large amount of green precipitate. The separated precipitate was heated in air at 270° C. for 2 h to obtain black nano-NiOx particles. The nano NiOx particles were dissolved in water to prepare a NiOx nanoparticle solution with a concentration of 20 mg / ml.

[0088] Step 2: Preparation of Thin Film Battery

[0089] The glass substrate coated with the ITO layer was cleaned with acetone, micron-scale se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com